A 90° flip door frame transfer flip mechanism and its application method

A technology of turning mechanism and door frame, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, time-consuming and labor-intensive, and large door frame volume, so as to improve work efficiency, shorten time interval, and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

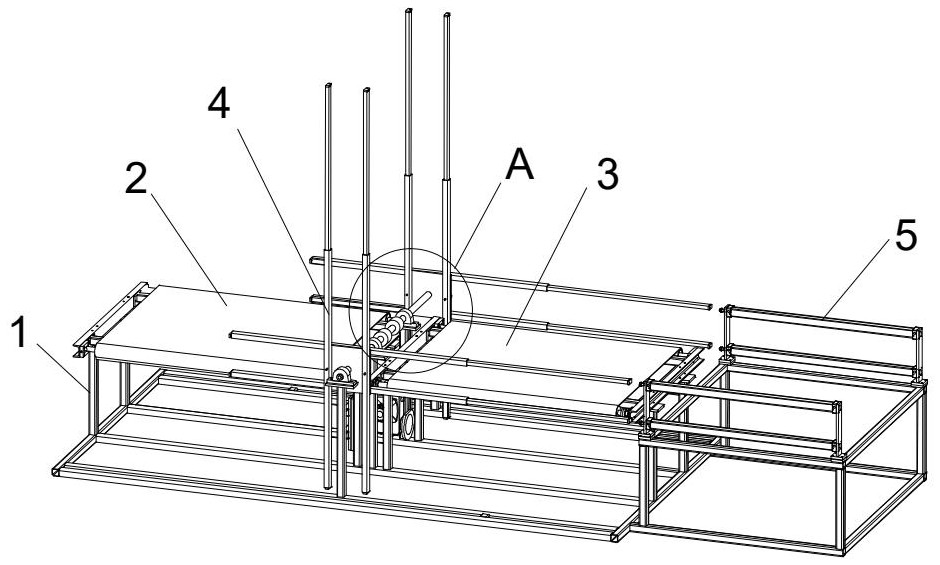

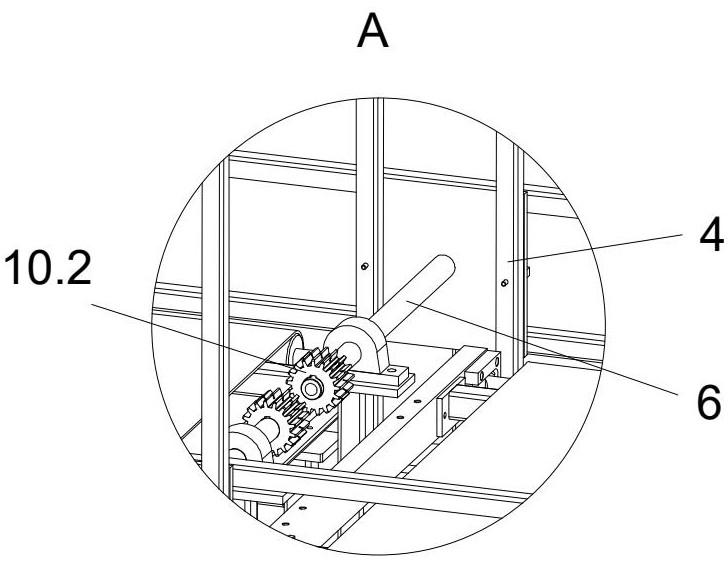

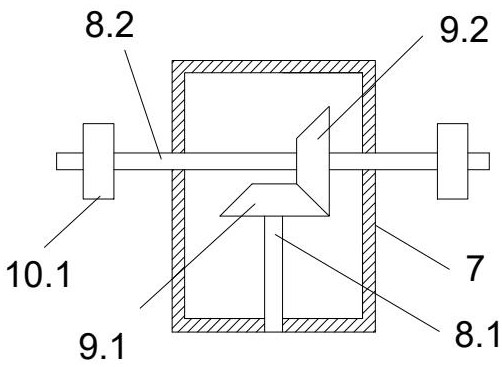

[0032] see Figure 1 to Figure 6 , the embodiment of the present invention provides a 90° flip door frame transfer and flip mechanism, including a bracket 1, a feed area 2 and a discharge area 3 arranged on the bracket 1, a flip assembly for flipping the door frame, and A driving device and a controller for driving the overturning assembly to realize overturning; the overturning assembly includes a pair of overturning units 4 that can be overturned synchronously, and the overturning units 4 are arranged on both sides of the bracket 1 and are rotationally connected with the bracket 1 through a rotating shaft 6; The overturning unit 4 includes two sets of rotating arms perpendicular to each other; each set of rotating arms includes two parallel sleeves 4.1 and a sliding tube 4.2 inside the sleeve 4.1; a spring is passed between the sliding tube 4.2 and the sleeve 4.1 Ball plunger connection; one end of the discharge area 3 of the support 1 is provided with a cylinder assembly 5 ...

Embodiment 2

[0044] Embodiment 2 provides a method for using a 90° flip door frame transfer flip mechanism, including the following steps:

[0045] S1. The first feeding: the first door frame 11 is horizontally sent into the feeding area 2 through the belt feeding mechanism. After the photoelectric sensor detects that the door frame is in place, the signal is fed back to the controller, and the controller controls the second motor in the feeding area 2. Pause; at the same time, the controller controls the cylinder assembly 5 to start, the piston rod of the cylinder stretches out, and the sliding tube 4.2 that pushes the rotating arm stretches out from the casing 4.1 to the feeding area 2;

[0046] S2, the first flip: when the cylinder reaches the maximum stroke, the sliding tube 4.2 moves into place, at this time the controller controls the cylinder assembly 5 to reset; at the same time, the first motor starts to drive the flip unit 4 to rotate 90 degrees clockwise, the first The block doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com