Vacuumization thermal packaging equipment

A vacuuming and thermal packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of time-consuming and laborious, poor sealing performance of plastic packaging bags, poor product uniformity, etc., to achieve convenient use, save production costs, Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

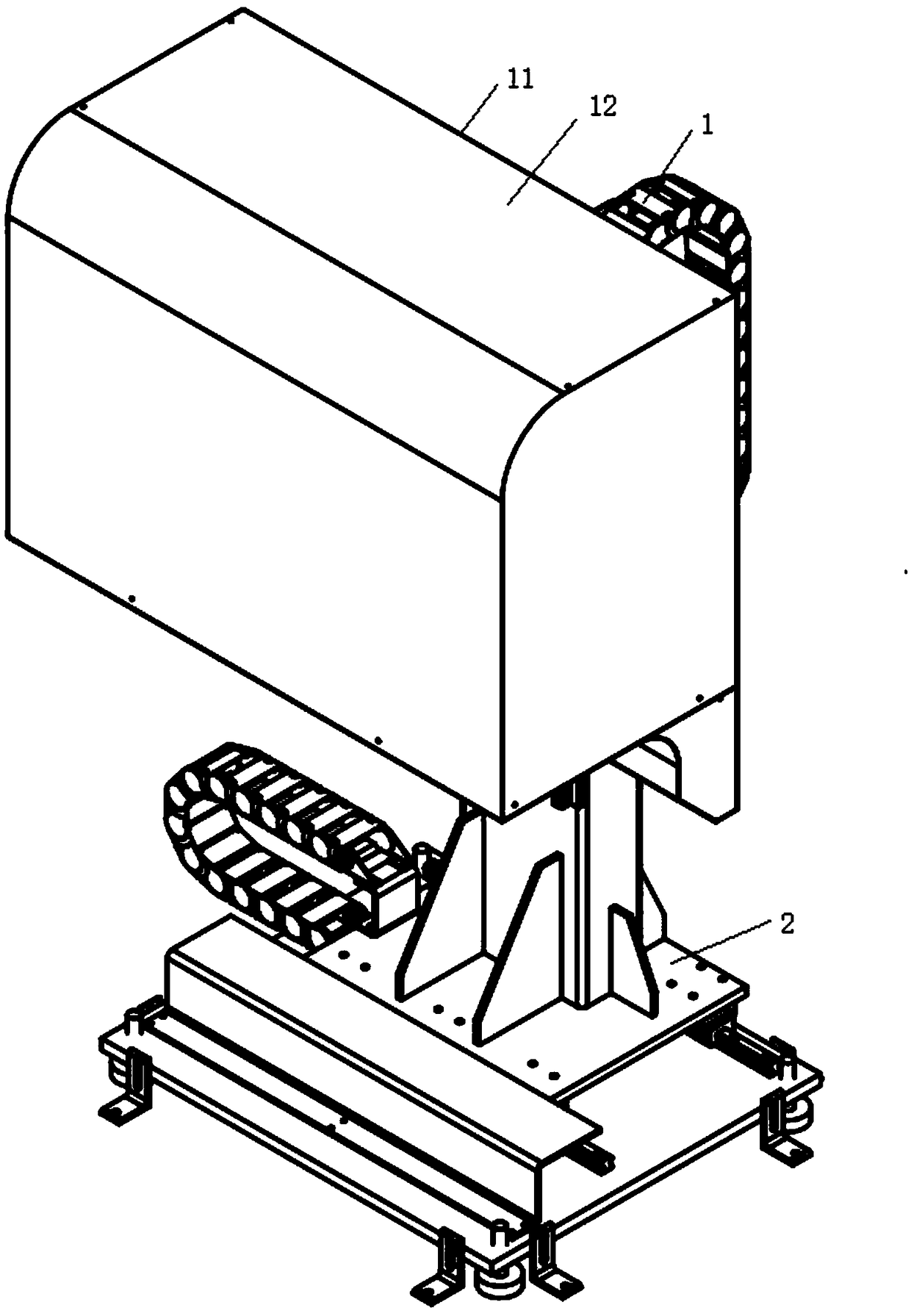

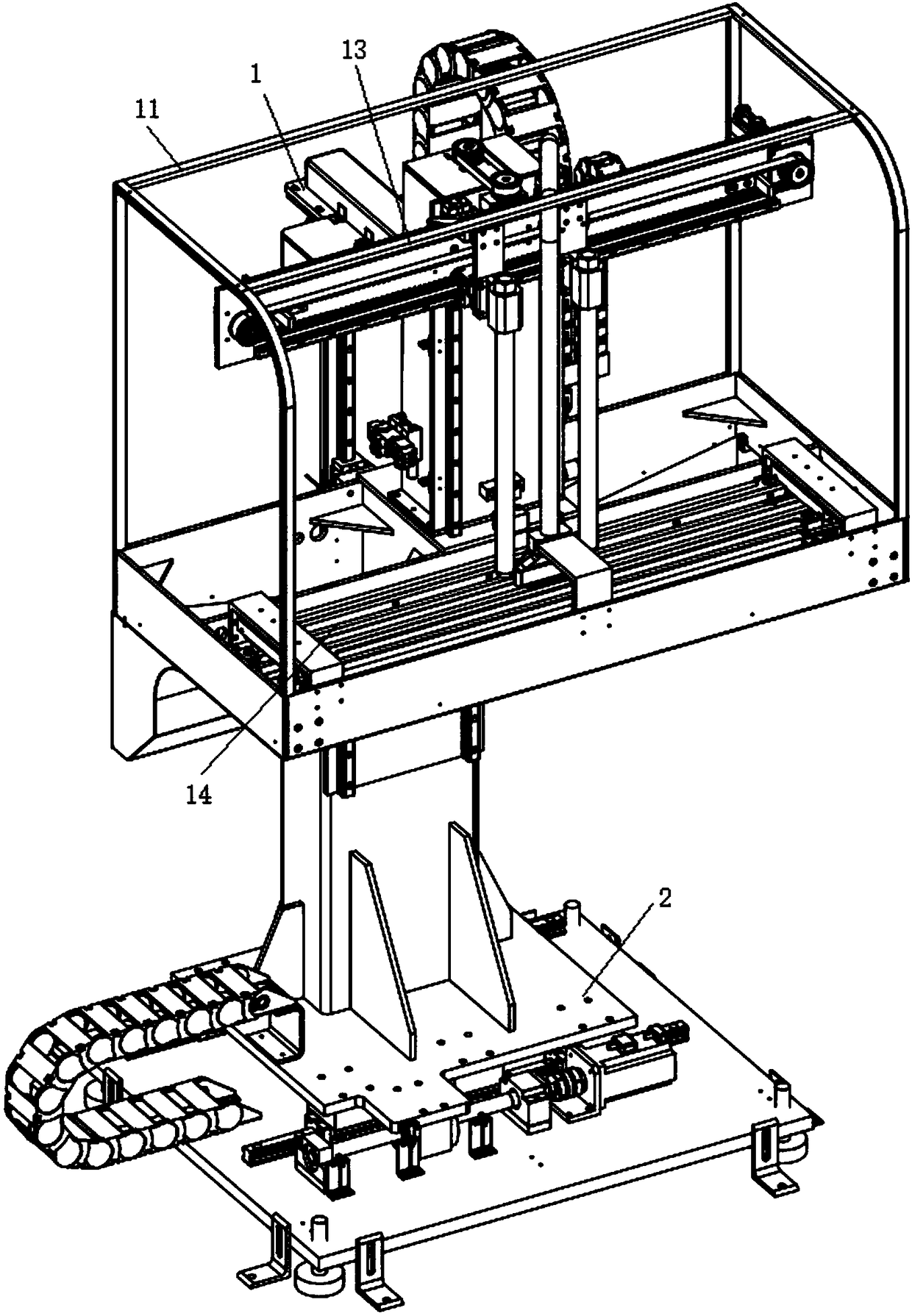

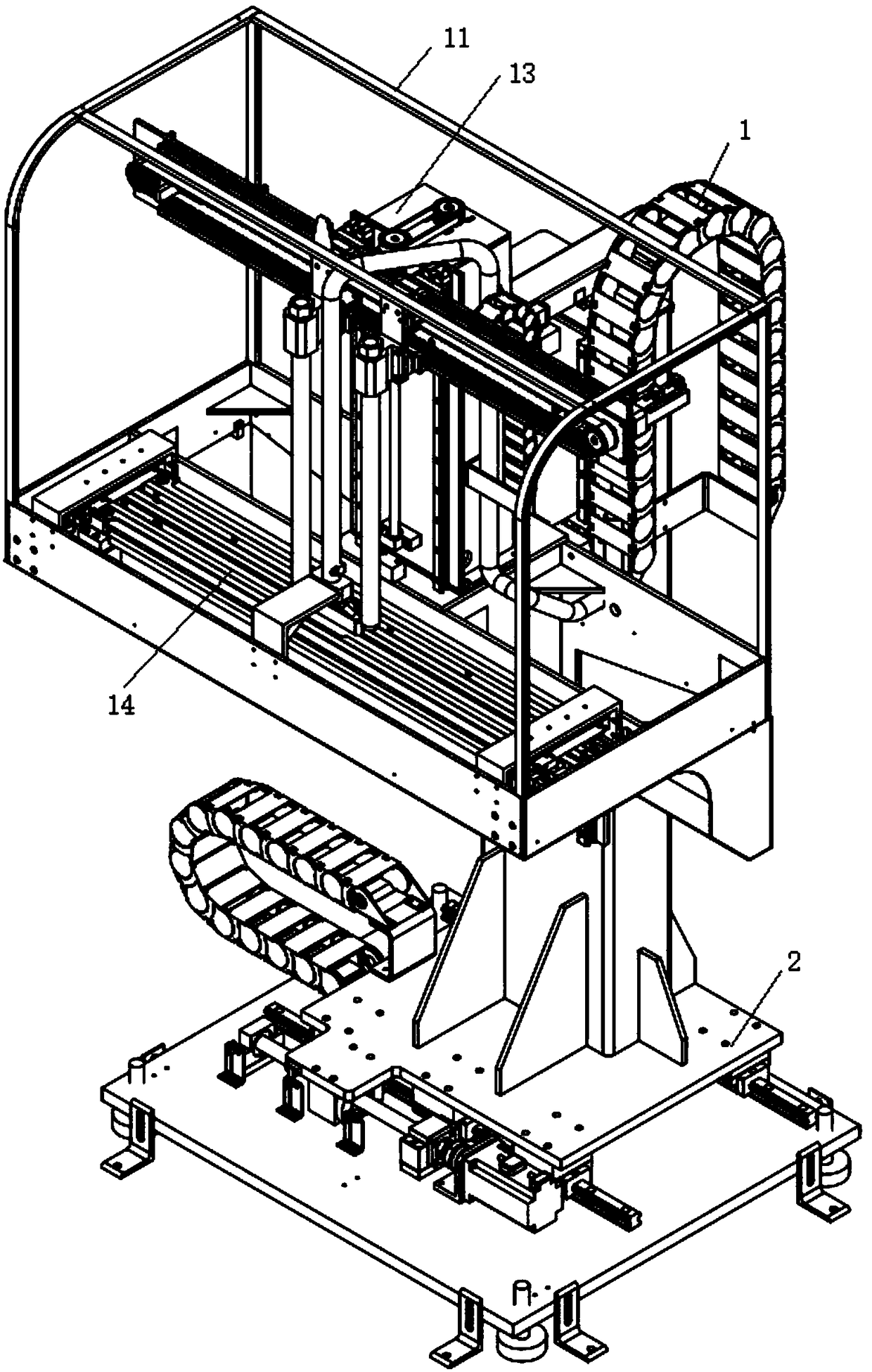

[0064] A kind of vacuum heat sealing equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the device includes a bag sealing mechanism 1 and a moving mechanism 2, and the bag sealing mechanism is slidingly connected to the moving mechanism;

[0065] The bag sealing mechanism includes an outer cover 12, a base frame 11, a servo bag supporting mechanism 13, and a sealing vacuum heat sealing mechanism 14. The servo bag supporting mechanism and the sealing vacuum heat sealing mechanism are fixed on the base frame. The bag stretching mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com