Cylindrical capacitance-type heterotype electronic component whole foot equipment

An electronic component and cylindrical technology, which is applied in the field of electronic component lead forming equipment, can solve the problems of difficult to guarantee the qualified rate, high labor intensity and high labor cost, achieve the improvement of precision and consistency of the whole foot, and improve the whole foot. Efficiency, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

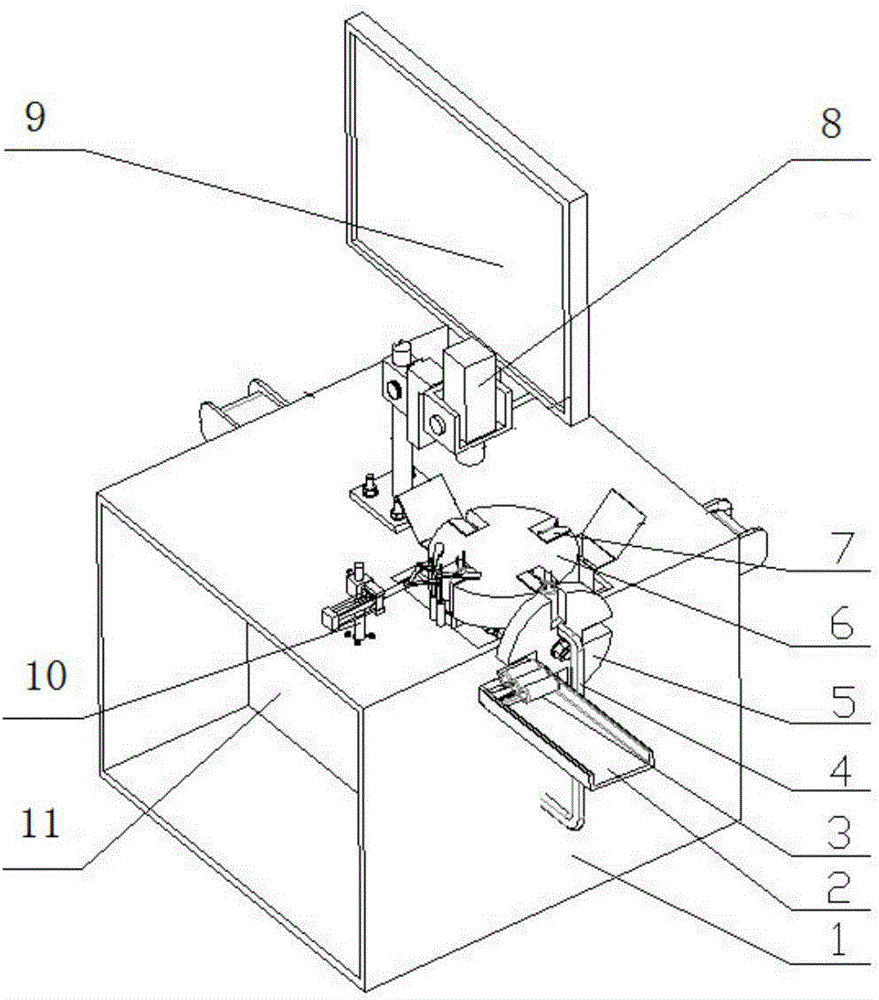

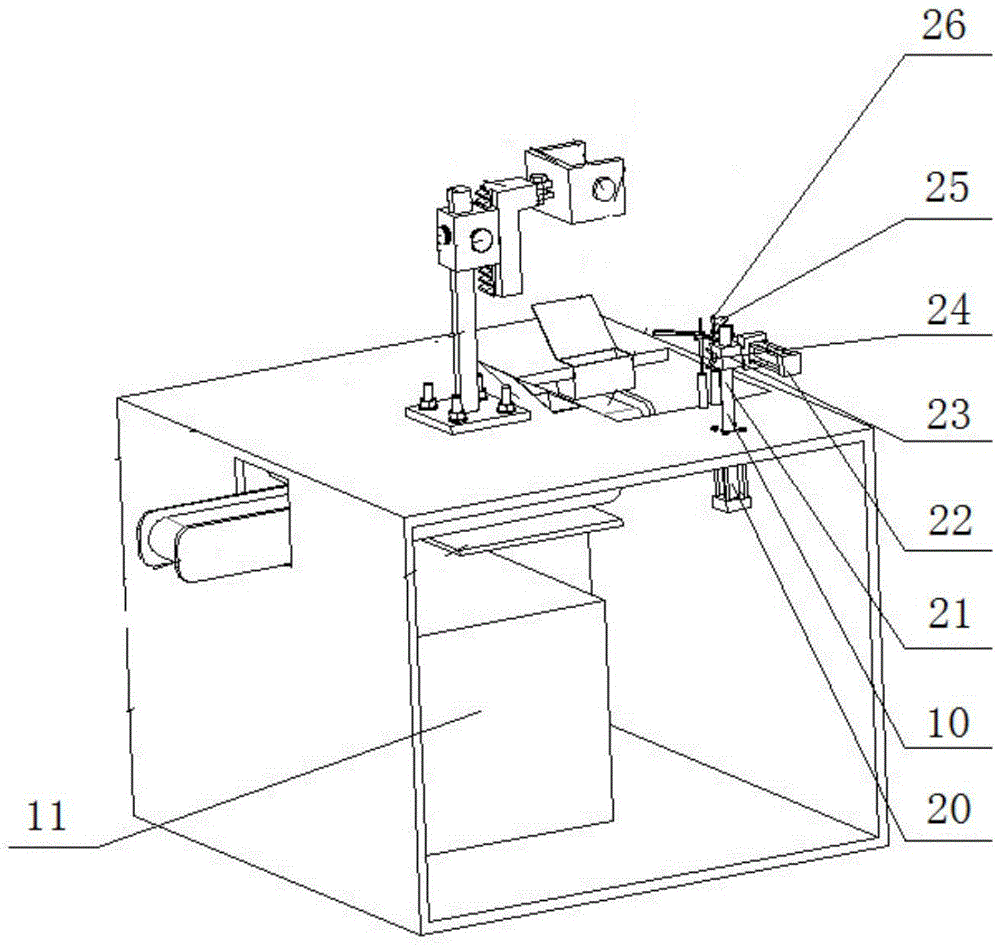

[0024] The specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawing, and present embodiment is the whole foot equipment with detection system, and detection system is mainly image acquisition equipment, promptly gathers the capacitor pin photo after whole foot by camera (8) , analyze the photo of the capacitor pin on the display terminal (9), and obtain the detection result.

[0025] See Figure 1~6 , the present invention mainly comprises frame (1), transmission system, automatic material distribution system and whole foot system, and transmission system, automatic material distribution system and whole foot system are all located on the frame (1).

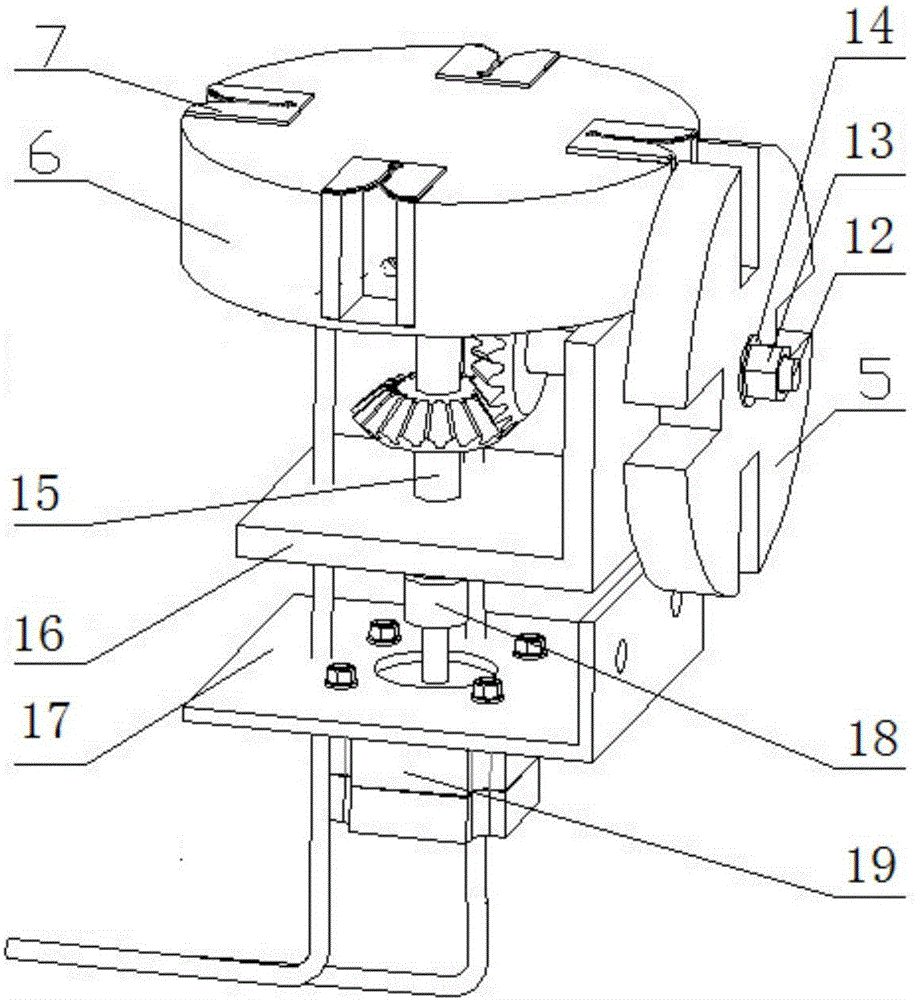

[0026] See figure 2 , the transmission system mainly includes a distribution tray (5), a work tray (6) and a stepping motor (19), the distribution tray (5) is vertically arranged on the frame (1), and the work tray (6) is horizontally arranged on On the frame (1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com