System and method for whole-leg detection of cylindrical capacitive irregular-shaped electronic components

A technology for electronic components and detection systems, applied in instruments, measuring devices, optical devices, etc., can solve the problems of difficult to guarantee the pass rate, high labor intensity and high labor cost, and achieve the improvement of accuracy and consistency of the whole foot, improve the The efficiency of the whole foot and the effect of reducing the work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

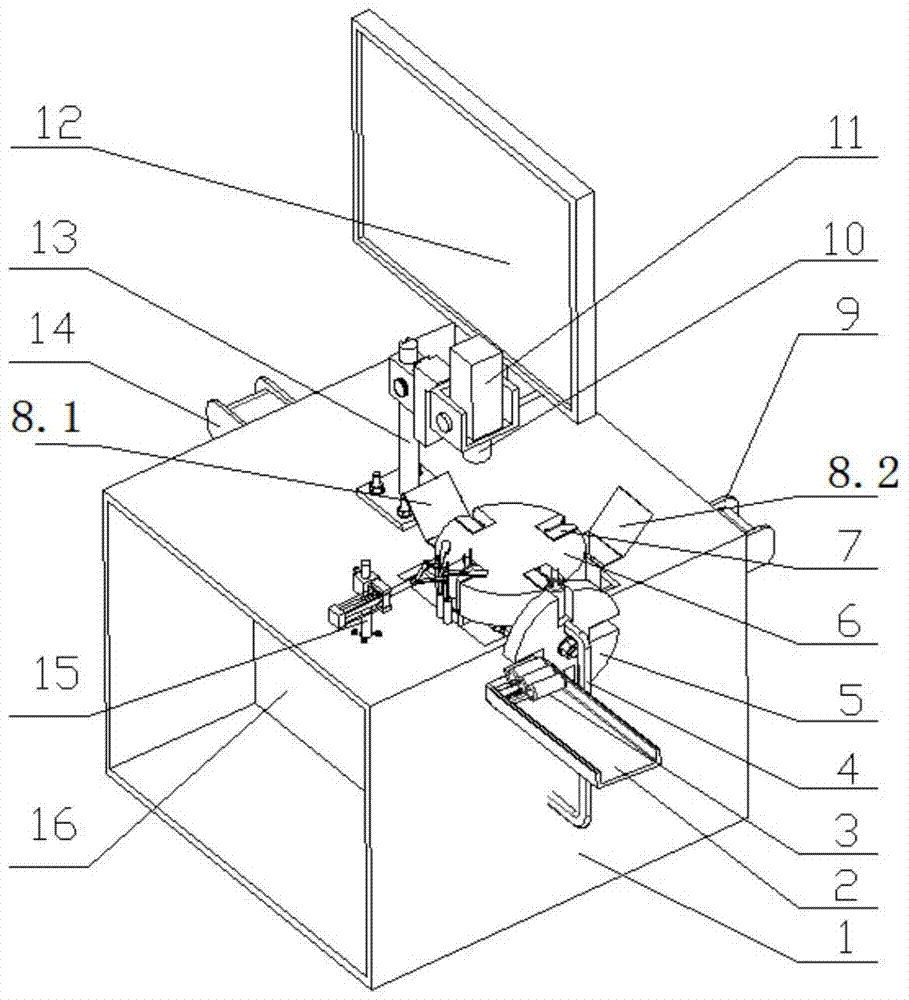

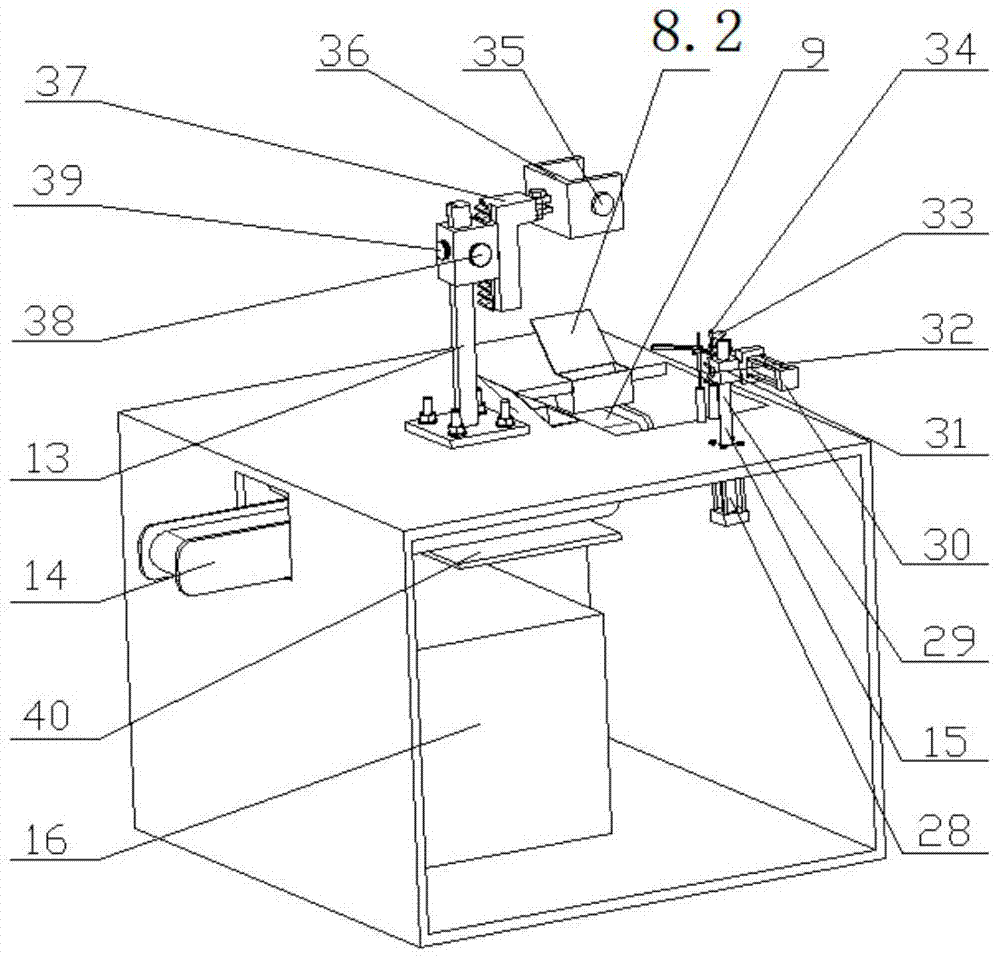

[0036] See Figure 1~6 , the present invention mainly includes a frame (1), a transmission system, an automatic material distribution system, a leg adjustment system (15), a visual inspection system and a transmission system.

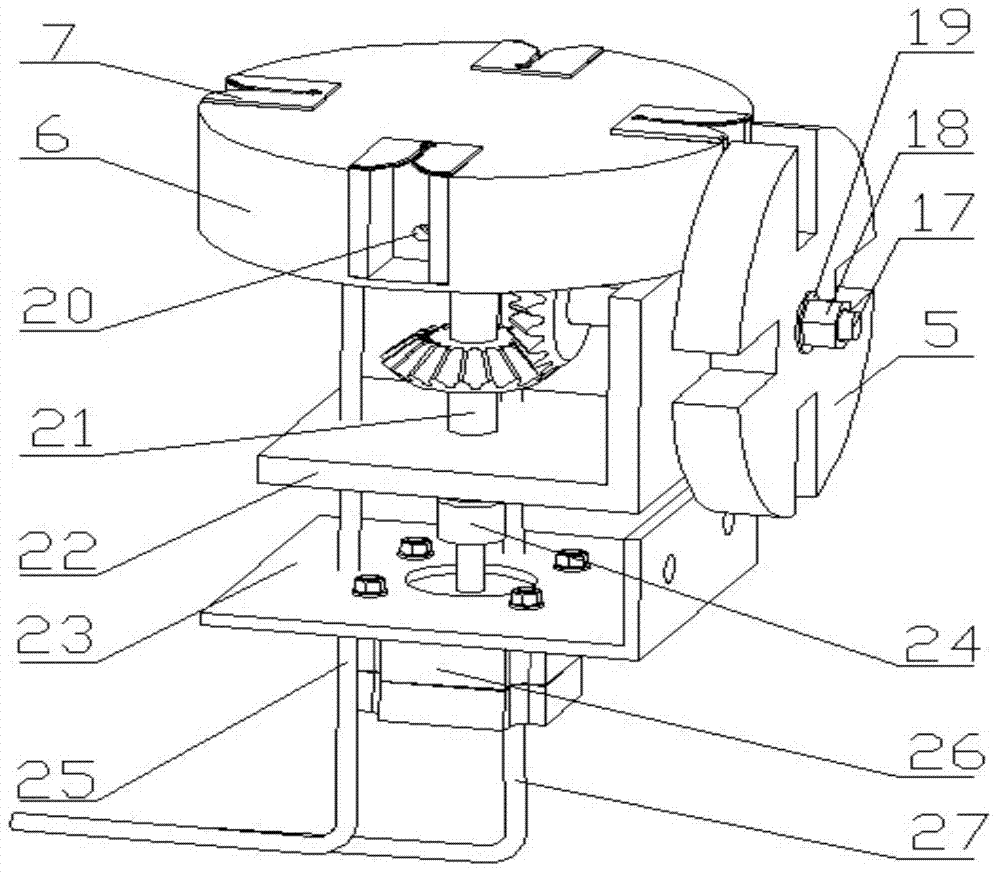

[0037] See figure 2 , the transmission system mainly includes a distribution tray (5), a work tray (6) and a stepping motor (26), the distribution tray (5) is vertically arranged on the frame (1), and the work tray (6) is horizontally arranged on On the frame (1), the stepper motor (26) is located below the work disk (6). Distributing troughs matching the shape and size of the capacitor are evenly provided around the material distribution tray (5); working troughs matching the shape and size of the capacitor are evenly provided around the working plate (6), and a limit piece (7) is provided above the working trough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com