Built-in centering chuck

A built-in, collet technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems such as unsafe, inconvenient disassembly of discs, slow speed, etc., and achieve the effect of large clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

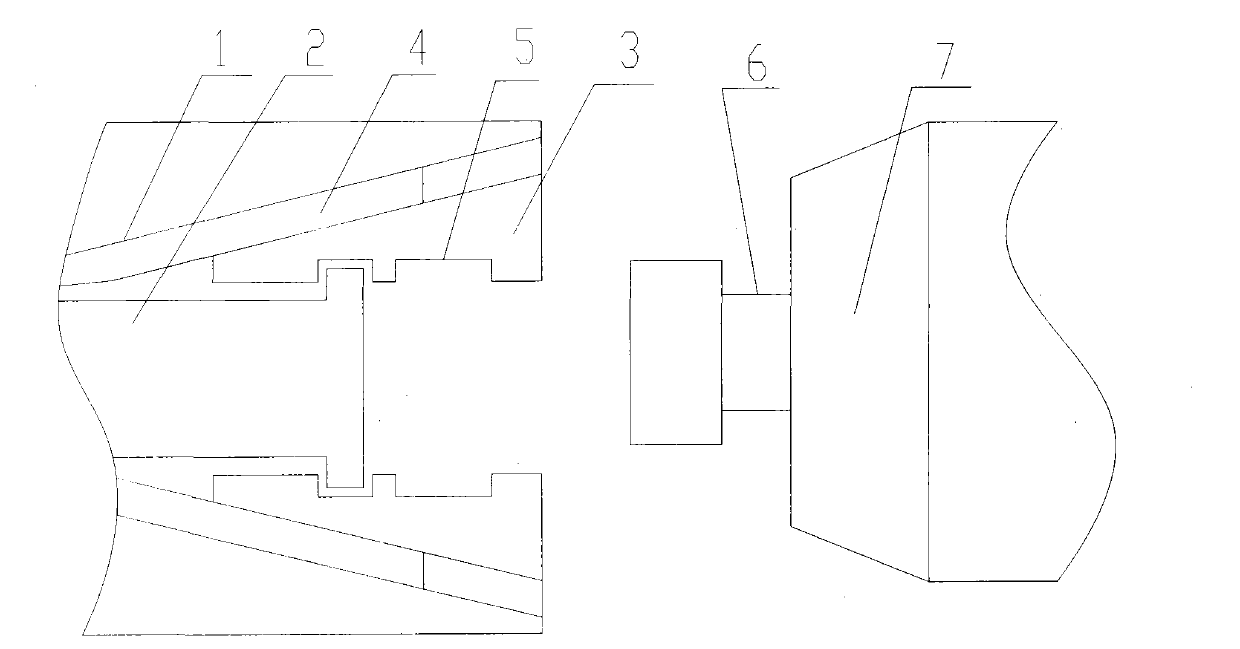

[0016] like figure 1 As shown, a built-in centering chuck, the inner inclined surface 1 of the main shaft of the built-in centering chuck is fixed with a positioning sleeve 4, and there is a sliding movable claw 3 in the movable groove of the positioning sleeve 4, and the movable claw 3 is provided with an inner Hole (not shown), the outer end face of movable claw 3 is slidingly matched with main shaft inner slope 1, and a movable push-pull rod 2 is arranged on the inside of movable claw 3, and passive protruding shaft 6 matches with inner hole (not shown). The passive protruding shaft 6 has a passive protruding shaft slope 7 on the right side. The inclination angles of the inner inclined surface 1 of the main shaft, the positioning sleeve 4, the outer surface of the movable claw 3 and the inclined surface 7 of the passive convex shaft are all between 3° and 38°. There is a groove 5 on the inner hole (not shown in the figure), and it can also be configured in other forms matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com