Automatic tyre cutting machine

A cutting machine and tire technology, applied in the field of machinery, can solve the problems that the tire cannot be divided into two parts, the operation of the machine tool is inconvenient, and manual cutting is laborious, etc., so as to achieve the effect of easy maintenance, labor saving, and increased control panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

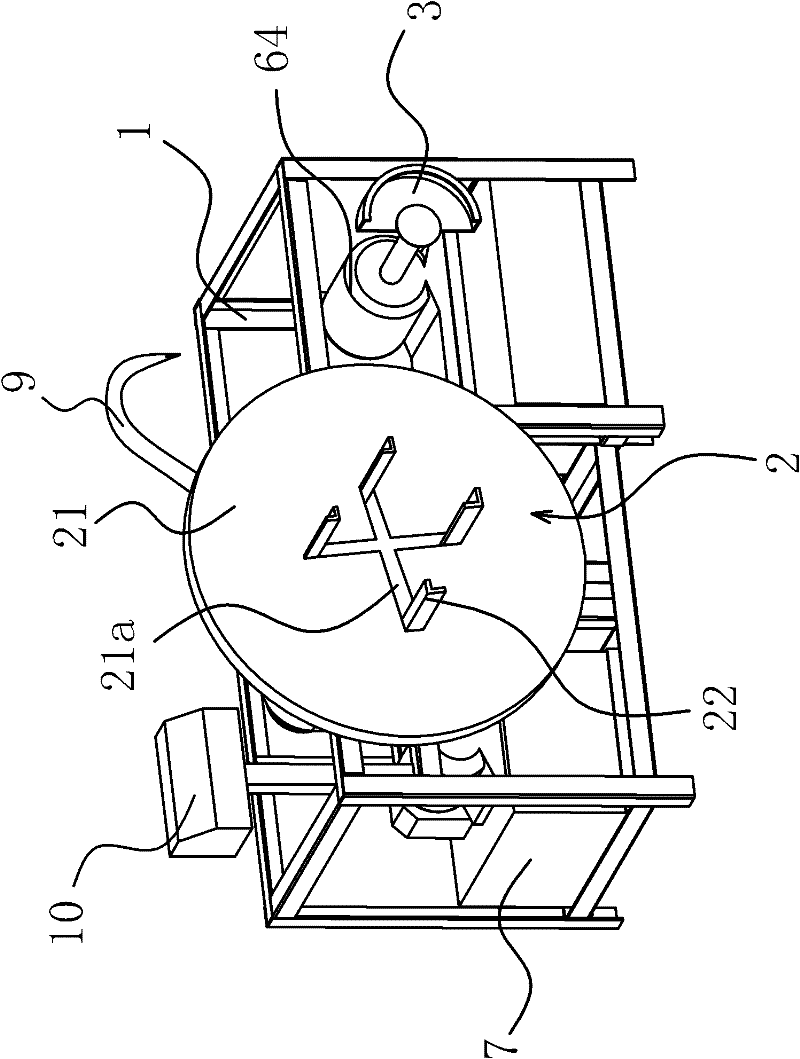

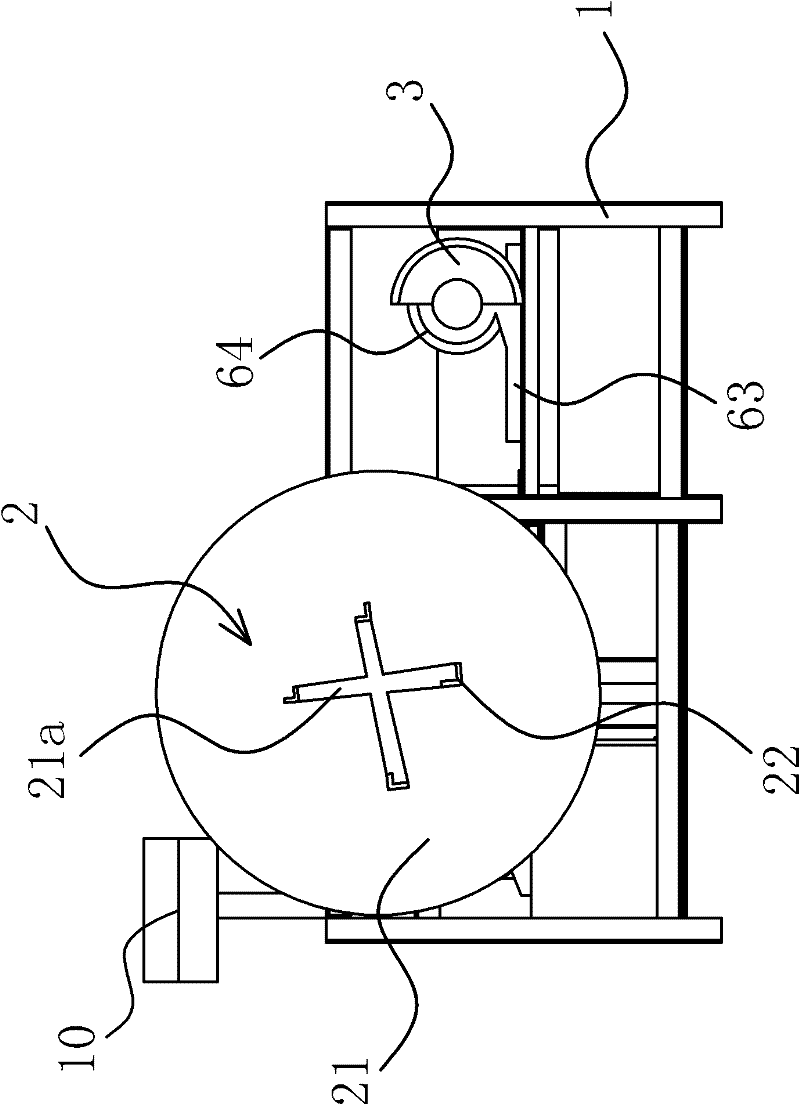

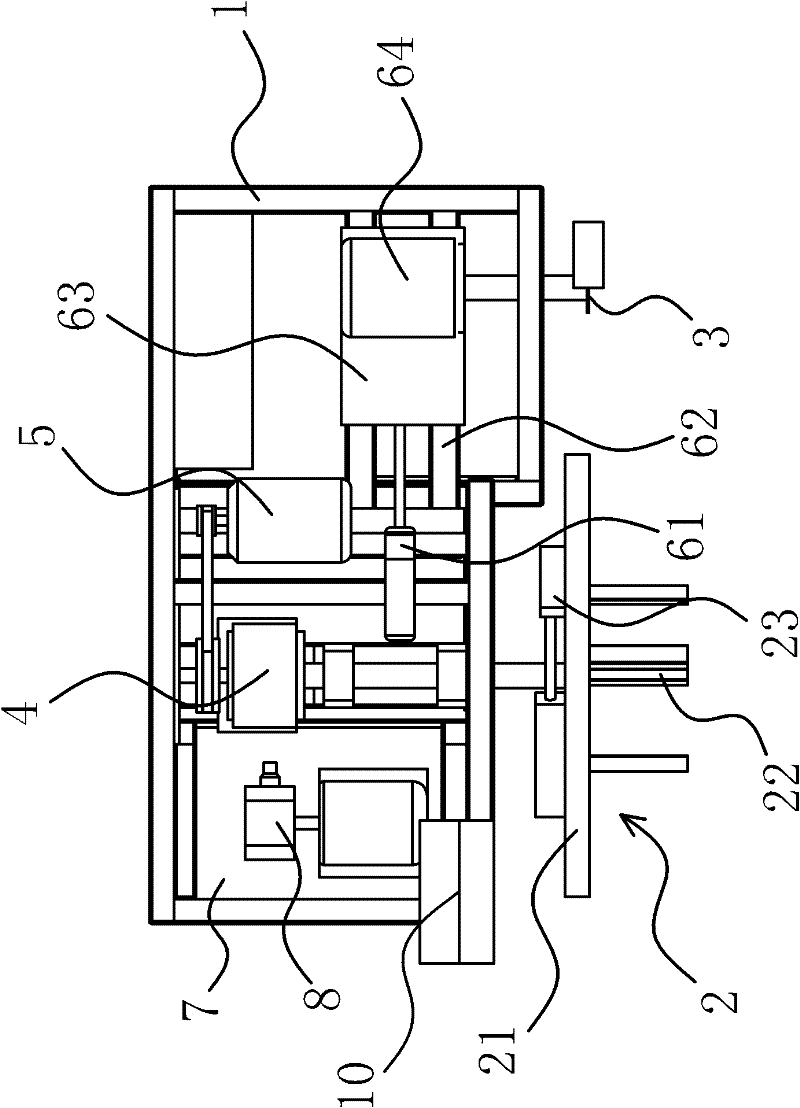

[0033] like figure 1 Shown tire automatic cutter, is made of frame 1, motor 5, motor two 64, cutter 3, clamp 2 etc. The frame 1 is welded by channel steel and triangle iron, the middle part of the frame 1 is provided with a motor 5, and the side close to the motor 5 is provided with a reducer 4, such as Figure 4 As shown, the reducer 4 is connected with the motor 5 through a belt, and the rotation of the motor 5 can drive the operation of the reducer 4 . The output end of speed reducer 4 is connected with a connecting shaft, and the outer end of this connecting shaft stretches out the side part of frame 1, and the clamp 2 for clamping waste tires is provided at the outer end of connecting shaft. The motor 5 rotates to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com