Multifunctional aero-engine cleaning machine

A technology for aero-engines and washing machines, applied in cleaning methods and utensils, multi-stage treatment of water/sewage, cleaning methods using liquids, etc., can solve problems such as low work efficiency, reduced engine power, cracks, etc. The effect of improving the level, improving work efficiency and saving cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

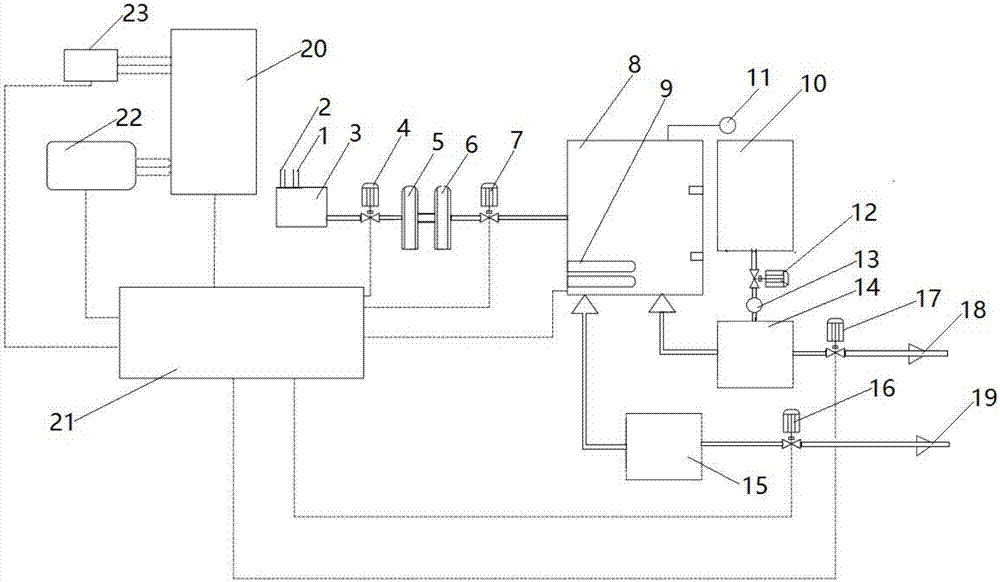

[0031] In specific implementation, such as figure 1 Shown, a kind of multifunctional aero-engine cleaning machine, comprises electric device, control device, water inlet device, filtering device, storage device and mixed cleaning device; Said control device is electrically connected with each device in order to control each device to run, so The water inlet device is connected to the filter device through a pipeline, and the filter device includes an impurity filter 5 and a deionization filter 6. The impurity filter 5 is provided with a multi-layer filter structure, and the impurity filter 5 is connected to a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com