High-precision intelligent wearable film pasting equipment

A technology of smart wearable and film-attaching equipment, which is applied in the directions of automatic packaging control, external support, transportation and packaging, etc. It can solve the problems of insufficient automation, poor film-attaching precision, and easy-to-attach crookedness, achieving strong overall reliability, saving manpower and material resources, The effect of improving the accuracy and efficiency of film application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

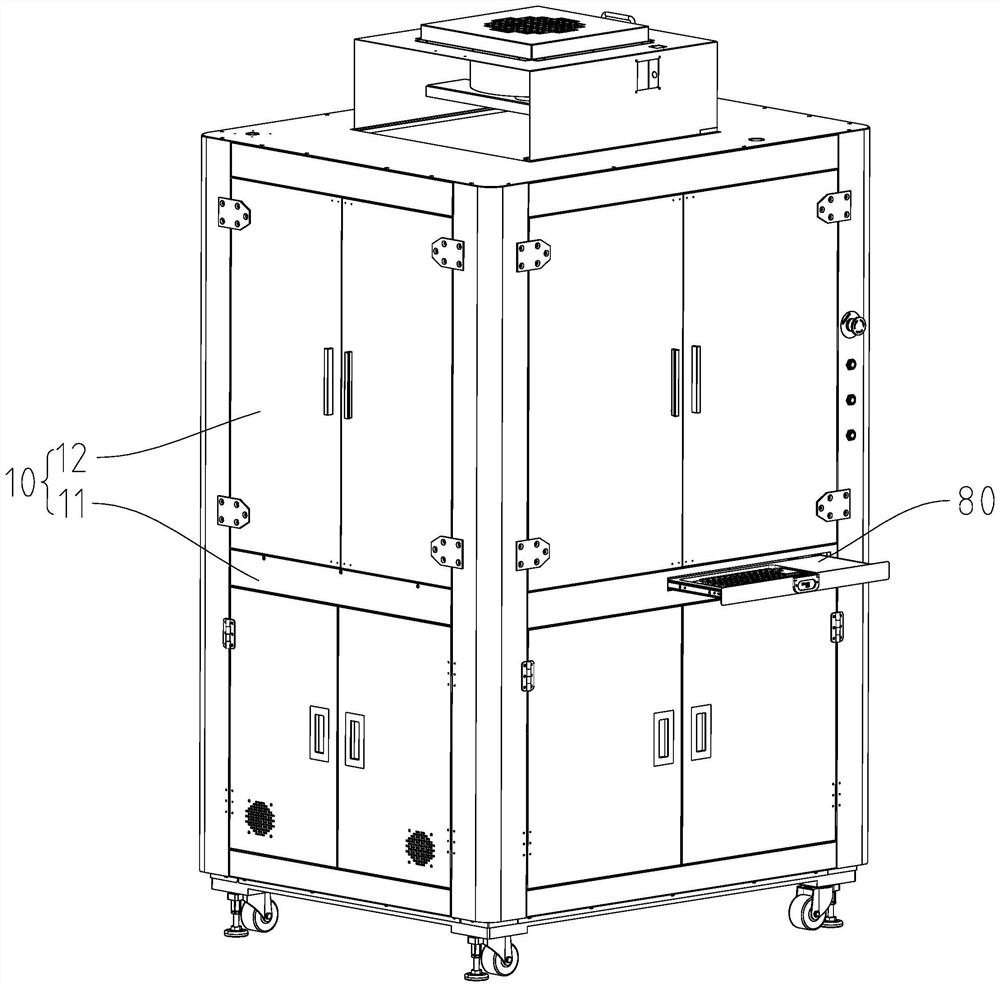

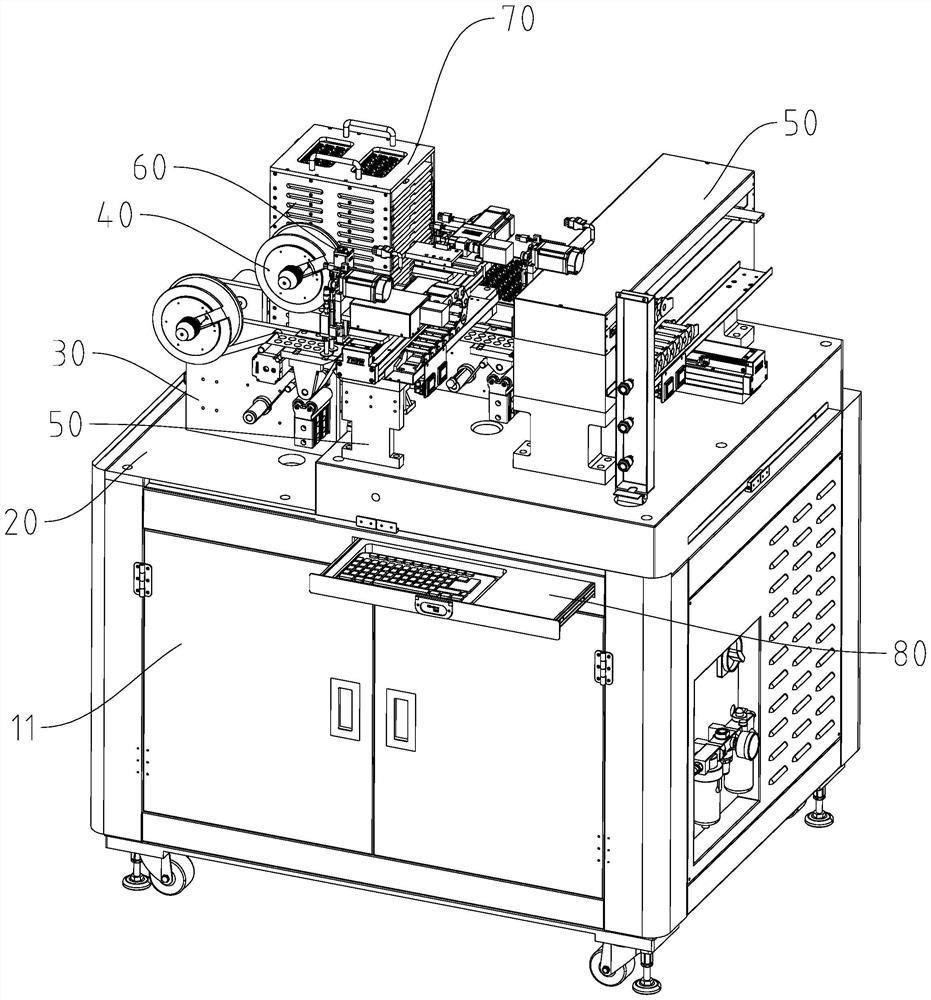

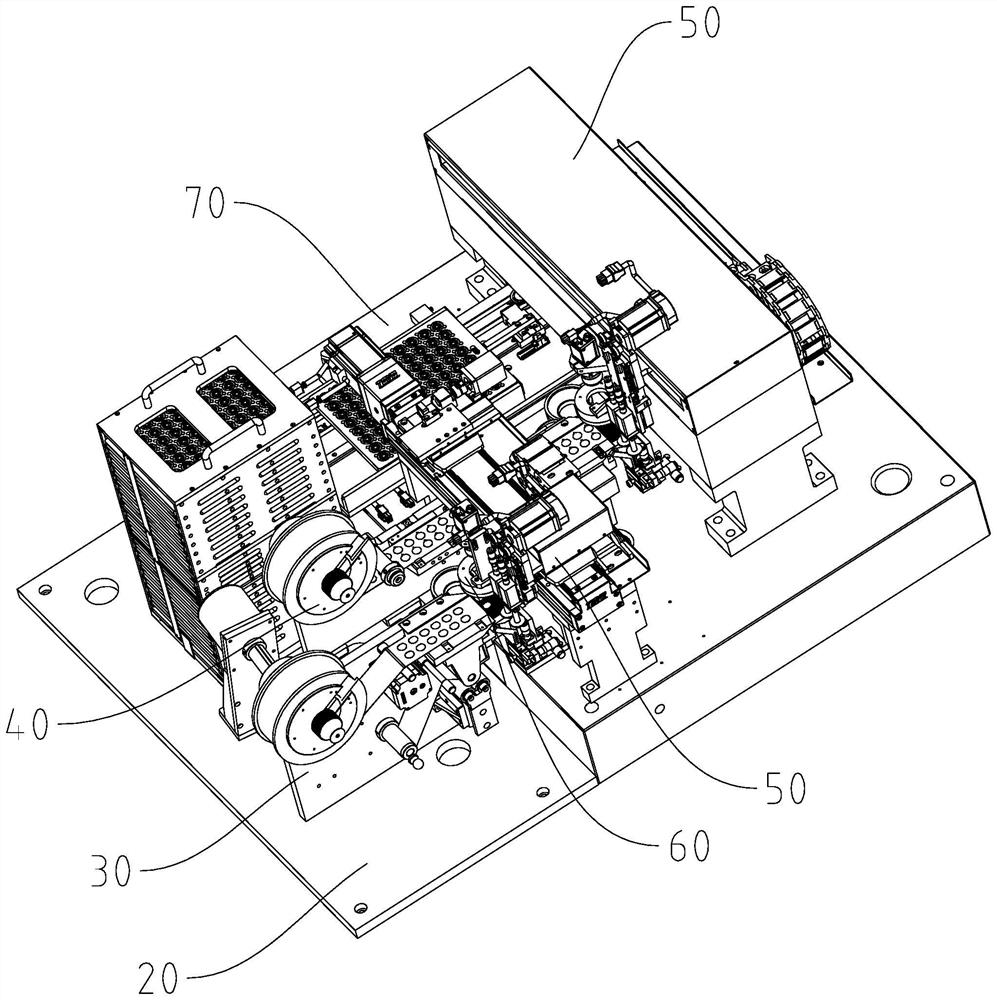

[0033] like Figure 1 to Figure 16As shown, it is a schematic structural diagram of a high-precision smart wearable film sticking device provided by the present invention. A high-precision smart wearable film sticking device is used to stick the Fennel film on the sapphire touch screen 140, including a frame 10, a workbench 20 set on the frame 10, and a workbench 20 set on the workbench 20. The first feeding mechanism 30 and the second feeding mechanism 40 are arranged on the workbench 20 and are used for retrieving and discharging the first feeding mechanism 30 and the second feeding mechanism 40 respectively. A feeding and discharging mechanism 50, two detection mechanisms 60 arranged on each of the feeding and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com