Automatic laminator

A laminating machine, automatic technology, applied in packaging and other directions, can solve the problems of lack of fixed-point equidistant conveying and ejection of multiple products, inability to reach designated stations, low lamination efficiency, etc., to improve lamination accuracy and lamination efficiency, shorten the time The effect of filming time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

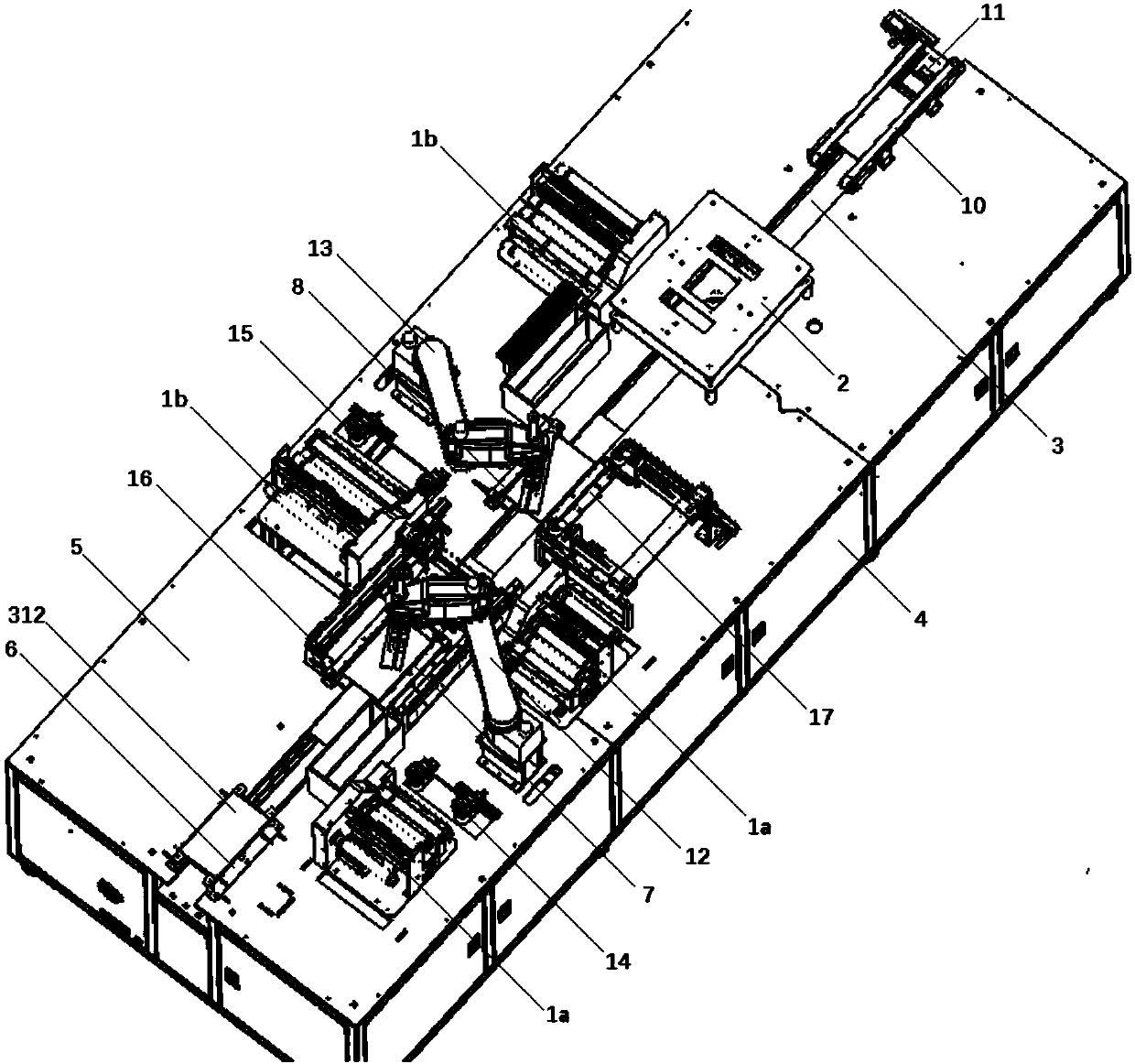

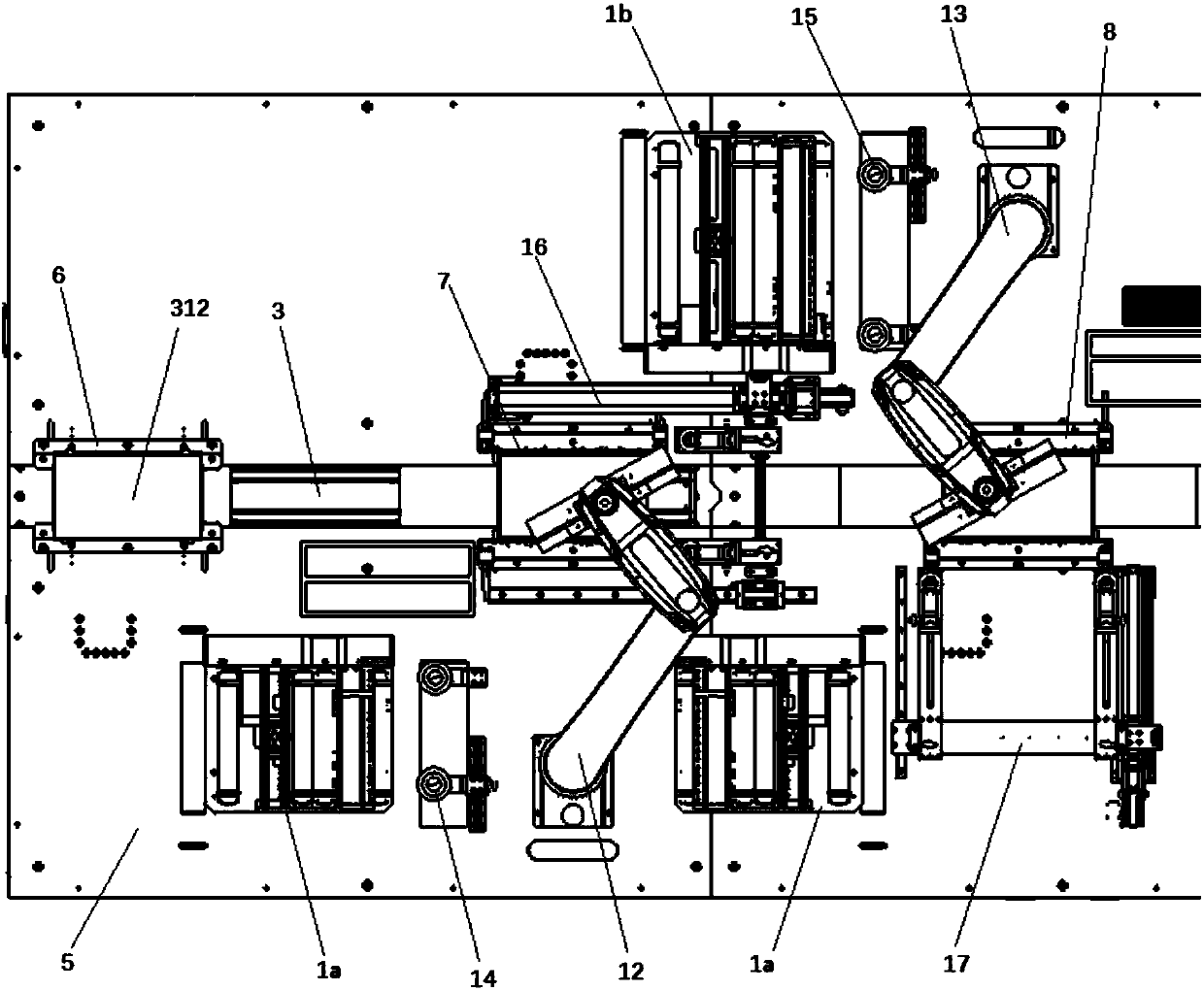

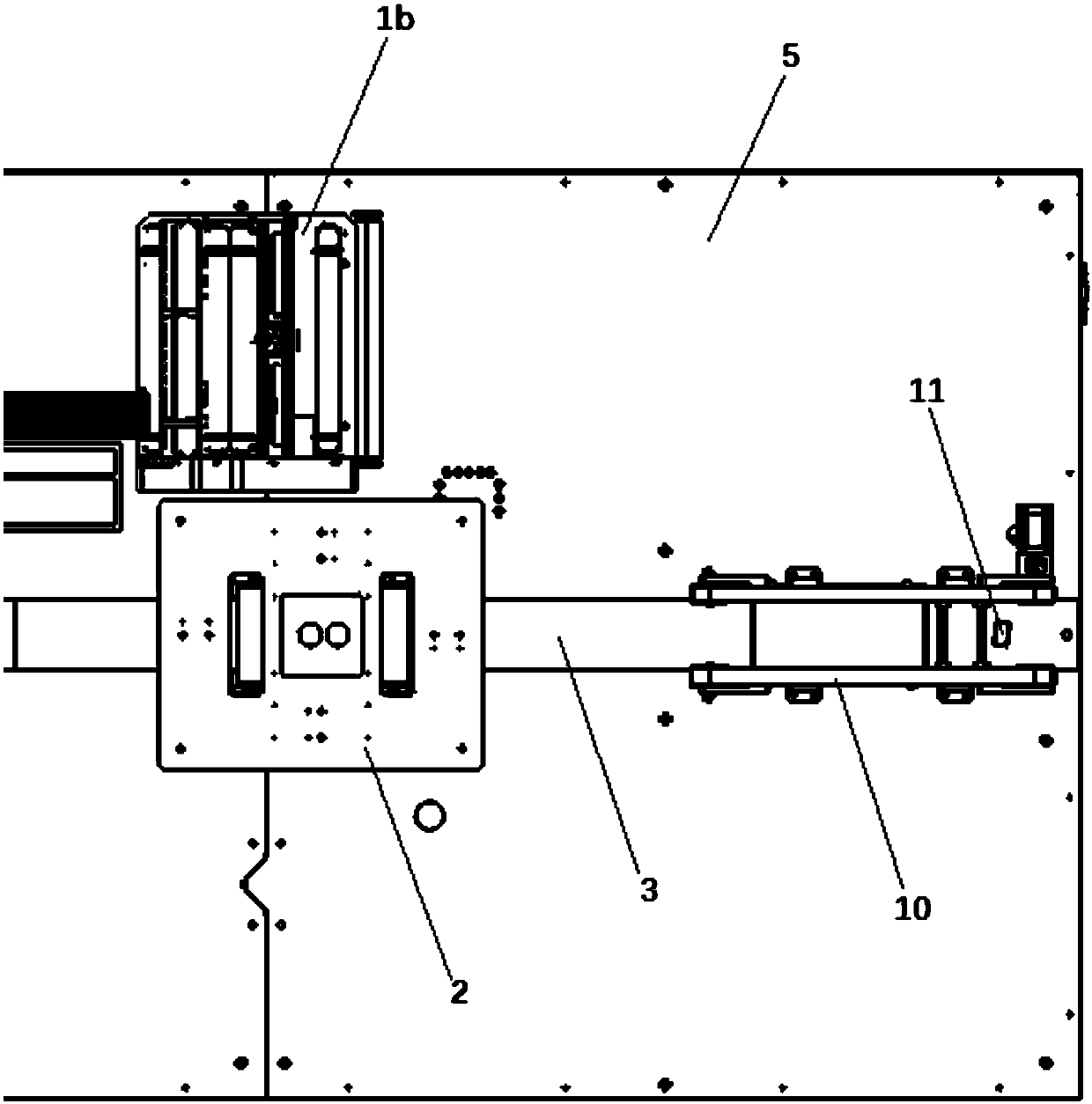

[0054] see Figure 1-5 As shown, an automatic film laminating machine includes an operating table 5 fixed on a frame 4, and the central axis of the operating table 5 is equally divided into 5 stations, which are respectively a product positioning station and a short side material laminating worker. position, long side material filming station, product edge wrapping station and product output station; a transplanting jacking mechanism 3 is buried on the central axis of the operation table 5, and the transplanting jacking mechanism 3 is formed by transplanting The device is composed of 5 jacking devices 307 arranged on the transplanting device. When the transplanting device is in the initial position, the 5 jacking devices 307 are divided into 5 stations, and The five jacking devices 307 are all higher than the operating table 5;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com