Gum topping equipment

A technology for pasting glue and equipment, which is applied in the direction of sustainable manufacturing/processing, sending objects, climate sustainability, etc. It can solve the problems of reduced production efficiency, uneven quality, and unsightly appearance, so as to save labor costs and improve production Consistency, productivity and quality improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is further described:

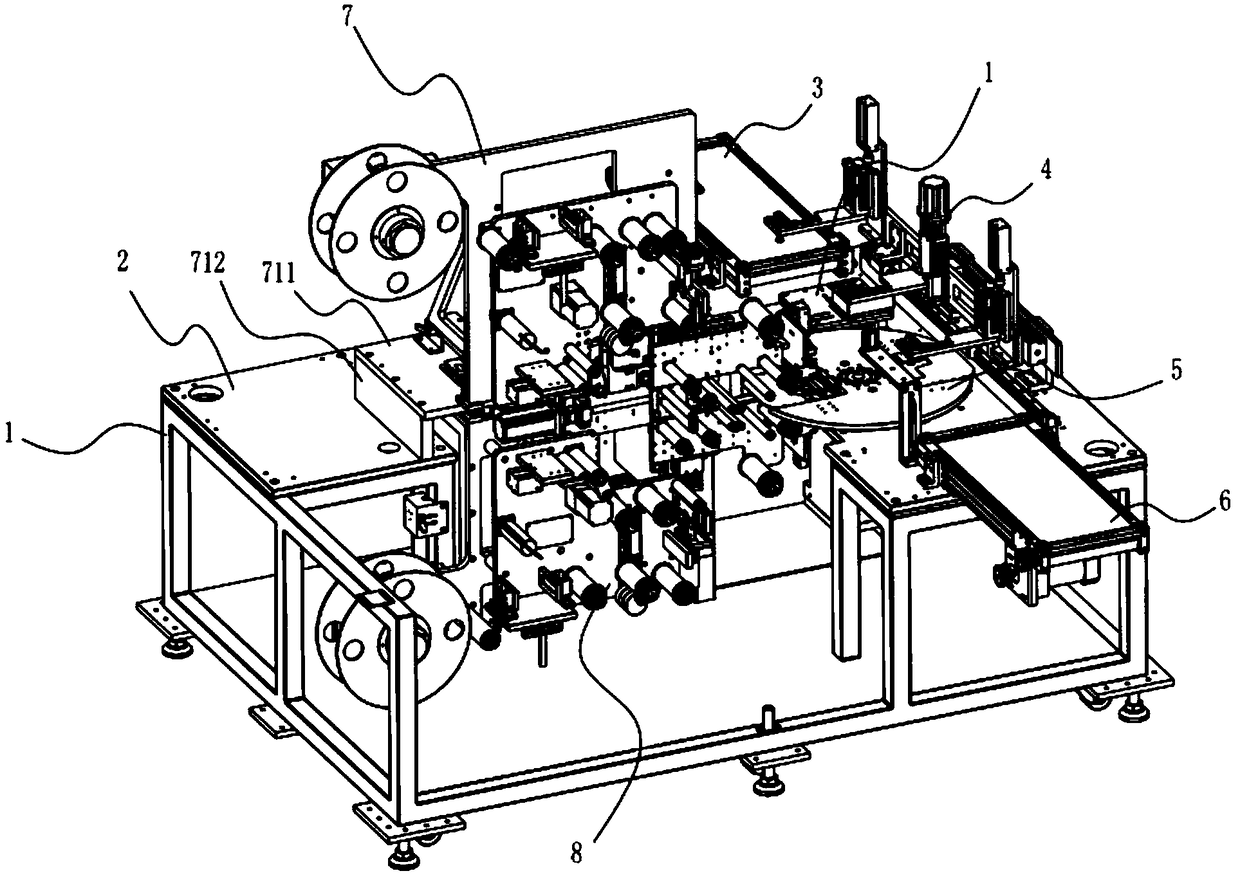

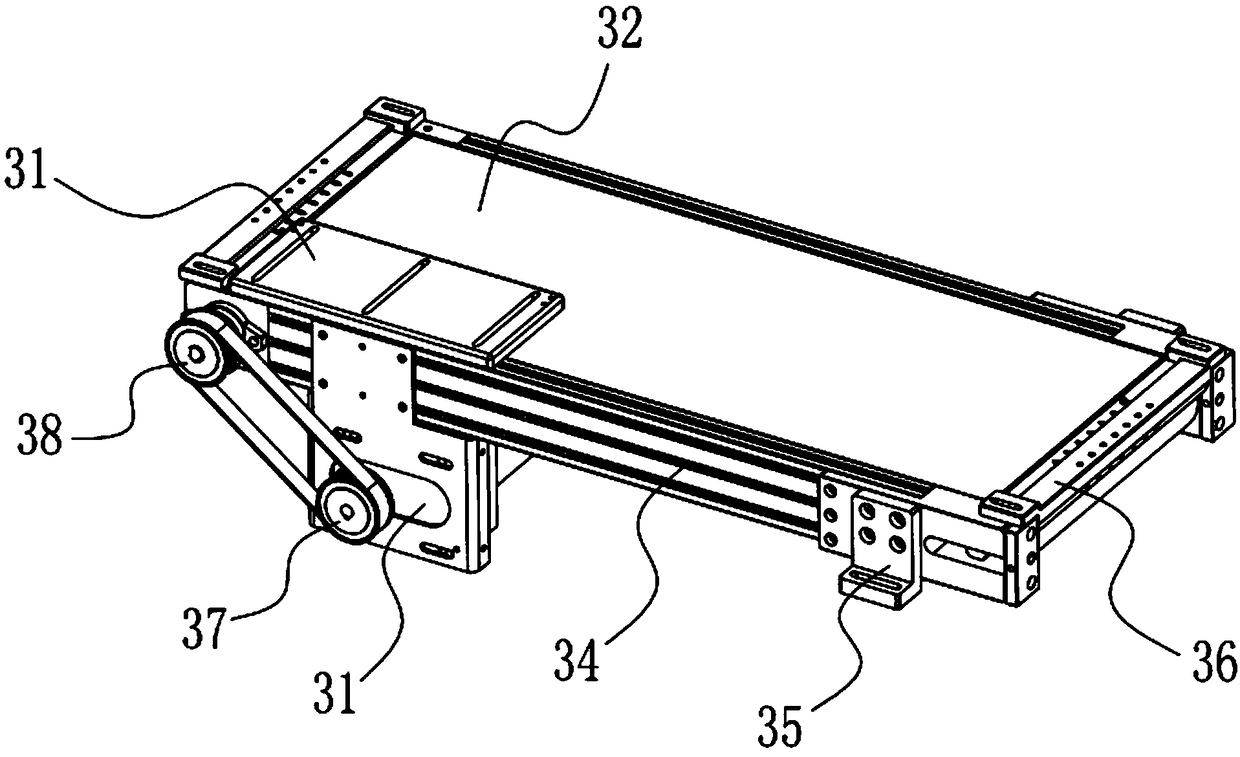

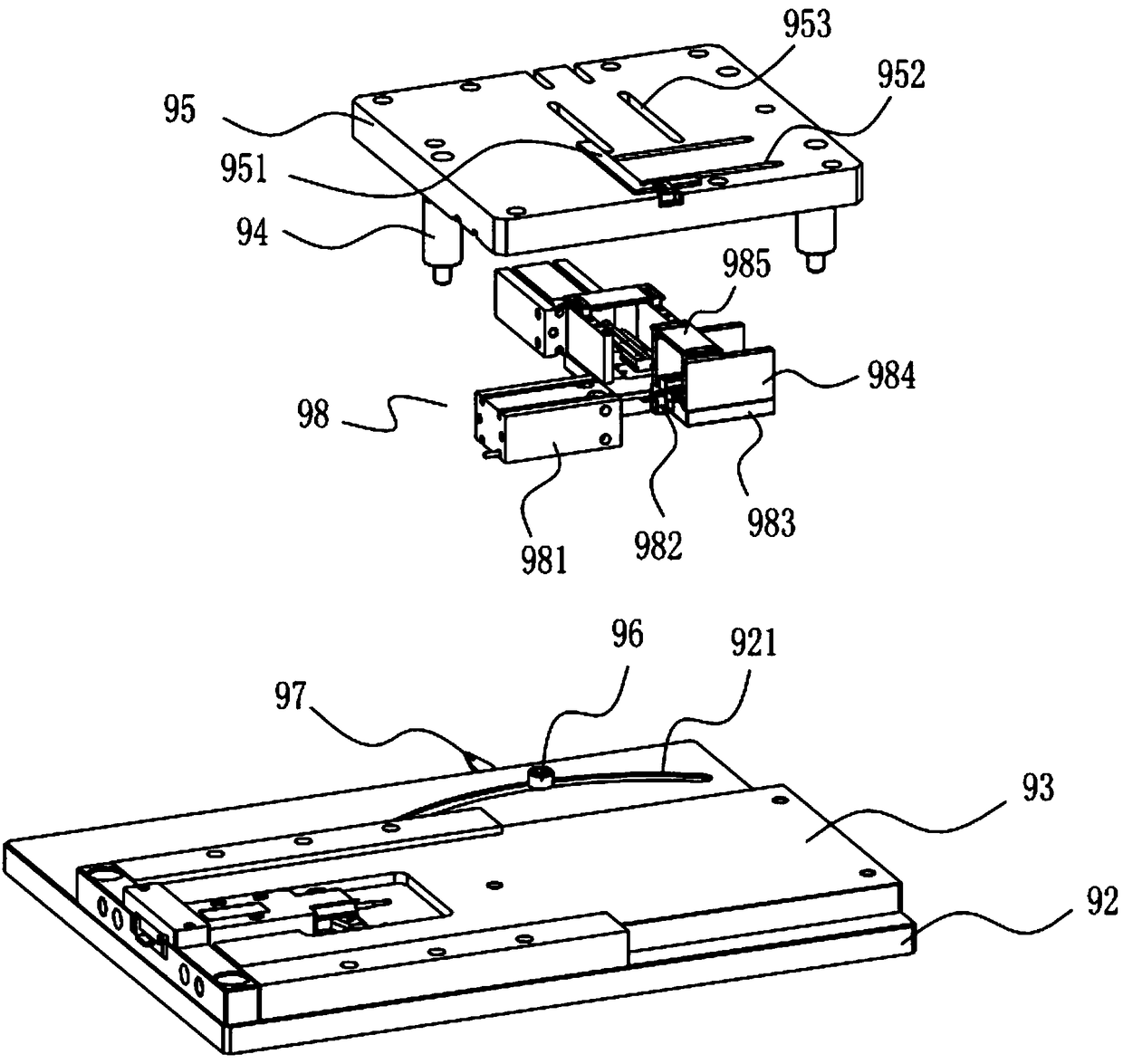

[0039] Please refer to figure 1 with Figure 7 , a kind of gluing equipment, comprising frame 1, base plate-2 installed on frame 1 and positioning device 9 installed on base plate-2, manipulator device 4, loading and unloading device 5, double-sided gluing device and outlet The feeding device 6, the positioning device 9, the manipulator device 4, the loading and unloading device 5, the double-sided gluing device and the discharging device 6 are all arranged around the loading and unloading device 5, and the positioning device 9 and the discharging device 6 are all along the X axis Relatively arranged, the double-sided gluing device and the manipulator device 4 are evenly arranged opposite to each other along the Y axis. The double-sided gluing device includes a symmetrically arranged upper gluing assembly 7 and a lower gluing assembly 8. On the loading and unloading device 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com