Special-shaped part film pasting device and method

A film sticking device and special-shaped parts technology, which is applied in the field of product processing, can solve the problems of low precision and slow speed, and achieve the effect of high-precision special-shaped parts film sticking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

[0027] Aiming at the problems of low film laminating precision existing in the current special-shaped film laminating device, resulting in poor product processing quality and low efficiency, the present invention sets a positioning table and a profiling film positioning block, and the two cooperate with each other to carry out three-point high-precision positioning of the product and profiling film. Positioning, to ensure the accuracy of the product film and product quality.

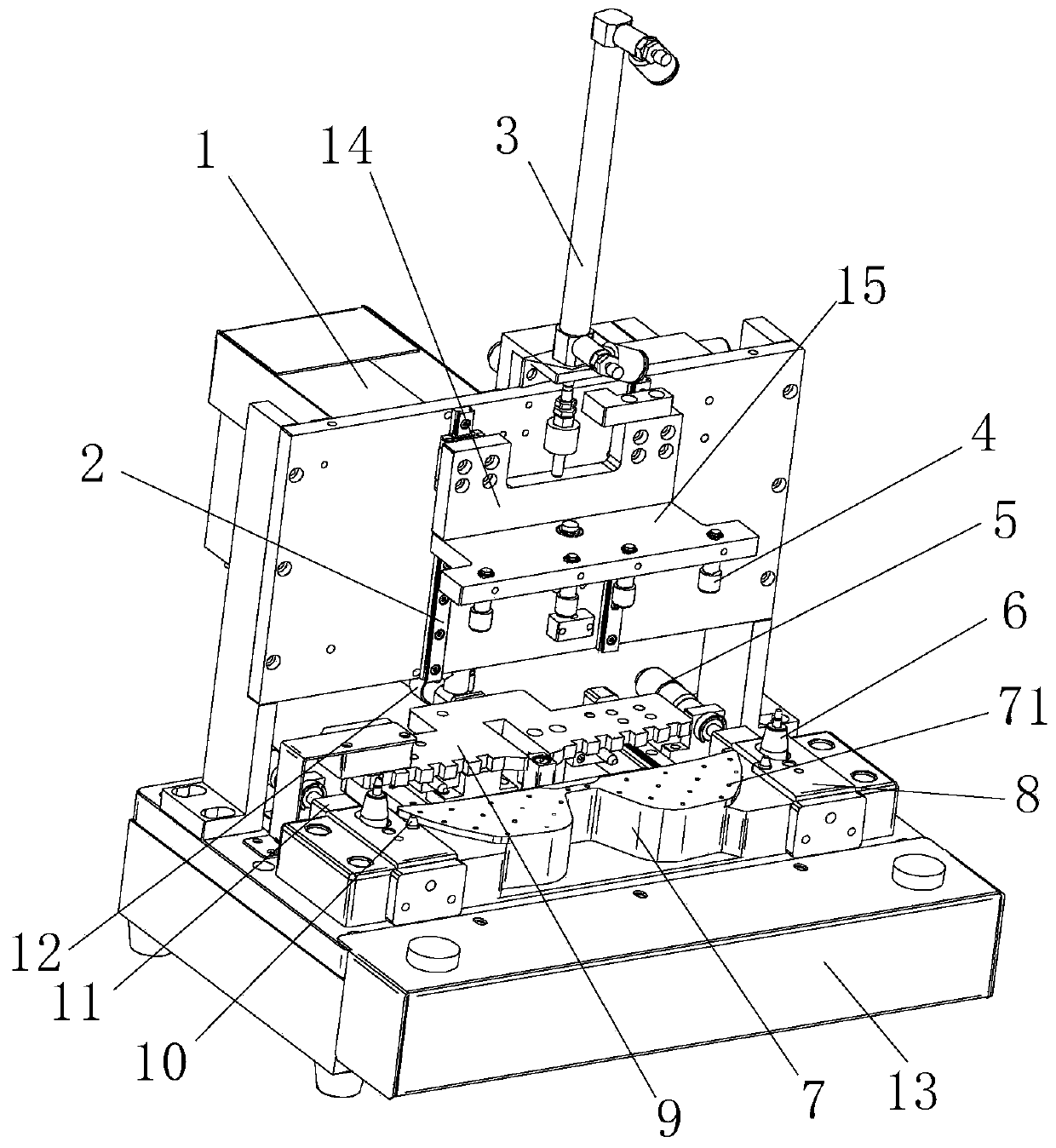

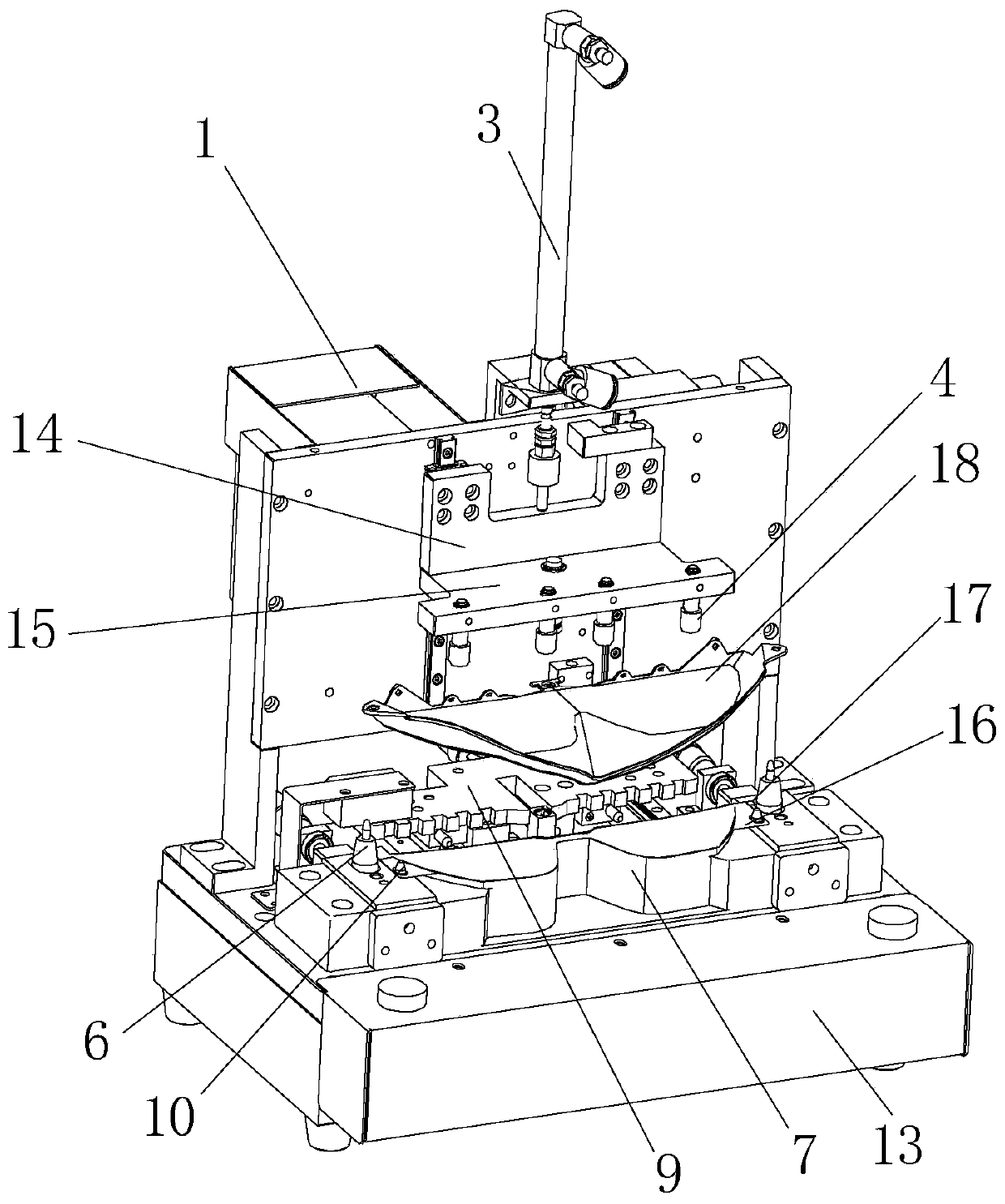

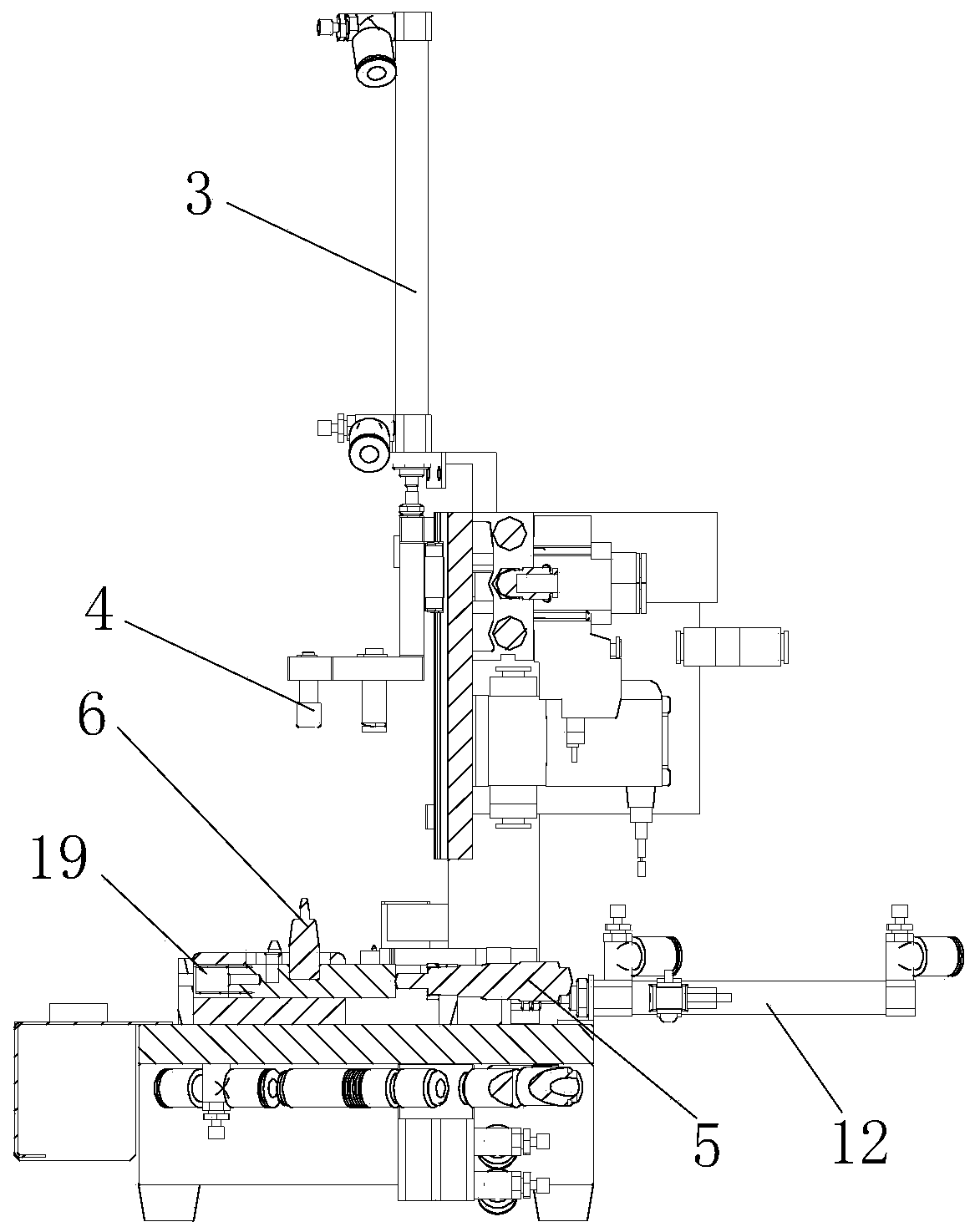

[0028] In order to describe in detail the structure of the special-shaped piece fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com