Patents

Literature

186results about How to "Reduce the cost of protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

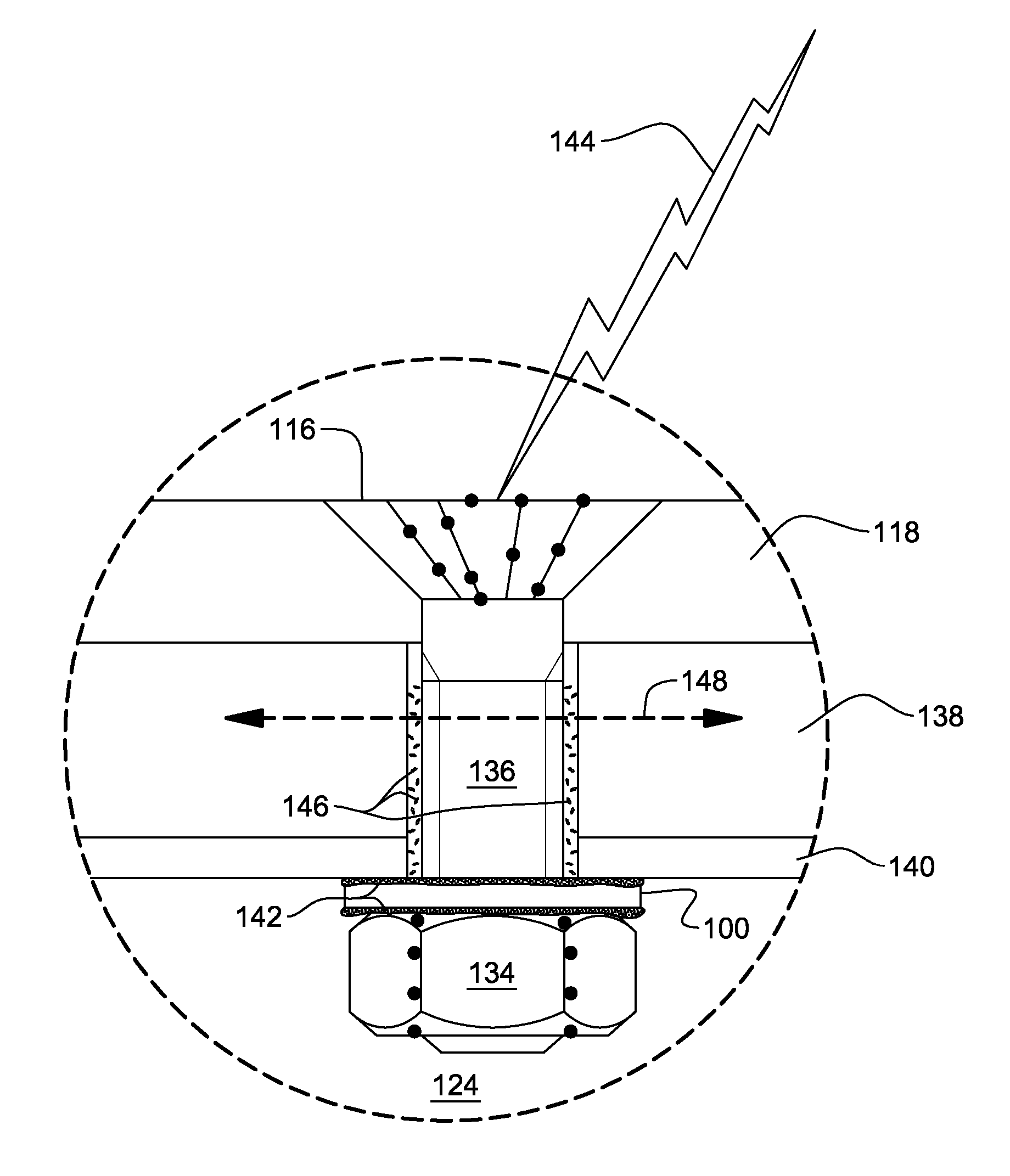

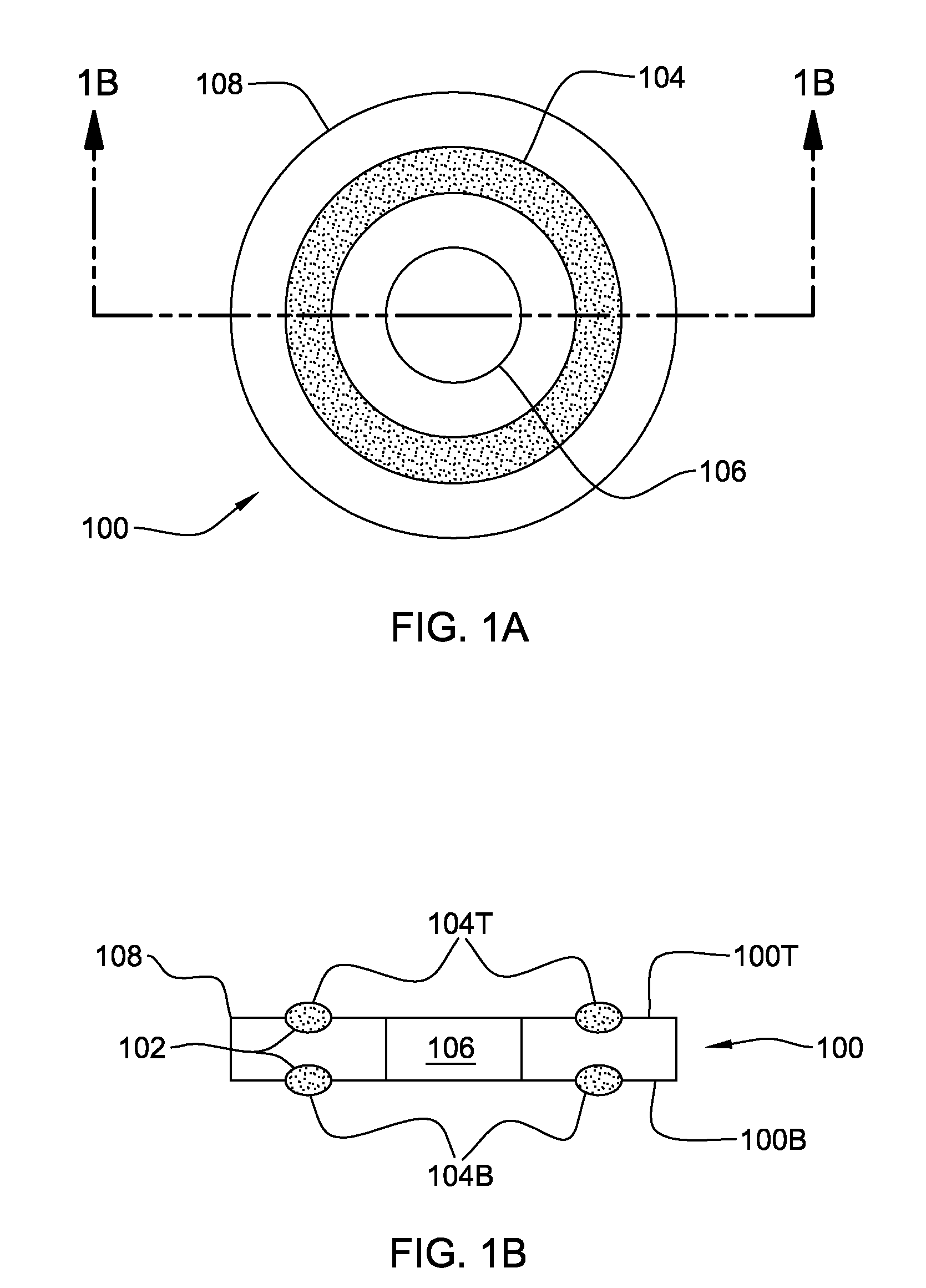

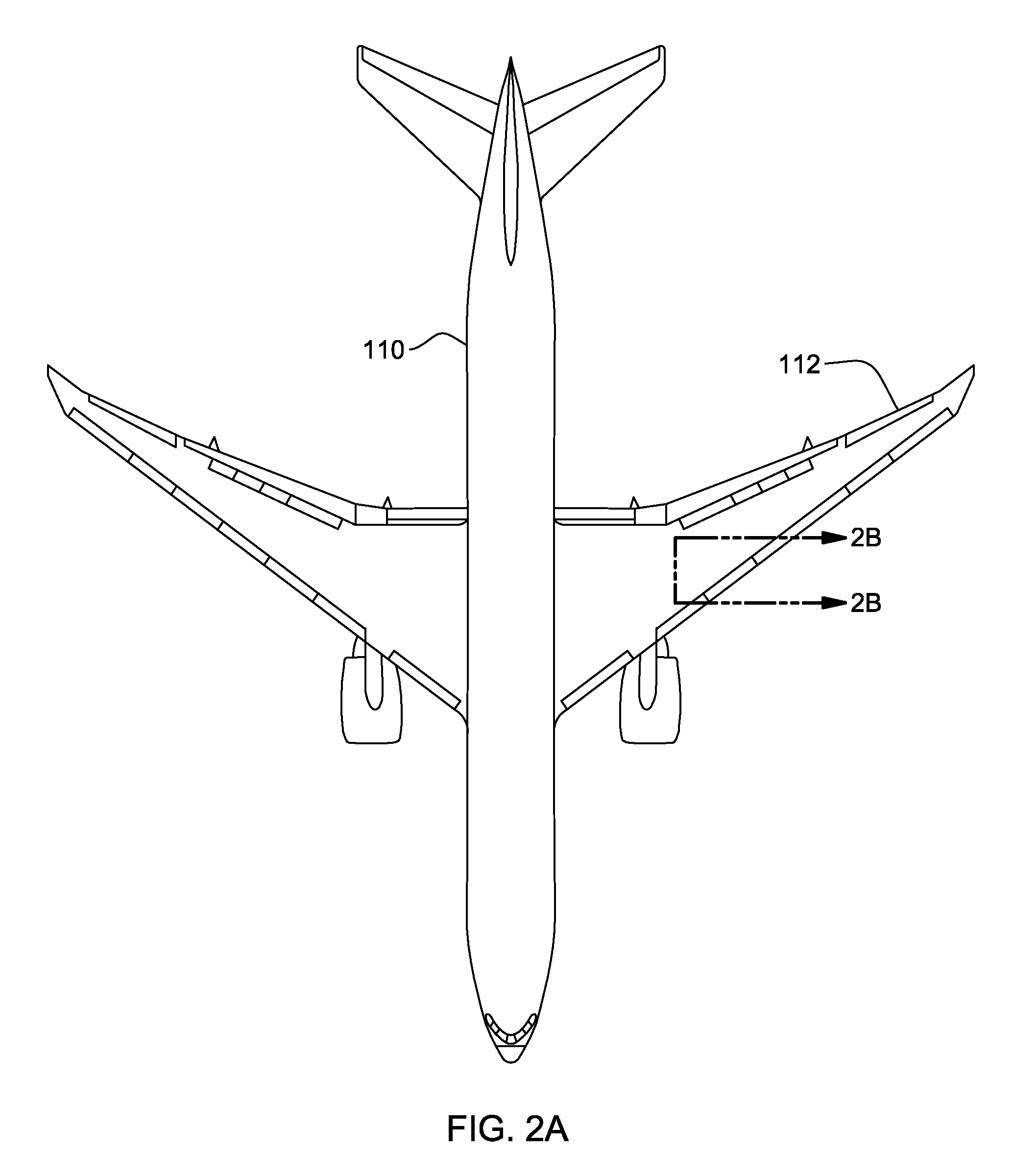

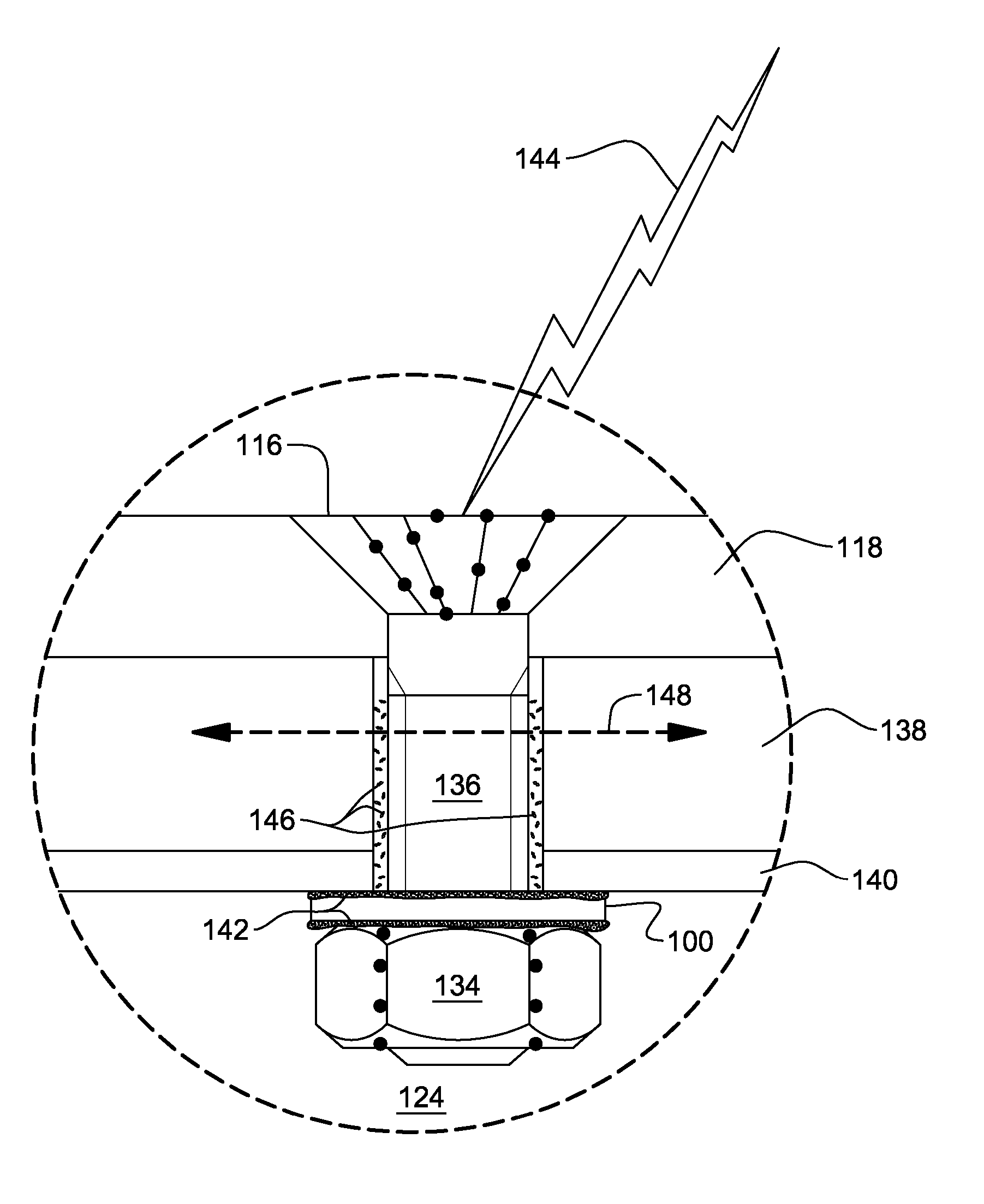

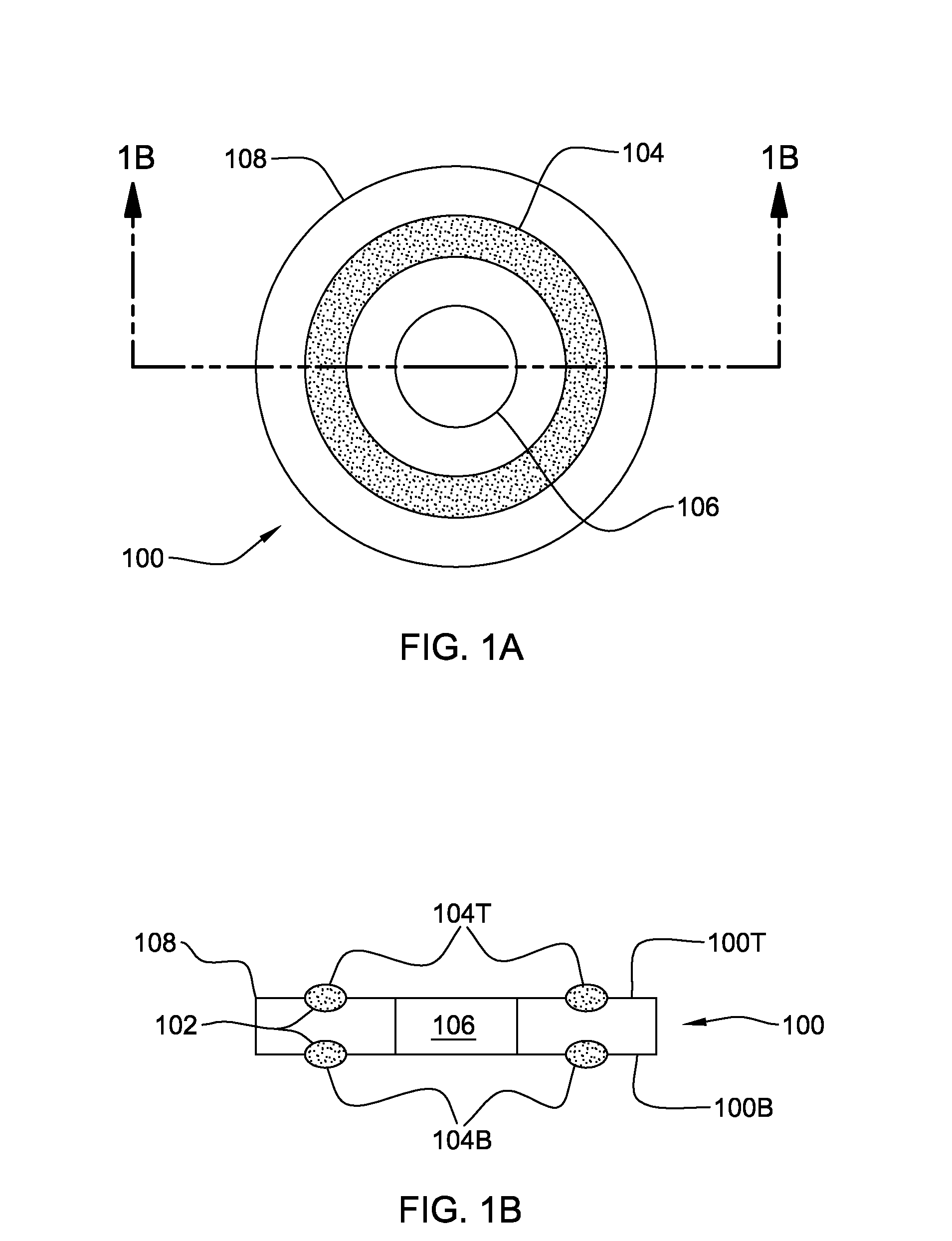

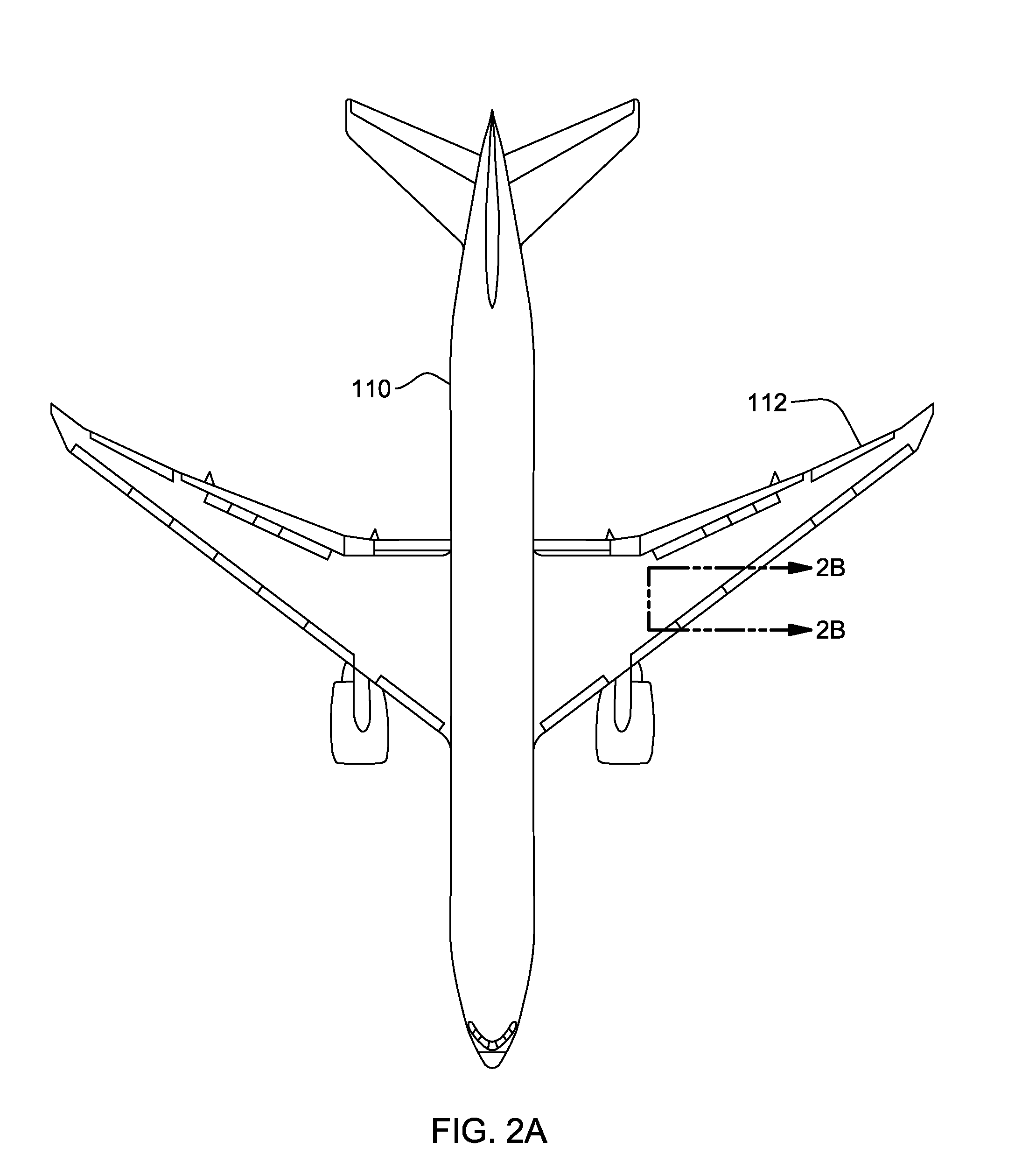

Fastening assembly including washer for sealing the assembly for lightning strike protection in composite structures

InactiveUS7755876B2Voltage potentialEasy to produceWashersAircraft lighting protectorsLightning strikeEngineering

A washer, a fastening assembly including the washer and a composite structure including the washer sealing the assembly for internal lightning strike protection. The washer includes one or more concentric ribs that are dielectric rings on both sides. When used (e.g., with a nut and bolt) internal to a structure, especially a composite structure, the washer seals the fastener hole (i.e., that the bolt passes through) and contains any sparking and hot gasses that may arise in the fastener hole from entering the structure.

Owner:THE BOEING CO

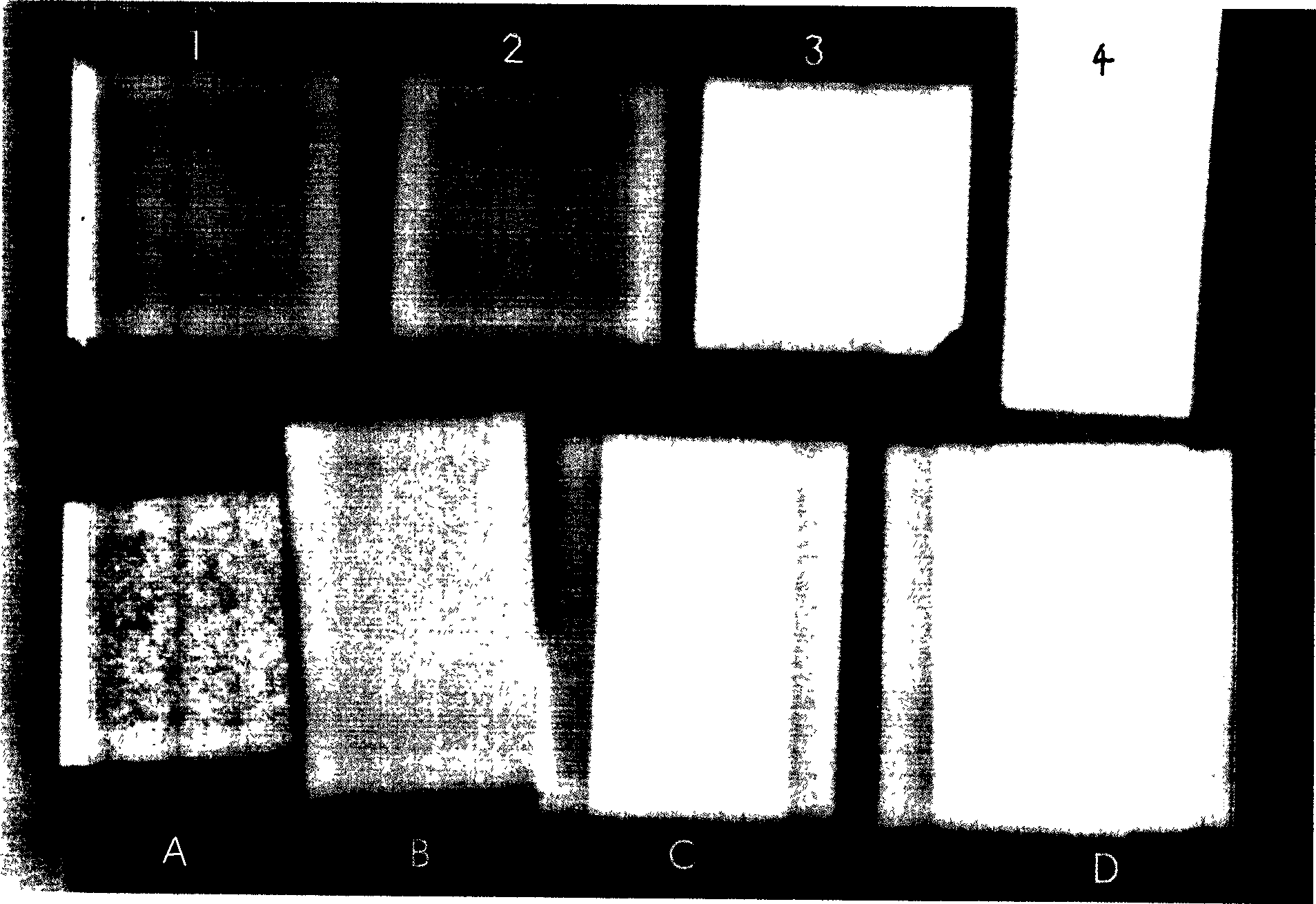

Synergistic insecticidal composition containing chloronicotynyle and pyrethroids compounds

InactiveUS20060014724A1Highly effectiveReduce the cost of protectionBiocideDead animal preservationCompound aCompound (substance)

A synergistic insecticidal composition is formed containing a Chloronicotynyle compound and a Pyrethroids compound. The Chloronicotynyle compound is provided in an amount preferably ranging from 0.1 to 5.0% by weight of the synergistic insecticidal composition. The Pyrethroids compound is provided in an amount preferably ranging from 1 to 60% by weight of the synergistic insecticidal composition. The synergistic insecticidal composition also preferably includes 35 to 98.90% by weight of conventional agriculturally acceptable carrier(s) and / or excipients.

Owner:UNITED PHOSPHORUS LTD

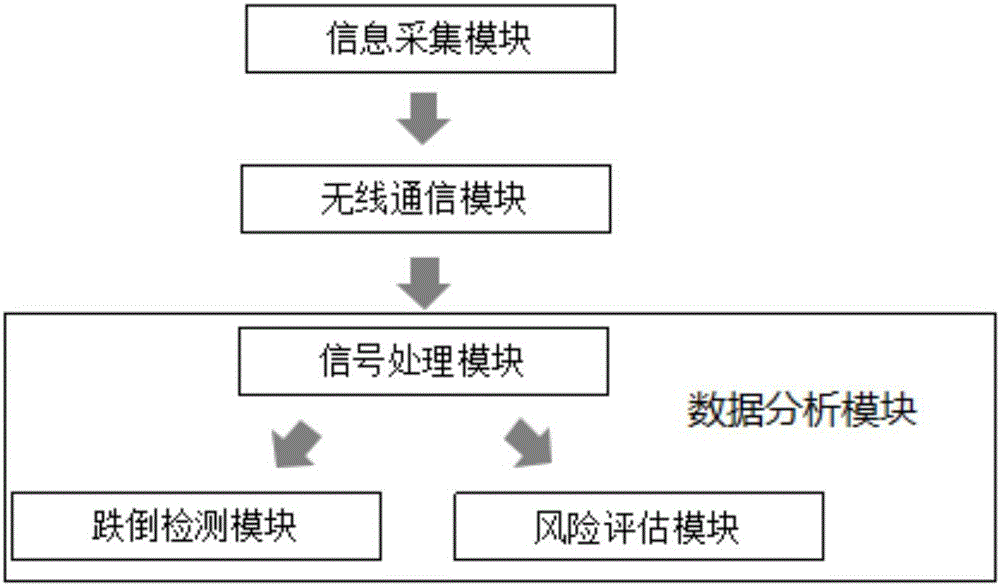

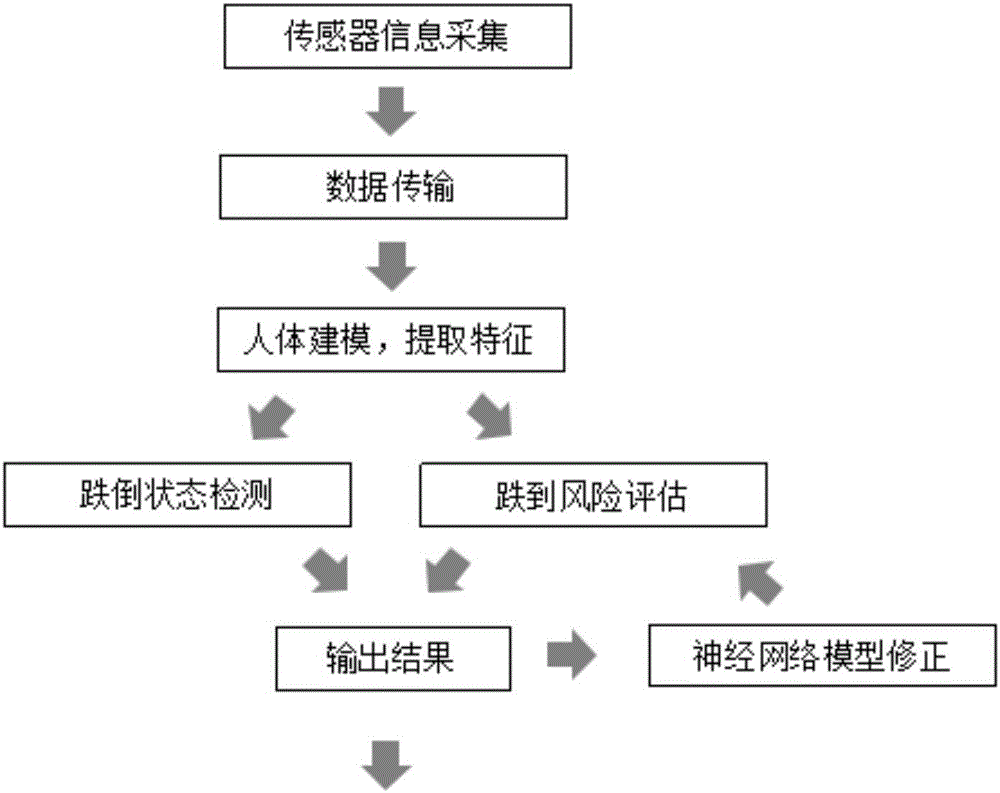

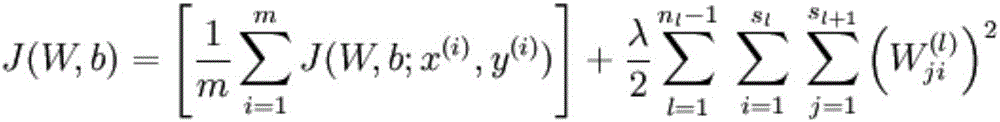

Tumbling risk assessment, monitoring system and assessment method on basis of multi-motion sensors

InactiveCN106539587AReduce volumeEasy to carryDiagnostic recording/measuringSensorsFall riskOriginal data

The invention provides a tumbling risk assessment, a monitoring system and an assessment method on the basis of three nine-shaft motion sensors. According to the tumbling risk assessment, the monitoring system and the assessment method, the tumbling state detecting, the tumbling risk detecting and tumbling protecting device control are achieved. The monitoring system comprises an information collecting module, a wireless communication module and a date analyzing module. The three nine-shaft motion sensors are mainly used, two of the nine-shaft motion sensors are placed in two shoes, and another is placed on the wrest; original data of the accelerated speed, the angular speed and the angle are obtained through the three sensors, a Bluetooth module is used for transmitting a data signal, and the signal is transmitted to a data analyzing terminal. The tumbling state is detected by analysis on various data signals through the motion sensors, and the tumbling risk is assessed and fed back to a tester by the combination with the standard of a Tinetti assessing table. The invention further discloses a gait assessment method, according to the method, through various signal types such as the accelerated speed, the angular speed and the angle, modeling is conducted on human bodies, gait characteristics are extracted, and assessment is conducted with Tinetti.

Owner:ZHEJIANG UNIV

Fastening assembly including washer for sealing the assembly for lightning strike protection in composite structures

InactiveUS20070258182A1Voltage potentialEasy to produceWashersAircraft lighting protectorsLightning strikeInto-structure

A washer, a fastening assembly including the washer and a composite structure including the washer sealing the assembly for internal lightning strike protection. The washer includes one or more concentric ribs that are dielectric rings on both sides. When used (e.g., with a nut and bolt) internal to a structure, especially a composite structure, the washer seals the fastener hole (i.e., that the bolt passes through) and contains any sparking and hot gasses that may arise in the fastener hole from entering the structure.

Owner:THE BOEING CO

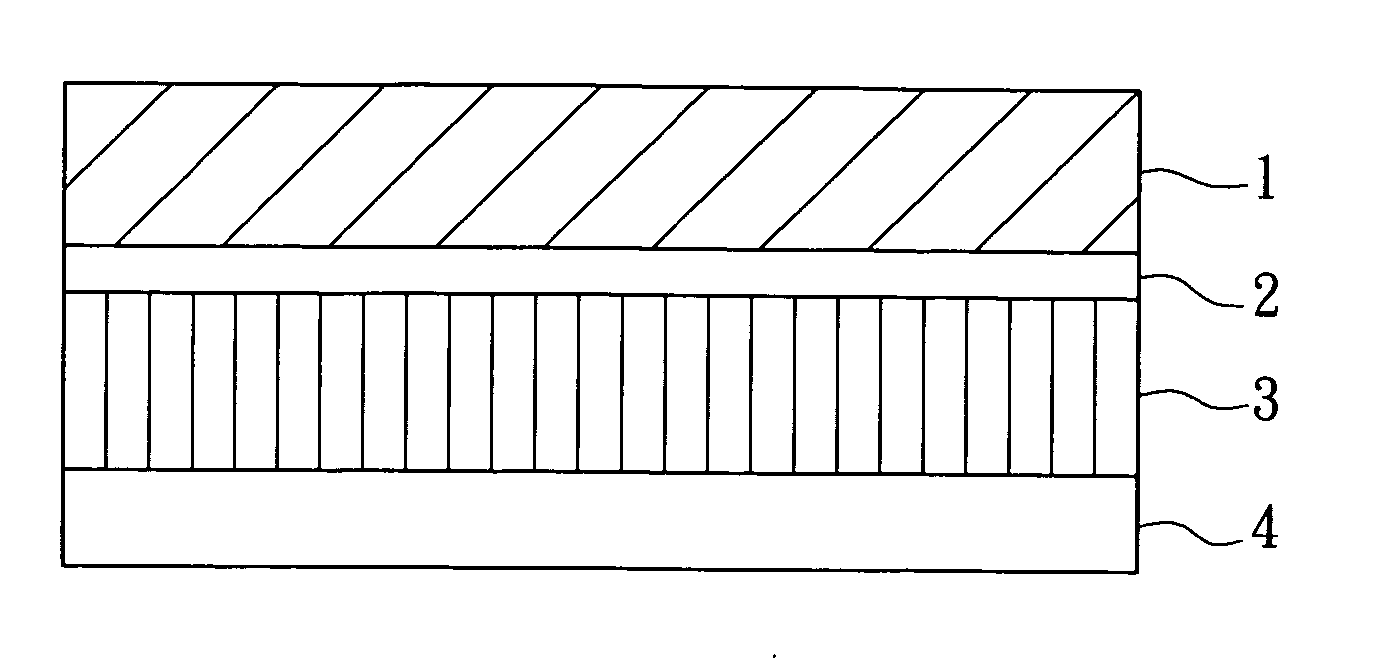

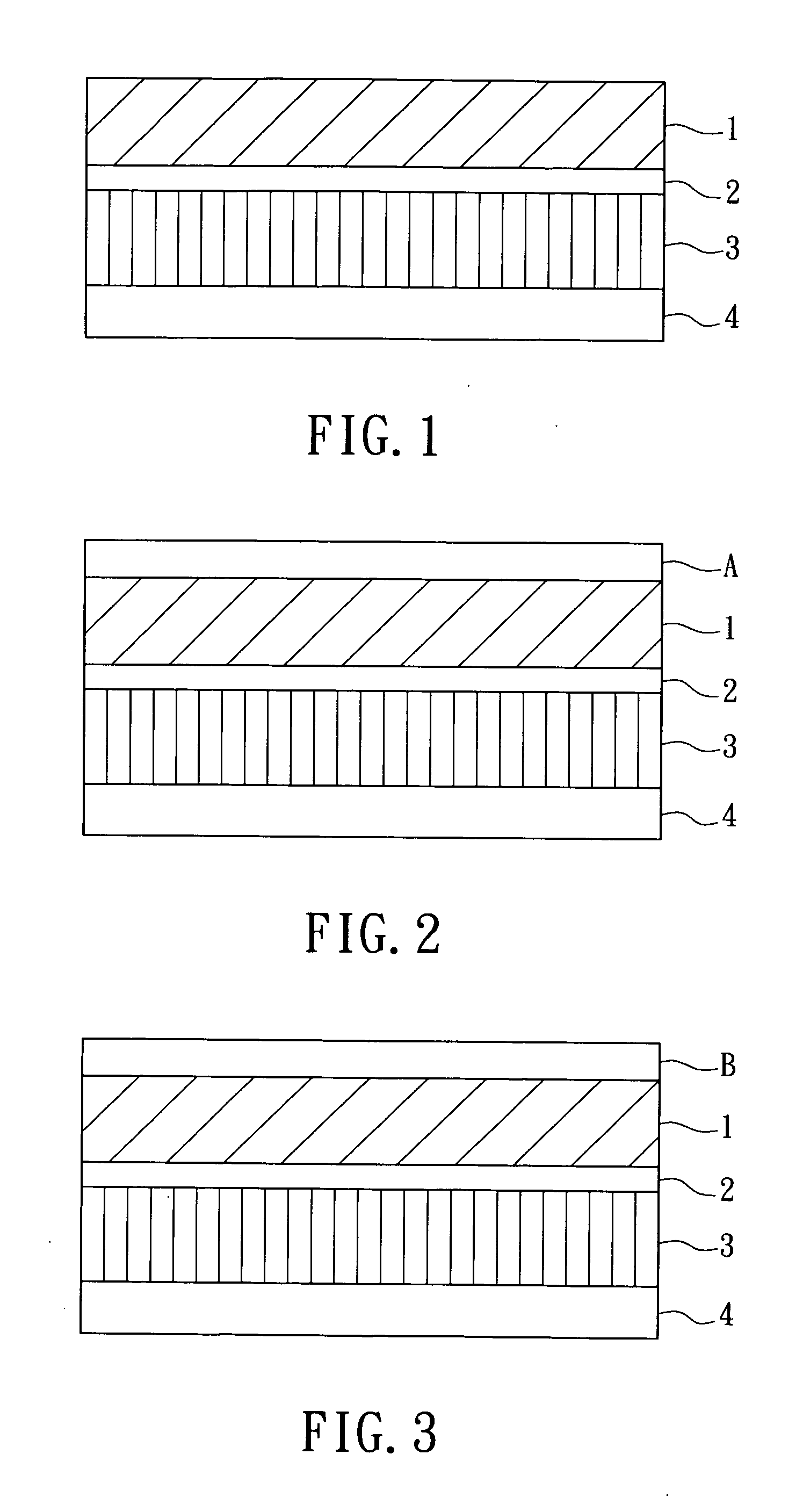

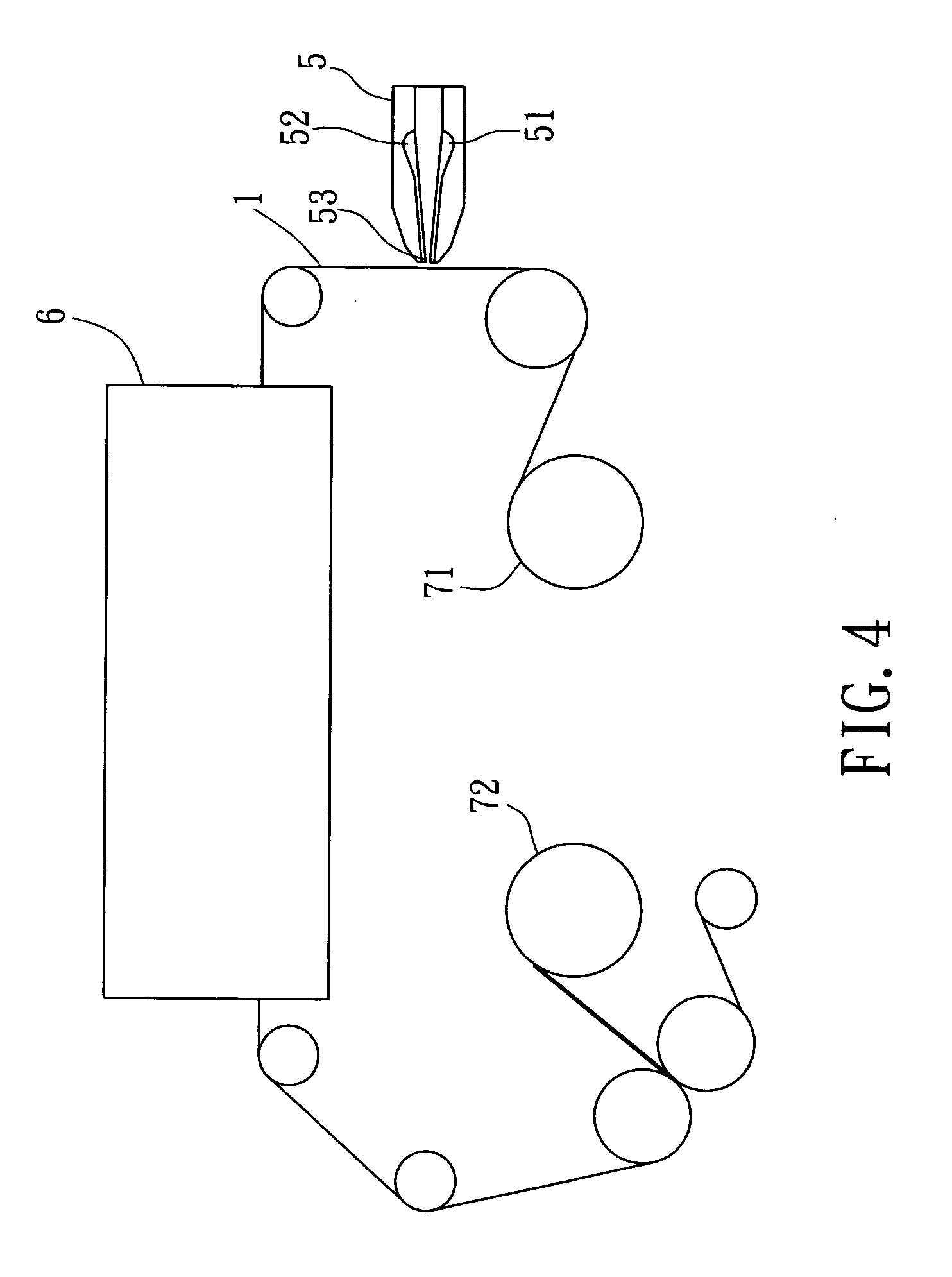

Protection film and method of making the same

InactiveUS20050249946A1Improve cohesionCapabilityFilm/foil adhesive primer layersSemiconductor/solid-state device detailsPolycarbonatePolypropylene

The present inventions provide a protection film and the method of making the same. The protection film comprises a substrate, made of a compound selected from the group consisting of polycarbonate (PC), polyethylene (PE), polypropylene (PP), and aryl polyester (PET); an adhesive layer, attached on at least one of the surfaces of the substrate; and an acrylic primer, arranged between the substrate and the adhesive layer for enhancing the cohesiveness. The protection film not only has a better anti-stress capability, but also is capable of reduce the thickness of the adhesive layer so as to reduce the manufacturing cost of the protection film.

Owner:OPTIMAX TECHNOLOGY CORPORATION

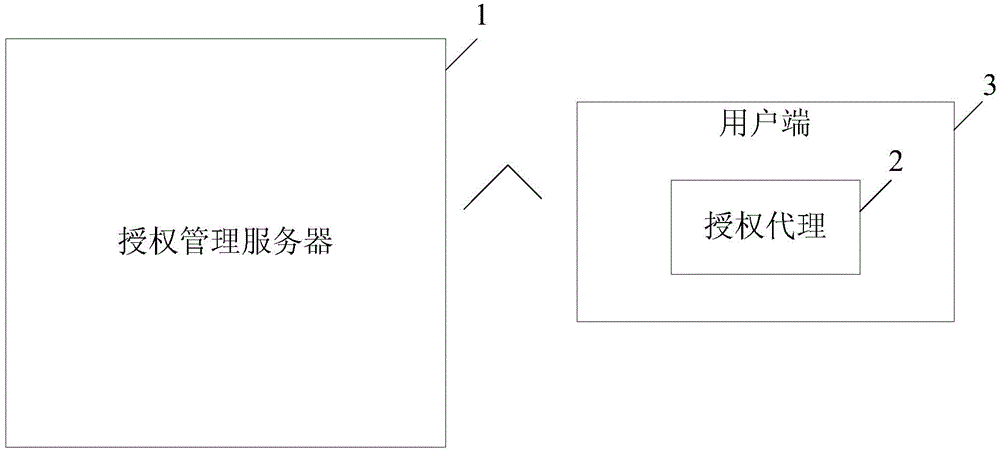

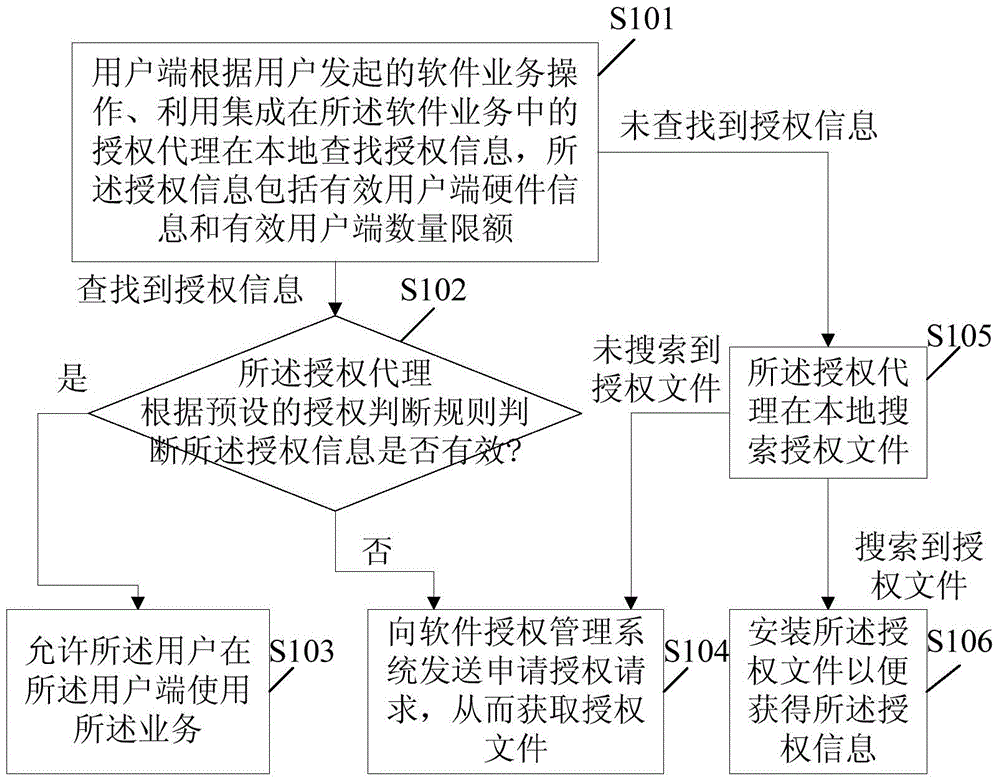

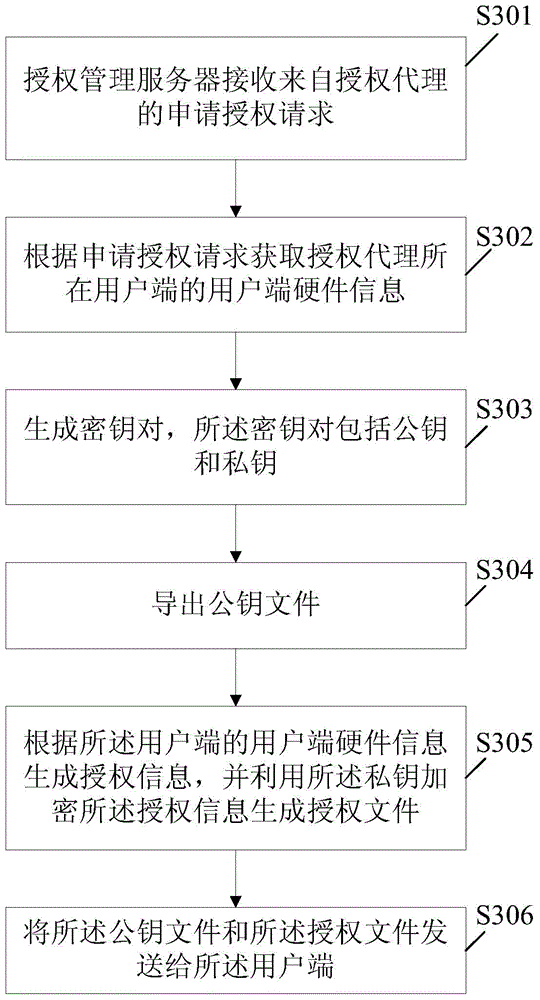

Software authorization management method and software authorization management system

ActiveCN104580316AQuality improvementMeet different needsUser identity/authority verificationProgram/content distribution protectionAuthorization ModeSoftware engineering

The embodiment of the invention discloses a software authorization management method and a software authorization management system. The software authorization management method comprises the following steps: a user side searching authorization information locally by utilizing an authorized agency integrated in software business according to the operation of the software business initiated by a user, wherein the authorization information comprises effective user side hardware information and effective user side quantitative restriction; if the authorization information is searched, the authorized agency judging whether the authorization information is effective or not according to a preset authorization judgment rule, if the authorization information is effective, permitting the user to use the business on the user side; if the authorization information is ineffective, sending an application authorization request to an authorization management server, and thus obtaining an authorization file; if the authorization information is not searched, the authorization agency searching the authorization file locally, and if the authorization file is searched, installing the authorization file so as to obtain the authorization information; if the authorization file is not searched, sending the application authorization request to the authorization management server, and thus obtaining the authorization file.

Owner:深圳市国信互联科技有限公司

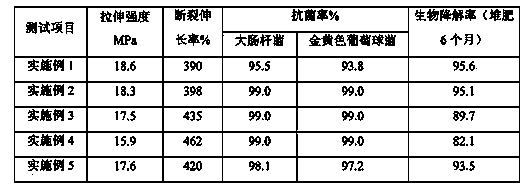

Antimicrobial biodegradable packaging hose material and method for preparing hose using same

ActiveCN103980686AMitigate the environmental situationProtect the stability of useFlexible pipesChemistryAntimicrobial

The invention relates to an antimicrobial biodegradable packaging hose material and a method for preparing a hose using the same. The packaging hose material is characterized by comprising the following raw material components in percentage by mass: 60-98% of biodegradable resin, 0.5-15% of antimicrobial masterbatch, 0.5-1.0% of antioxidant, 0.5-15% of plasticizer and 0.5-10% of other additives. The method for preparing the hose comprises a method for preparing the antimicrobial masterbatch and a method for preparing the hose, wherein the method for preparing the antibacterial masterbatch comprises the step of carrying out double-layer coating on an antimicrobial agent on the surface of the fluidized bed; the method for preparing the hose comprises the steps of firstly mixing raw materials according to the raw material components of the packaging hose material and the mass percent, preparing into by an extrusion blending method in an extruder, molding the hose material, carrying out four-section layered cooling method and double-layer opposed rotation cutter treatment, molding an injection head, casting the shoulder, and then adding a layer of a photocured waterborne pre-printing processing layer on the surface of entire hose body.

Owner:浙江嘉亨包装技术有限责任公司

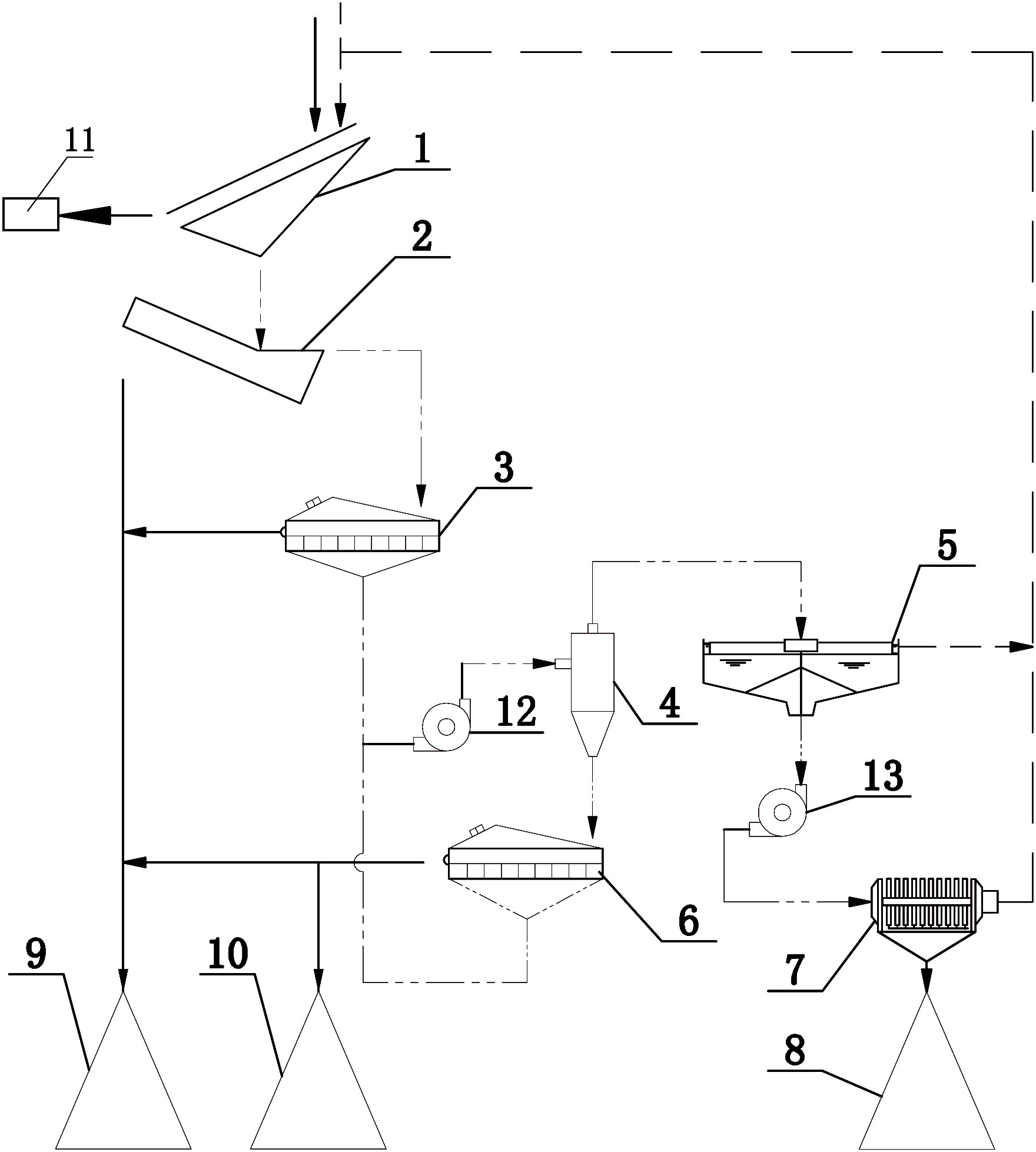

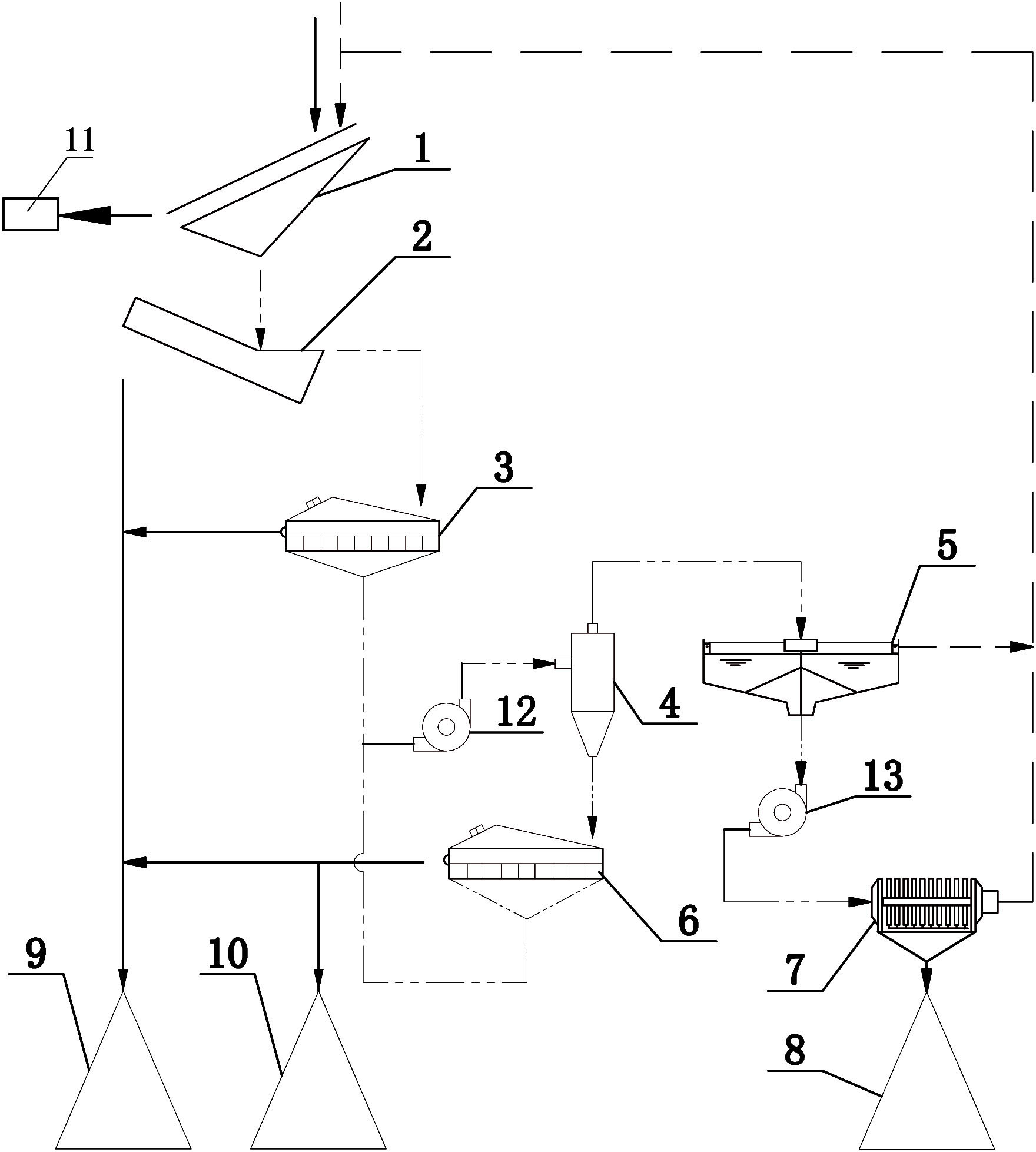

Method for grading and utilizing waste material of sandstone system production

InactiveCN101961674AAchieve recyclingImprove resource utilizationSievingScreeningWastewaterEngineering

The invention relates to a method for grading and utilizing waste material of sandstone system production, including the following steps: 1) sieving and washing are carried out; 2) slurry obtained by sieving is subject to separation of fine sand powder and slurry by virtue of a hydrocyclone grading device; 3) the fine sand powder is subject to high frequency sieving and dewatering, and the slurry is placed into a setting device, so as to further separate water and concentrated slurry; 4) water is returned to the washing step, and the concentrated slurry is subject to filter pressing or filtering and then is delivered to a waste material stock yard. In the method for grading and utilizing waste material of sandstone system production provided by the invention, a hydrocyclone grading device is added in slurry sand grading production process to separate fine sand powder and slurry, and a high frequency sieving dewater procedure is adopted, recycling of fine sand powder from slurry is realized, by adopting the method of the invention, more than 90% of useful material can be recycled from slurry, and more than 70% of recycling can be realized after waste water is purified.

Preparation process of inorganic copper imitation coating and process for replacing protective and decorative copper layer of metal surface with inorganic copper imitation coating

InactiveCN103665973AGood protection and decorationImprove bindingAlkali metal silicate coatingsPretreated surfacesCopper coatingAdhesive

The invention provides a preparation process of an inorganic copper imitation coating and a process for replacing a protective and decorative copper layer of a metal surface with the inorganic copper imitation coating, and belongs to the field of metal protection and decoration. The preparation process of the inorganic copper imitation coating comprises the following steps of: by taking potassium silicate and silica sol as adhesives of the coating, adding fumed silica as filler of the coating to a mixed solution of potassium silicate and silica sol; then adding a silane coupling agent and a wetting dispersant as assistants used for improving the coating performance; finally adding antique brass pigment fillers to obtain the copper imitated inorganic silicate coating. The coating prepared by the method can replace the protective and decorative copper layer of the metal surface, and is applicable to the field of metal protection and decoration. The inorganic copper imitation coating prepared by the method is high in protection and decoration performance, avoids galvanic corrosion caused by the copper layer, saves the protection cost, has performance superior to a copper coating, and also has the advantages of being low in cost, environment-friendly, high in corrosion resistance, high in cohesion, etc.

Owner:HARBIN INST OF TECH

Synergistic insecticidal composition containing chloronicotynyle and pyrethroids compounds

InactiveUS7531187B2Reduce riskEffective and economic controlBiocideDead animal preservationCompound aPyrethrin

A synergistic insecticidal composition is formed containing a Chloronicotynyle compound and a Pyrethroids compound. The Chloronicotynyle compound is provided in an amount preferably ranging from 0.1 to 5.0% by weight of the synergistic insecticidal composition. The Pyrethroids compound is provided in an amount preferably ranging from 1 to 60% by weight of the synergistic insecticidal composition. The synergistic insecticidal composition also preferably includes 35 to 98.90% by weight of conventional agriculturally acceptable carrier(s) and / or excipients.

Owner:UNITED PHOSPHORUS LTD

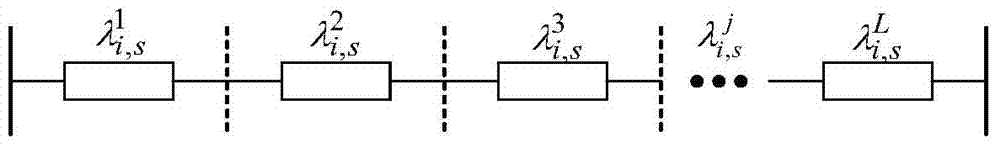

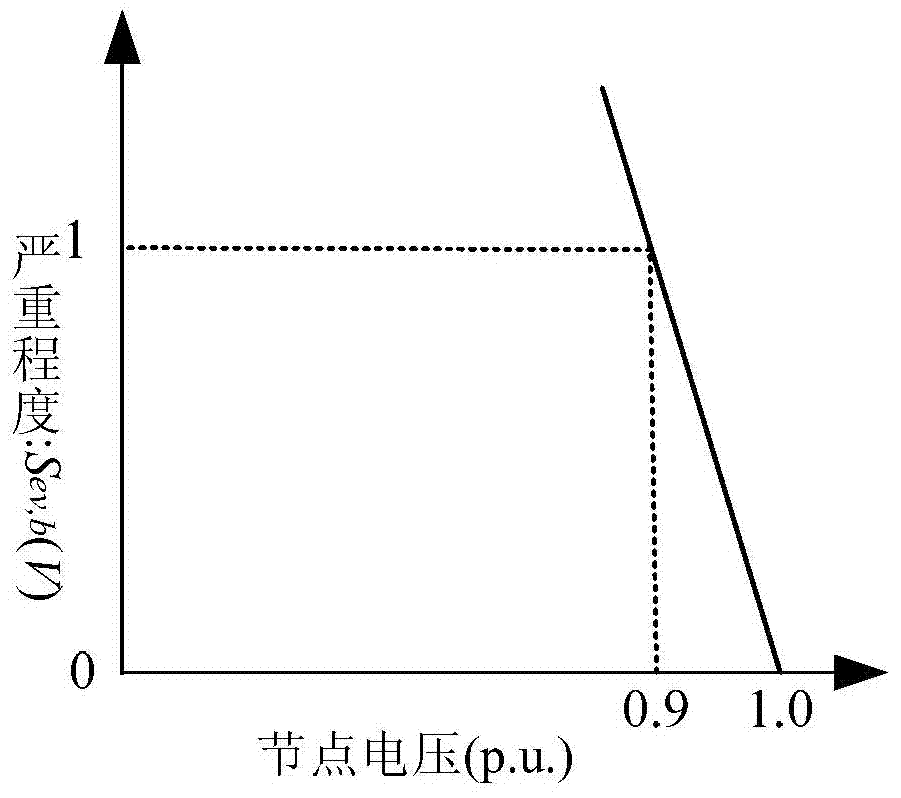

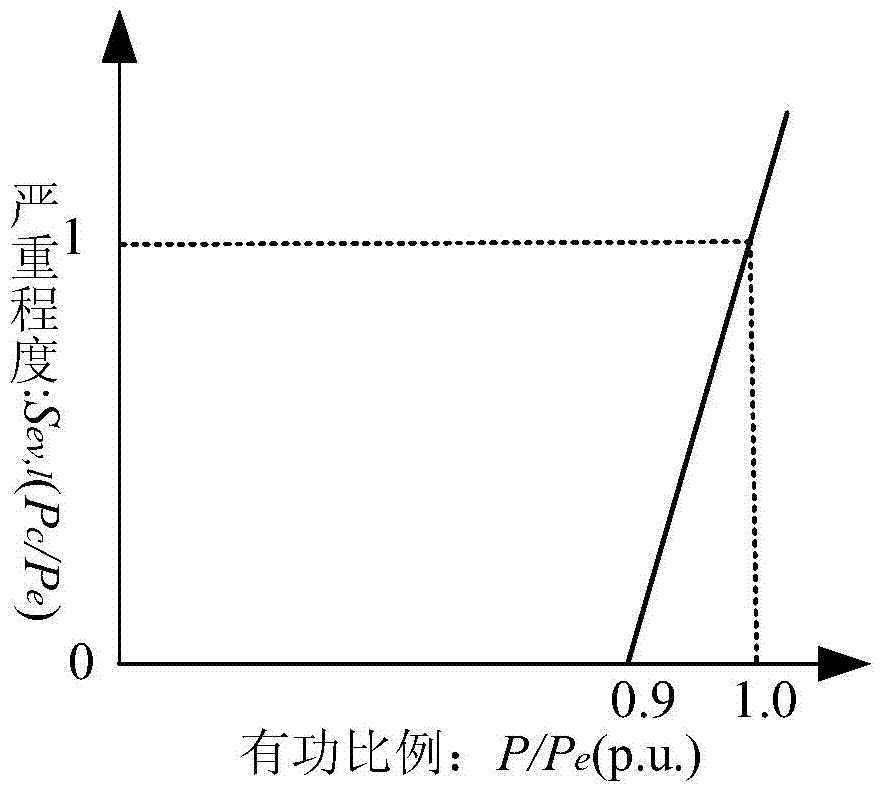

Differentiation based power transmission network anti-disaster ability planning method

InactiveCN103679294AImprove disaster resilienceOptimize disaster resistance protection levelForecastingLoad SheddingPower grid

The invention discloses a differentiation based power transmission network anti-disaster ability planning method which is used for improving an anti-disaster ability of a power transmission network when a meteorological disaster occurs. The differentiation based power transmission network anti-disaster ability planning method comprises the steps of: firstly, developing an IEEE standard based tri-state meteorological condition to obtain a relationship between a fault rate of a power transmission line at different anti-disaster protection levels and the meteorological disaster; obtaining a fragility index and a goal by utilizing Monte Carlo simulation and an optimized load shedding algorithm. The fragility index and a planned construction cost serve as an objective function of multi-goal power transmission network planning; an NSGA-II algorithm is used for obtaining optimal Pareto disaggregation of a power distribution network planning scheme and is used for decision-making in the later period. The verification shows that the provided power distribution network planning method can determine the anti-disaster protection level of each power distribution line exactly, accordingly improves the anti-disaster ability of the power distribution network efficiently when the meteorological disaster occurs, meanwhile reduces line construction cost to the maximum extent and achieves important reference value for the planning of the power distribution network in the environment where meteorological disasters occur frequently.

Owner:STATE GRID CORP OF CHINA +2

Synergistic insecticidal composition containing Chloronicotynyle and Organosphosphorus compounds

ActiveUS20060008493A1Delays dominanceWide range of activitiesBiocidePhosphorous compound active ingredientsCompound aExcipient

A synergistic insecticidal composition is prepared by combining a Chloronicotynyle compound and an Organophosphorus (OP) compound. The preferred synergistically effective amount of the Chloronicotynyle compounds is an amount preferably ranging from 0.1 to 5% by weight of the composition. The preferred synergistically effective amount of the Organophosphorus (OP) compounds is an amount preferably ranging from 30 to 75% by weight of the composition. The composition also preferably includes 69.9 to 20% by weight of conventional agriculturally acceptable carrier(s) and / or excipient.

Owner:UNITED PHOSPHORUS LTD

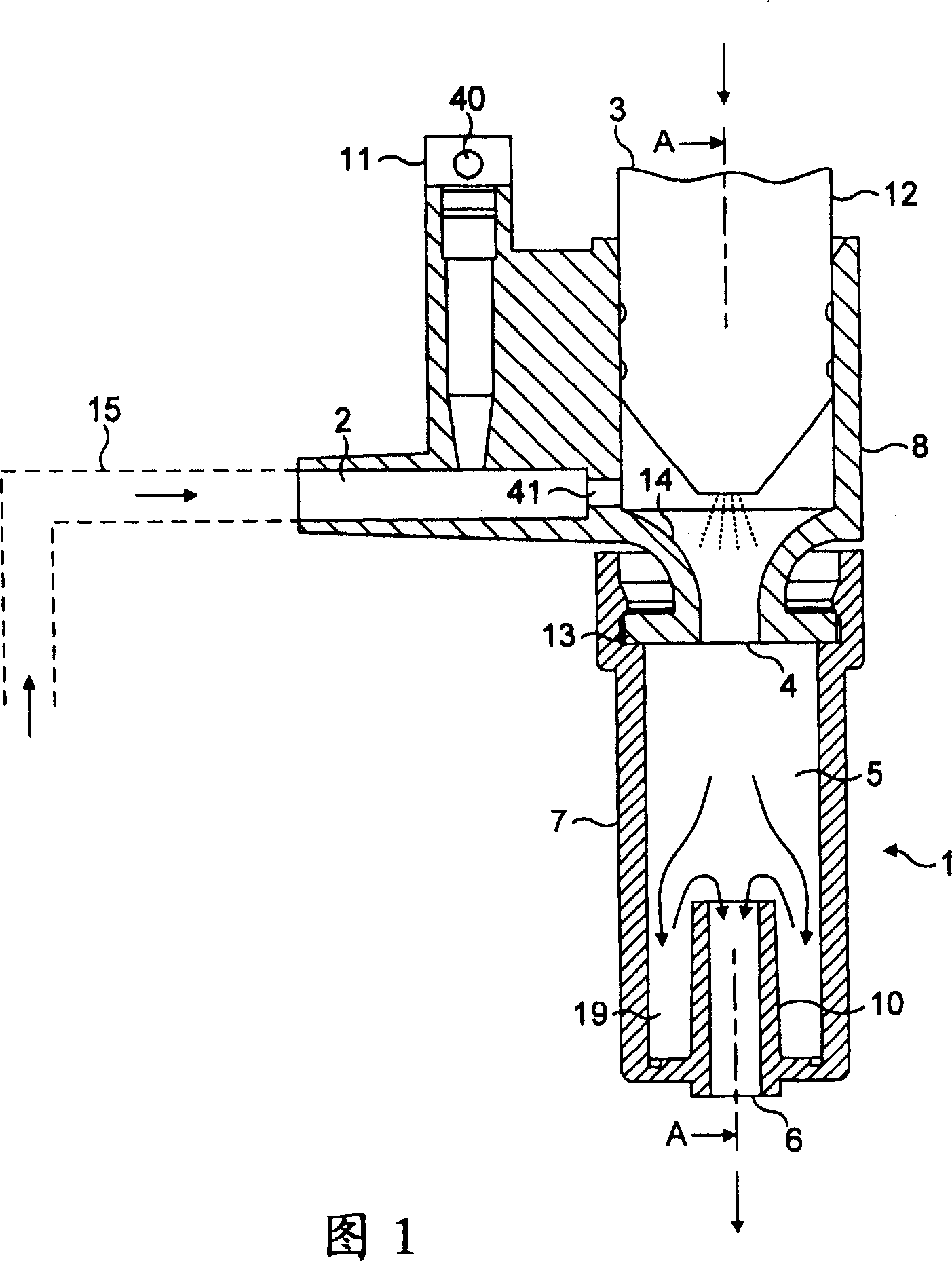

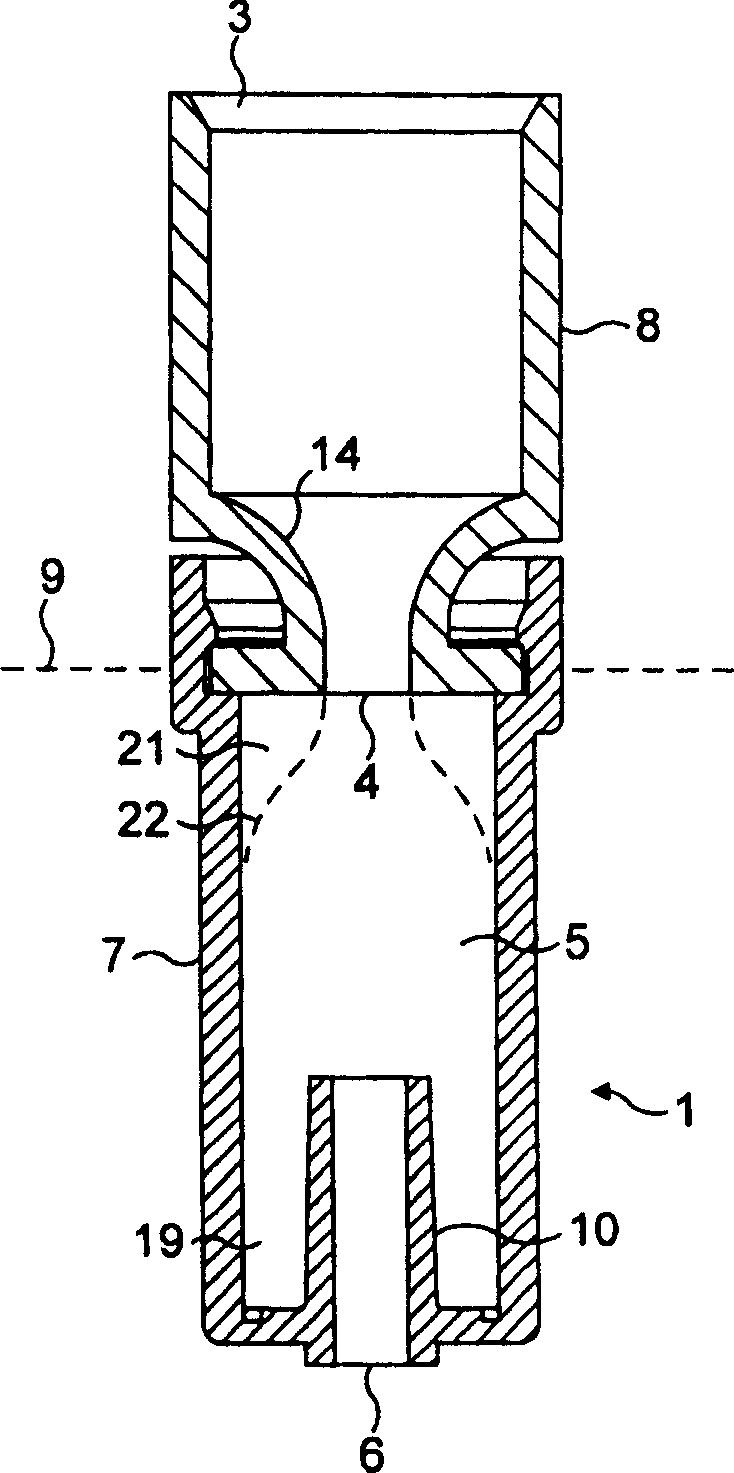

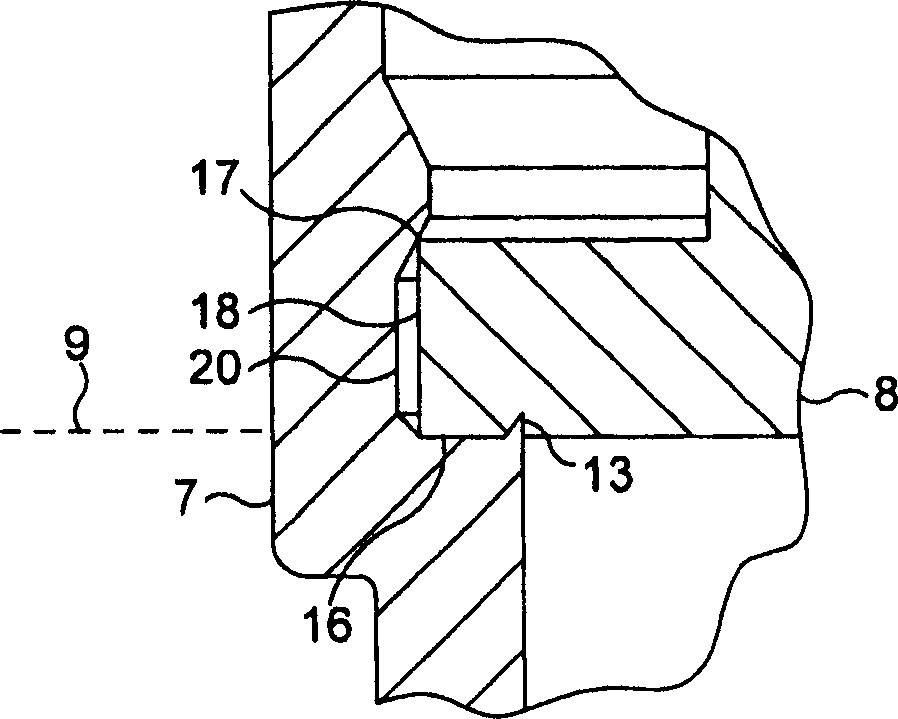

Replaceable nozzle for producing a frothed liquid

A nozzle adaptable to the steam outlet of a coffee machine is designed to froth a liquid such as e.g. milk. Said nozzle comprises in the direction of the steam flow path: a steam inlet opening, a restriction with limited cross-section adapted to accelerate the velocity of the steam flow, and at least one cavity having a cross-section larger than the restriction and from which the frothed liquid can be drained. The nozzle further comprises an outer casing comprising a smoothening reservoir and a jet breaking surface facing the opening and at least one outlet opening radially offset relatively to the opening of the portion of the enlarged mixing cavity. The outer casing is arranged at least partially around the tubular portion of mixing cavity.

Owner:SOC DES PROD NESTLE SA

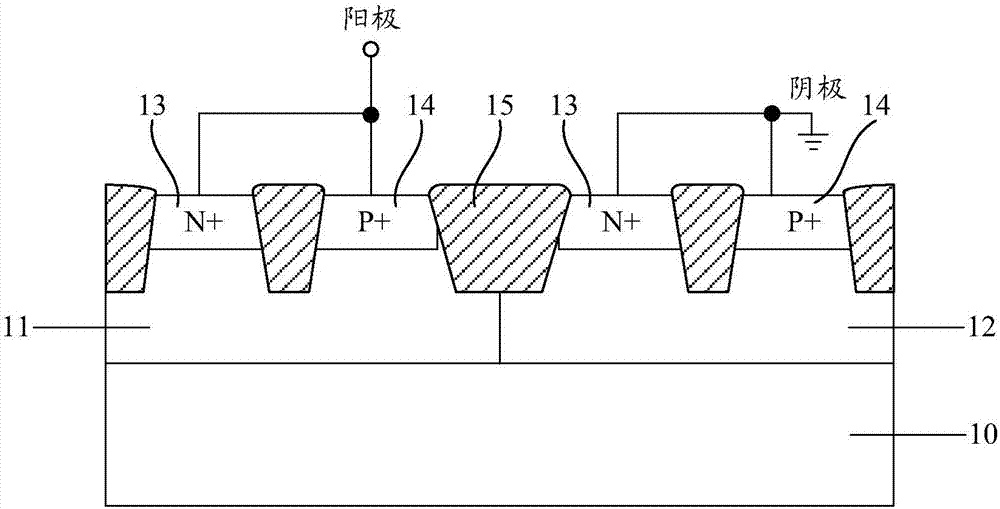

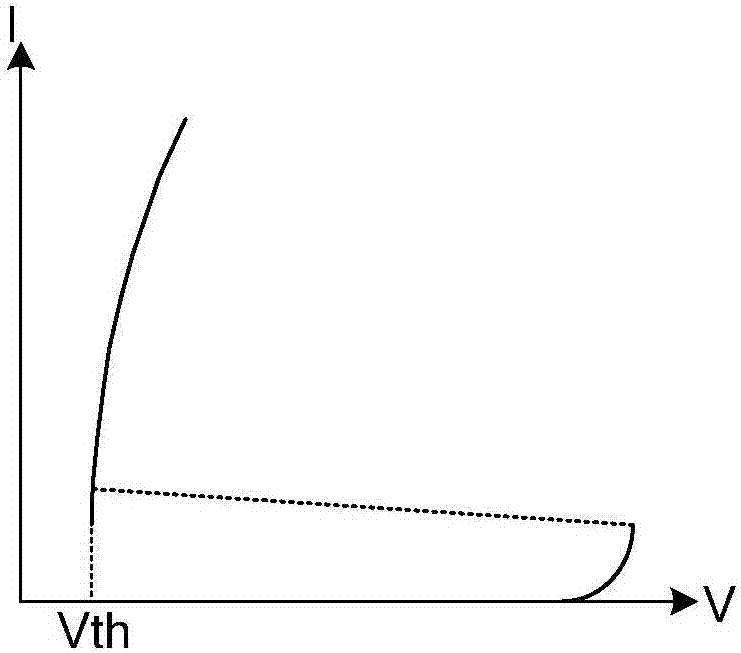

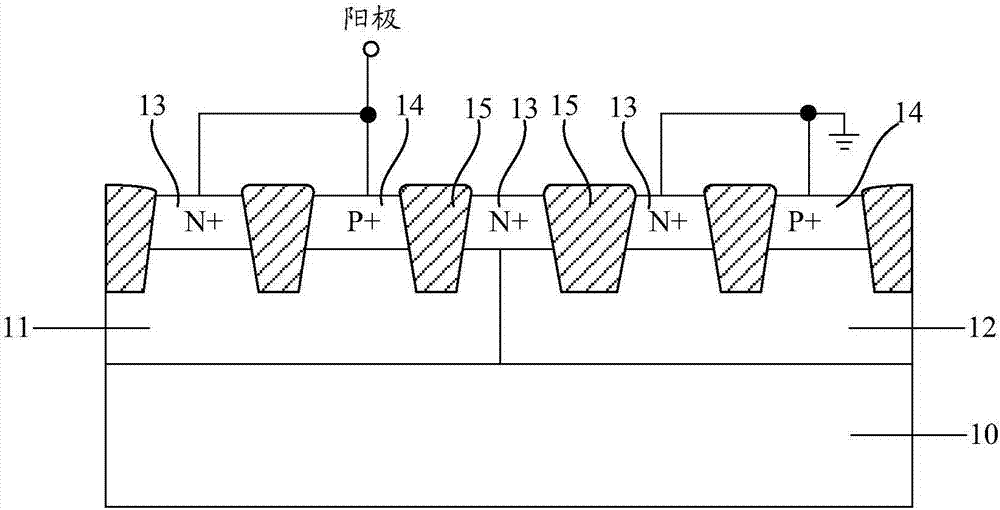

SCR for electrostatic protection, chip and system

InactiveCN107093596AImprove reliabilityImprove robustnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention provides a semiconductor controlled rectifier (SCR) for electrostatic protection, a chip and a system, relates to the electronic technology field and can realize start voltage reduction and maintenance voltage improvement. The SCR comprises a semiconductor substrate, and a first well, a second well and a third well which are arranged on the semiconductor substrate, wherein conductive types of the first well and the third well are identical, the second well is in a different conductive type, the first well is internally provided with a first heavily doped region and a second heavily doped region, the first heavily doped region and the second heavily doped region are different in conductive types, the first heavily doped region and the first well are identical in conductive types, the third well is internally provided with a third heavily doped region, the third heavily doped region and the third well are identical in conductive types, the second well is internally provided with a fourth heavily doped region, the four heavily doped region and the second well are identical in conductive types, the fourth heavily doped region extends to the first well and the third well, a first gap is arranged between the fourth heavily doped region and the second heavily doped region, and a metal gate is arranged at the first gap.

Owner:HUAWEI TECH CO LTD

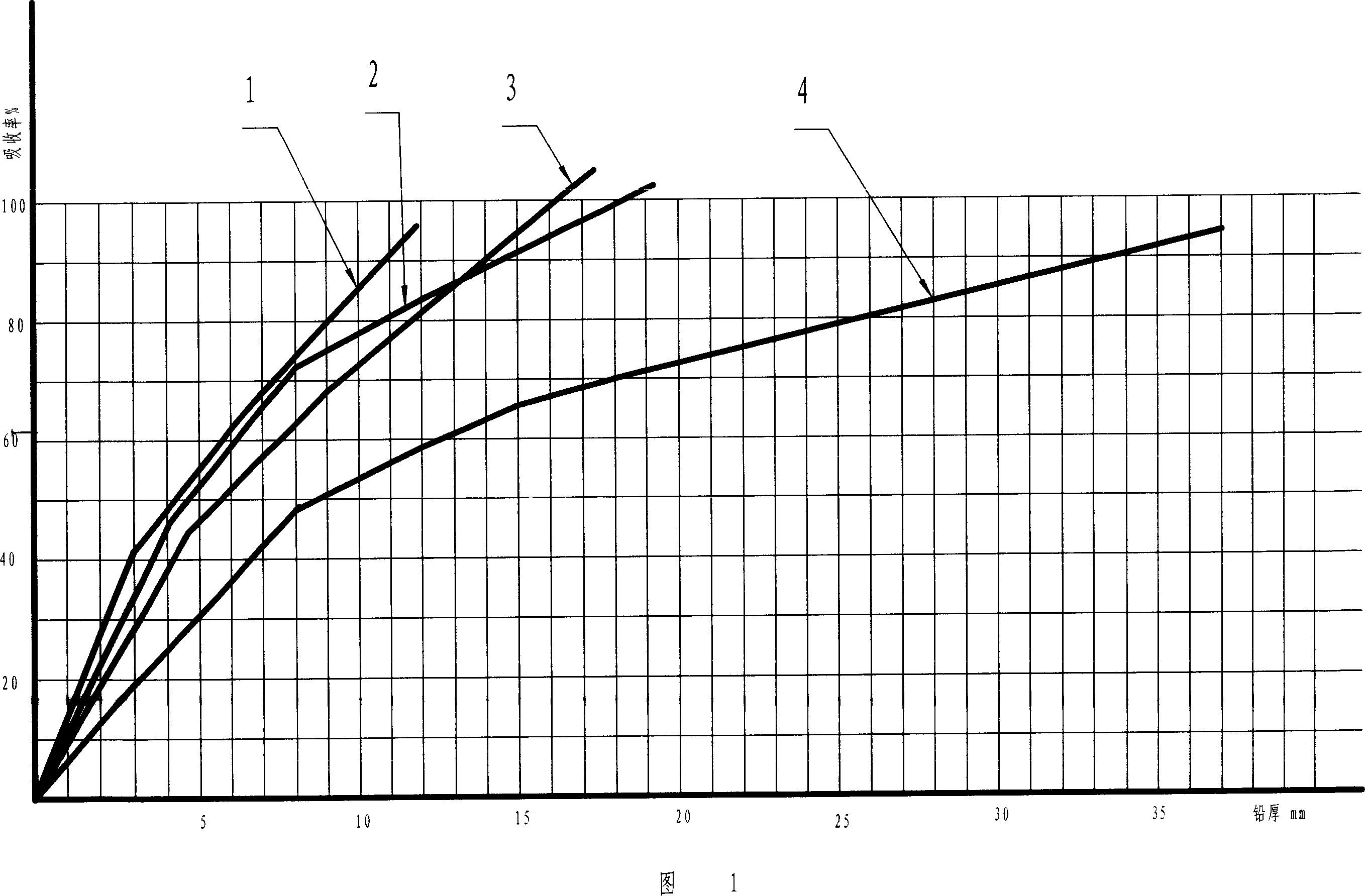

Radiation protection material and method for making same

The invention discloses a radiation protection sheet and its production methods as protection of X and gamma radiation, particle bombardment or particulate radiation, especially the protection that is characteristic of the materials. The radiation protection sheet uses the mixture of magnesia and magnesium chloride as bonding materials, the mixture of two or three in fine iron powder, fine lead power, barium powder, and borax as the protective material, the glass fiber as enhanced materials. The composite protective sheet is made of according to the weight ratio: the adhesive material 1, protective materials 2-6, and enhanced materials 0.3-0.5. The radiation protection sheet in the invention has good effects on protection of X-ray and gamma-ray-ray and other radiations. In addition, based on different requirements for protecting, the most cost-effective formula for the production of sheet can be determined. Its protective effects are good, and its cost is low. So, it can be applied to medical diagnosis or treatment of radiation protection, can also be used for industrial radiation detection and monitoring protection.

Owner:山东康宇防护屏蔽器材有限公司

Set-top box protection method and set-top box

InactiveCN102196317AGuaranteed one-to-one correspondenceReduce the cost of protectionSelective content distributionEncryptionSet top box

The invention discloses a set-top box protection method and a set-top box. The method comprises the following steps of: acquiring a public key, wherein the public key is an identification code of the set-top box; decrypting encrypted codes of the set-top box by using the public key, wherein the encrypted codes are generated by encrypting the identification code of the set-top box and a code of the set-top box by a preset encryption algorithm; and judging whether the decrypted identification code is consistent with the public key or not, and if the decrypted identification code is judged to be inconsistent with the public key, quitting a system. The invention correspondingly provides a technical scheme of the set-top box. By the set-top box protection method, the uniqueness of software and hardware of the set-top box can be ensured, the set-top box can be protected from piracies, and the protection cost can be reduced.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

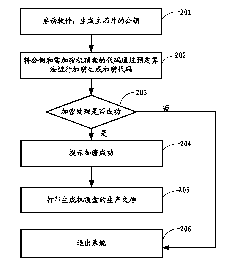

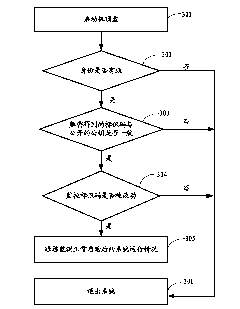

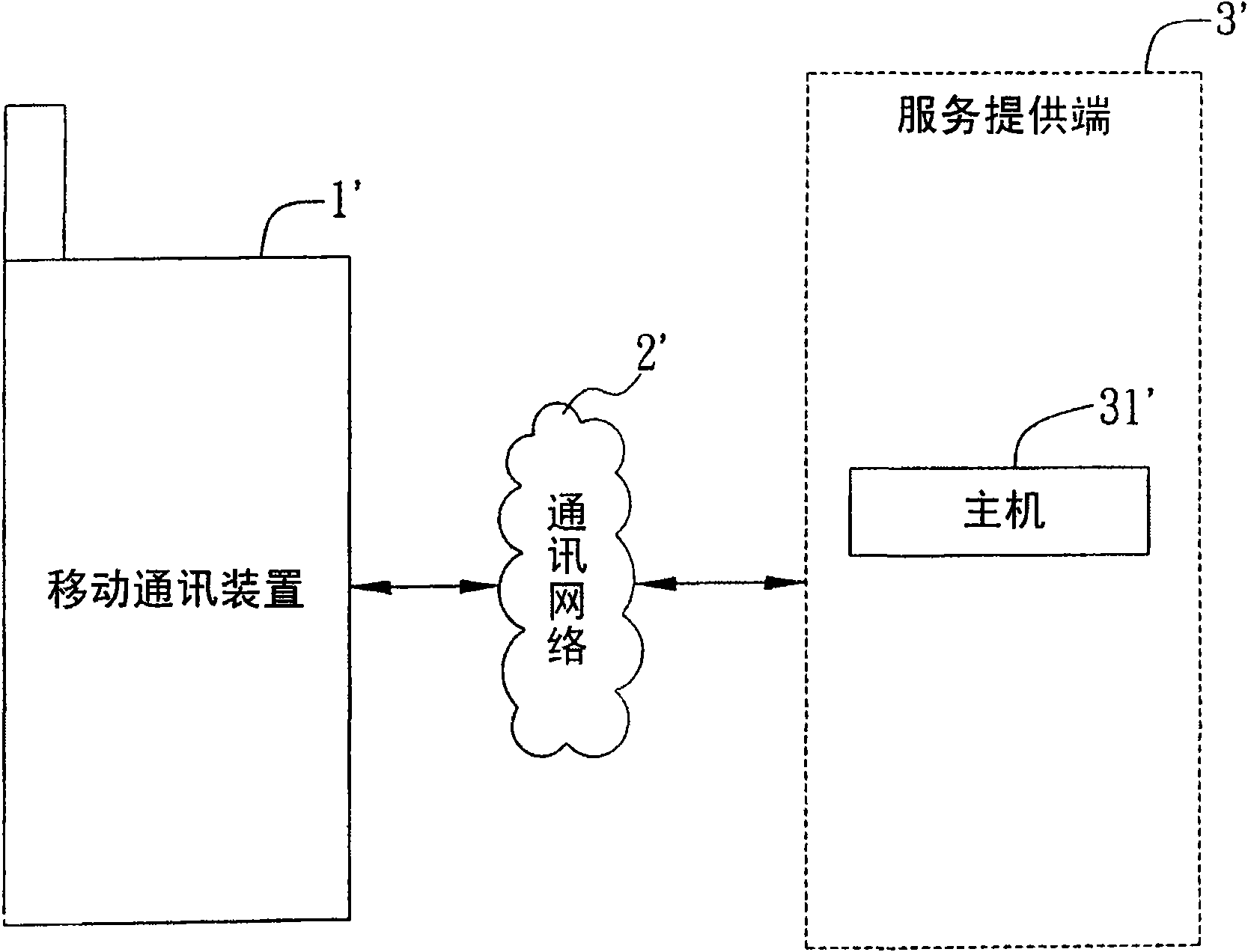

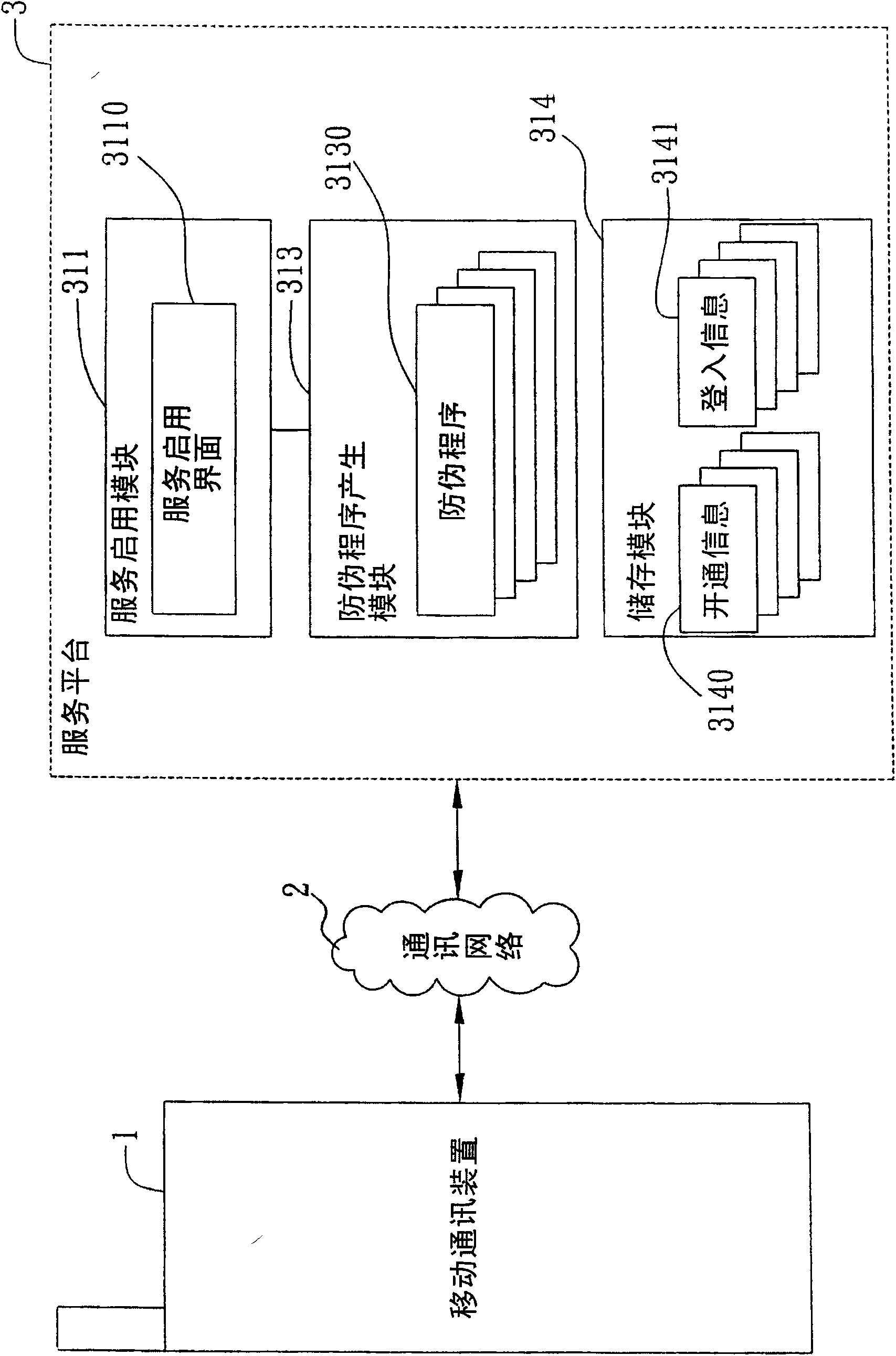

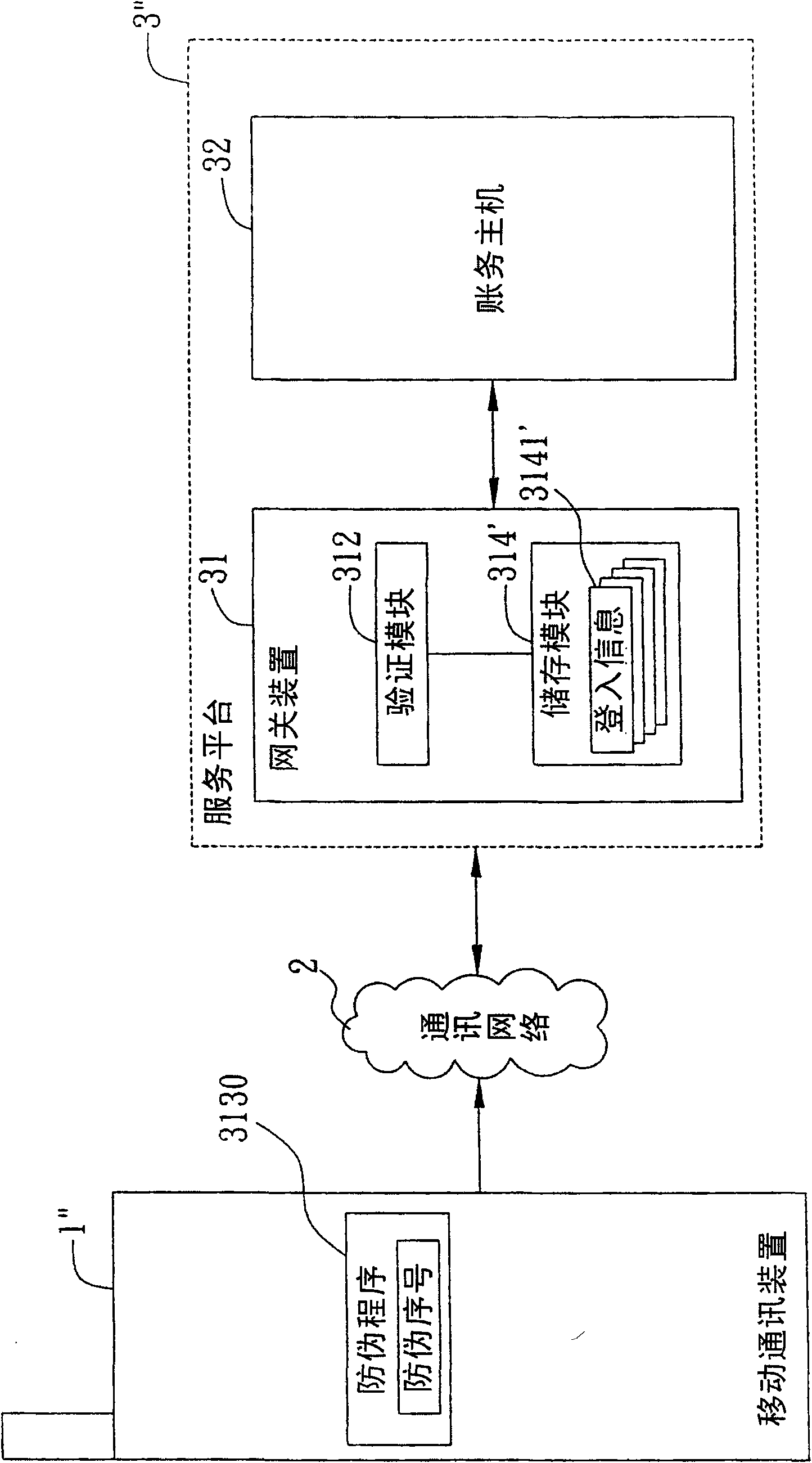

Login authentication system and method

InactiveCN101854627ALow costReduce the cost of protectionSecurity arrangementPasswordNetworked system

The invention discloses login authentication system and method. The login authentication system is a safety login mechanism for a client to login a service platform through a network system by using a mobile communication device. The service platform demands the mobile communication device to input an account number and a password to carry out opening authentication. After the mobile communication device is subjected to the opening authentication of the service platform, the service platform automatically generates an anti-counterfeiting program with a software serial number and returns the anti-counterfeiting program to the mobile communication device to write in the mobile communication device so that the mobile communication device logins the service platform by using the anti-counterfeiting program with the software serial number.

Owner:邱宏达

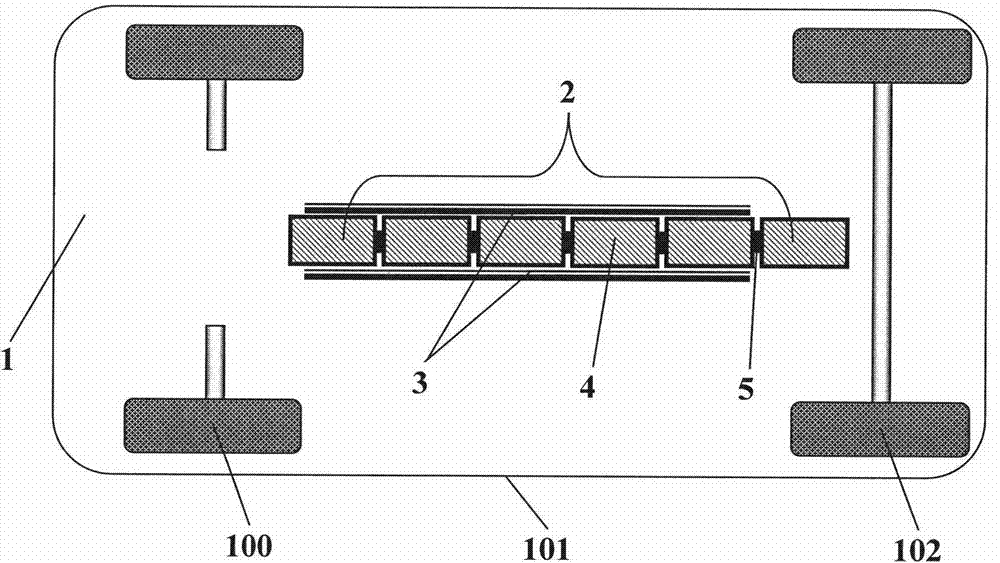

Electric vehicle arranging structure

InactiveCN103895484AReduce loadLight steeringElectric propulsion mountingVehicle sub-unit featuresDisplay deviceRoad surface

The invention belongs to the field of electric vehicle arranging, and provides an electric vehicle arranging structure which ingeniously solves the problems that battery arranging is hard, temperature is not even, the battery can easily catch a fire when being collided, the whole vehicle is not reasonable in arrangement, and cost is high. A battery pack (2) is arranged in a center channel (3) in the front-back longitudinal direction of a whole vehicle (1), movable joints (5) are arranged between battery pack bodies (4), and a gear switch (6), a hand brake (7), an emergency stop switch (8) and a balancing, temperature-controlling and liquid level display device of the battery pack (2) are arranged on the center channel (3). The two ends of the battery pack (2) are respectively provided with an electric control part (19), a direct-current convertor (20) and a mechanical buffer (21). The electric vehicle arranging structure is used for electric sightseeing vehicle, scooters, cars and the like, the whole vehicle is compact in arrangement, and a large space is saved; the axle load ratio can be easily adjusted; battery temperatures are consistent, and batteries are more safe when being collided; cost of the vehicle body and wiring harnesses is lowered; starting driving force is strong, and steering is flexible; electric energy can be saved when the vehicle passes through an uneven road face; the electric vehicle arranging structure is scientific, convenient to operate and more attractive.

Owner:崔玲

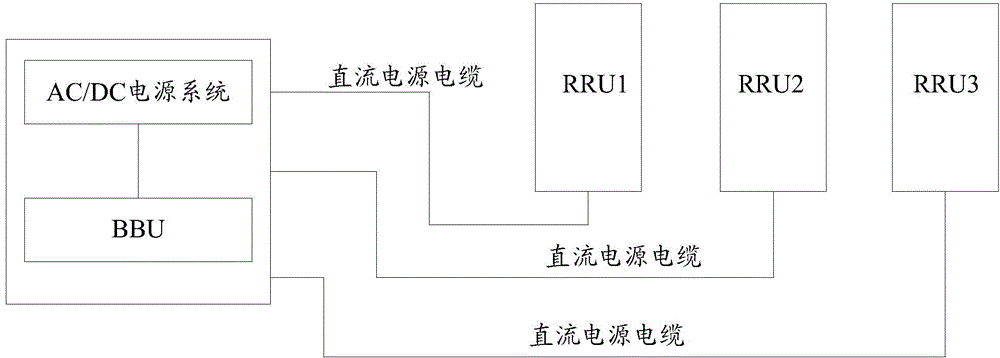

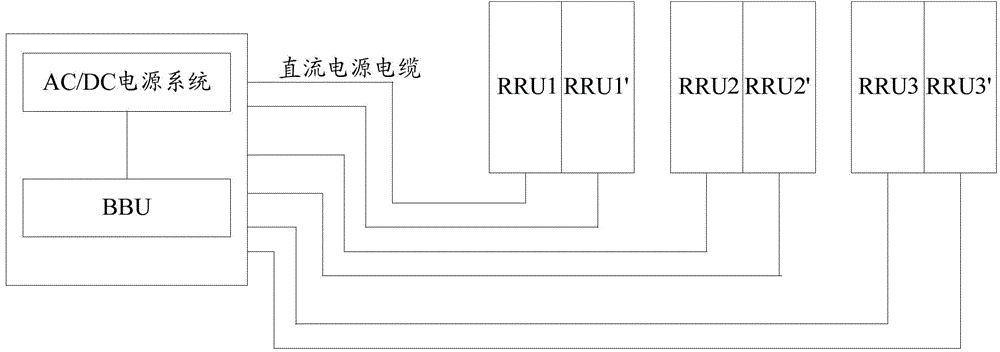

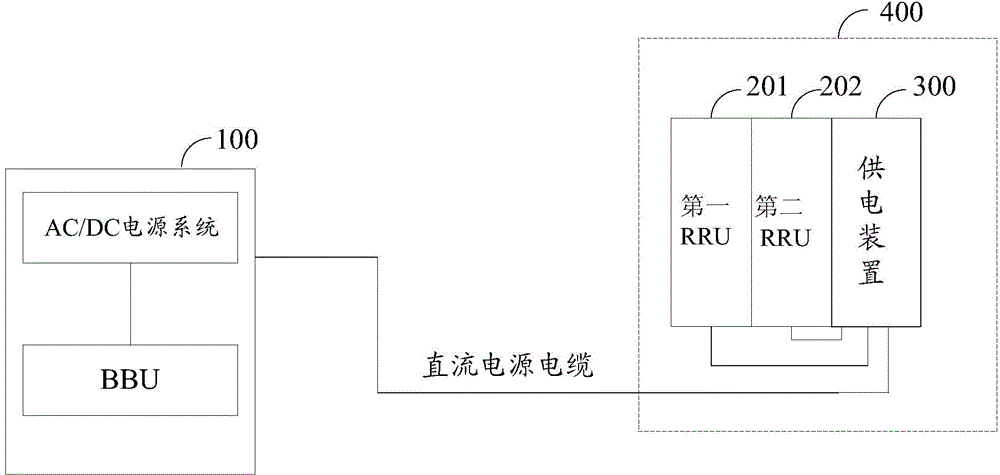

Distributed base station and communication system

ActiveCN105472786AShorten the lengthReduce engineering costsPower managementBatteries circuit arrangementsPower cableCommunications system

The invention relates to the technical field of communication, and discloses a distributed base station, comprising a power system, a power supplying device and at least two radio remote units (RRU), wherein one end of the power supplying device is connected to the power system, and the other end thereof is connected to the at least two RRUs; the power supplying device is used for receiving power output by the power system, and providing the power to the at least two RRUs; and the distance between either of the RRUs connected to the power supplying device and the power supplying device is less than the distance between the RRU and the external power system. By adopting the distributed base station, the length of a DC power cable is reduced in laying the DC power cable, and engineering expenses and later protection costs are saved. In addition, the invention further provides a communication system.

Owner:HUAWEI TECH CO LTD

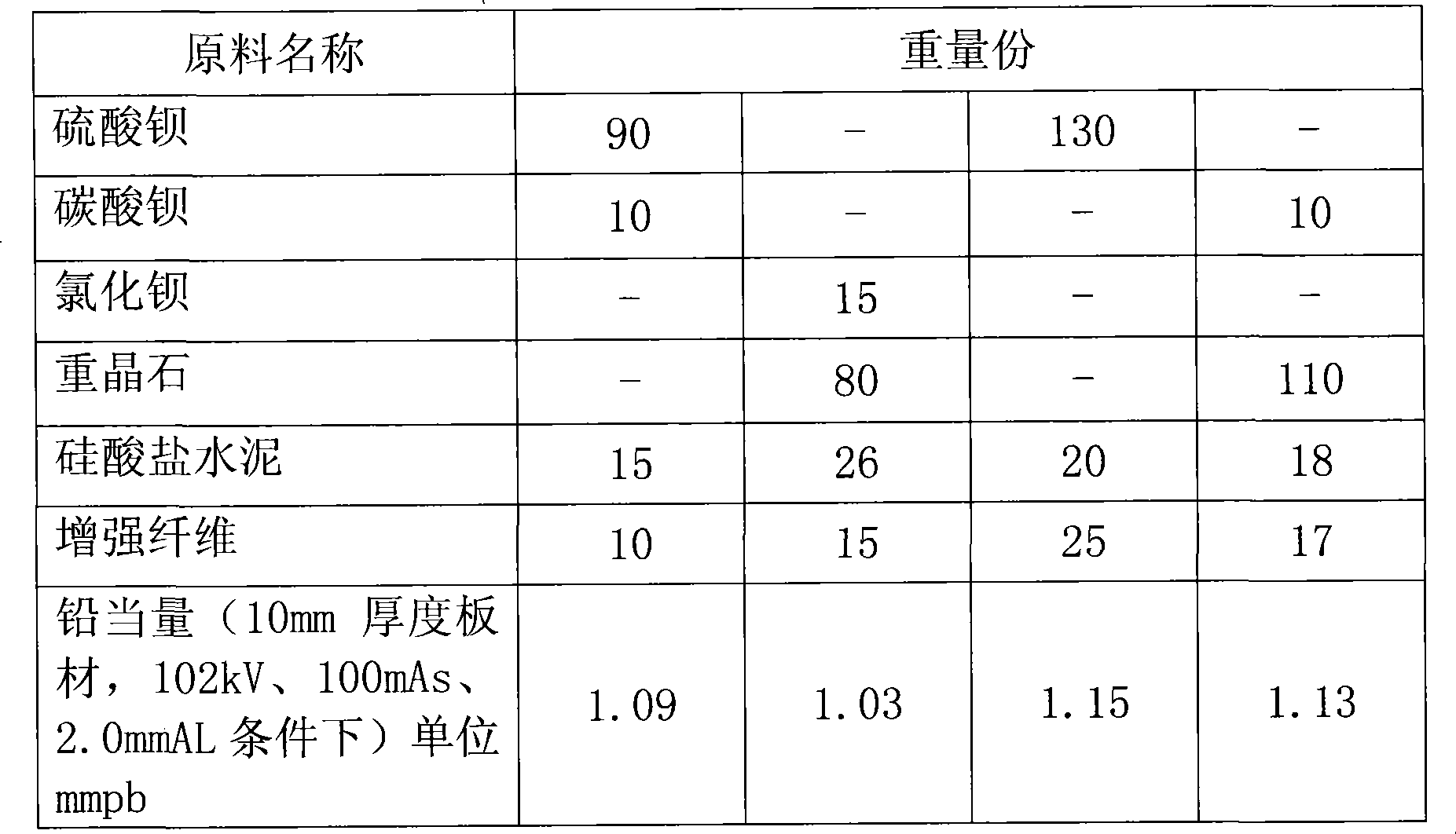

Leadless radiation protection barium plate and method for producing the same

The invention relates to a radiation protection material in the ionizing radiation protection field, and a production method thereof, in particular to a lead-free radiation protection barium board and a production method thereof. The lead-free radiation protection barium board adopts raw materials which are barium salt with the granularity of 300-500 meshes, portland cement and reinforcing fiber, and comprises the following components (part by weight): barium salt: 80-130, portland cement: 15-35 and reinforcing fiber: 5-28. The raw materials are made into mixed slurry and then made into boards with the thickness of 6mm-12mm on a cylinder extrusion machine, and multilayer boards are superposed and pressurized on a punch press of 2500T for 30-70 minutes for molding; the boards are treated with high-temperature steaming for 10-26 hours at 60-120 degrees, and then the lead-free radiation protection barium board is obtained after sanding. The product has stable protection performance, no lead or lead compounds contained in the raw materials, safety and harmlessness, fire prevention, moisture-proof performance, high-temperature resistance, stable geometric dimension, mechanization batch production, low cost with the price of only 1 / 3 of that of the lead plates with the same thickness, and simple production method.

Owner:JINAN DAHUA YITE ENVIRONMENTAL PROTECTION ENG

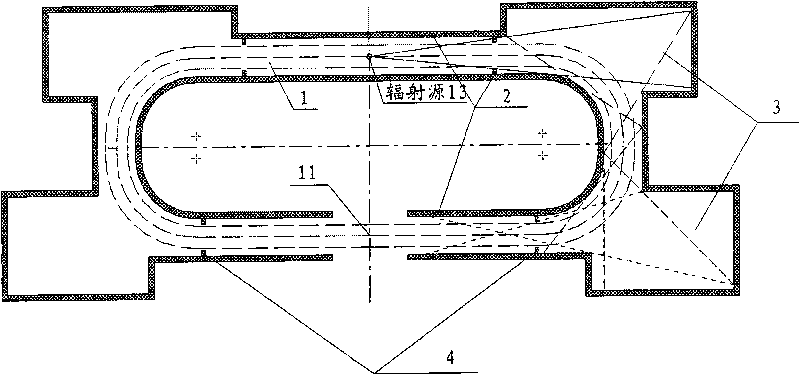

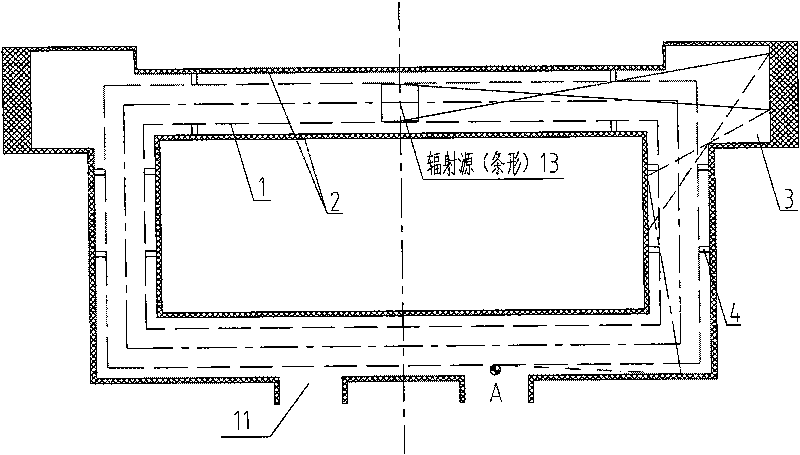

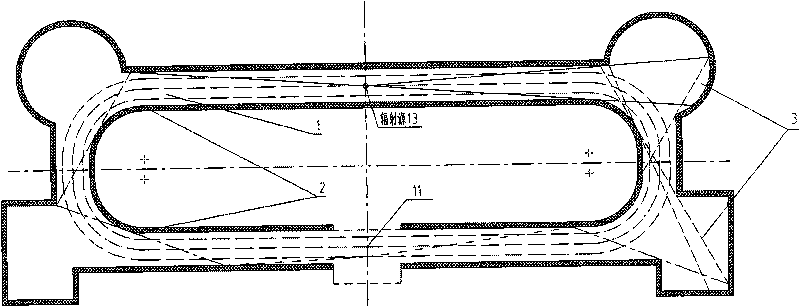

Radiation shield device and radiation system

ActiveCN101740155AAchieving Radiation LevelsReduce the scattered areaShielded cellsIrradiation devicesUltrasound attenuationAcoustics

The invention discloses a radiation shield device comprising a space, an opening and a trap (2), wherein, the space is formed by a shield wall; a radiation source is arranged in the space; the opening is formed in the shield wall; the trap (2) is formed by the outward bulge of part of the shield wall; by the shield wall of the trap (2), the number that the radial generated by the radiation source is scattered by the barrier shield in the space when achieving the opening is increased. The invention utilizes a compact labyrinth structure with the trap to carry out radiation shield and protection; the labyrinth wall and the trap carries out effective shield and rapid attenuation on the transmitted ray generated in the radiation source and scattering ray generated in ray transmission process to realize the condition that the radiation level of a labyrinth shield device at peripheral boundary meets the design requirements; a throat sheet in a certain shape is designed in a proper position, which can decrease scattering area of the ray and further lower radiation level leaking out; the compact labyrinth structure with the trap has small occupation area and low protection cost, and can satisfy the requirements of continuous and rapid operation of the radiation system.

Owner:NUCTECH CO LTD

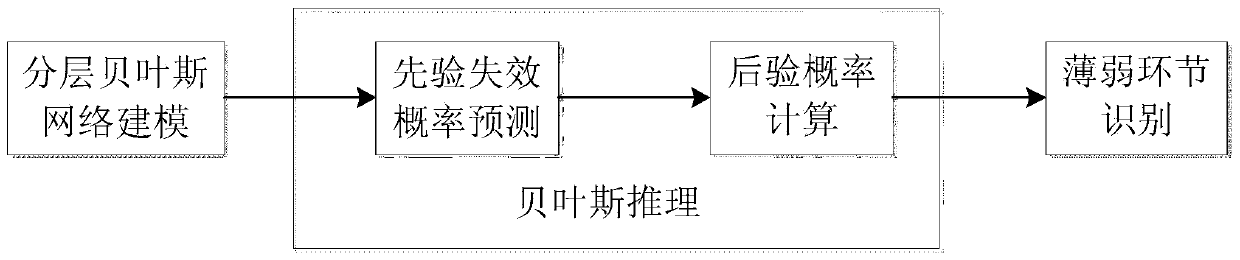

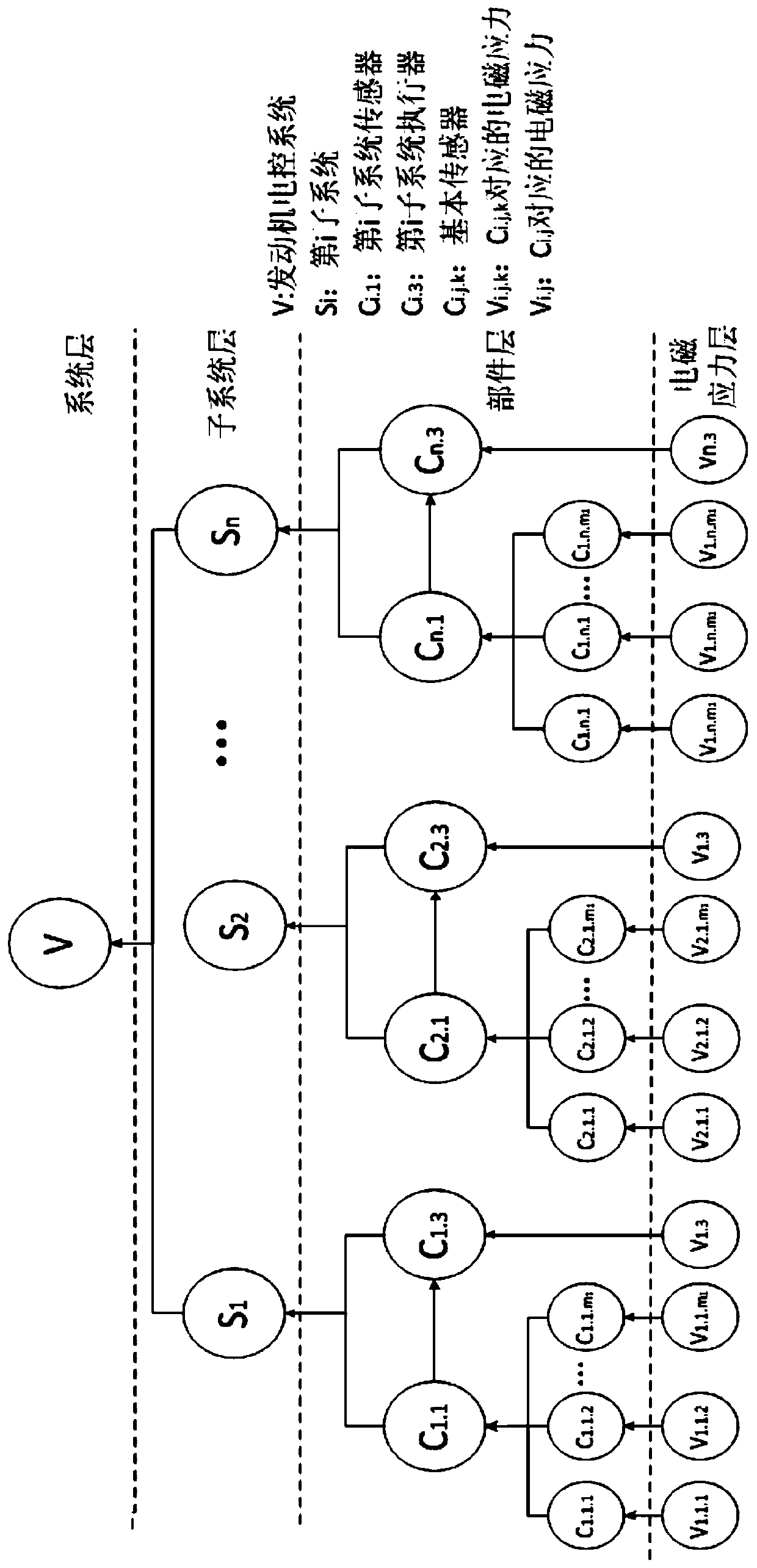

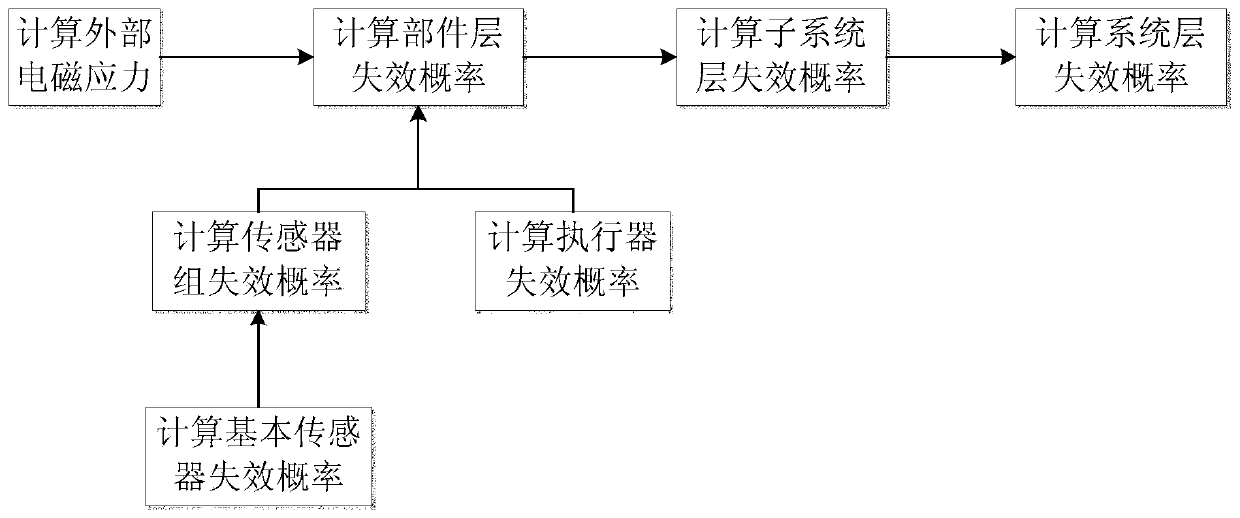

Weak link identification method of diesel engine electronic control system under strong electromagnetic pulses

ActiveCN110147849AImprove electromagnetic environment adaptabilitySolve the problem of significantly increased calculationCharacter and pattern recognitionResourcesElectronic control systemEngineering

The invention relates to a weak link identification method for a diesel engine electronic control system under strong electromagnetic pulses, and belongs to the field of weak link identification of systems under strong electromagnetic pulses. Firstly, the prior failure probability from a part to a system level under strong electromagnetic pulses is predicted, then the posterior probability of faults of all electric control parts under the engine failure condition is calculated according to a Bayesian probability formula and ranked to identify weak links of the electric control parts, and the part needing key protection is selected when an electromagnetic protection scheme is designed. Advantages are as follows: under the condition that the samples are limited, weak links of the diesel engine electric control part under strong electromagnetic pulse irradiation can be identified; the method has universality, and solves the problems that the test method is high in cost, weak link identification cannot be carried out under the condition that sample data is limited, and the test method is poor in universality due to multiple uncertain factors of parameters such as a strong electromagnetic pulse irradiation source and electromagnetic sensitivity of an electric control part; protection cost is saved, and electromagnetic environment adaptability of the engine is improved.

Owner:JILIN UNIV

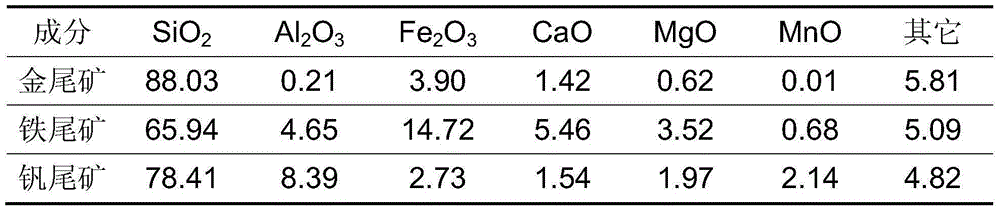

Methodof producing zeolite molecular sieve by utilizing tailings

ActiveCN105036151AImprove adsorption capacityReduce the cost of protectionSolid waste disposalCrystalline aluminosilicate zeolitesMolecular sieveSolid particle

The invention discloses a method of producing a zeolite molecular sieve by utilizing tailings. The method comprises the following steps: (1) preprocessing tailings: carrying out acid pickling, high-temperature melting and magnetic absorption on the tailings to remove iron impurities in the tailings; (2) preparing alkali fusion clinker: mixing alkaline solid particles and the tailings to obtain a mixture I, grinding the mixture I, then adding an aluminum compound into the mixture I to adjust an Si / Al ratio, and then roasting the mixture I to obtain the alkali fusion clinker; (3) hydrothermally synthesizing: cooling the alkali fusion clinker, then porphyrizing the alkali fusion clinker, adding deionized water into the alkali fusion clinker, mixing, stirring and aging to obtain a mixture, crystallizing the mixture under self-generated pressure, taking out the mixture, cooling, filtering, washing, and then drying to obtain a finished product molecular sieve. The tailings are used as a main raw material, a zeolite molecular sieve is prepared in an alkali fusion hydrothermal method, the specific surface area of the prepared zeolite molecular sieve reaches 564.2m<2> / g, the density reaches 2.11g / cm<3>, and the prepared zeolite molecular sieve has the performance parameters of a commodity molecular sieve. By adopting the method, solid waste is recycled, the gap of the prior art is filled, and the high-added-value regeneration and utilization of the tailings is realized.

Owner:陕西宏科绿色建材有限公司

Method for protecting highway barrier and highway barrier

InactiveCN101672022AWith safety protection functionWith lighting functionLighting applicationsPoint-like light sourceEngineeringPolymer composites

The invention provides a method for protecting a highway barrier and the highway barrier. The method comprises the following steps: adopting a protecting support made of polymer composites and adopting a barrier made of polymer composites. The protecting support is provided with the same cross sections. A sleeve is fixedly arranged on the upper part of the protecting support and is integrally provided with a frame plate. The barrier is a hollow barrel and both ends of the barrier are respectively sleeved in the sleeve of the protecting support to form the highway barrier. The method is simplein construction. The highway barrier has various functions such as safety protecting, lighting and warning at night, has low manufacturing, installation and maintenance costs and reasonable structuredesign, can play better roles of protecting, lighting and warning at night and can be suitable for various occasions including the bridges where street lamps are not easy to install.

Owner:BEIJING HAIBO SIQIANG BRIDGE NEW TECH

Prevention and control method for falling of pumice at roof and two slopes of stope in medium-long hole mining

ActiveCN104963688AReduce ore inputReduce mining operation costsUnderground miningSurface miningMining engineeringPumice

The invention relates to a prevention and control method for falling of pumice at the roof and two slopes of a stope in medium-long hole mining. According to the invention, a protection air bag is installed at a central-and-upper position of a subsection; high pressure wind is injected into the protection air bag through a pressure ventilation pipeline in the stope so as to allow the wall of the air bag to extrude rock, so falling of loose ore blocks at the two slopes is prevented and ore blocks falling from the roof are prevented from directly falling into a bottom cleaning work zone of the subsection; thus, operation safety in the subsection is guaranteed.

Owner:SHANDONG GOLD GROUP +1

Highway slope protection ecological carpet preparation method

InactiveCN103174153AReduce the cost of protectionAvoid churnExcavationsNon-woven fabricsEnvironmental resource managementCarding

The invention discloses a highway slope protection ecological carpet preparation method. The preparation method comprises the following steps: A, utilizing polypropylene (PP) fibers and waste natural fibers as raw materials, adding other fibers, adopting an opener to respectively open the PP fibers, the waste natural fibers and other fibers, using a mixing cotton machine to mix after the opening, then adopting a carding machine for carding, and uniformly distributing the PP fibers, the waste natural fibers and other fibers; and B, utilizing a lapping machine to carry out cross lapping on the carded fibers so as to form a fibrous net, and carrying out post-processing on the fibrous net so as to form a highway slope protection ecological carpet. The method has the advantages that the preparation method is simple, the prepared ecological carpet can ensure the safety of highways and vehicles, and the protection cost of a hard material is lowered.

Owner:NANTONG UNIVERSITY

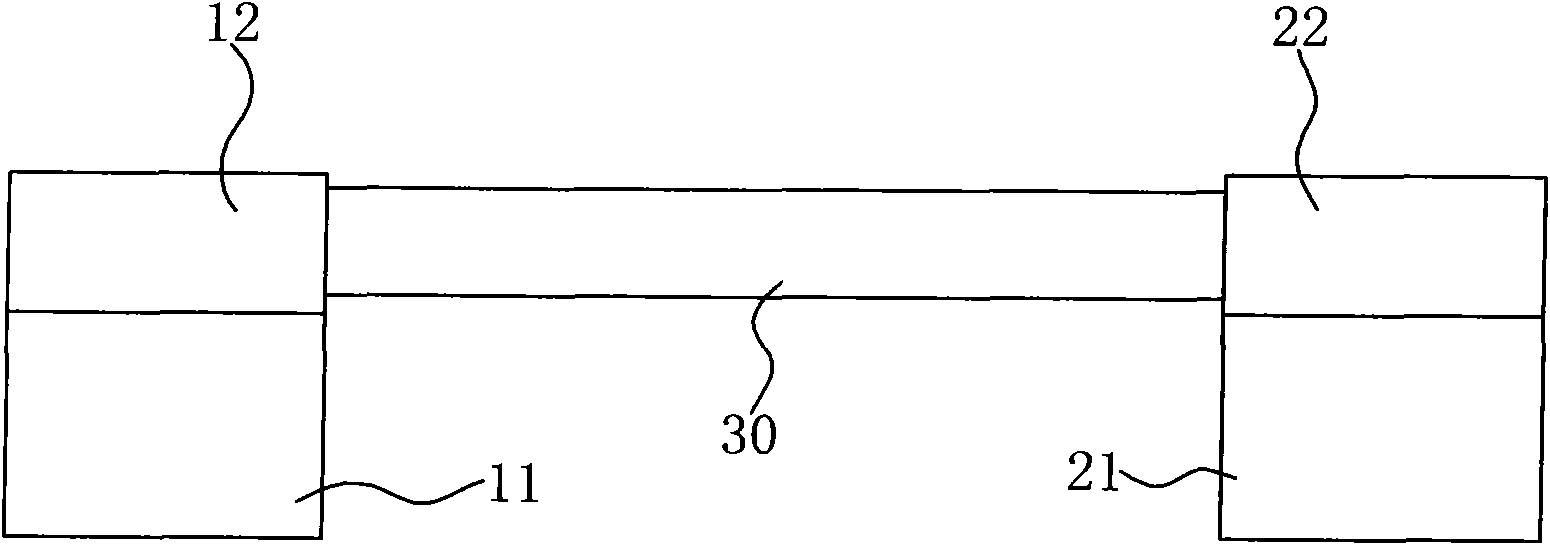

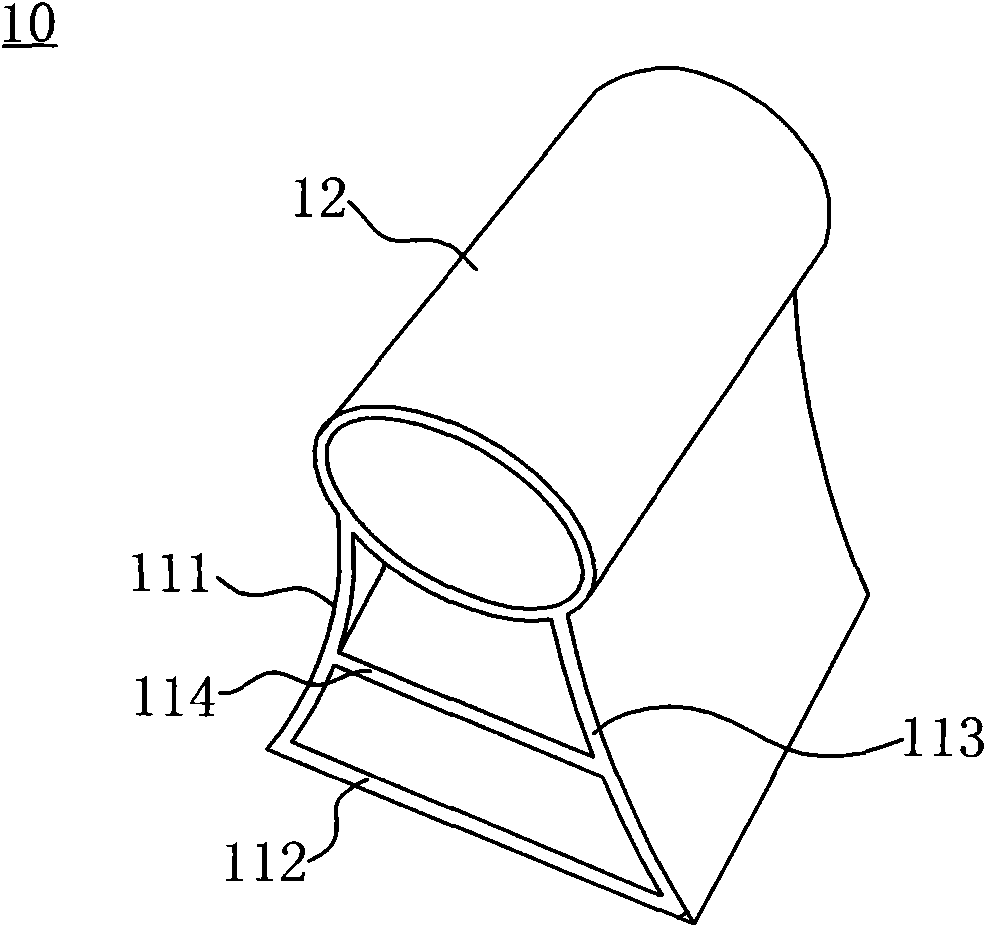

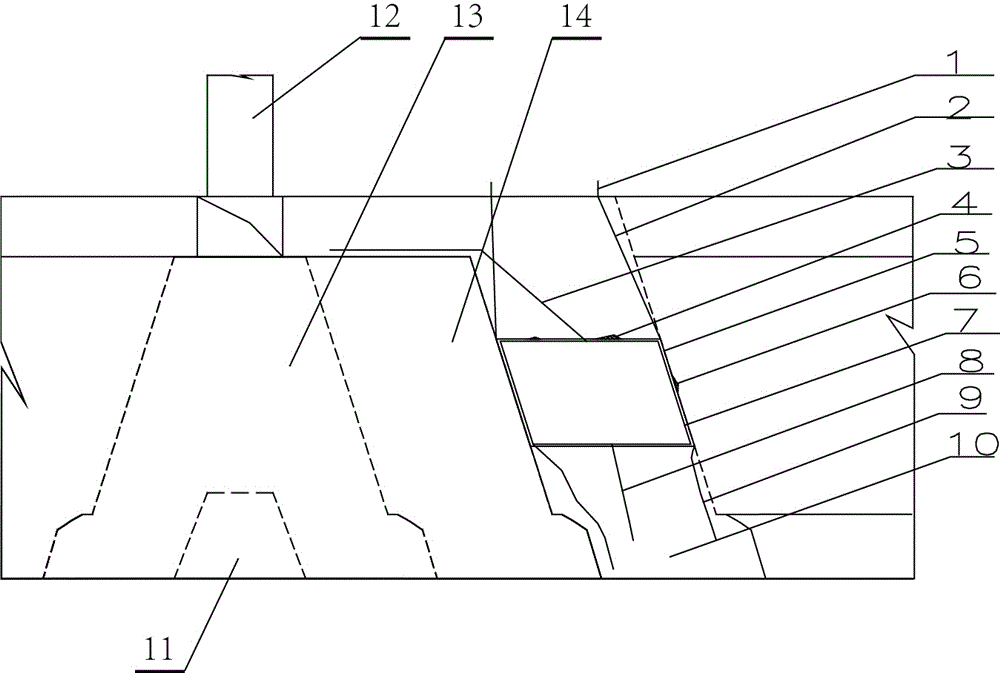

Long-acting building guy cable

InactiveCN101775781AExtended service lifeAvoid erosionBridge structural detailsBuilding material handlingLong actingEngineering

The invention discloses a long-acting building guy cable with good protection effect and long service life, comprising a guy cable body (1) and a guy cable anchor head (2). The guy cable body (1) passes through a building structure body (3) and is fixedly connected with the anchor head (2); a protective cover (21) fixedly connected with the building structure body (3) is coated outside the anchor head (2); anti-corrosive grease (22) is filled in the protective cover (21); foaming agent (23) is filled among the guy cable body (1), the anchor head (2) and the building structure body (3); the top of the foaming agent (23) is injected with a cement plaster layer (24); the upper part of the cement mortar layer (24) is provided with a steel cover plate (25) which is closely combined with the building structure (3); an additional protective layer is arranged outside the guy cable body (1), and comprises a flameproof textile (11) wrapped outside the guy cable body (1), a steel sleeve (12) and a flameproof coating (13) or comprises the steel sleeve (12) sleeved outside the guy cable body (1), a mortar layer (14) injected between the outside surfaces of the steel sleeve (12) and the mortar layer (14), and the flameproof coating (13) coated outside the steel sleeve (12).

Owner:深圳中建院建筑科技有限公司 +1

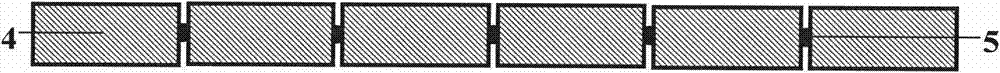

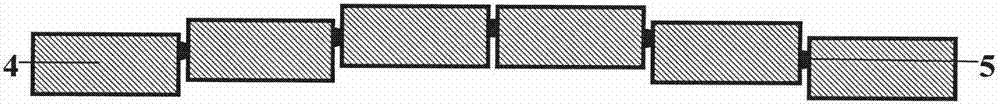

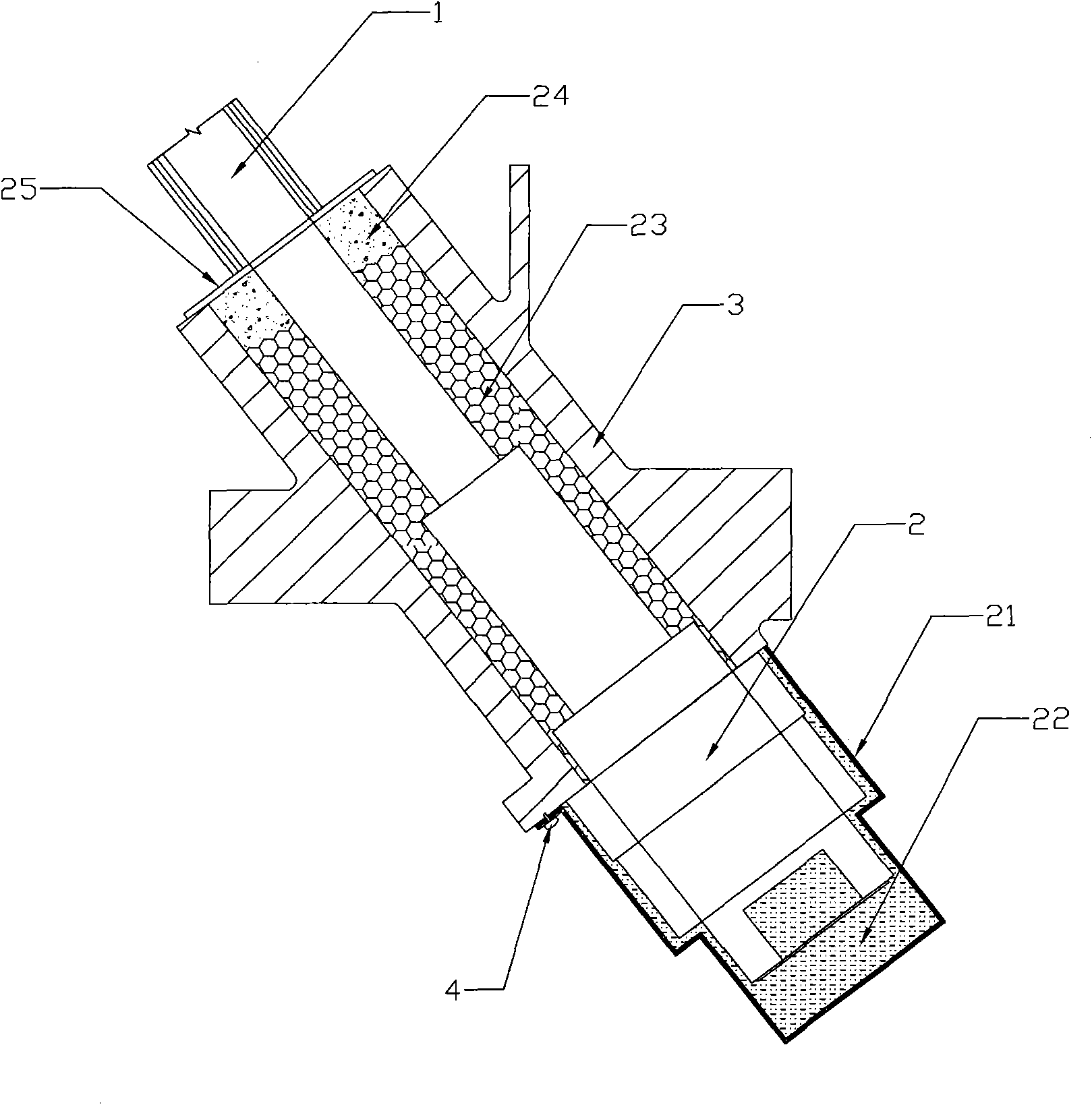

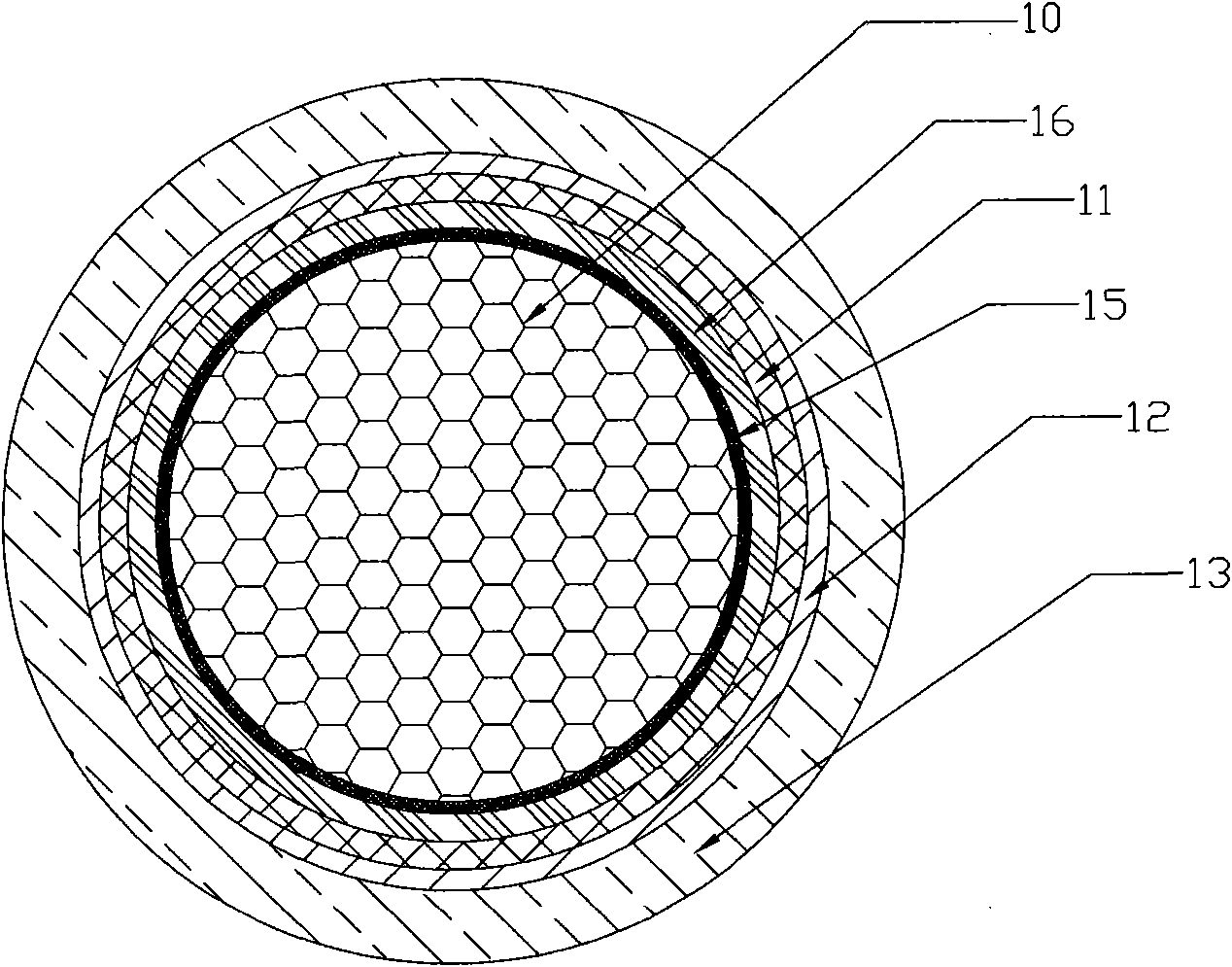

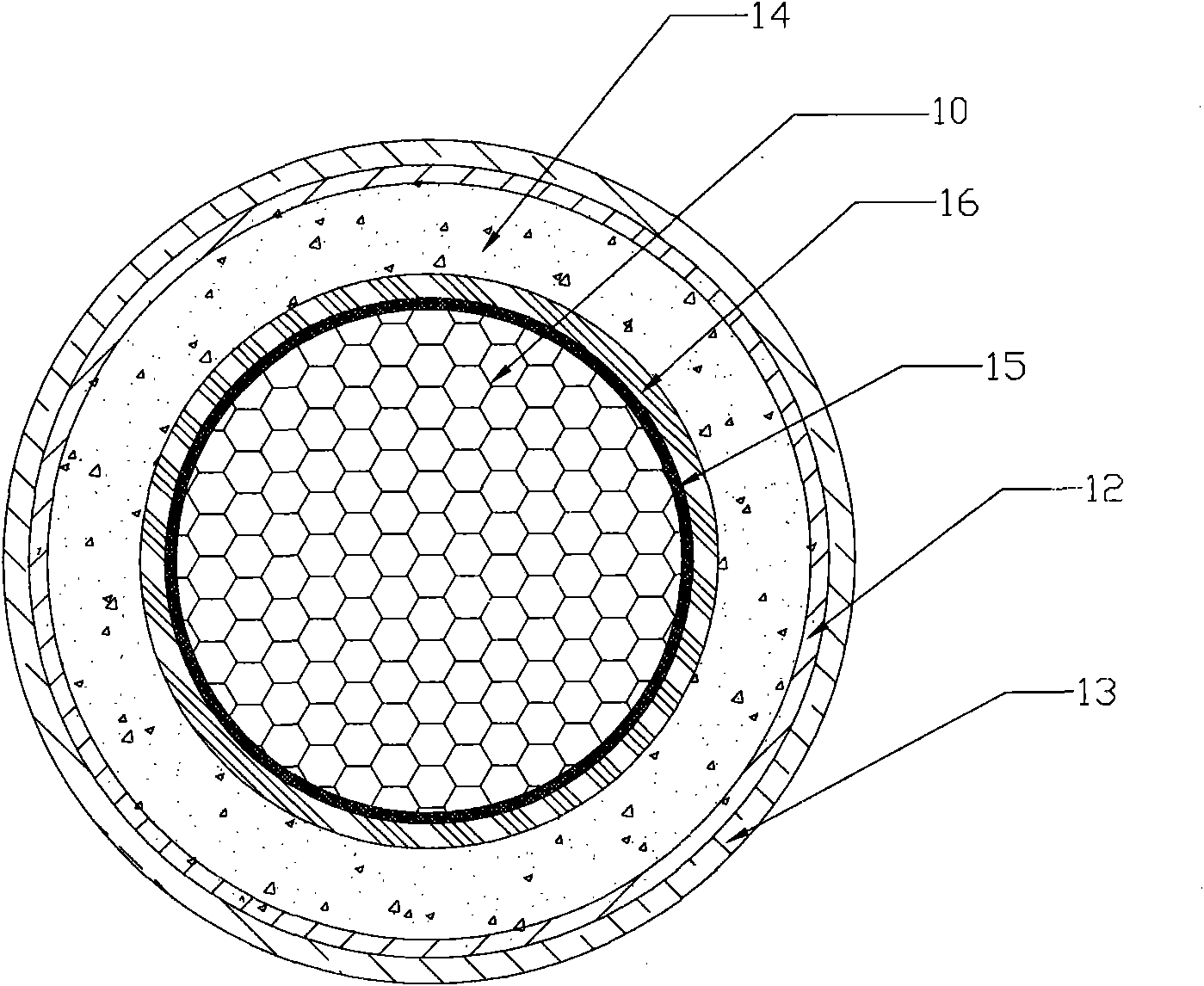

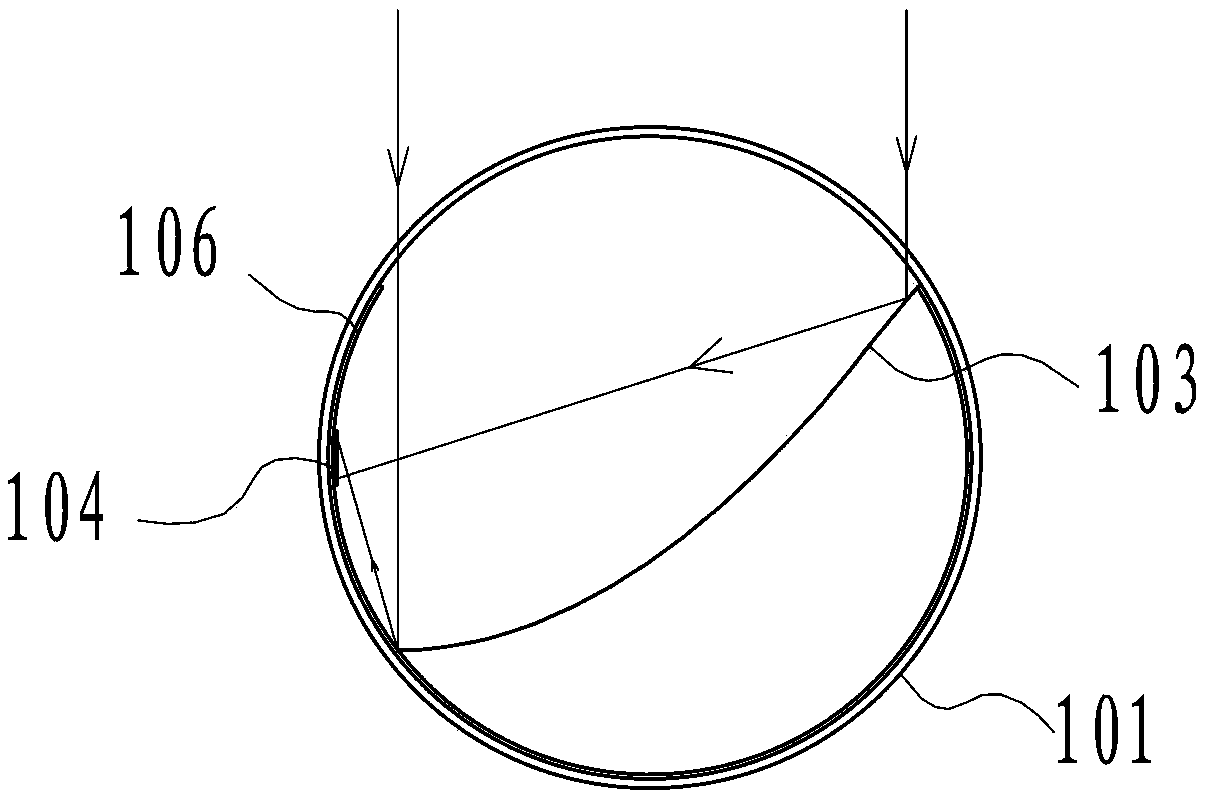

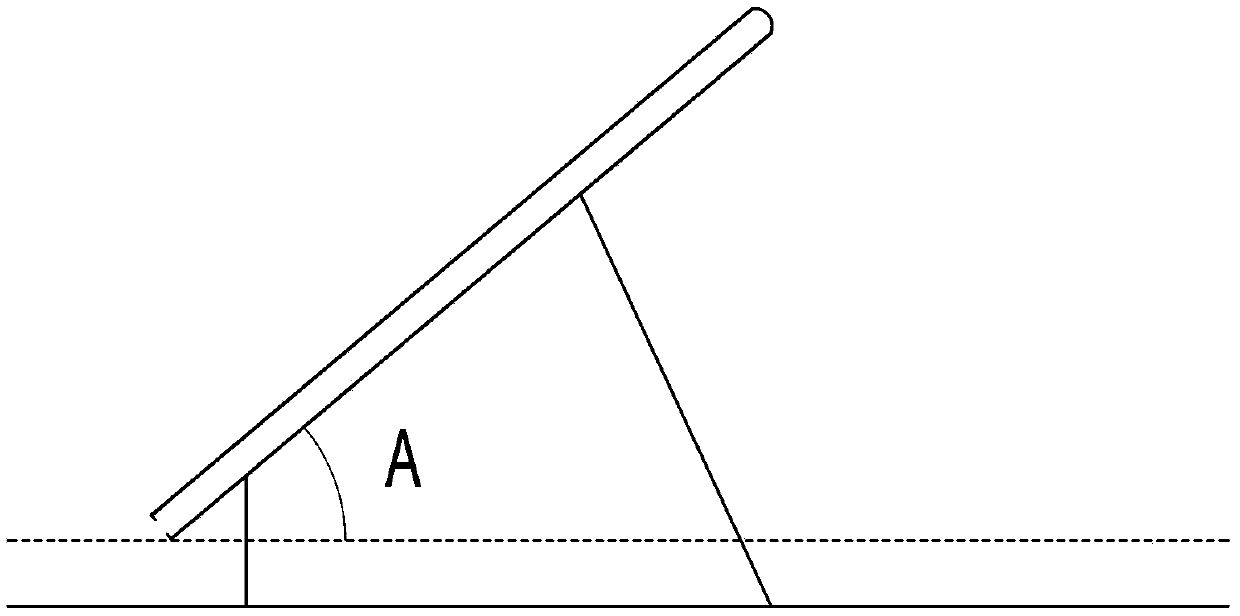

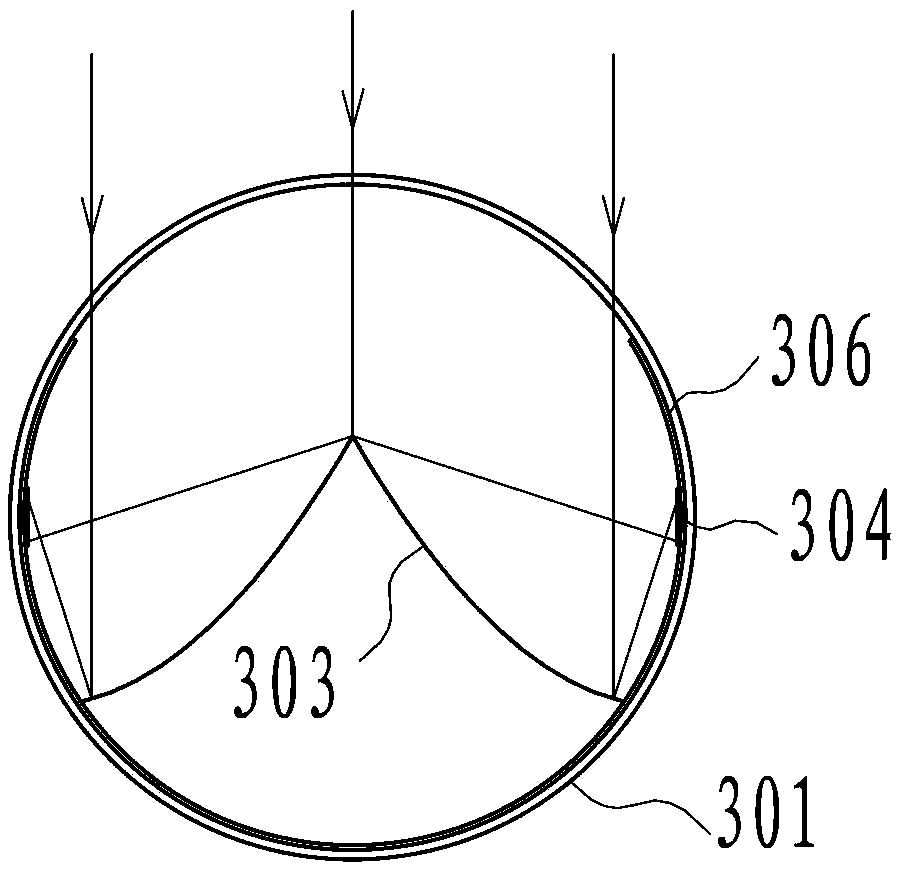

A tubular concentrator photovoltaic cell assembly

ActiveCN103456823BOptimize heat dissipation structureEconomical and reliable heat dissipation structureSolar heating energySolar heat devicesCell assemblyEngineering

Owner:刘庆云

Synergistic insecticidal composition containing Chloronicotynyle and Organosphosphorus compounds

ActiveUS7445791B2Delays dominanceWide range of activitiesBiocidePhosphorous compound active ingredientsCompound aCompound (substance)

A synergistic insecticidal composition is prepared by combining a Chloronicotynyle compound and an Organophosphorus (OP) compound. The preferred synergistically effective amount of the Chloronicotynyle compounds is an amount preferably ranging from 0.1 to 5% by weight of the composition. The preferred synergistically effective amount of the Organophosphorus (OP) compounds is an amount preferably ranging from 30 to 75% by weight of the composition. The composition also preferably includes 69.9 to 20% by weight of conventional agriculturally acceptable carrier(s) and / or excipient.

Owner:UNITED PHOSPHORUS LTD

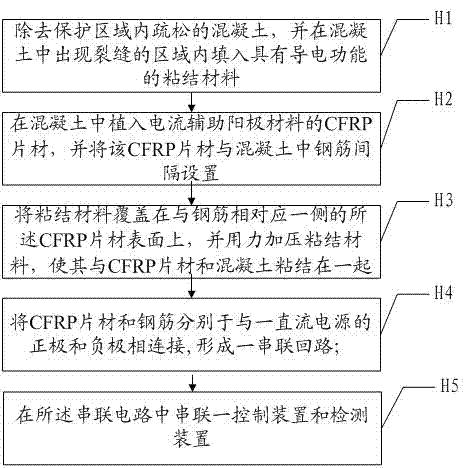

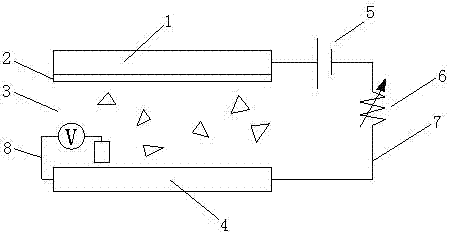

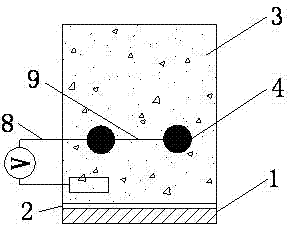

Cathode protection method and cathode protection device for reinforced concrete adopting CFRP (carbon fibre reinforced plastics) anode

The invention discloses a cathode protection method and a cathode protection device for reinforced concrete adopting a CFRP (carbon fibre reinforced plastics) anode. The device comprises a reinforcing steel bar embedded with concrete, a CFRP sheet material used as a current auxiliary anode material, and a direct-current power supply used for supplying power to the device, wherein a binding material for connecting the CFRP sheet material with concrete is arranged between the CFRP sheet material and concrete. The CFRP sheet material is used as the auxiliary anode of the protection device, so that the cost is greatly reduced while an ideal protection effect is obtained; and the CFRP sheet material is bound with the concrete by the binding material in the installation method, so that the device has the characteristics of being large in coverage area, and simple and convenient to install.

Owner:SHENZHEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com