Long-acting building guy cable

A construction, long-term technology, applied in the direction of construction, building structure, construction materials, etc., can solve the problems of HPDE easy aging, impact of cable life, HDPE cracking, etc., achieve good anti-corrosion effect, eliminate air and water vapor erosion , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

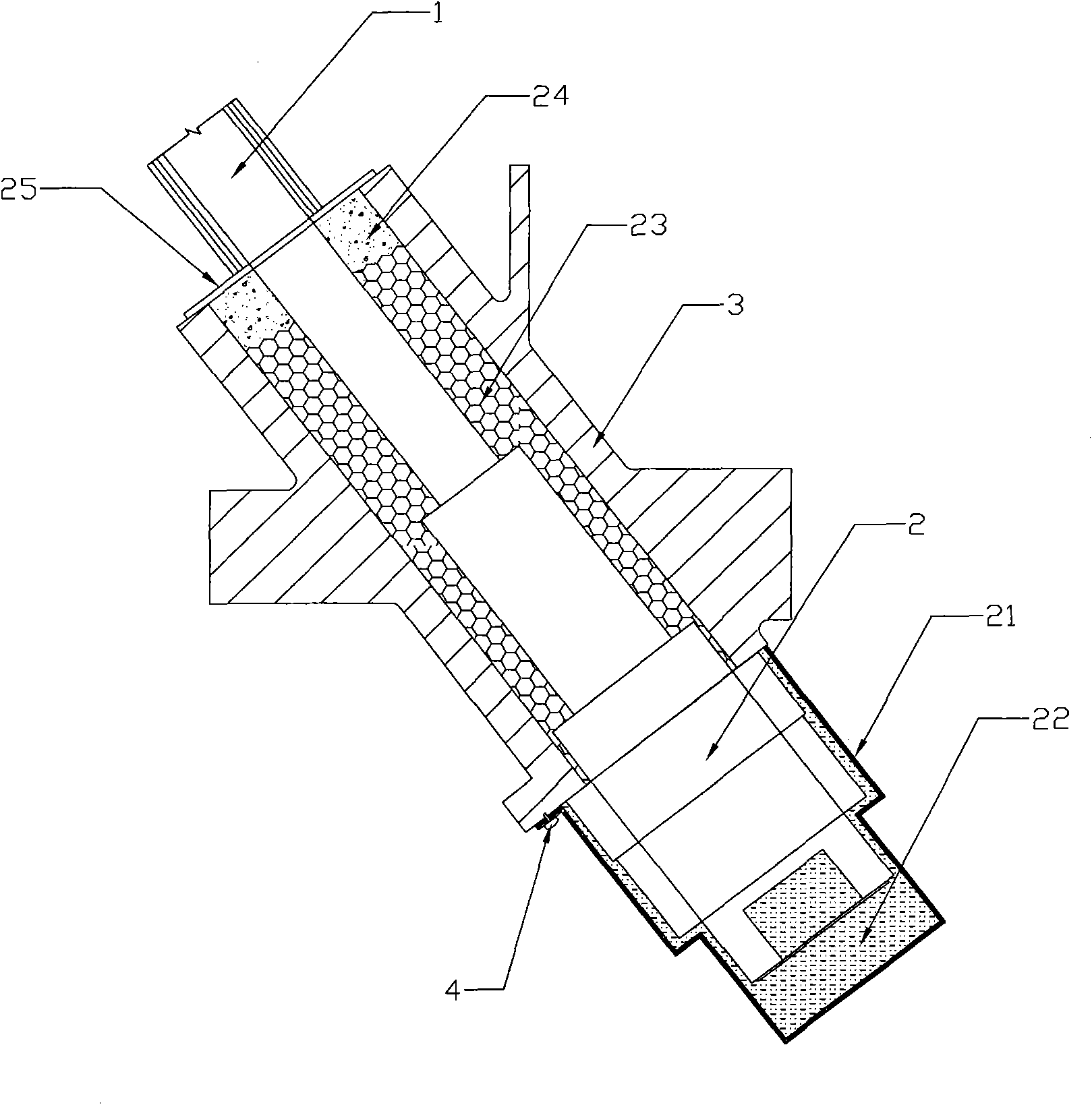

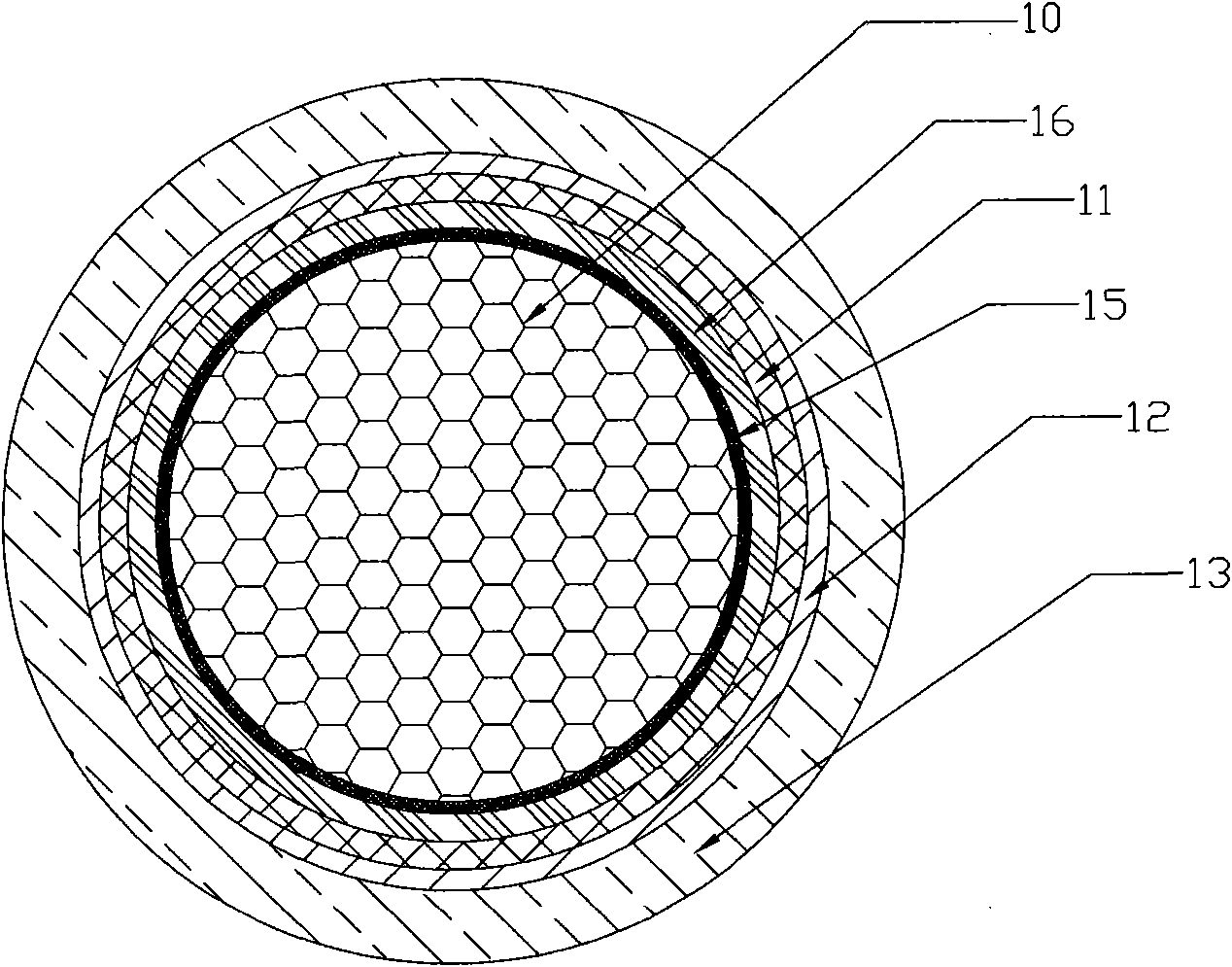

[0025] Such as figure 1 , figure 2 As shown, the present invention includes a cable body 1 and a cable anchor head 2, the end of the cable body 1 passes through a building structure 3 and is fixedly connected with the cable anchor head 2, and the cable anchor head 2 The part protruding from the building structure 3 is covered with a protective cover 21, the protective cover 21 is fixedly connected with the building structure 3 and covers the cable anchor head 2 inside, the protective cover 21 and the building structure 3 are fixedly connected by screws 4, and of course can also be sealed and fixed by welding. The protective cover 21 is filled with anti-corrosion grease 22, and the cable body 1 and the anchor head 2 of the cable are connected to the The voids between the building structures 3 are filled with a foaming agent 23, the top of the foaming agent 23 is filled with a cement mortar layer 24, the upper part of the cement mortar layer 24 is provided with a steel cover p...

Embodiment 2

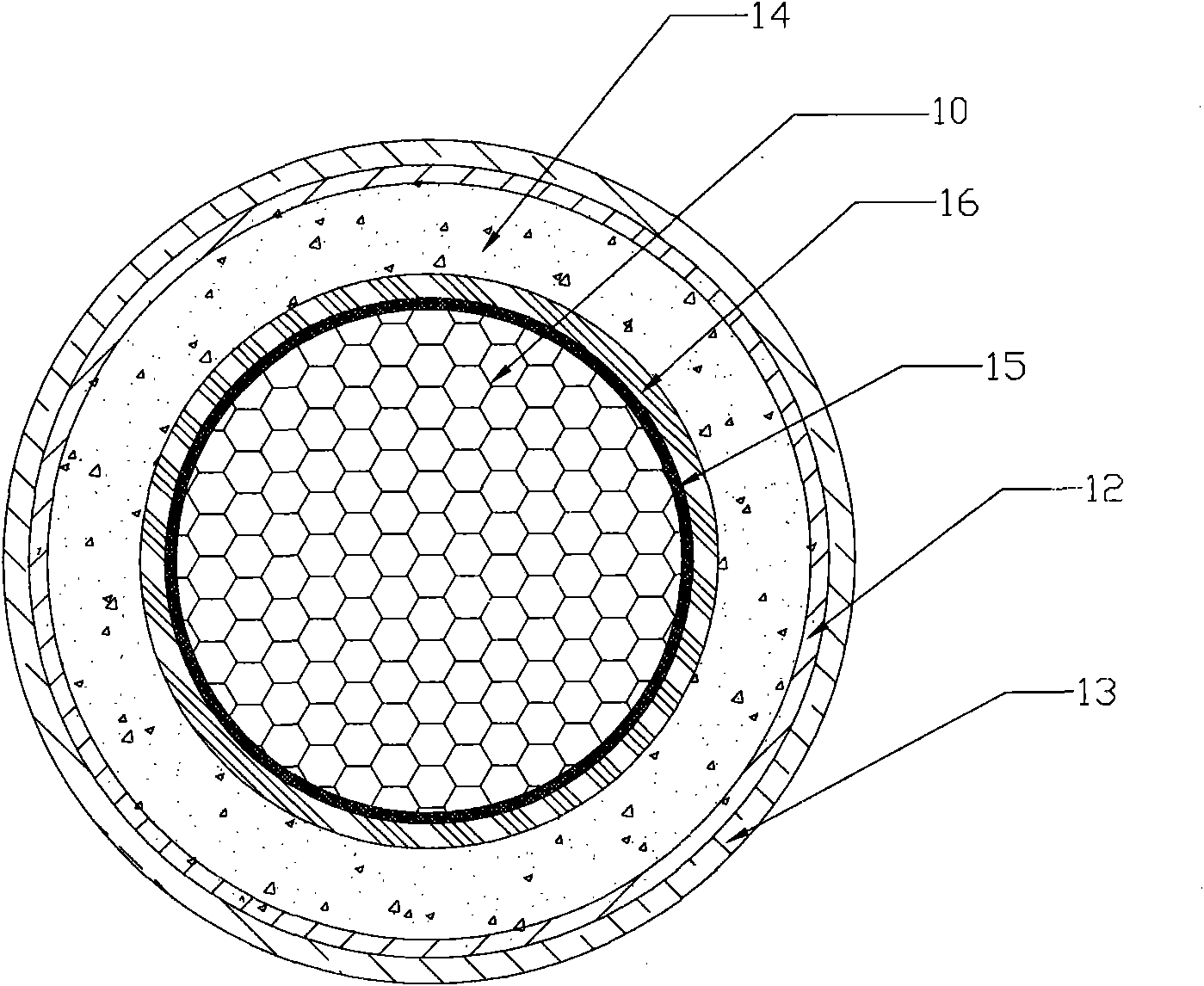

[0029] Such as figure 1 , image 3As shown, the difference between the present embodiment and the first embodiment lies in the additional protective layer. The additional protective layer of the present embodiment includes a steel sleeve 12 sleeved on the periphery of the cable body 1, poured into the The mortar layer 14 between the steel casing 12 and the outer surface of the cable body 1, and the fireproof coating 13 coated on the outer surface of the steel casing 12, the pouring mortar layer 14 is applied to the cable body 1 The protection can obtain the expected protective effect and achieve the purpose of protection. Therefore, the thickness of the fireproof coating 13 provided on the outer surface of the steel sleeve 12 can be appropriately reduced compared with Embodiment 1, so as to reduce the overall cost of the cable.

[0030] The remaining features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com