Replaceable nozzle for producing a frothed liquid

A nozzle and liquid technology, applied in the nozzle field, can solve the problems of discarding, discomfort, bulky, etc., and achieve the effect of structural solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

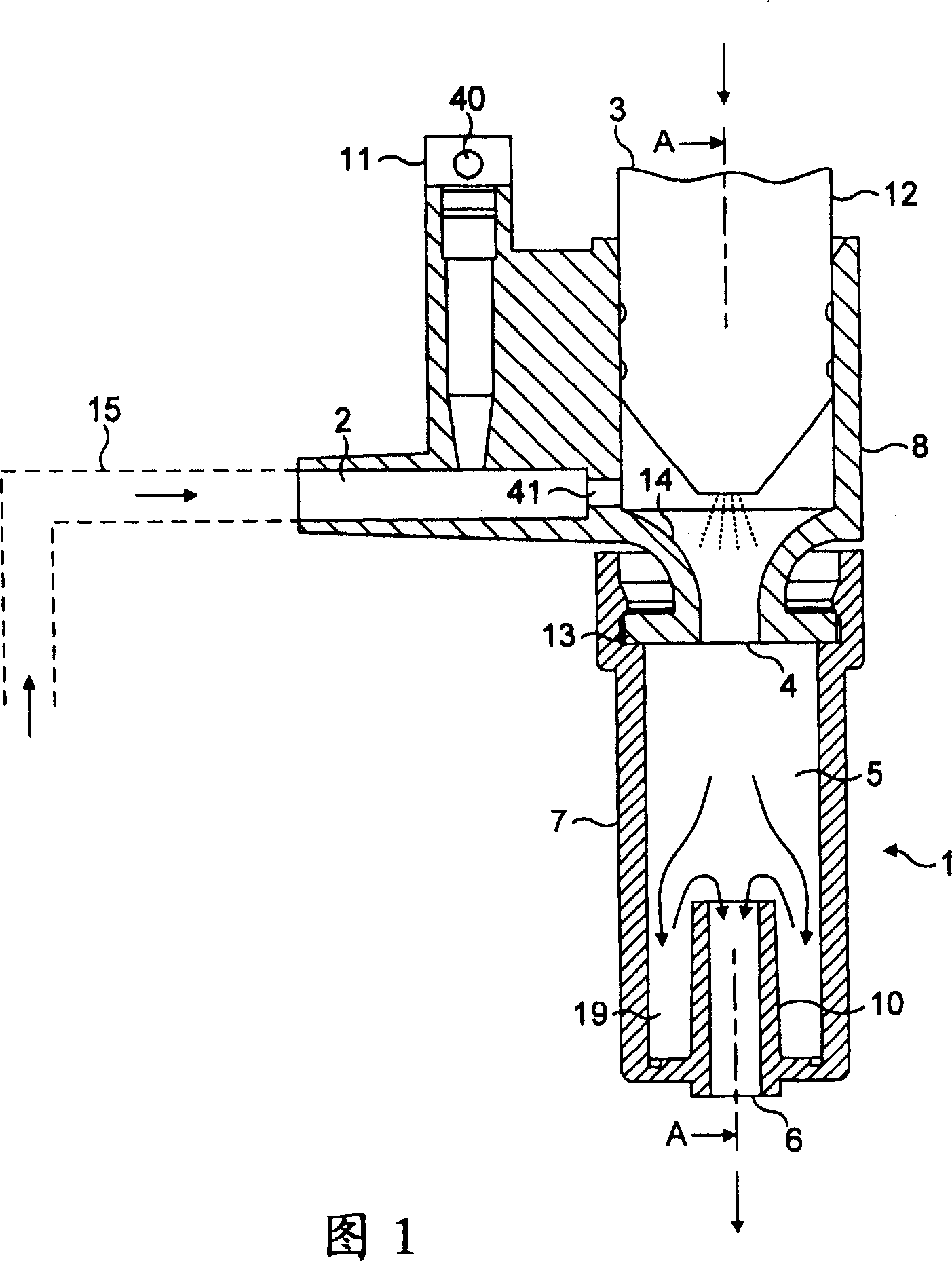

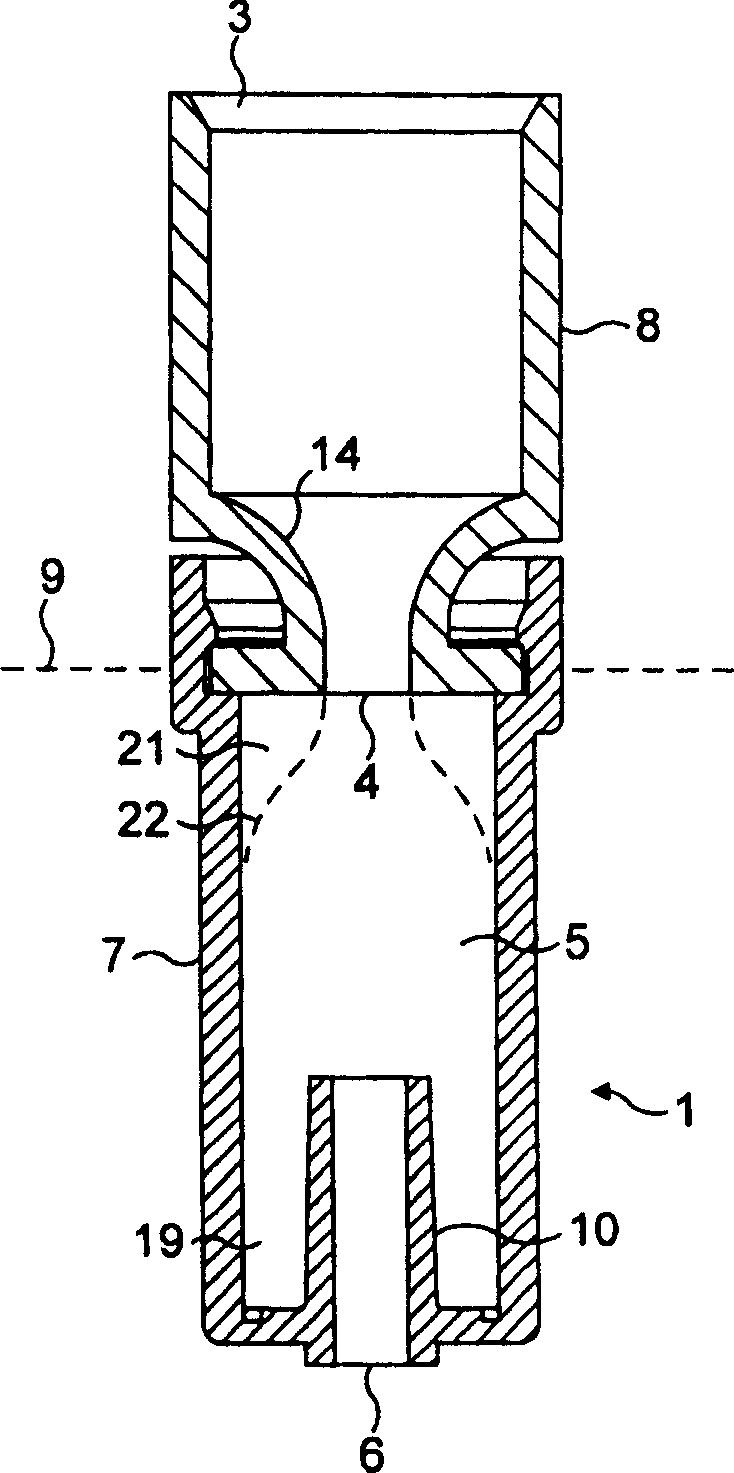

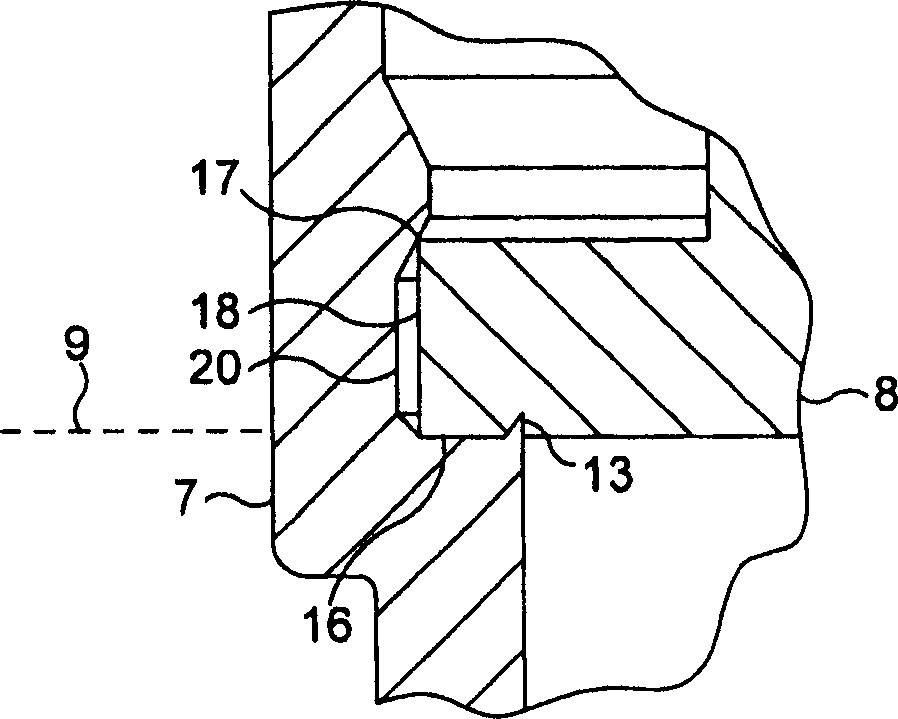

[0046] Figure 1 shows a cross-sectional view of a nozzle 1 mountable on a steam outlet 12 of a coffee machine for preparing cappuccinos. The steam outlet 12 can be inserted into the steam opening 3 of the nozzle 1, which is adapted either to a mating steam outlet 12 of a particular size (in the case of a non-elastomeric material for the steam opening 3), or to a steam outlet of a different size. Steam outlet (in case of a flexible material such as silicone for the steam opening 3).

[0047] Into the duct 2 can be inserted a suction tube 15, for example for aspirating liquid, eg milk, from a milk supply.

[0048] In case the production of hot milk is envisaged, it is sufficient to mix the milk supplied via the pipe 2 with the steam supplied from the steam inlet 3 . When producing cappuccino-flavored coffee, it is necessary to froth the hot milk. To this end, an air inlet 40 is provided which leads into the duct 2 for supplying milk.

[0049]The main body of the nozzle 1, ie ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com