Method for protecting highway barrier and highway barrier

A highway guardrail and guardrail technology, which is applied to roads, roads, road safety devices, etc., can solve the problems of high steel production costs, difficult to achieve maintenance, high use and maintenance costs, and achieve low production, installation and maintenance costs, and structural design. Reasonable and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

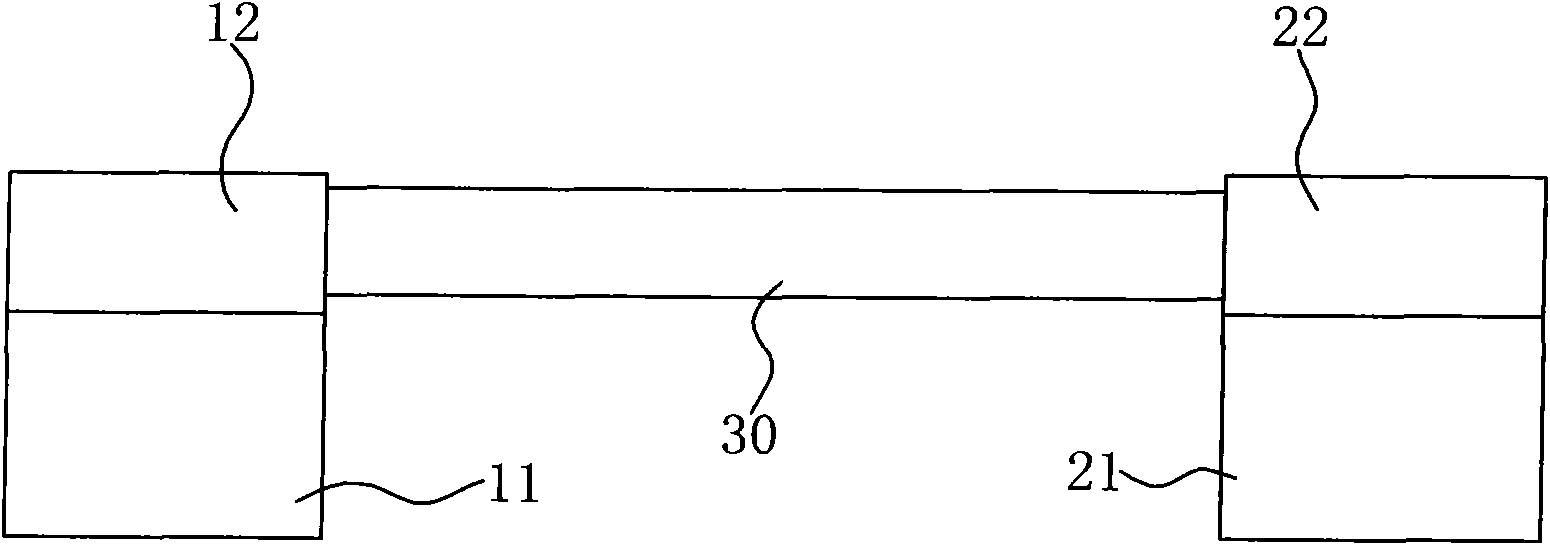

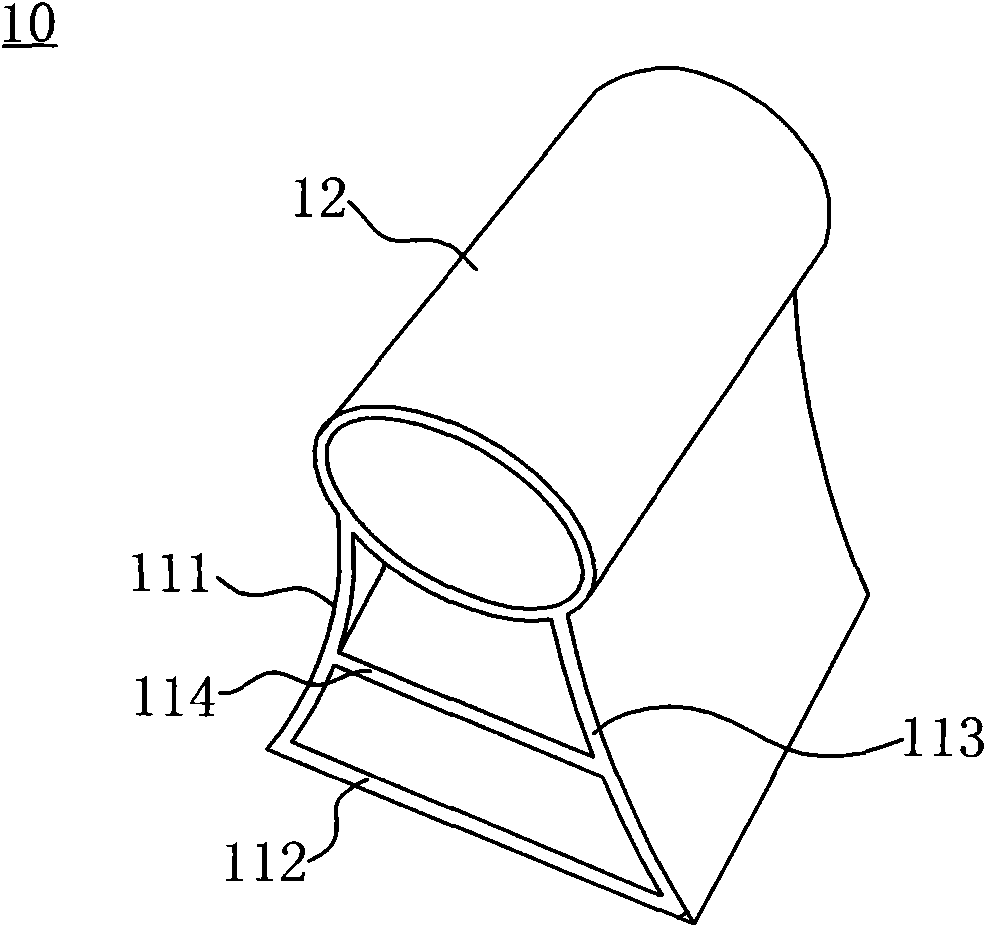

[0025] The highway guardrail protection method adopts a protective bracket and a guardrail of a polymer composite material, both of which can be manufactured by extrusion molding equipment. The protective bracket has the same transverse section, the upper part of the protective bracket is fixedly provided with a sleeve, and the sleeve is integrally formed with a shelf plate; Inside the tube, a highway guardrail is formed. Wherein the protective bracket has a bottom support plate, the two ends of the bottom support plate are connected with inclined side plates, the two side plates are inclined inward, and the end is provided with a sleeve, and the bottom support plate, the side plate and the sleeve are integrally formed . The protective fence is made of transparent and translucent composite fiber reinforced material and a cylinder covered with polymer resin, which is equipped with lighting fixtures. The lighting fixtures are LED lamps distributed and arranged in the barrel th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com