Laser processing robot control system with safety protection function

A technology of safety protection and laser processing, which is applied in the direction of laser welding equipment, metal processing equipment, program control manipulator, etc., can solve the problems of reducing the safety protection effect of robots, lack of protective measures for detection and control, and incapable of robot protection and adjustment, so as to improve safety. Protective effect, improve protective effect, increase the effect of coping methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

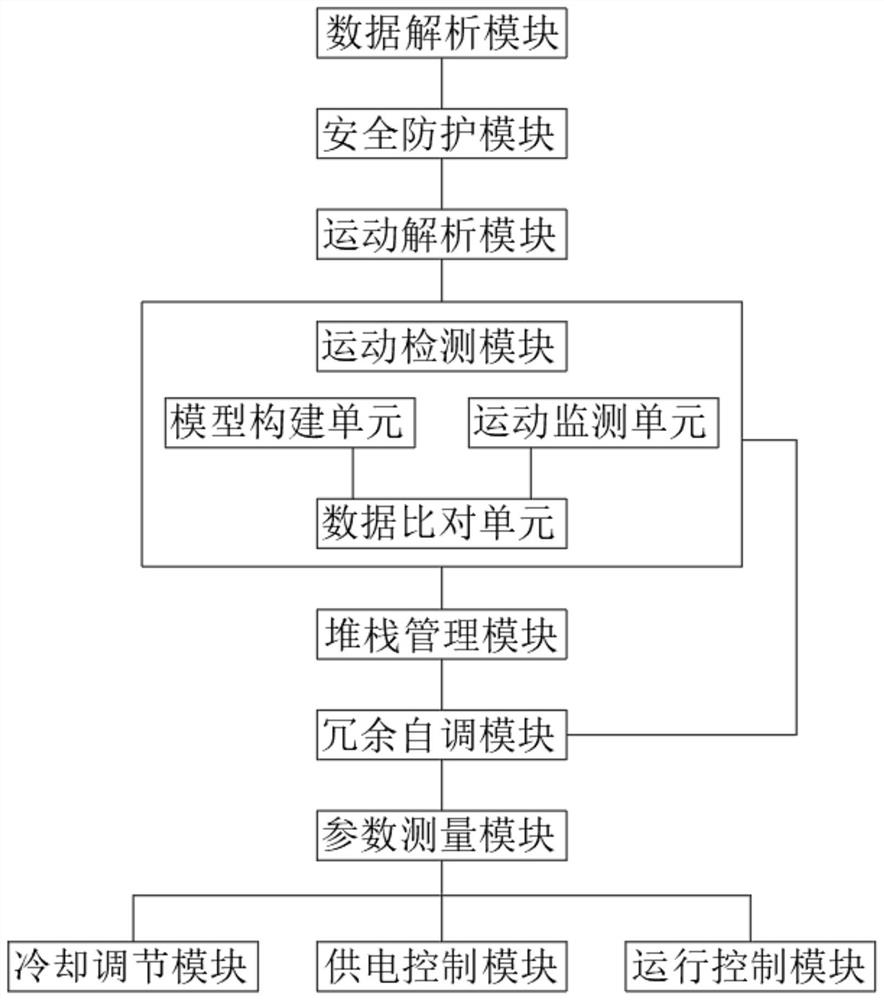

[0028] see figure 1 , a laser processing laser processing robot control system with safety protection function, including a parameter measurement module, a cooling adjustment module, a power supply control module, an operation control module, and also includes a data analysis module, a safety protection module, a motion analysis module, and a motion detection module , stack management module, redundant self-adjustment module; where:

[0029] The parameter measurement module is used to measure the operating parameters of the laser processing robot, and record the parameter changes during the operation of the laser processing robot in real time, including the measurement of axis parameters, structural parameters and energy parameters; the axis parameters include the measurement of the range of motion of the axis and the measurement of rotation speed; The measurement of structural parameters includes the measurement of the mechanical operating temperature, and the measurement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com