Double-tensioning-wheel tensioning device for compensating rope

A technology of tensioning device and tensioning wheel, which is applied in the field of elevators, can solve problems such as pressure friction, affecting service life, and unfavorable car stability, so as to prevent jumping and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

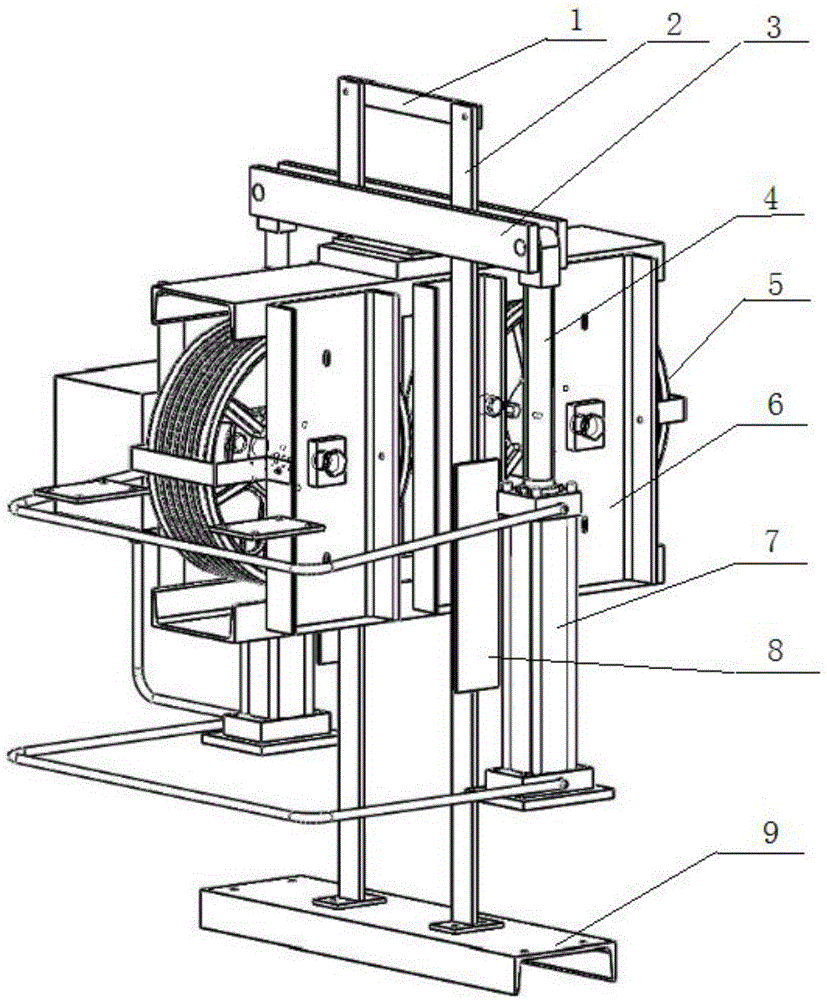

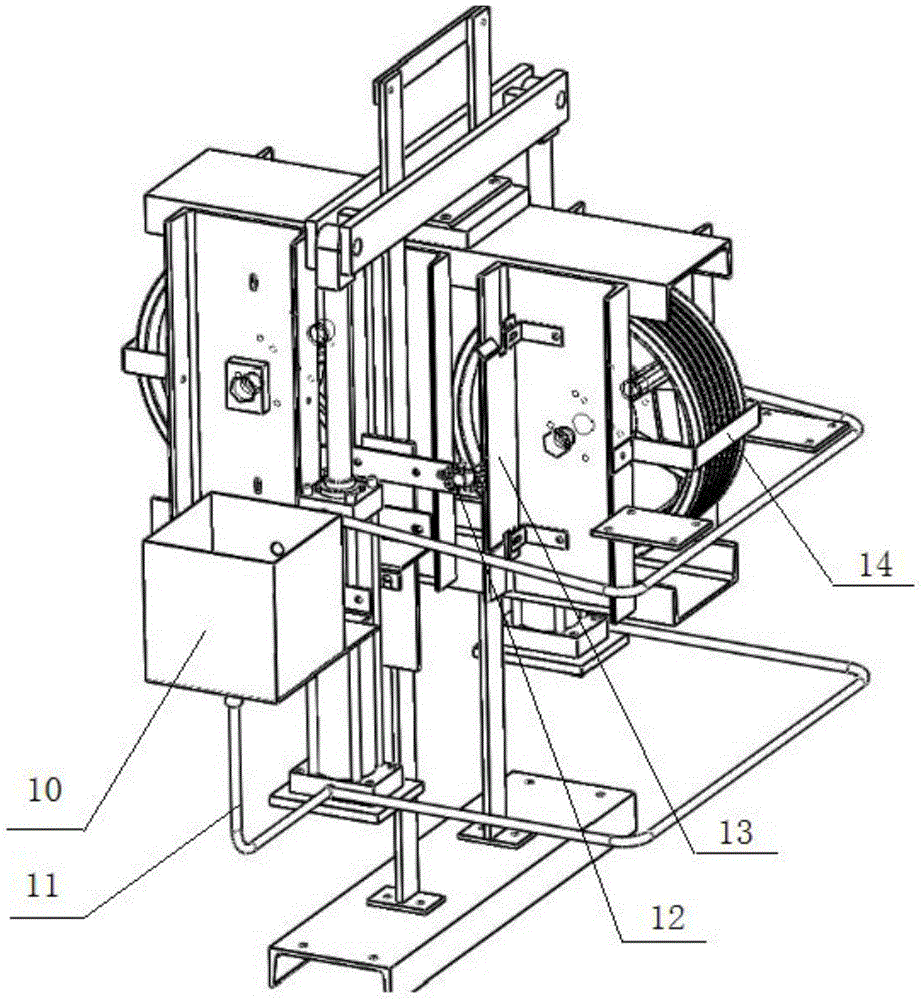

[0018] A double tensioner compensation rope tensioning device, such as figure 1 As shown in , it includes a fixed frame, a lifting mechanism, a compensation rope tensioner 5, and a tensioner frame 6. The fixed frame is composed of a mounting base 9, rail frames 2 on both sides and a limit rod 1 on the top. The lifting mechanism consists of The hydraulic cylinder mounting base (omitted in the figure), the symmetrical hydraulic cylinder 7 and the lifting beam 3 driven by the push rod 4 of the hydraulic cylinder are composed of two compensation rope tensioners, and the two compensation rope tensioners are installed on the Inside the tensioner frame. A rope retaining plate 14 positioned at the outside of the tensioner wheel is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com