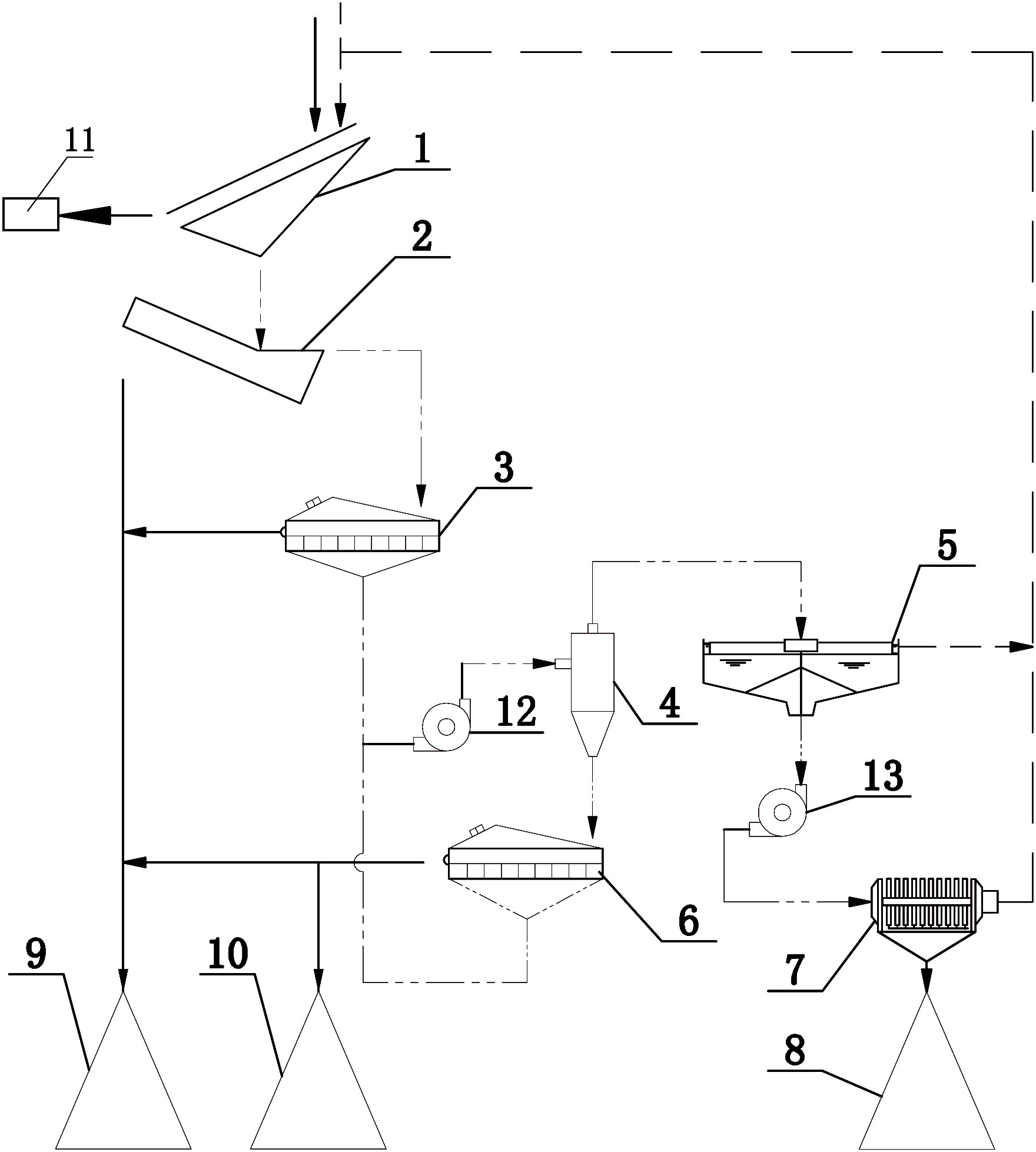

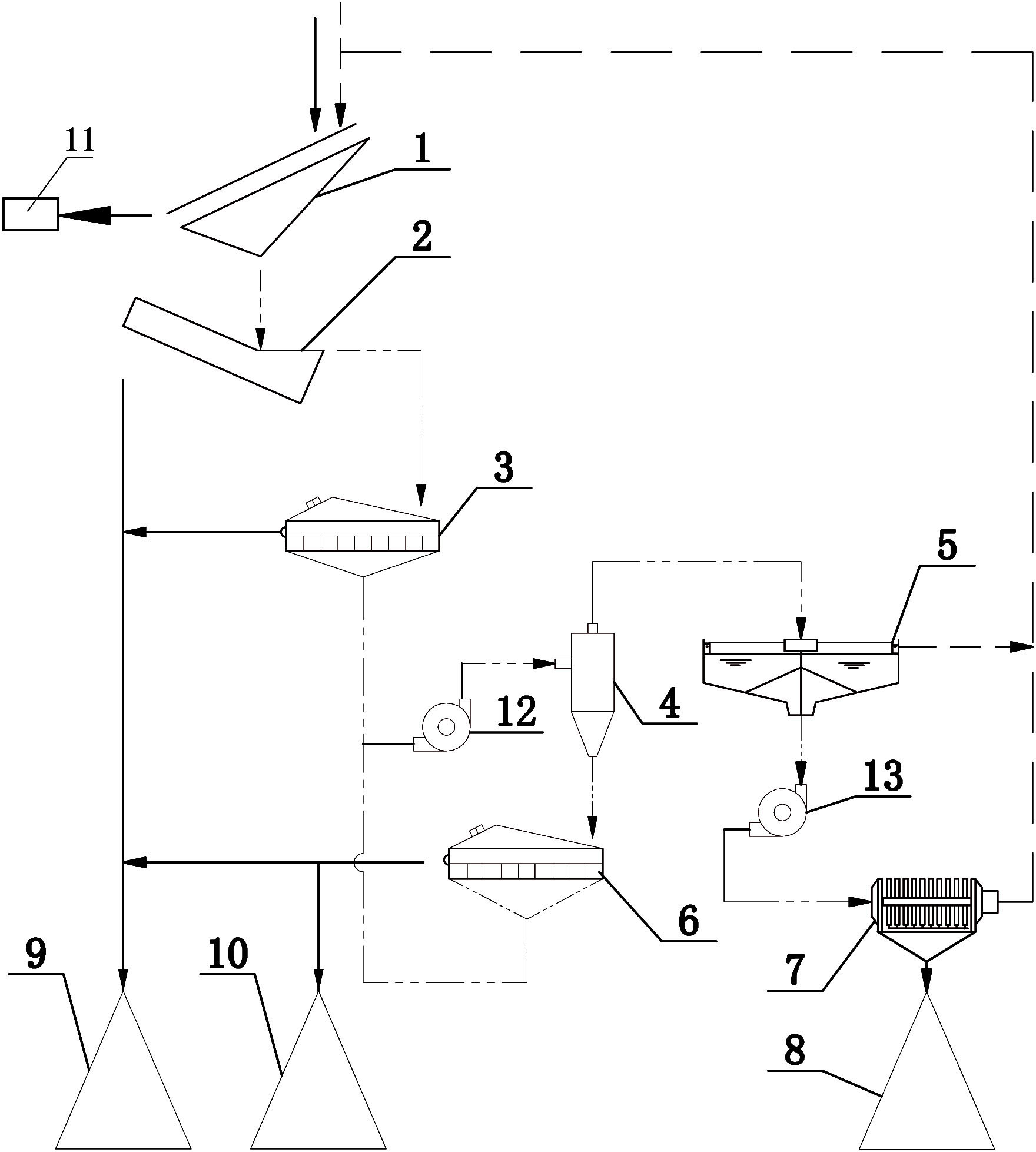

Method for grading and utilizing waste material of sandstone system production

A sand and gravel classification device technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problem that the water resource reuse rate is less than 50%, and there is no awareness of the use of materials in the recovery of mud, and the use of materials and mud Problems such as inability to be effectively separated can achieve the effect of reducing the load of subsequent equipment and facilities, realizing water and soil conservation, and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for grading and utilizing waste materials produced in a sand and gravel system,

[0046]1. The sand and gravel system adopts wet production. The material is screened and classified by the screening machine 1 to obtain coarse aggregate 11, which is washed by the sand washing machine 2 with pressure water, and the mixed slurry under the screen is washed to produce finished sand 9. Sand washing equipment It can be a spiral classifier or a bucket wheel sand washing machine. The mud and sand slurry formed by the mixed liquid after sand washing has a maximum particle size of less than 5mm, and the preparation for mud and sand classification is completed. In the mud and sand preparation and grading link, it can be used for both sand washing and stone washing, or a combination of the above two links at the same time and multiple times. If the stone washing link is used, a subsequent sand washing link must be added to prevent the sand from being larger than 5mm The part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com