A tubular concentrator photovoltaic cell assembly

A technology of concentrating photovoltaics and photovoltaic cells, which is applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of difficult discharge of air bubbles, long time consumption, shortened replacement cycle of photovoltaic cells, etc., to improve efficiency and service life, materials and structures. Economical and reliable, the effect of overcoming the decline of module efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

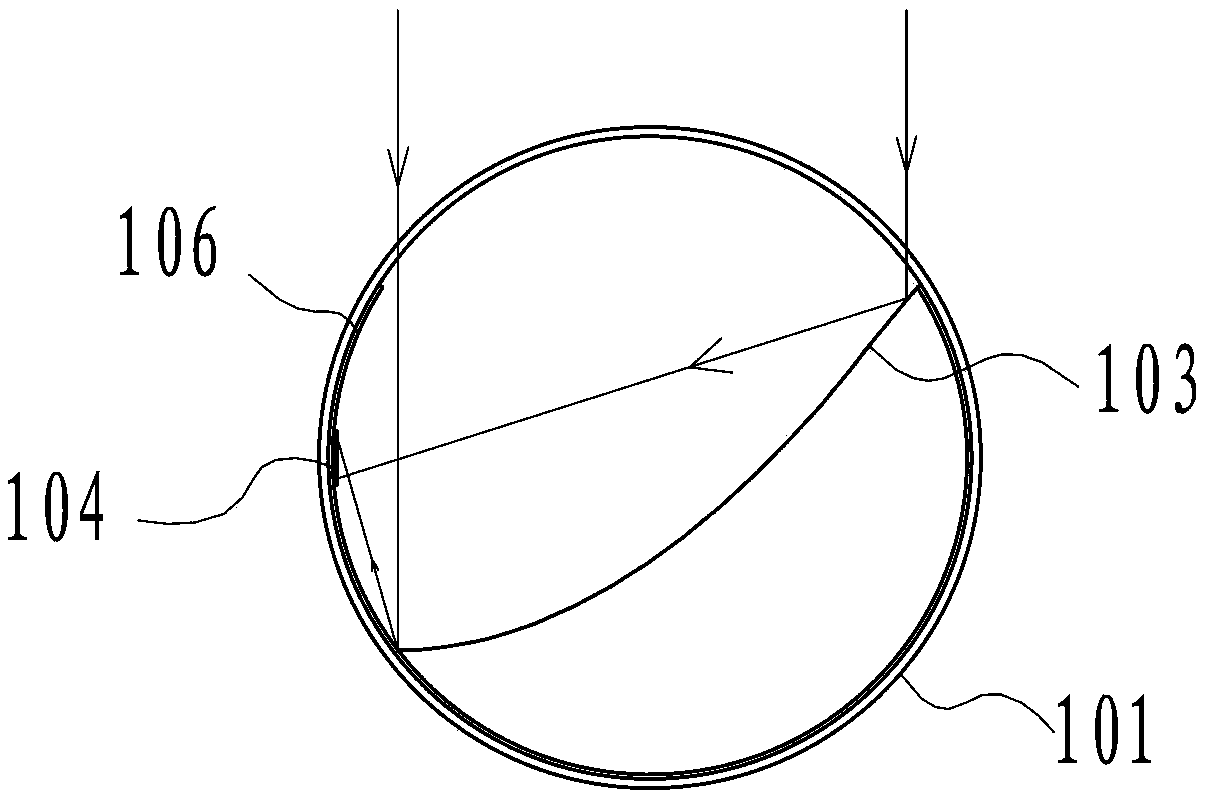

[0041] figure 1 It is a schematic structural view of the first embodiment of the tubular concentrating photovoltaic module of the present invention; as figure 1As shown, the tubular concentrating photovoltaic module includes a glass tube 101, at least one set of correspondingly arranged concentrating optical systems and photovoltaic cell arrays arranged in the glass tube 101, and in this embodiment, only A set of concentrating optical systems 103 arranged correspondingly.

Embodiment 1

[0042] The photovoltaic cell array in Embodiment 1 includes several photovoltaic cell array units; the photovoltaic cell array unit includes at least one photovoltaic cell 104 and a thermal diffusion structure 106 arranged on the back of the photovoltaic cell 104, and the thermal diffusion structure 106 and the photovoltaic cell 104 The back is in thermal contact and arranged close to the inner wall of the glass tube 101 to diffuse the heat of the photovoltaic cell array unit to the large-area glass tube wall, and transfer the heat to the external environment of the glass tube 101 through the glass tube wall. The thermal diffusion structure 106 is arranged on the side wall of the glass tube and the partial area of the bottom tube wall relative to the incident light direction, so as to maximize the incident width of the sunlight of the concentrating optical system 103; the thermal diffusion structure in the photovoltaic cell unit The front side of 106 is combined with the phot...

Embodiment 2

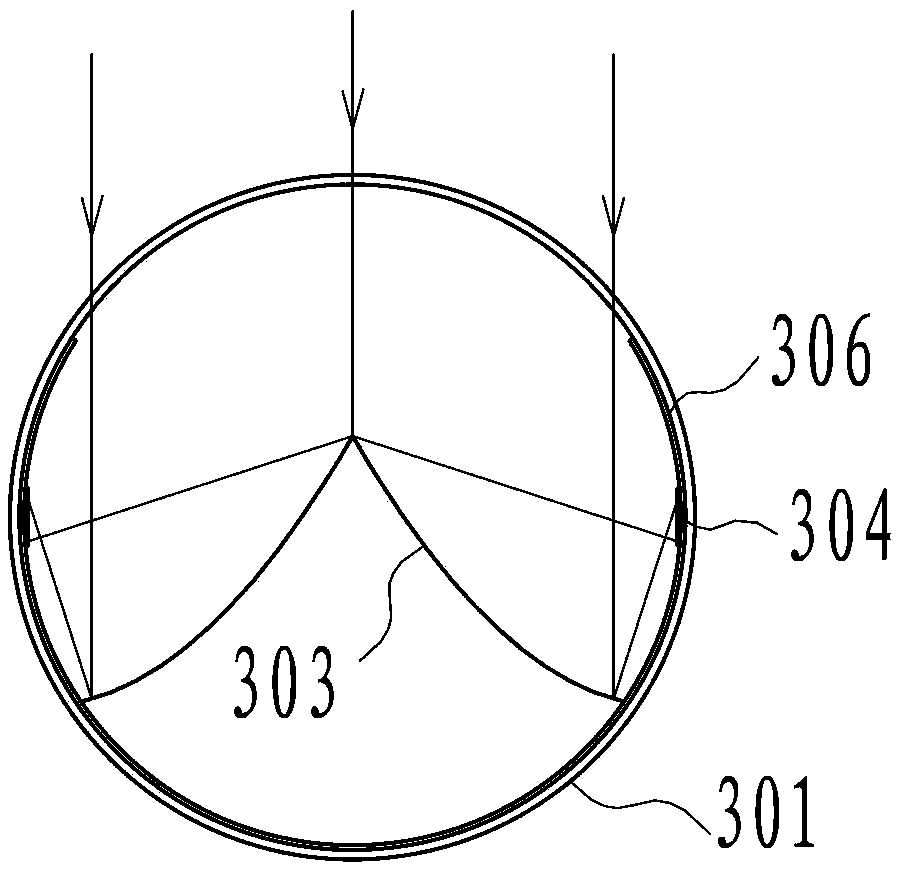

[0048] image 3 It is a structural schematic diagram of the second embodiment of the tubular concentrating photovoltaic module of the present invention. Such as image 3 As shown, the tubular concentrating photovoltaic cell assembly includes a glass tube 301 , at least one set of correspondingly arranged concentrating optical systems 303 arranged in the glass tube 301 and a photovoltaic cell array. Two groups of corresponding concentrating optical systems 303 and photovoltaic cell arrays are arranged symmetrically inside the glass tube 301; The thermal diffusion structure 306 is arranged on the back of the photovoltaic cell. The difference between Embodiment 2 and Embodiment 1 is that, inside the same glass tube 301, there are mutually symmetrical concentrating optical systems 303 and corresponding photovoltaic cell arrays; The part of the tube wall that is less or not affected by the glass tube, for example, the heat diffusion structure 306 is arranged on the side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com