Printing and punching production line for solar water tank shells

A solar water tank and production line technology, applied in other home appliances, home appliances, applications, etc., can solve the problems of poor product quality, lack of connection production lines, and many production personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

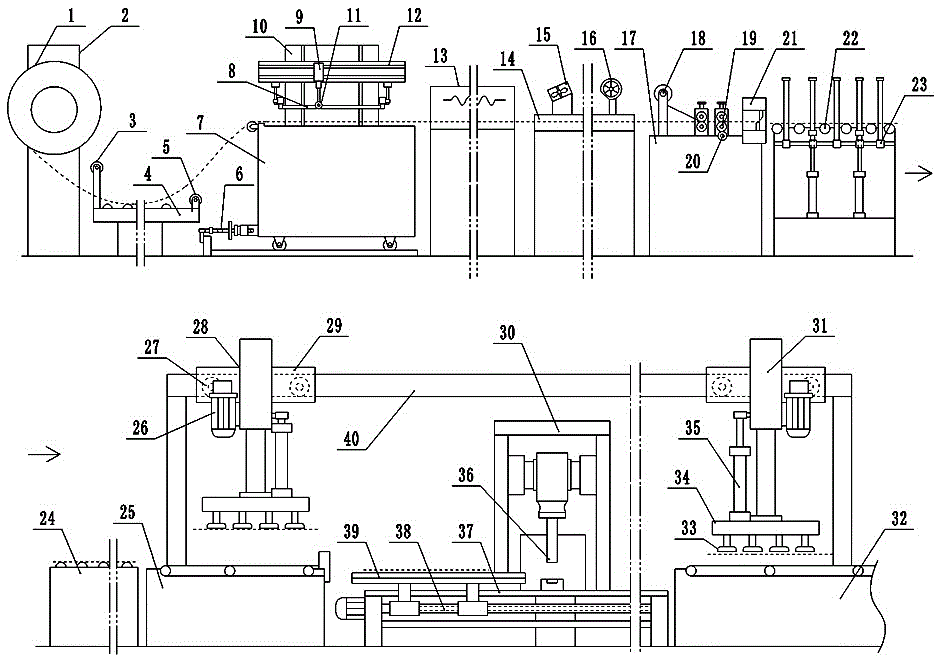

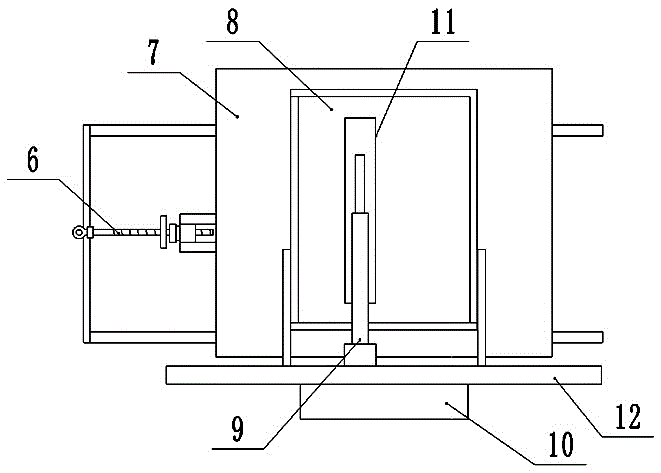

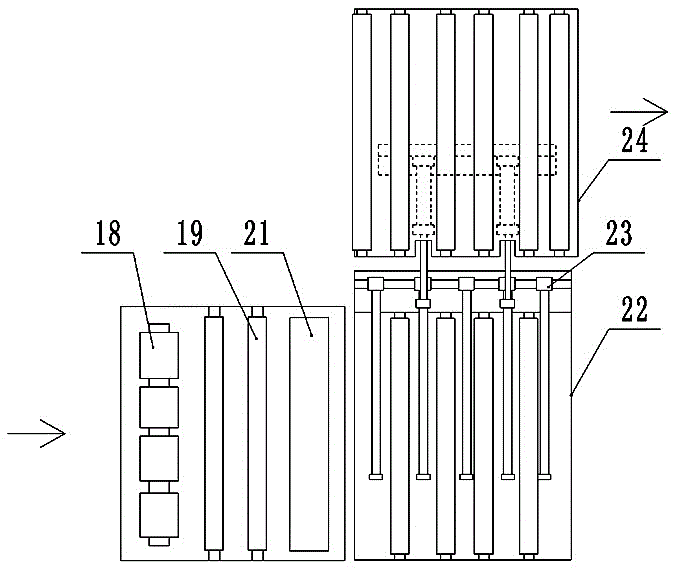

[0010] Examples such as figure 1 , figure 2 and image 3 Shown: a solar water tank shell printing and punching production line, the unwinding speed buffer platform 4 is installed at the rear end of the unwinding rack 2 of the metal strip roll 1 of the production line, and the unwinding motor is installed at the front end of the unwinding speed buffering platform 4 The start sensor switch 3 is installed with the unwinding motor stop sensor switch 5 at the rear end; the flat printing machine 7 is installed at the rear end of the unwinding speed buffer platform 4, and the front and rear position adjustment mechanism 6 of the flat printing machine is installed under the front end of the flat printing machine 7 , a lifting support plate 10 is installed on the frame of the flat printing machine, a lifting arm 12 is installed on the lifting support plate 10, a moving frame 9 is installed on the lifting arm 12, an inking roller 11 is installed on the lower end of the moving frame 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com