Glitter PVC (polyvinyl chloride) table cloth and production process thereof

A production process and technology of glitter powder, applied in the field of glitter powder PVC tablecloth and its production process, can solve the problem of surface pattern color brightness, saturation, layering, softness reduction, unmaintainable pattern on the tablecloth surface, decorative effect Not strong and other problems, to achieve the effect of colorful patterns, realistic three-dimensional patterns, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

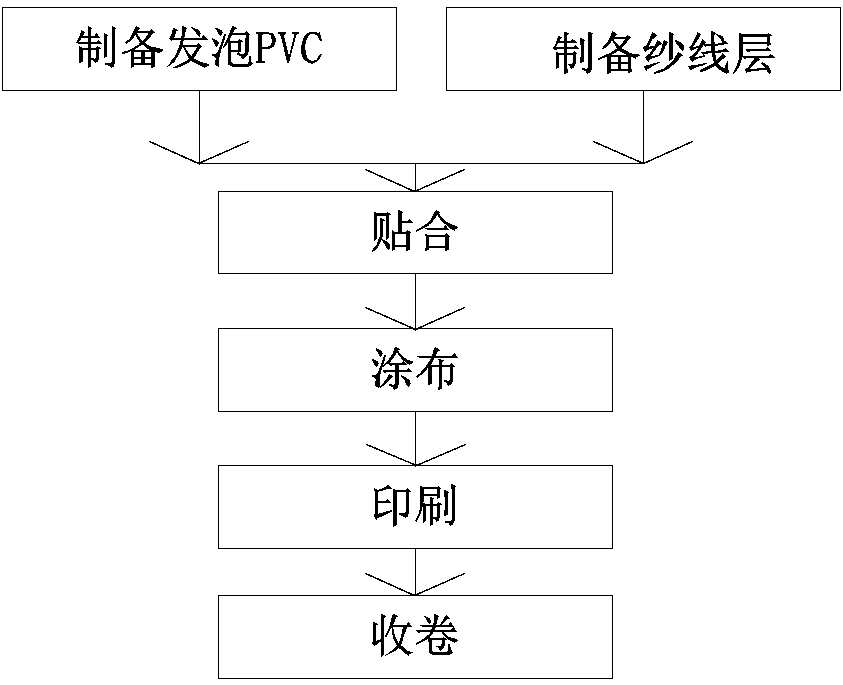

[0030] The production process of the glitter powder PVC tablecloth includes the following steps: S1: preparation of foamed yarn PVC, specifically preparing a foamed PVC layer and a yarn layer, and laminating the two to obtain foamed yarn PVC; S2: Coating, specifically coating the mixture of high-gloss transparent medium blending agent and gold powder or silver powder on the PVC surface of the foamed yarn; S3: printing, specifically printing patterns on the PVC surface of the foamed yarn after coating; S4: winding .

[0031] In S1, when making the foamed PVC layer, in parts by mass, it includes 65 parts of dioctyl phthalate, 58 parts of PVC resin powder, 70 parts of calcium carbonate filler, 3 parts of OBSH foaming agent, natural rubber 2.2 parts, 1.5 parts of paraffin, 0.05 parts of heat stabilizer, 0.16 parts of toner, and 0.09 parts of processing aid.

[0032] Processing aids include anti-aging and UV protection agents, flame retardants. The calcium carbonate filler consis...

Embodiment 2

[0041] The production process of the glitter powder PVC tablecloth includes the following steps: S1: preparation of foamed yarn PVC, specifically preparing a foamed PVC layer and a yarn layer, and laminating the two to obtain foamed yarn PVC; S2: Coating, specifically coating the mixture of high-gloss transparent medium blending agent and gold powder or silver powder on the PVC surface of the foamed yarn; S3: printing, specifically printing patterns on the PVC surface of the foamed yarn after coating; S4: winding .

[0042] In S1, when making the foamed PVC layer, in parts by mass, it includes 65 parts of dioctyl phthalate, 58 parts of PVC resin powder, 70 parts of calcium carbonate filler, 3 parts of OBSH foaming agent, natural rubber 2.2 parts, 1.5 parts of paraffin, 0.05 parts of heat stabilizer, 0.16 parts of toner, and 0.09 parts of processing aid.

[0043] Processing aids include anti-aging and UV protection agents, flame retardants. The calcium carbonate filler consis...

Embodiment 3

[0052] The production process of the glitter powder PVC tablecloth includes the following steps: S1: preparation of foamed yarn PVC, specifically preparing a foamed PVC layer and a yarn layer, and laminating the two to obtain foamed yarn PVC; S2: Coating, specifically coating the mixture of high-gloss transparent medium blending agent and gold powder or silver powder on the PVC surface of the foamed yarn; S3: printing, specifically printing patterns on the PVC surface of the foamed yarn after coating; S4: winding .

[0053] In S1, when making the foamed PVC layer, in parts by mass, it includes 65 parts of dioctyl phthalate, 58 parts of PVC resin powder, 70 parts of calcium carbonate filler, 3 parts of OBSH foaming agent, natural rubber 2.2 parts, 1.5 parts of paraffin, 0.05 parts of heat stabilizer, 0.16 parts of toner, and 0.09 parts of processing aid.

[0054] Processing aids include anti-aging and UV protection agents, flame retardants. The calcium carbonate filler consis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com