Light sensitive glass film binding agent

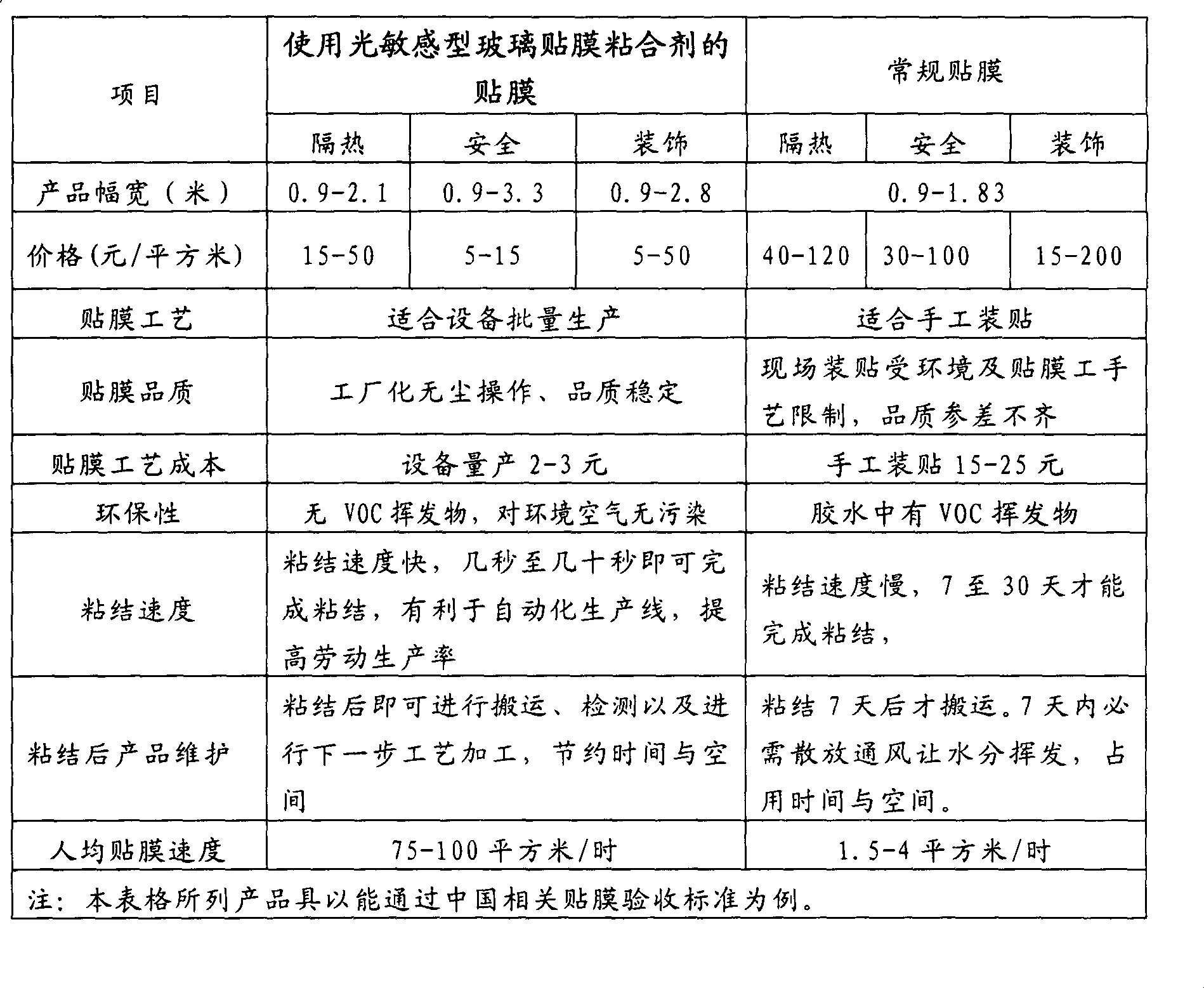

A glass film and adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, modified epoxy resin adhesives, etc. The effect of productivity, stable quality and fast filming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a photosensitive glass film adhesive, which is prepared by the following preparation method:

[0030] Put 40% by weight of the base resin and 51% by weight of the active monomer into the stirred tank, and stir for 30 minutes; put 8% by weight of the photoinitiator into the stirred tank, and stir for 30 minutes; A total of 1% by weight of the agent and the coupling agent were put into a stirring tank and stirred for 30 minutes to obtain the finished product of component A of the light-sensitive glass film adhesive. Put 32% by weight of the base resin, 28% by weight of the active monomer and 31% by weight of the solvent into the stirred tank, and stir for 30 minutes: put 8% by weight of the photoinitiator into the stirred tank, and stir for 30 minutes; A total of 1% by weight of the defoamer, leveling agent and coupling agent was put into the stirring tank and stirred for 30 minutes to obtain the finished product of component B of the photosensiti...

Embodiment 2

[0036] This embodiment provides a photosensitive glass film adhesive, which is prepared by the following preparation method:

[0037] Put 37% by weight of the base resin and 60% by weight of the active monomer into the stirred tank, and stir for 30 minutes: put 2% by weight of the photoinitiator into the stirred tank, and stir for 30 minutes; put the defoamer, leveling A total of 1% by weight of the agent and the coupling agent were put into a stirring tank and stirred for 30 minutes to obtain the finished product of component A of the light-sensitive glass film adhesive. This embodiment provides a decorative film glass, which can be prepared by the following method. Coat a piece of 6mm transparent float glass with a component A photosensitive glass film adhesive through a glue roller, and the coating amount is 10-15g / m 2 .Lay the printed surface of the PET decorative film with the pattern printed by the gravure printing machine on the glued surface of the glass. Use the scr...

Embodiment 3

[0039] This embodiment provides a photosensitive glass film adhesive, which is prepared by the following preparation method:

[0040] Put 41% by weight of the base resin and 50% by weight of the active monomer into the stirred tank, and stir for 30 minutes: put 8% by weight of the photoinitiator into the stirred tank, and stir for 30 minutes; A total of 1% by weight of the agent and the coupling agent were put into a stirring tank and stirred for 30 minutes to obtain the finished product of component A of the light-sensitive glass film adhesive.

[0041] This embodiment provides a heat-insulating and energy-saving film-coated glass, which can be prepared by the following method.

[0042] Coat a piece of 6mm transparent float glass with a component A photosensitive glass film adhesive through a glue roller, and the coating amount is 10-15g / m 2.Lay an aluminized PET composite film with a light transmittance of 35% to the glued surface of the glass. Use a roller press to discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com