Lens cleaning equipment

A technology for cleaning jigs and lenses, which is applied to cleaning methods and tools, manufacturing tools, cleaning flexible objects, etc., can solve the problems of low cleaning efficiency, unclean lens cleaning, lens damage, etc., and achieve the effect of improving the efficiency of glue removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

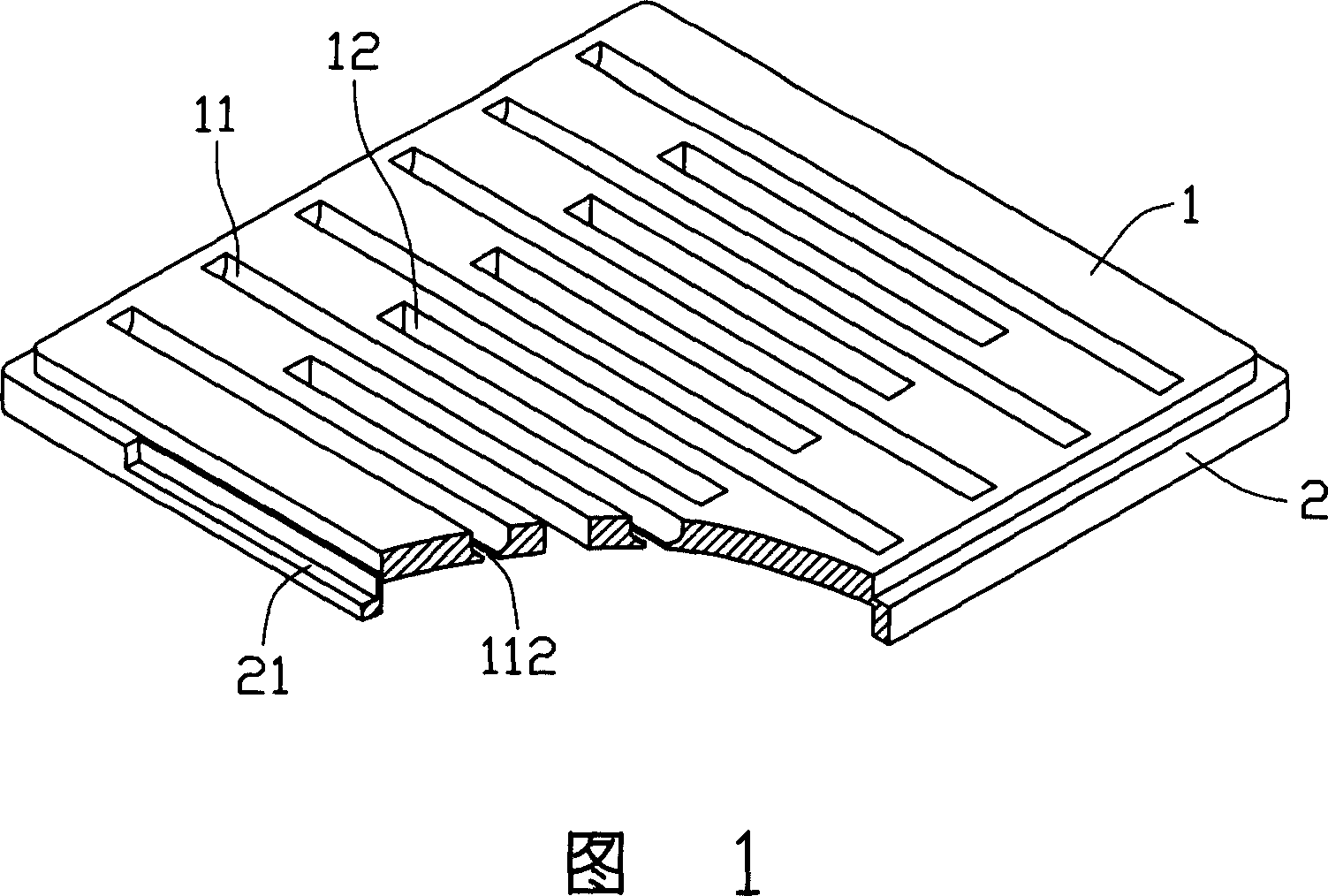

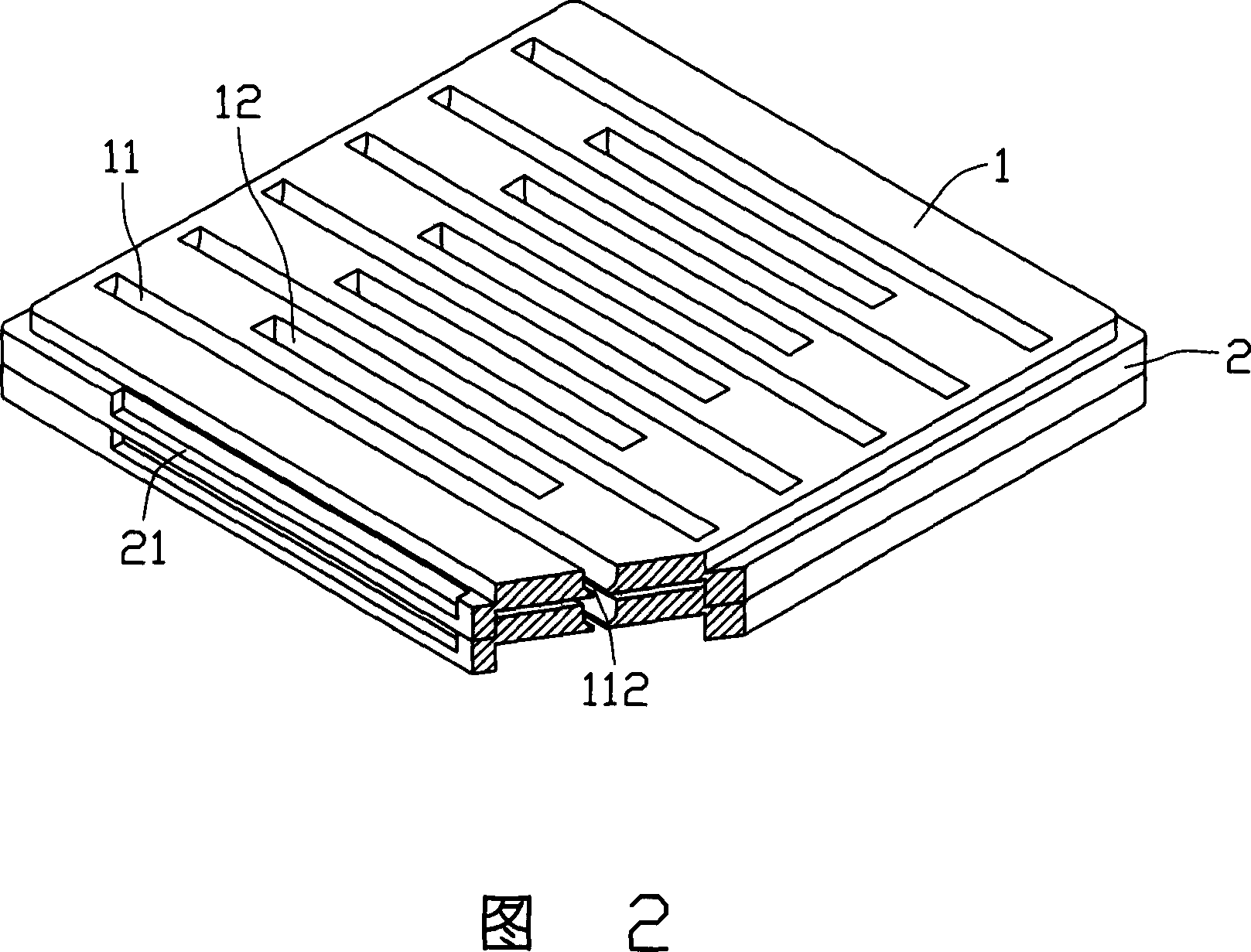

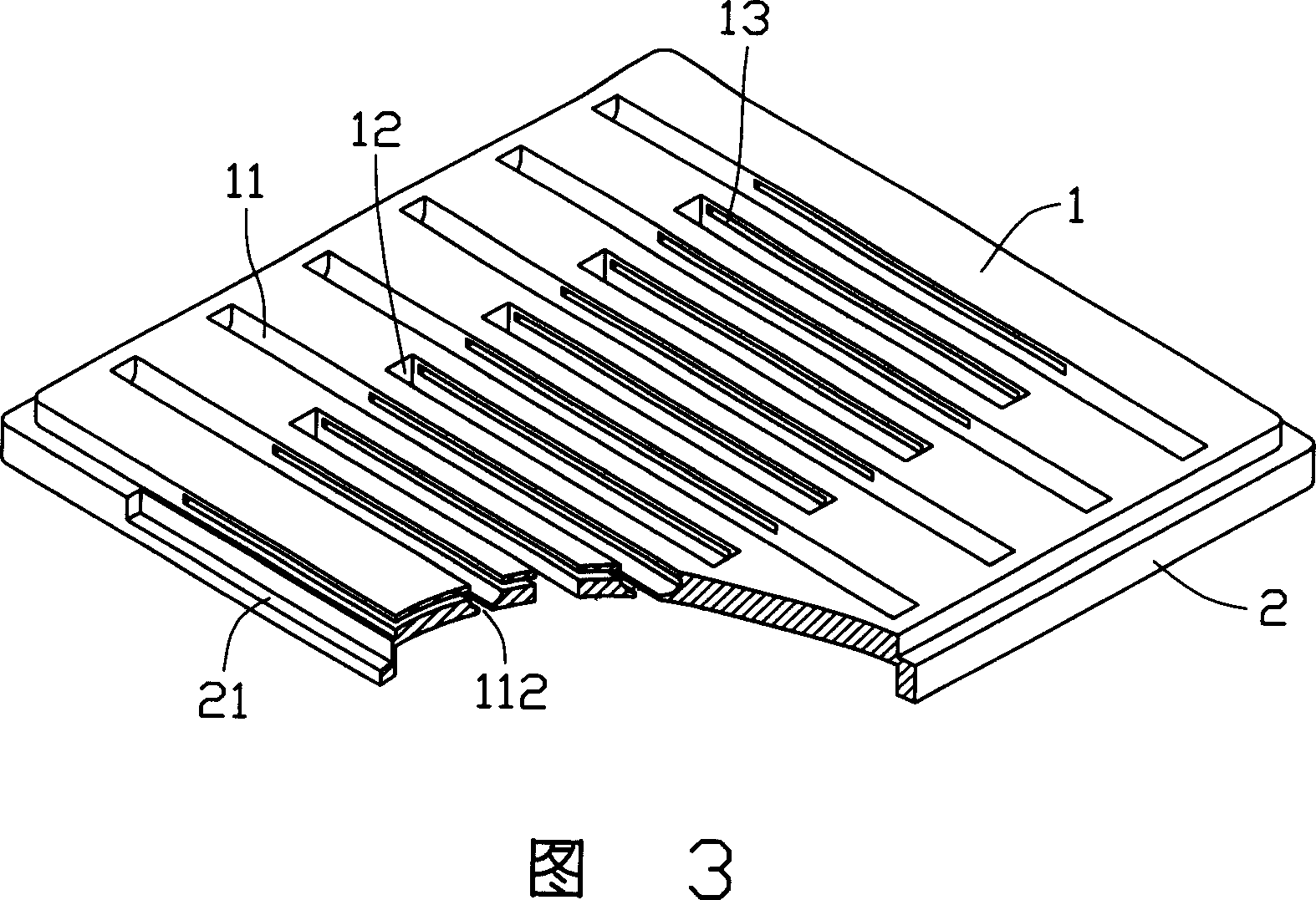

[0012] Please refer to FIG. 1 , the lens cleaning jig according to the preferred embodiment of the present invention is square, and includes a main body 1 and a frame 2 .

[0013] The main body 1 is a square plate body, on which a plurality of accommodating grooves 11 and a plurality of adhesive removing solvent channels 12 are separated. The accommodating grooves 11 are used for accommodating the cylindrical glued body of the lens to be cleaned, and its width is consistent with the diameter of the lens to be cleaned. The groove bottom of each accommodation groove 11 is opened with an opening 112 along its extending direction, and the width of the opening 112 is smaller than the diameter of the lens to be cleaned. The glue-removing agent flow channel 12 opens two opposite surfaces of the main body 1 , and the accommodating grooves 11 and the glue-removing agent flow channels 12 are arranged on the main body 1 at a distance from each other.

[0014] The frame 2 is a frame, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com