High-pressure adsorption production line for inorganic composite polyphenyl A-grade insulation board

A high-pressure adsorption and composite polystyrene technology, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of adjusting width requirements, affecting the working effect of equipment, and failing to meet the calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

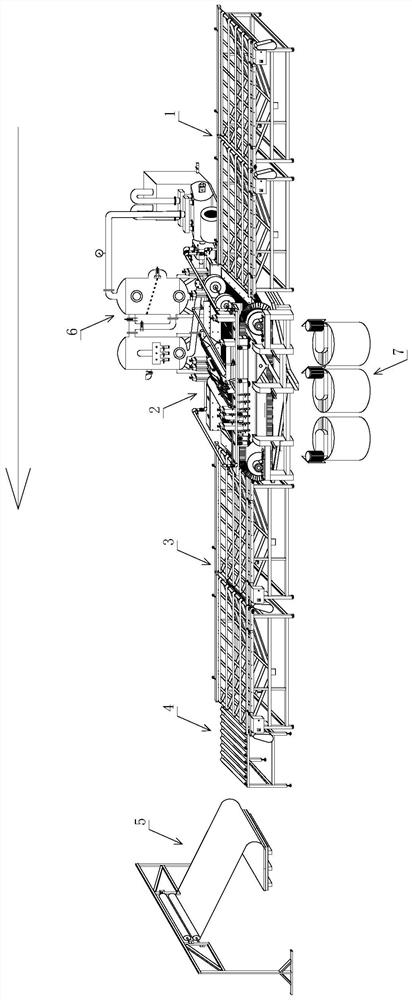

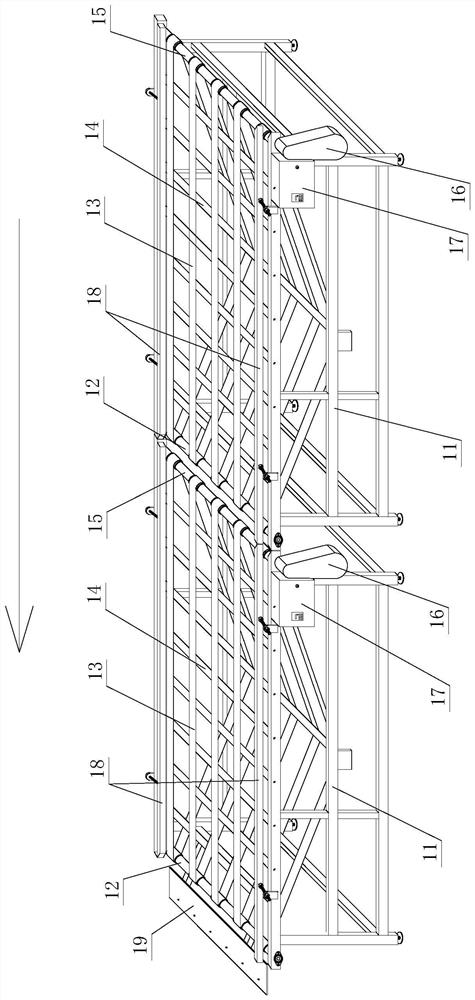

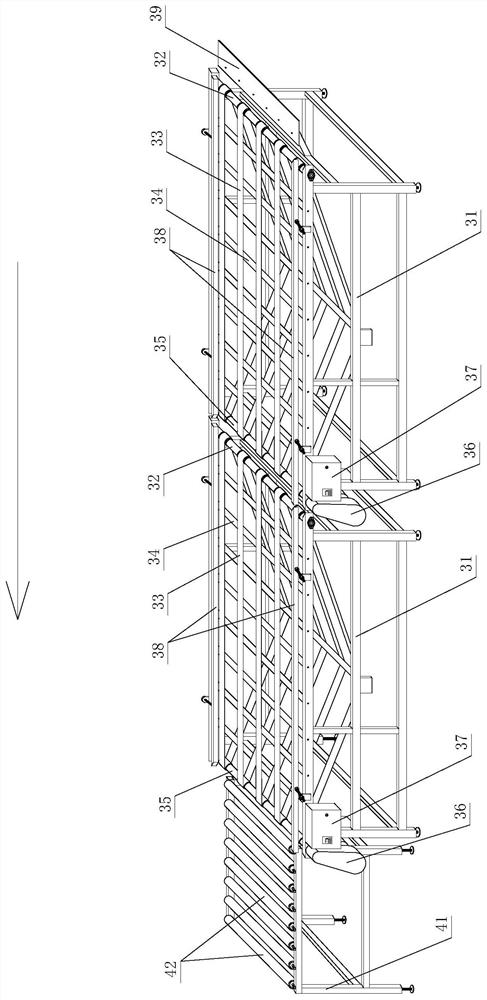

[0078] refer to figure 1 , the high-pressure adsorption production line of inorganic composite polystyrene grade A thermal insulation board described in this embodiment includes a feeding mechanism 1, a high-pressure adsorption equipment host 2, a discharging mechanism 3, a discharging mechanism 4, and a thermal insulation board shaped clinker interlayer device 5 , the high-pressure adsorption recovery system 6 and the slurry stirring tank group 7 (such as Figure 23 shown).

[0079] The function of the slurry stirring tank group 7 is to produce inorganic slurry and transport the inorganic slurry to the host machine 2 of the high-pressure adsorption equipment. When producing inorganic slurry, put various raw materials into the No. 1 mixing tank 71 according to the proportion and stir until the inorganic slurry in a uniform state, and then pump the slurry in the No. 1 mixing tank 71 to the feeding recovery and stirring with a mud pump. In the tank 73, start the No. 2 stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com