Method for manufacturing flow sensor chip

A technology of flow sensor and manufacturing method, which is applied in the direction of exposure device, coating, gaseous chemical plating, etc. of photolithography process, and can solve the problems of reducing the stability of the sensor, reducing the service life of the sensor, and being unable to accurately control the corrosion area and depth, etc. Achieve the effects of improving device stability, flat sensor surface, and realizing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention discloses a manufacturing method of a flow sensor chip, in particular to a manufacturing method that can not damage the stability and strength of the overall structural plate of the chip.

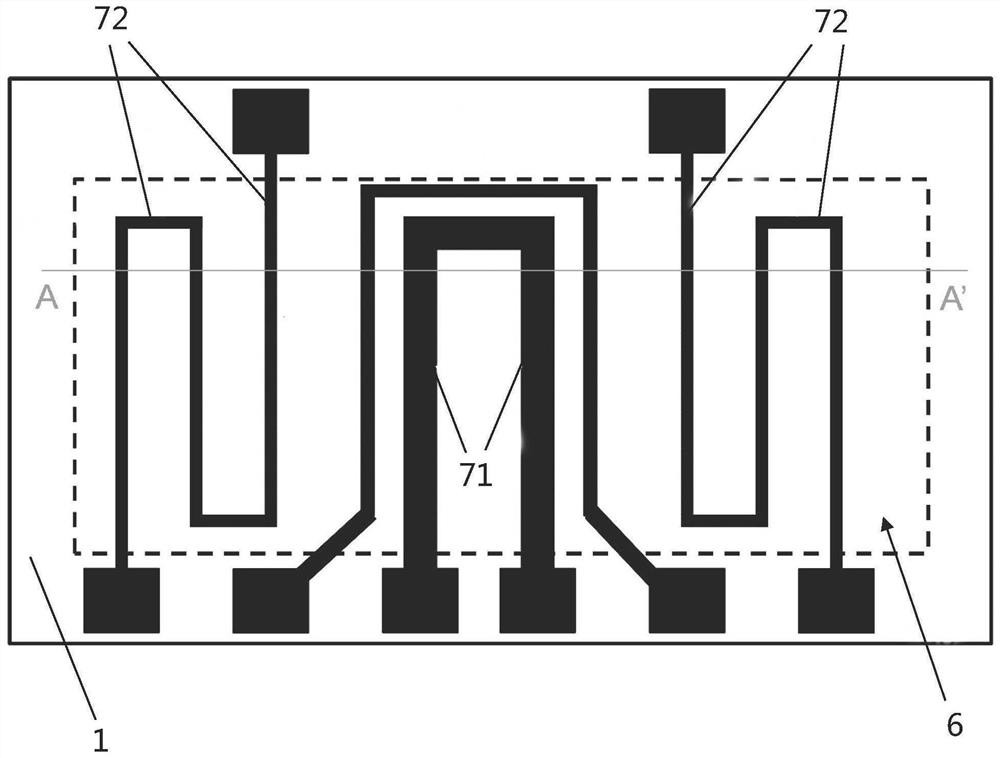

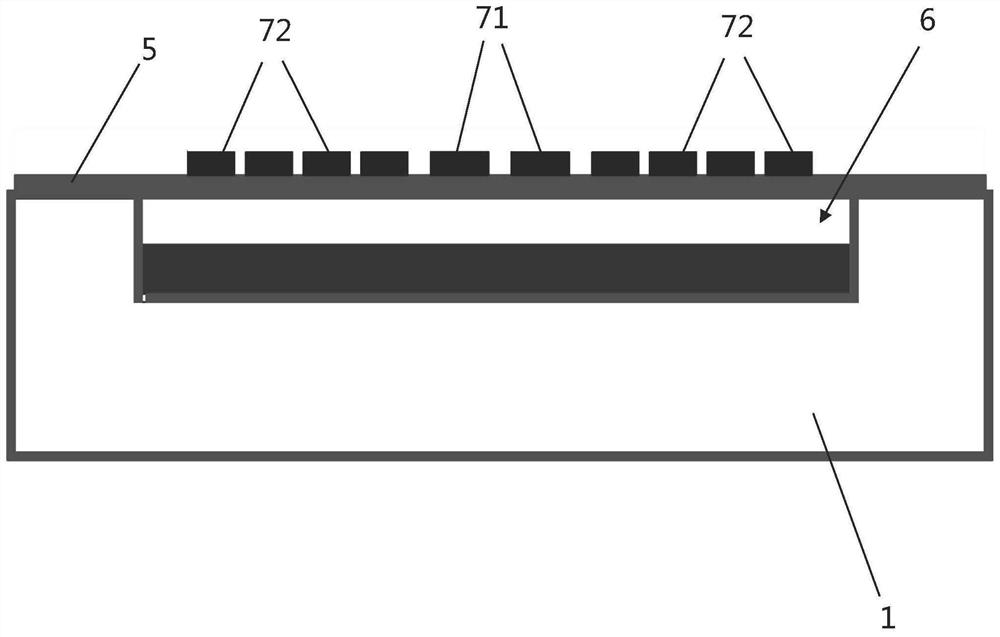

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and an embodiment of the present invention.

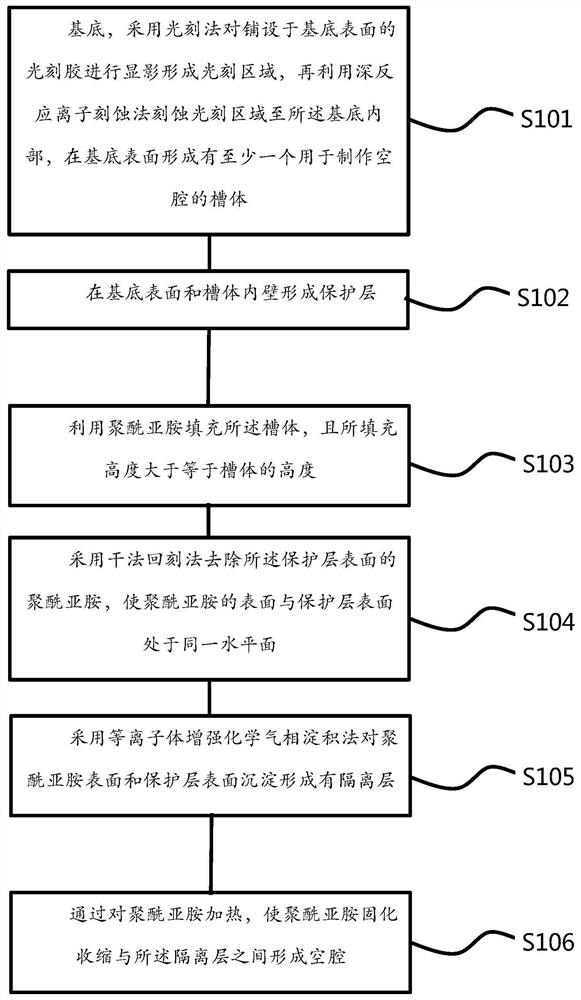

[0049] Such as figure 1 As shown, the method steps for manufacturing the flow sensor include:

[0050] Step S101: substrate 1, using photolithography to develop the photoresist laid on the surface of substrate 1 to form a photoresist area, and then using deep reactive ion etching to etch the photoresist area to the inside of substrate 1 to form a photoresist on the surface of substrate 1 There is at least one tank body 2 for making a cavity 6;

[0051] Step S102: forming a protective layer 3 on the surface of the substrate 1 and the inner wall of the tank body 2;

[0052] Step S103: Fill the tank body 2 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com