Device package structure and method for stress release in packaging process

A technology for stress release and device packaging, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve problems such as prone to warping, impossibility of follow-up processes, and affecting the quality and performance of packaged products, so as to improve Quality and performance, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

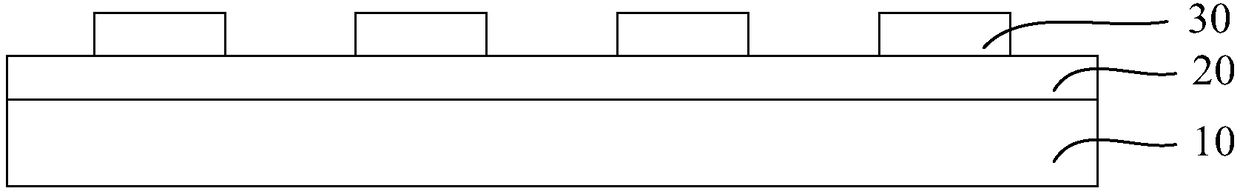

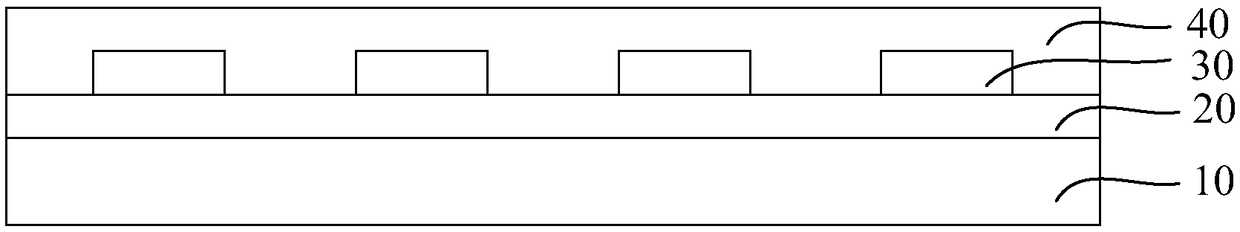

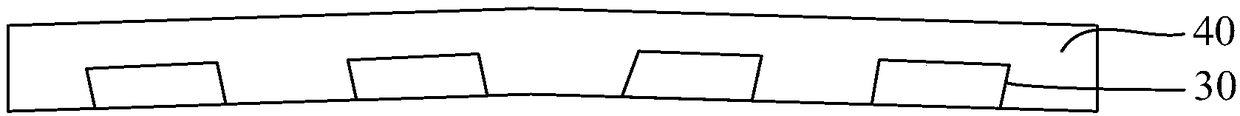

[0034] Figure 1a~1c It is a structural schematic diagram of each step of a device packaging method. Such as Figure 1a ~ Figure 1c As shown, the device packaging method includes the following steps: first: provide a carrier part 10, form an adhesive layer 20 on the carrier part 10, and then fix a plurality of units to be packaged 30 on the adhesive layer 20 at intervals . Secondly, a plastic sealing layer 40 is formed on the adhesive layer 20, and the plastic sealing layer 40 covers the adhesive layer 20 and the unit 30 to be packaged. Finally, the adhesive layer 20 loses its viscosity by ultraviolet light irradiation, heating or other methods, and the carrying part 10 and the adhesive layer 20 are removed, finally forming a device packaging structure. However, due to the thermal expansion and contraction characteristics of each material in the device packaging structure, volume changes will occur under the action of temperature, resulting in strain; when the strain of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com