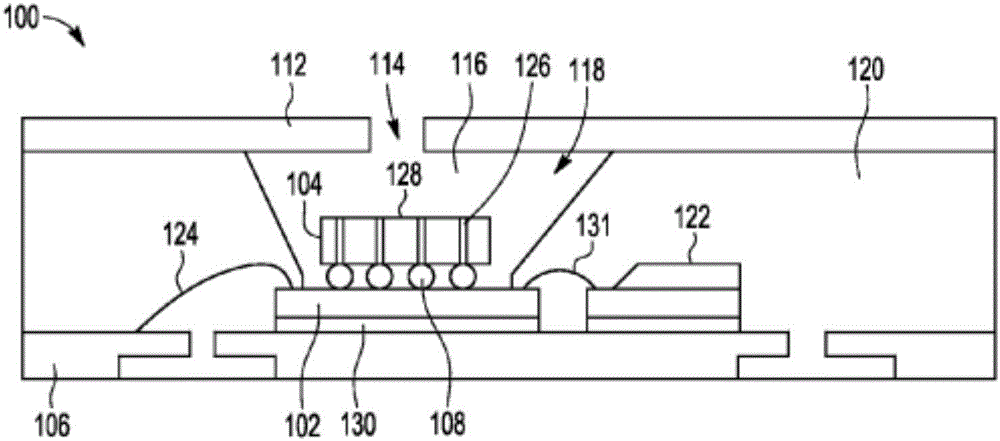

Piezoresistive pressure sensor applicable to surface mounting process and manufacturing method thereof

A pressure sensor and manufacturing method technology, applied in the sensor field, can solve the problems affecting device performance, failure to realize pressure sensor processing, residual stress, etc., and achieve the effects of improving selectivity, reducing equipment investment and processing costs, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

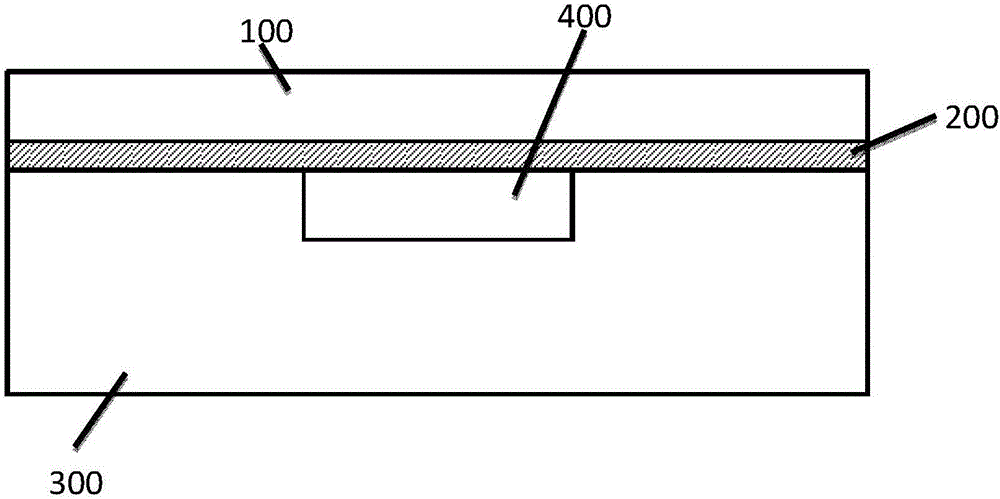

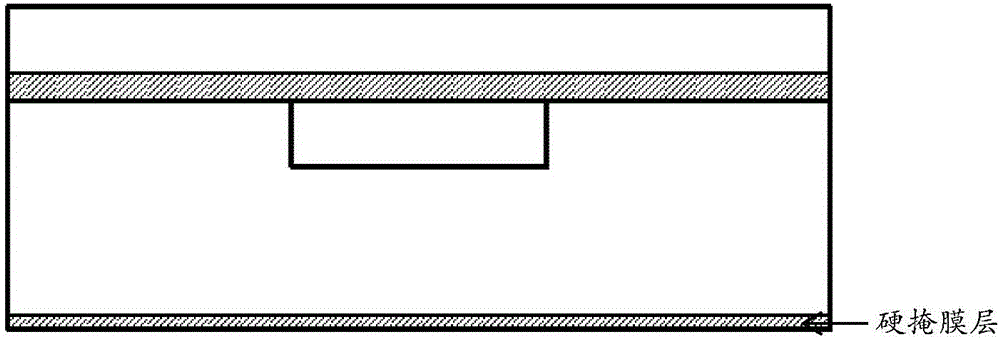

[0057] The embodiment of the present invention is based on a silicon (Cavity-SOI) wafer on a prefabricated cavity insulating substrate, and the wafer structure is as follows figure 2 As shown, the wafer includes a silicon substrate 300 , an insulating layer 200 (silicon dioxide), and a top layer of silicon 100 ; The doping concentration and crystal orientation of the top-layer silicon 100 and the substrate silicon 300 can be freely selected according to actual needs, but the doping of the top-layer silicon 100 and the substrate silicon 300 must be opposite. The embodiment of the present invention only lists a typical application: both the top layer silicon 100 and the substrate silicon 300 adopt the (100) crystal orientation, the top layer silicon is N-type doped, and the substrate silicon is P-type doped (of course, it can also be the top layer Silicon is P-type doped, substrate silicon is N-type doped).

[0058] The relevant implementation steps can be as follows:

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com