Temporarily bonded/debonded materials, methods of preparation and applications thereof

A temporary bonding and debonding technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of incomplete temporary bonding, unrepeatable bonding, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also discloses a method for preparing temporarily bonded / debonded materials, comprising the following steps:

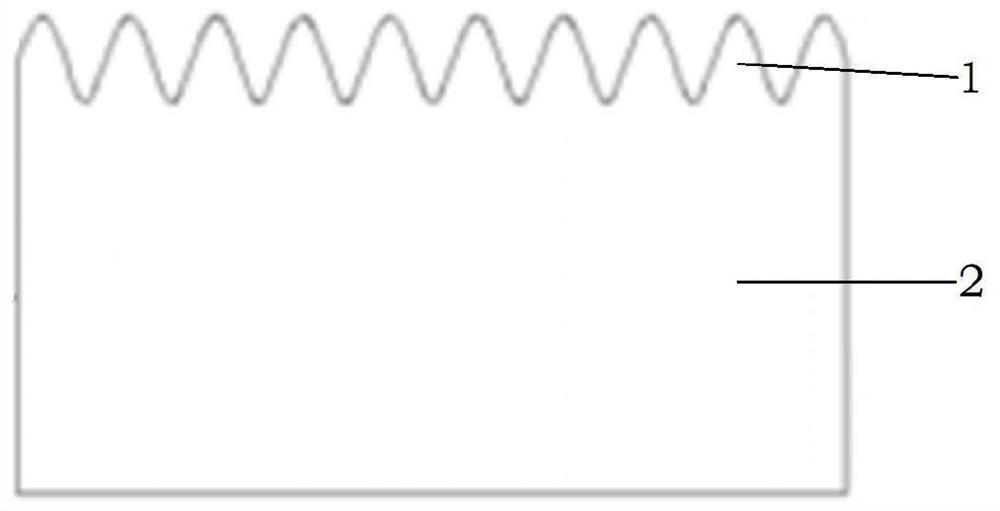

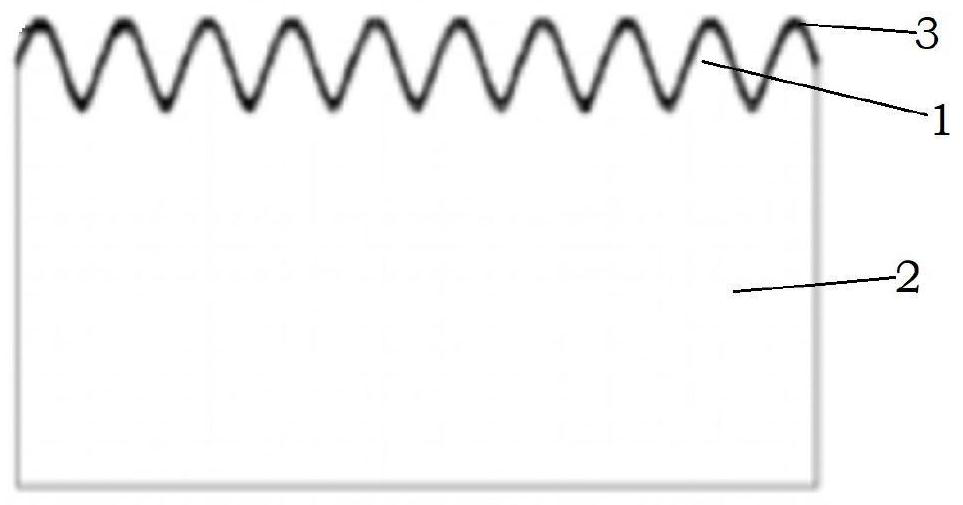

[0044] Step 1: Roughen the surface of the slide to obtain a roughened slide;

[0045] Step 2: attaching the graphite-based material to the rough surface of the roughened slide to obtain a temporarily bonded / debonded material.

[0046] Specifically, step 1 includes performing roughening treatment on the surface of the slide by chemical method or plasma etching method to obtain a roughened slide.

[0047] Specifically, step 2 includes attaching the graphite-based material to the rough surface of the roughened carrier by chemical vapor deposition or magnetron sputtering to obtain a temporarily bonded / debonded material.

[0048] The present invention also discloses the application of temporary bonding / debonding materials in wafer processing, including the following steps:

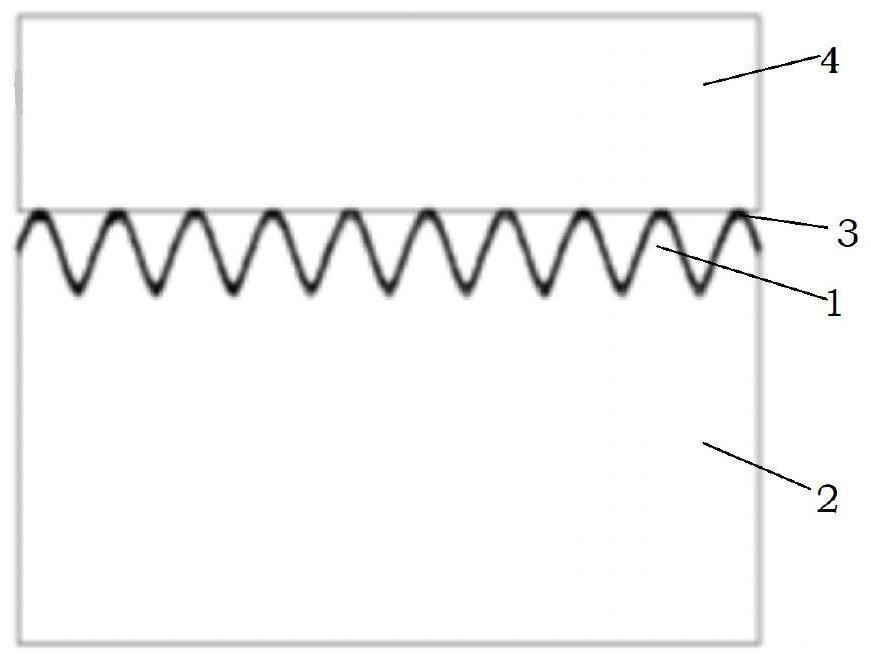

[0049] Step 1: Electroplating a metal layer on the surface of the wa...

Embodiment 1

[0065] The specific embodiment of the present invention provides a kind of temporarily bonded / unbonded material and its preparation method and application, and embodiment 1 comprises the following steps:

[0066] Step 1: Take an 8-inch silicon wafer, the thickness of the silicon wafer is 100 microns, and the front side of the silicon wafer is coated with a layer of 1 micron copper;

[0067] Step 2: Take a piece of glass as a slide, the thickness of the glass is 30 microns, and the diameter of the glass is the same as that of the silicon wafer;

[0068] Step 3: Form a layer of raised microstructure on the glass slide by photochemical etching, the height of the microstructure is 10 microns;

[0069] Step 4: the microstructure of the glass slide is plated with graphite by CVD, and the thickness of the graphite is 5 microns;

[0070] Step 5: temporarily bonding the copper-plated side of the silicon wafer to the graphite layer of the glass slide to obtain a temporary silicon wafer...

Embodiment 2

[0074] The specific embodiment of the present invention provides a kind of temporarily bonded / unbonded material and its preparation method and application, embodiment 2 comprises the following steps:

[0075] Step 1: Take an 8-inch gallium nitride wafer, the thickness of the gallium nitride is 700 microns, and the front side of the gallium nitride is coated with a layer of 1 micron gold;

[0076] Step 2: Take a piece of copper foil as a carrier, the thickness of the copper foil is 30 microns, and the diameter of the copper foil is 1 mm larger than that of gallium nitride;

[0077] Step 3: forming a layer of raised microstructure on the copper foil carrier by wet etching, the height of the microstructure is 15 microns;

[0078] Step 4: The raised structure of the copper foil carrier is plated with graphite by CVD, and the thickness of the graphite is 8 microns;

[0079] Step 5: temporarily bonding the gold-plated side of the gallium nitride wafer to the graphite layer of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com