Paper-based electrolytic cell for electrochemical detection, manufacturing method thereof, and three-electrode system

A production method and electrolytic cell technology, applied in the field of electrochemistry, can solve the problems of inability to make it in the laboratory, inconvenient carrying, limited use, etc., and achieve the effects of wide application range, convenient carrying, simple and fast production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

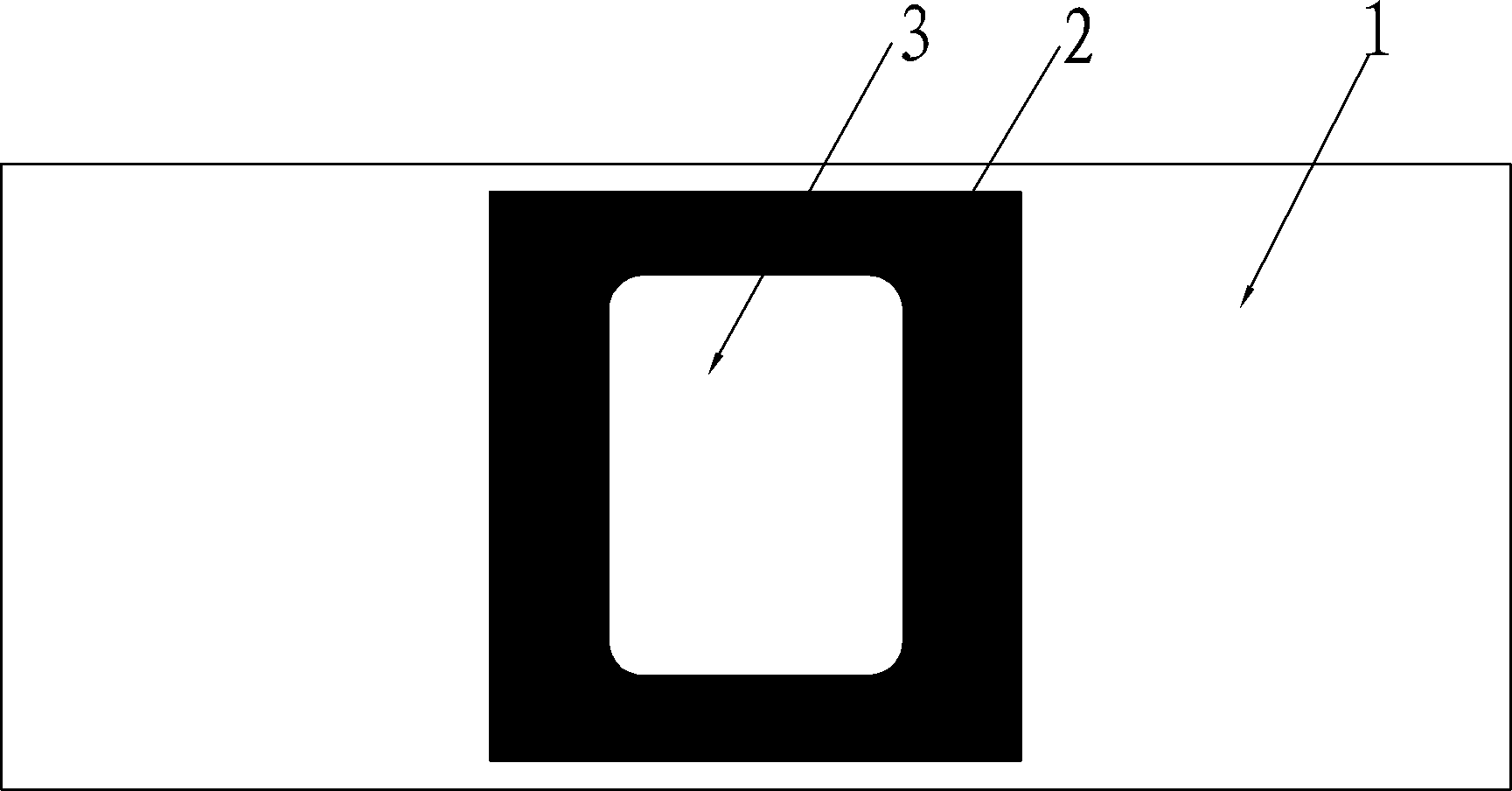

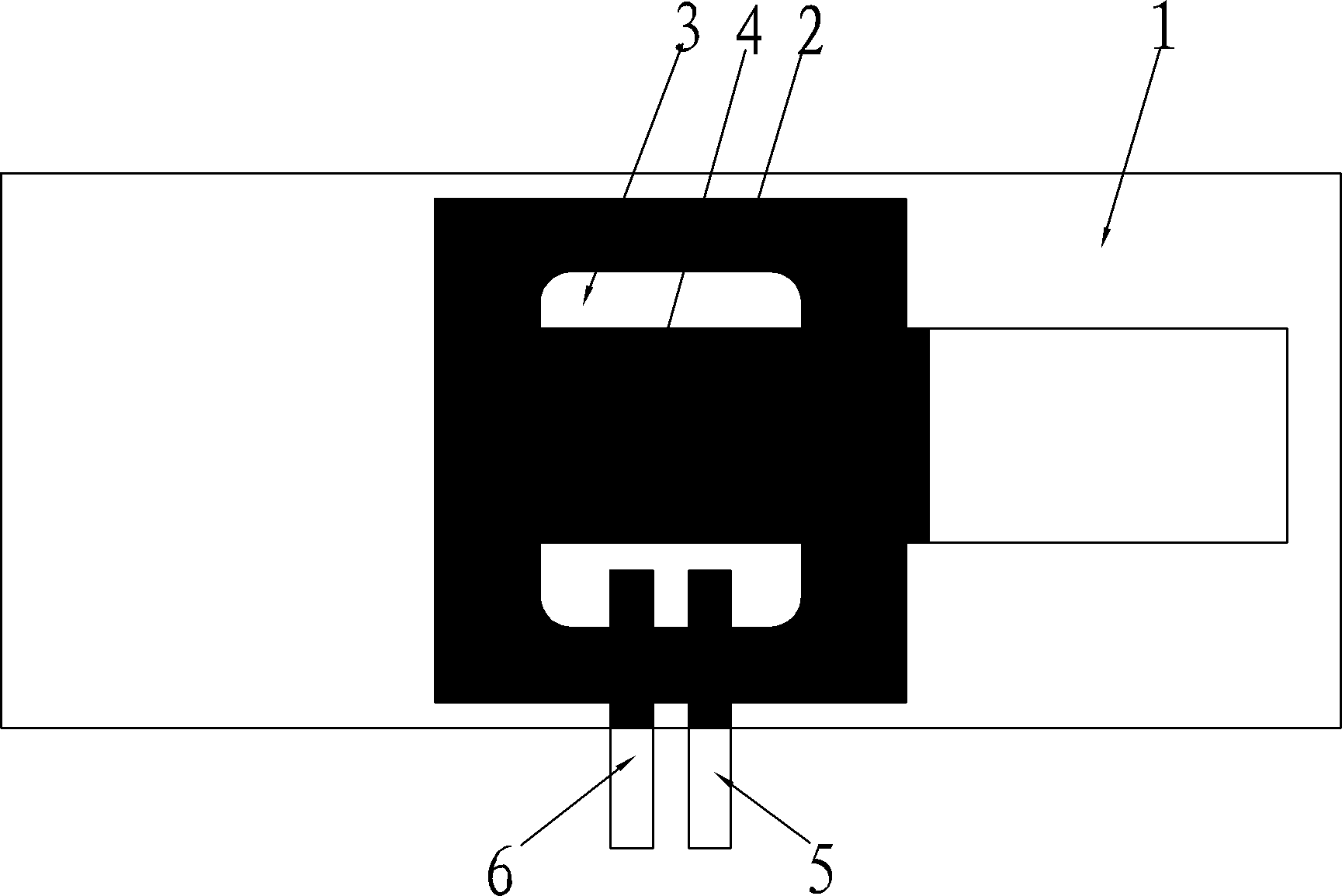

[0035] (1) Use WORD to make the toner area pattern on the computer,

[0036] (2) Use a general office laser printer with a resolution of 300dpi to print out the toner area on the filter paper,

[0037] (3) Heat the printed filter paper at a temperature of 120° C. for 300 minutes in an oven to obtain the paper-based electrolytic cell of the present invention.

Embodiment 2

[0039] (1) Use WORD to make the toner area pattern on the computer,

[0040] (2) Use a general office laser printer with a resolution of 500dpi to print out the toner area on the filter paper,

[0041] (3) Heat the printed filter paper at a temperature of 160° C. for 200 minutes in an oven to obtain the paper-based electrolytic cell of the present invention.

Embodiment 3

[0043] (1) Use WORD to make the toner area pattern on the computer,

[0044] (2) Use a general office laser printer with a resolution of 400dpi to print out the toner area on the filter paper,

[0045] (3) Heat the printed filter paper at a temperature of 180° C. for 60 minutes in an oven to obtain the paper-based electrolytic cell of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com