Multifocal lens and processing device and method thereof

A multi-focal lens and processing equipment technology, which is applied to lenses, microscopes, optics, etc., can solve the problems of poor optical characteristics, complex polishing process, difficult optical alignment, etc., and achieves high processing efficiency, simple processing equipment, and processing methods. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

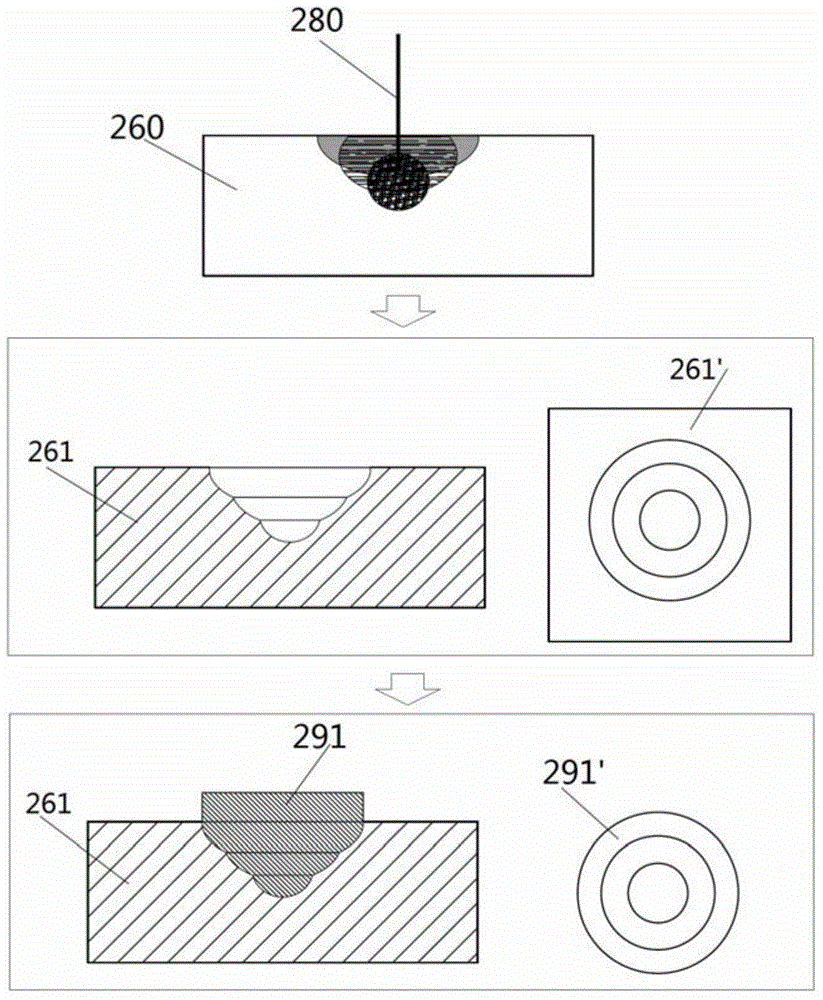

[0041] Reference figure 1 with figure 2 , Prepare a three-focus lens through a femtosecond laser modification and hydrofluoric acid etching process. It includes the following main steps:

[0042] Step 1. Cleaning of hard substrate materials: use acetone, ethanol, and deionized water to clean ultrasonically for 5 minutes respectively to effectively clean the hard substrate materials 260; the hard substrate 260 materials include fused silica, K9 glass, and silicon wafers. One of

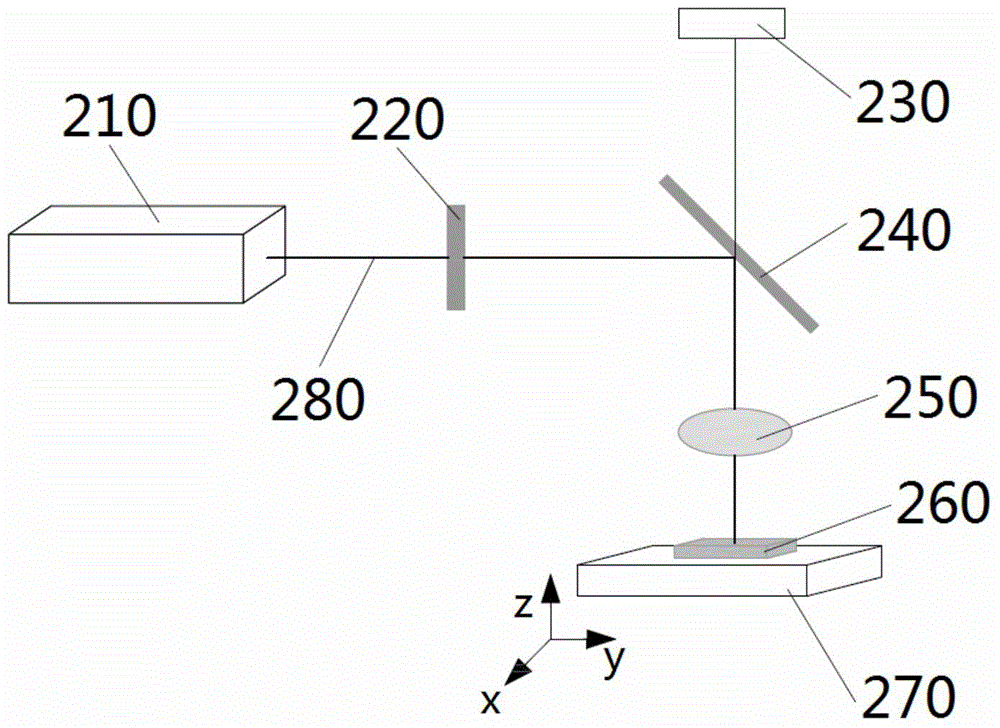

[0043] Step 2: Femtosecond laser modification: reference figure 1 , The femtosecond laser pulse 280 generated by the femtosecond laser generator 210 passes through the parameter modulation optical path 220, half mirror or narrow-band high-reflection film 240, and then focuses on the surface of the hard substrate 260 through the optical focusing lens 250; the hard substrate 260 is fixed on the programmable control three-dimensional translation stage 270. Reference figure 2 , The femtosecond laser affecte...

Embodiment 2

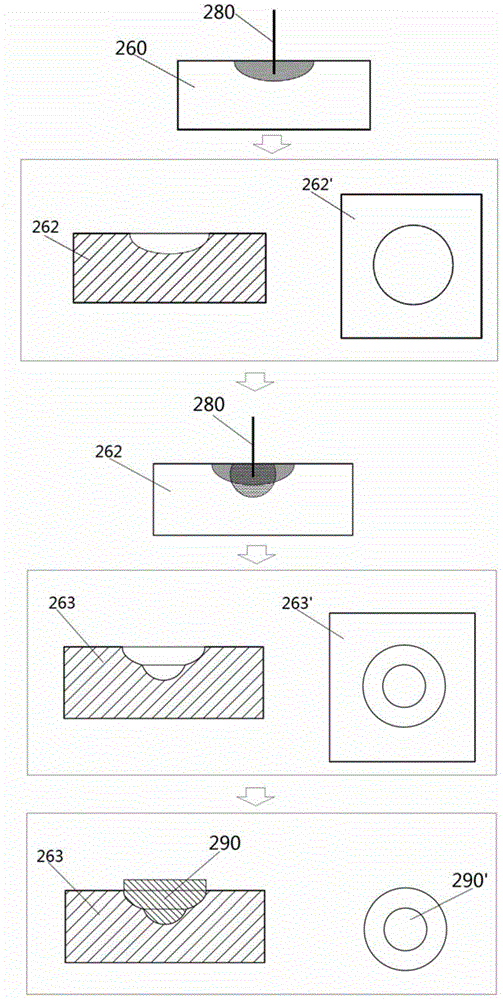

[0047] Reference image 3 with figure 1 , The bifocal lens is prepared through multiple femtosecond laser modification and hydrofluoric acid etching processes. It includes the following main steps:

[0048] Step 1. Cleaning of hard substrate materials: use acetone, ethanol, and deionized water to clean ultrasonically for 5 minutes respectively to effectively clean the hard substrate materials 260; the hard substrate 260 materials include fused silica, K9 glass, and silicon wafers. One of

[0049] Step 2: The first modification of femtosecond laser: reference figure 1 , The femtosecond laser pulse 280 generated by the femtosecond laser generator 210 passes through the parameter modulation optical path 220, half mirror or narrow-band high-reflection film 240, and then focuses on the surface of the hard substrate 260 through the optical focusing lens 250; the hard substrate 260 is fixed on the programmable control three-dimensional translation stage 270; the first material modificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com