Method for machining extra large circular arc plates

A processing method and arc plate technology, applied in the field of plate processing, can solve problems such as difficulty in grasping dimensional accuracy, and achieve the effects of saving processing time, reducing processing difficulty, and saving processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below with reference to accompanying drawing and embodiment:

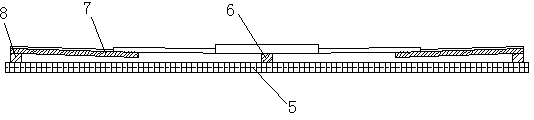

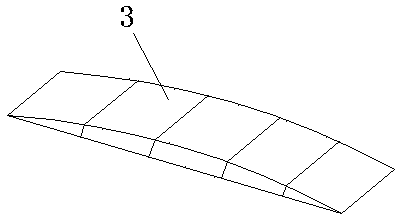

[0030] attached Figures 1 to 6 It can be seen that a method for processing an extra-large arc plate comprises the following steps:

[0031] A, making tire board;

[0032] B. Process the bottom surface of the sheet to be processed into a plane;

[0033] C. Weld the tire plate and the bottom surface of the sheet;

[0034] D. Fit the tire plate to the surface of the machine table;

[0035] E. Detect the radian of the upper arc surface formed by the bottom surface of the sheet; the upper arc surface and the arc surface of the finished arc plate form a conjugate surface;

[0036] F. Carry out milling processing on the upper plane of the sheet metal; ensure that the height difference of the arc plate meets the requirements of the processing drawings;

[0037] G. Remove the tire board; separate the tire board from the machine table and then separate the tire board ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com