Thermoplastic butadiene styrene rubber aqueous rubber latex asphalt modifying agent and preparation thereof

A technology of asphalt modifier and thermoplastic styrene-butadiene, which is applied in building components, building insulation materials, construction, etc., can solve the problems of poor thermal storage stability, unstable quality, and high processing cost of modified asphalt, and achieve equipment saving The effect of investment, not easy to segregate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

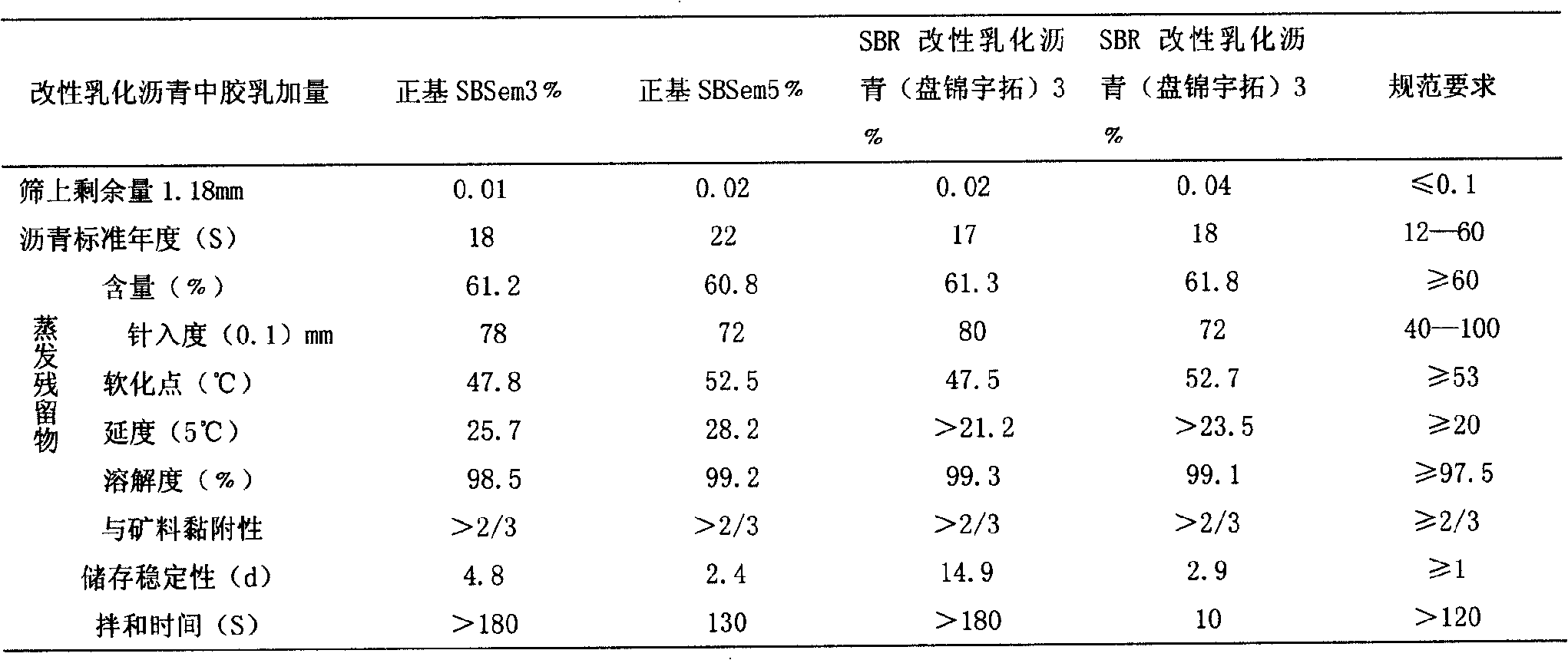

Examples

example 1

[0036] i) First add 25 grams of thermoplastic styrene-butadiene rubber SBS (1301-1), 32 grams of thermoplastic styrene-butadiene rubber SBS (4202) and 18 grams of thermoplastic styrene-butadiene rubber (SBS 1301-2) into a container containing 230 grams of chlorine In a propane beaker, heat up to 70°C and stir at a speed of 300-400 rpm to completely dissolve the thermoplastic styrene-butadiene rubber SBS, then add 2.5 grams of NP-6 and 4 grams of NP-18—this It is solution A; among them, SBS complies with the industry standard JTGF40-2004 of the People's Republic of China.

[0037] ii) Preparation of soap solution: in a beaker filled with 80 grams of water, slowly add 0.6 gram of water-soluble starch, and stir until completely dissolved, then add 6.3 gram of cationic surfactant cetyl trimethyl ammonium chloride , and then add 0.8 g of potassium chloride to the above solution, and stir until completely dissolved.

[0038] iii) First add a small amount of soap to solution A, star...

example 2

[0041] i) First, 55 grams of thermoplastic styrene-butadiene rubber SBS (1301-2) and 23 grams of thermoplastic rubber SIS (4211) are added to a beaker containing 120 grams of benzene and 130 grams of chloropropane, heated to 70 ° C, And stir at a speed of 300-400 rpm to completely dissolve the thermoplastic rubber SBS and SIS—this is solution A.

[0042] ii) Preparation of soap solution: in a beaker containing 80 grams of water, slowly add 0.6 gram of hydroxypropyl methylcellulose and 0.5 gram of water-soluble starch, and stir until all dissolve, then add 15 grams of cationic surfactant Octadecyltrimethylammonium chloride, and then add 0.5 g of potassium chloride to the above solution, and stir until completely dissolved.

[0043]iii) First add a small amount of soap to solution A, start the high-speed shear emulsification device, slowly add soap while cutting, and shear for 10 minutes at a speed of 3000 rpm, then, 8000 rpm Shear at rpm for 6 minutes.

[0044] iv) Finally, d...

example 3

[0046] i) First, add 30.4 grams of thermoplastic styrene-butadiene rubber SBS1301-1 solid into a beaker containing 150 grams of benzene, heat up to 70°C, and stir at a speed of 300-400 rpm to make the thermoplastic styrene-butadiene rubber The rubber SBS is completely dissolved, and then 0.7 g of nonylphenol polyoxyethylene ether NP-7 is added and stirred evenly, which is solution A.

[0047] ii) Preparation of soap solution: in a beaker containing 110 grams of water, slowly add 26.2 grams of water-soluble starch, and stir until completely dissolved, then, add 1.2 grams of cationic surfactant dodecyltrimethylammonium chloride , and then add 13 grams of potassium chloride to the above solution, and stir until completely dissolved.

[0048] iii) First add a small amount of soap to solution A, start the high-speed shearing device, slowly add soap while cutting, and cut for 10 minutes at a speed of 3000 rpm, and then cut it at a speed of 8000 rpm Cut down for 8 minutes.

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com