Electronic product middle frame and processing method thereof

A technology for electronic products and side frames, which is applied to the middle frame of electronic products and its processing field, can solve the problems of heavy middle frame, high production cost, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

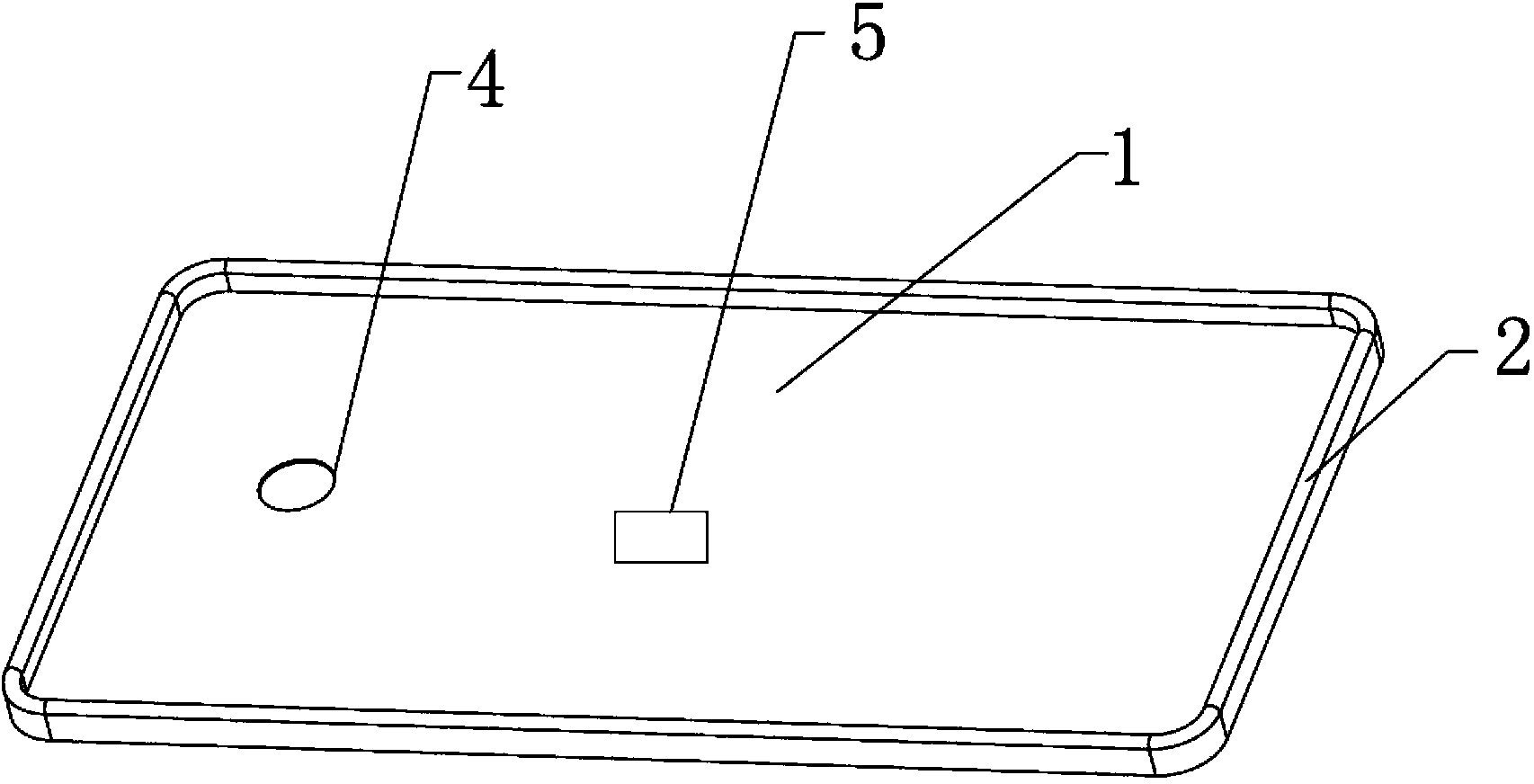

[0051] Such as figure 1 As shown, this embodiment describes a middle frame of an electronic product, including a panel 1 and a side frame 2 , the side frame 2 is formed by bending the edge of the panel 1 , and the side frame 2 surrounds the panel 1 along its surroundings.

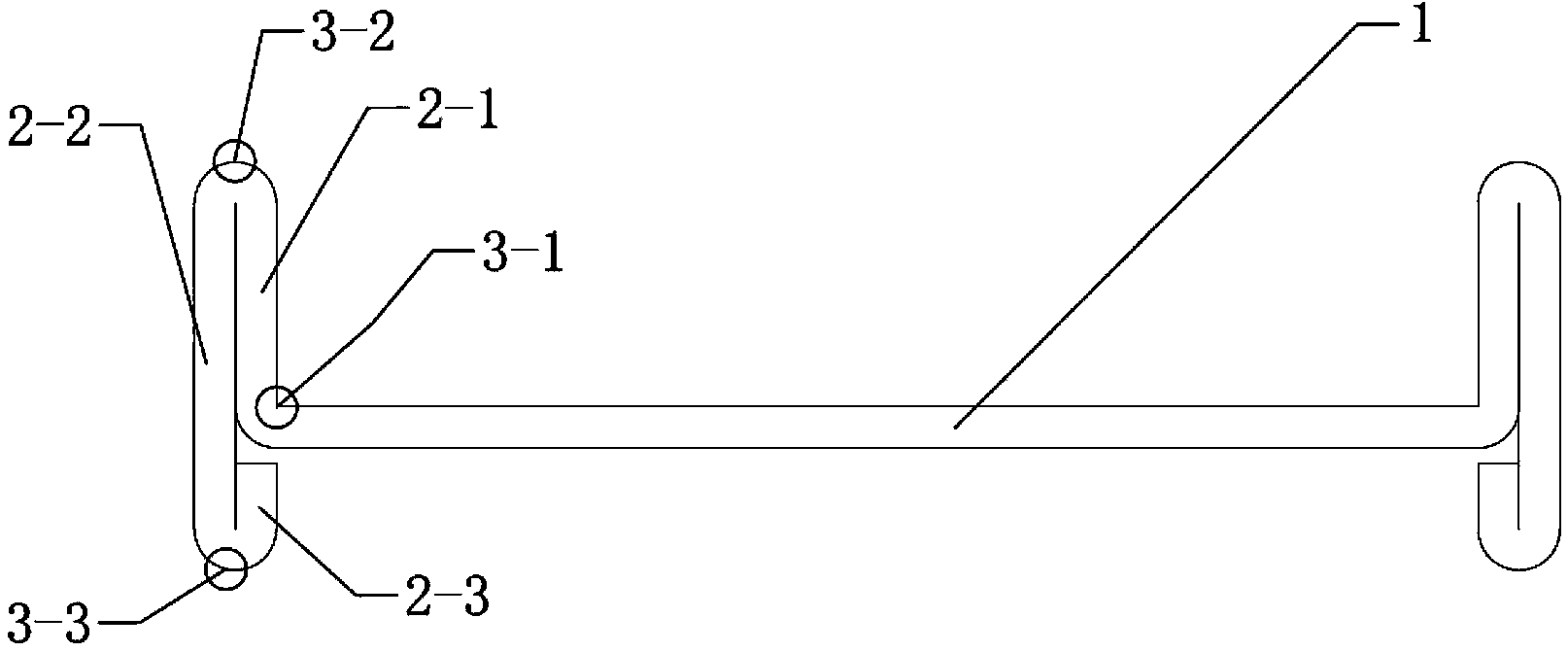

[0052] figure 2 gives figure 1 From the cross-sectional view of the middle frame of the electronic product shown, the specific structure of the side frame of the middle frame of the electronic product can be seen. The side frame includes three extension parts, the first extension part 2-1 is perpendicular to the panel 1 and connected to the panel 1 through the first connection part 3-1, the second extension part 2-2 is connected to the first extension part 2-1 Connected by the second connection part 3-2, the second extension part 2-2 is close to and parallel to the first extension part 2-1, and the third extension part 2-3 and the second extension part 2-2 pass through the third The connection part 3-3 ...

Embodiment 2

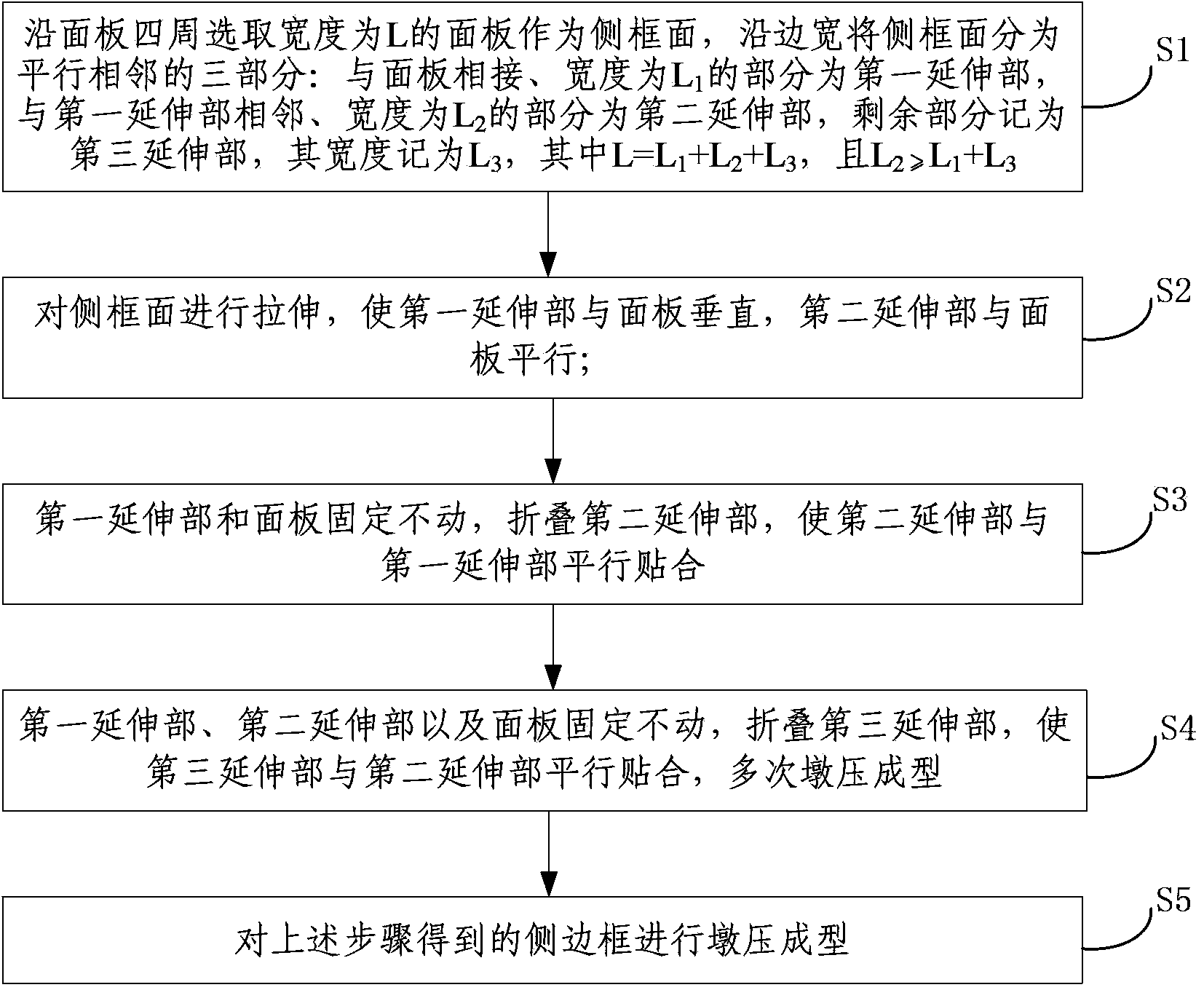

[0089] Based on the first embodiment, this embodiment describes a method for processing a middle frame of an electronic product. Such as Figure 8 As shown, in the processing method for the middle frame of an electronic product described in Embodiment 1, after step S2 and before S3, there are steps:

[0090] ④. Trim the notches at the bends of the second connecting portion 3-2 and / or the third connecting portion 3-3, so as to eliminate wrinkles generated during bending.

[0091] Due to the bending process of the panel, due to extrusion, some wrinkles will be generated at the folds, and these wrinkles may cause the first extension part 2-1 and the second extension part 2-2 and the second extension part 2-2 and the second extension part 2-2 The three extensions 2-3 are not tightly fitted; even if the above-mentioned extensions are closely fitted, these folds may cause distortion of the side frame and affect the appearance. Therefore, according to the specific situation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com