Step and zone type integral impeller electrolytic processing process and device

An integral impeller and processing device technology, which is applied in electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low machining accuracy, over-cutting or under-cutting of blade roots, etc., to save preparation time, shorten cycle time, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

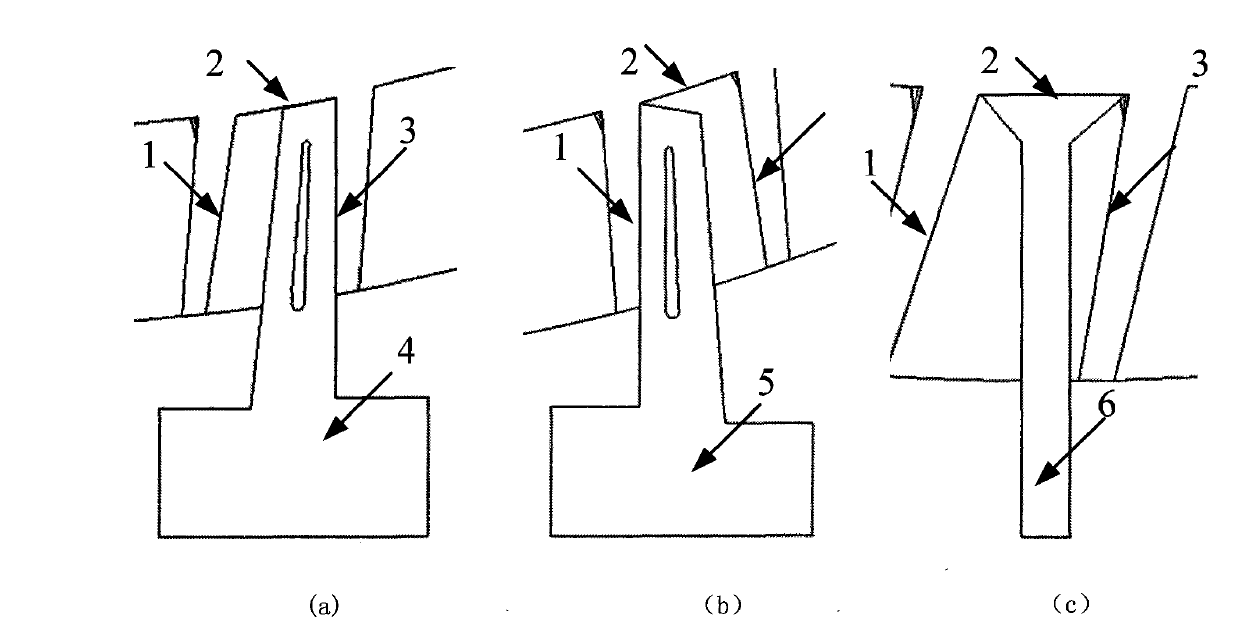

[0023] Such as figure 1 shown. It is a schematic diagram of the electrolytic machining of the overall impeller blade. Figure (a) is the machining of the blade back, Figure (b) is the machining of the blade pot, and Figure (c) is the machining of the blade root. In the step-by-step partition method integral impeller blade electrolytic processing process described in the present invention, the electrolytic processing of the integral impeller is divided into three processing procedures: the blade pot, the blade back and the blade root. root sequence for processing;

[0024] Divide the processing areas of the leaf back, leaf pot, and leaf root so that the cross-section of the leaf pot and leaf back processing area is trapezoidal, the width of the leaf back is greater than the width of the leaf pot, and the distribution of the leaf root processing area from left to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com