Sensitive material for tensile deformation test and preparation method thereof

A technology of tensile deformation and sensitive materials, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of inconvenience, large error of dial gauge test method, inconvenient use, etc., and achieve cost reduction and cost reduction Ideal, good sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

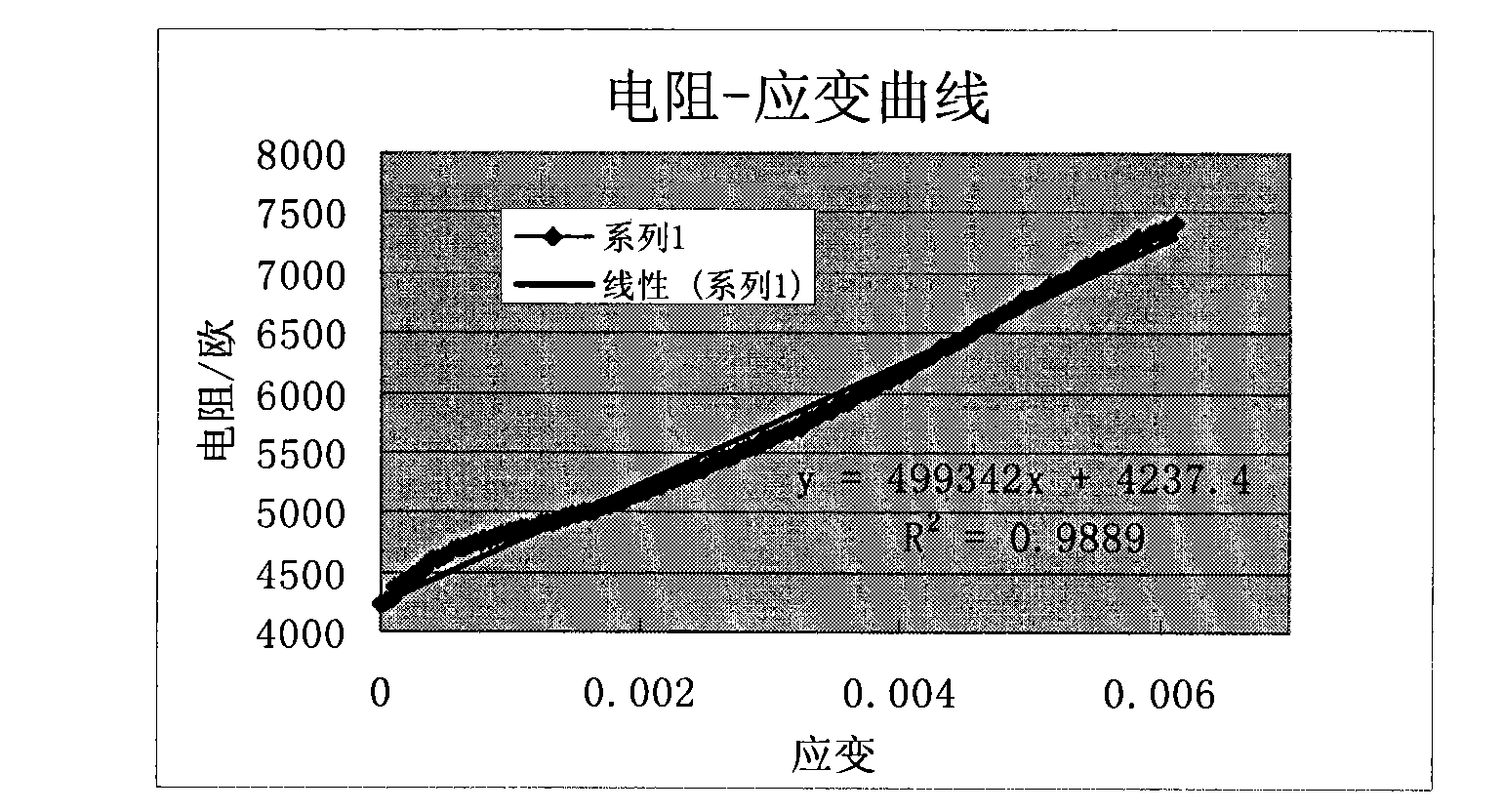

Embodiment 1

[0029] Embodiment one, weigh by mass proportioning:

[0030] Liquid silicone rubber: 100 parts;

[0031] 0.2mm chopped chopped carbon fiber: 50 parts;

[0032] Conductive carbon black: 0 parts;

[0033] nano-SiO 2 : 0 copies;

[0034] Curing agent: 5.5 parts;

[0035] Coupling agent: 0.4 parts;

[0036] The production steps are as follows:

[0037] (1) Weigh 100 parts of liquid silicone rubber, 50 parts of 0.2mm chopped carbon fiber, 5.5 parts of curing agent (dibutyltin dilaurate) and 0.4 parts of coupling agent (KH -550);

[0038] (2) First add 100 parts of liquid silicone rubber into the mixer for stirring, and the stirring speed is about 1200r / min;

[0039] (3) Then slowly add 50 parts of 0.2mm chopped chopped carbon fibers, and continue to stir;

[0040] (4) After stirring for about 30 minutes, add 0.4 parts of coupling agent (KH-550) and 5.5 parts of curing agent in sequence, and continue stirring for 2 minutes;

[0041] (5) Put the mixed solution into a vacuum...

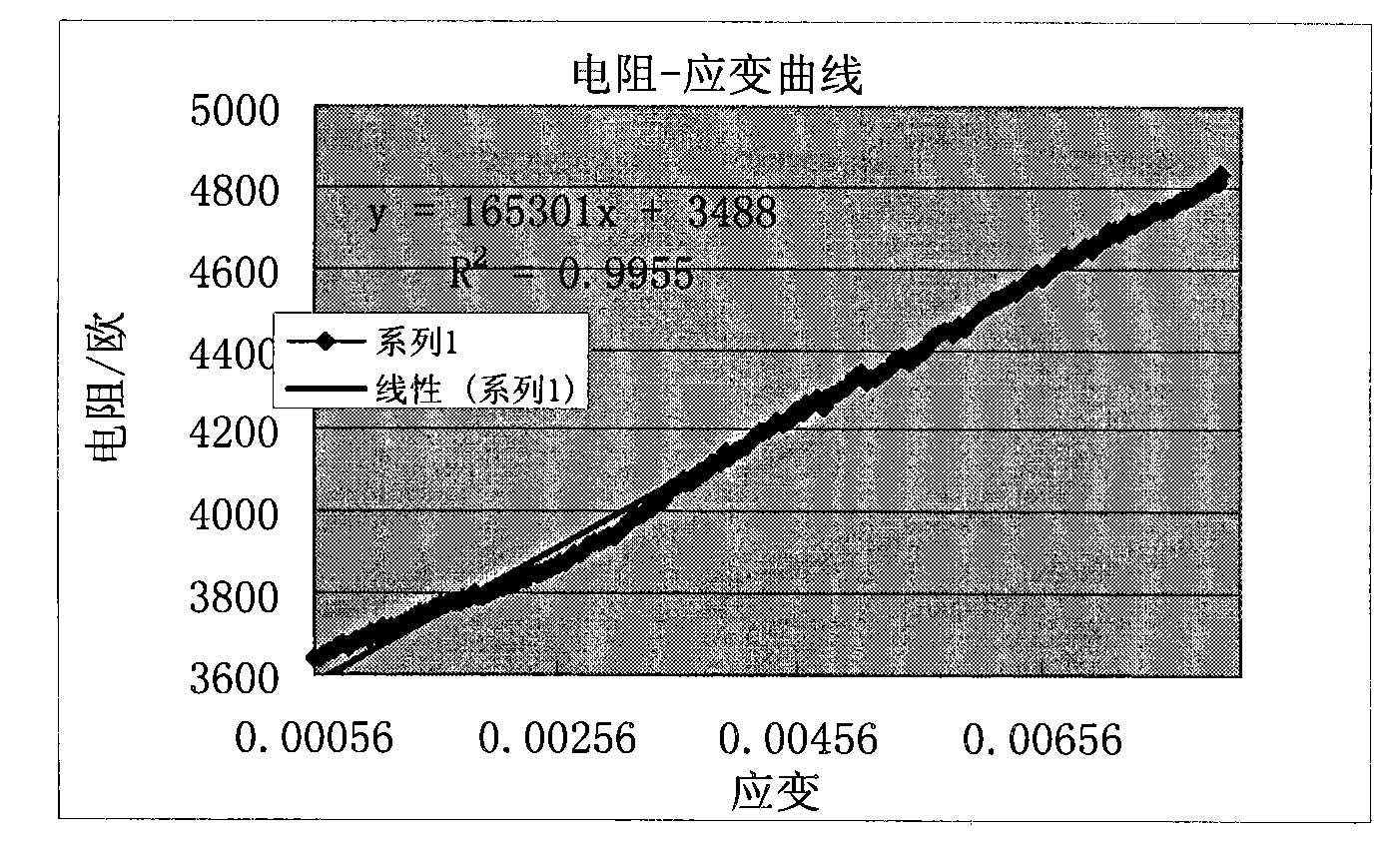

Embodiment 2

[0045] Embodiment two, weigh by mass proportioning:

[0046] Liquid silicone rubber: 100 parts;

[0047] 0.2mm chopped chopped carbon fiber: 35 parts;

[0048] Conductive carbon black: 1 part;

[0049] nano-SiO 2 : 1 copy;

[0050] Curing agent: 5.5 parts;

[0051] Coupling agent: 0.6 parts;

[0052] The production steps are:

[0053] (1) Weigh 100 parts of liquid silicone rubber, 35 parts of 0.2mm chopped carbon fiber, 5.5 parts of curing agent (dibutyltin dilaurate) and 0.6 parts of coupling agent (KH -550);

[0054] (2) First add 100 parts of liquid silicone rubber into the mixer for stirring, and the stirring speed is about 1500r / min;

[0055] (3) Then slowly add 1 part of conductive carbon black, then slowly add 35 parts of 0.2mm chopped carbon fiber, and continue stirring;

[0056] (4) After stirring for about 40 minutes, add 0.6 parts of coupling agent (KH-550) and 5.5 parts of curing agent in sequence, and continue stirring for about 3 minutes;

[0057] (5) P...

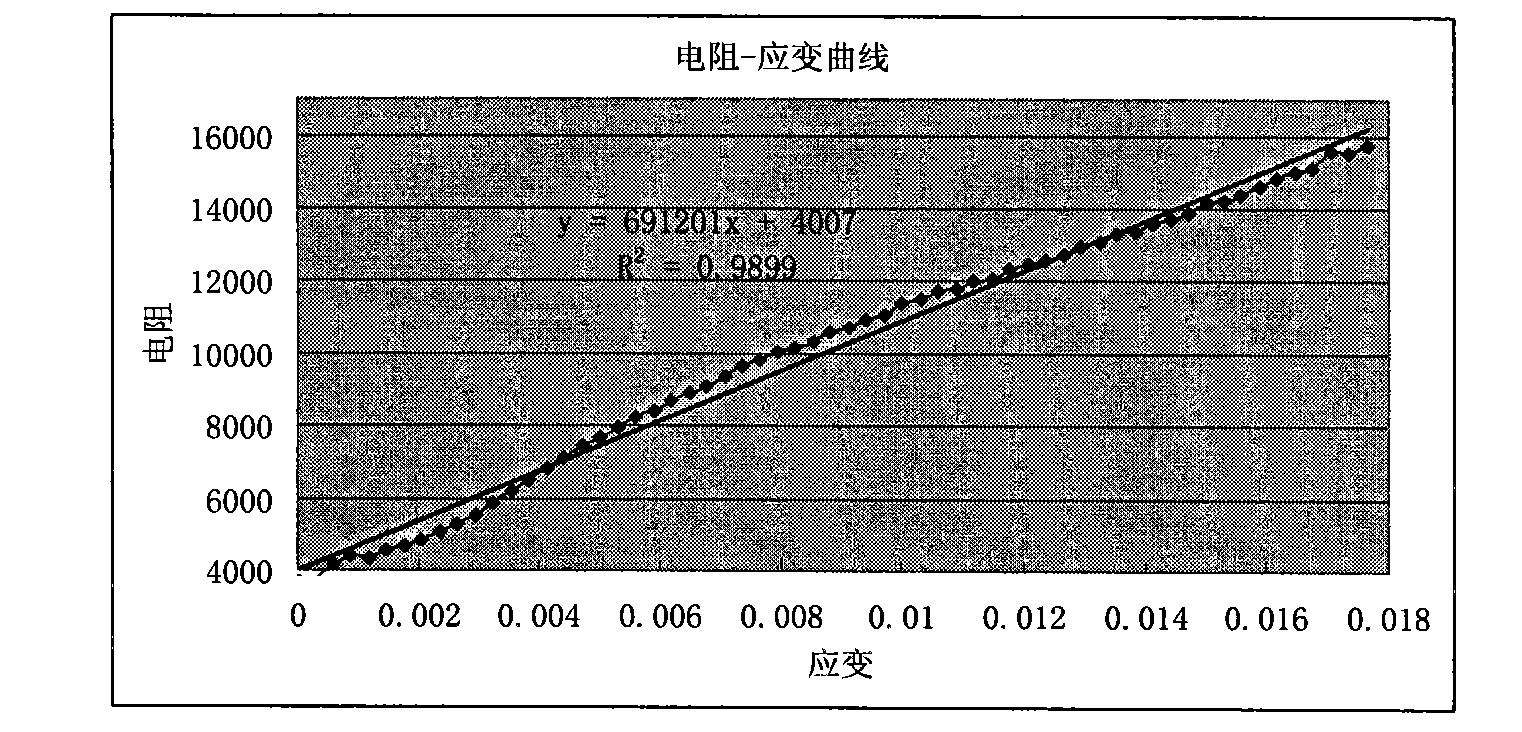

Embodiment 3

[0061] Embodiment three, weigh by mass proportioning:

[0062] Liquid silicone rubber: 100 parts;

[0063] 0.6mm chopped chopped carbon fiber: 10 parts;

[0064] Conductive carbon black: 0.5 part;

[0065] nano-SiO 2 : 2 copies;

[0066] Curing agent: 3 parts;

[0067] Coupling agent: 0.4 parts.

[0068] The production steps are:

[0069] (1) take by weight respectively 100 parts of liquid silicone rubber, 10 parts of 0.6mm chopped chopped carbon fiber, 3 parts of curing agent (dibutyltin dilaurate) and 0.4 part of coupling agent ( KH-550);

[0070](2) Add 100 parts of liquid silicone rubber into the mixer for stirring, and the stirring speed is about 1500r / min;

[0071] (3) Then slowly add 10 parts of 0.6mm chopped carbon fiber, then add 2 parts of nano-SiO 2 , continue stirring;

[0072] (4) After stirring for about 40 minutes, add 0.4 parts of coupling agent (KH-550) and 3 parts of curing agent (dibutyltin dilaurate) in sequence, and continue stirring for about 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com