Patents

Literature

53results about How to "Low tensile modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

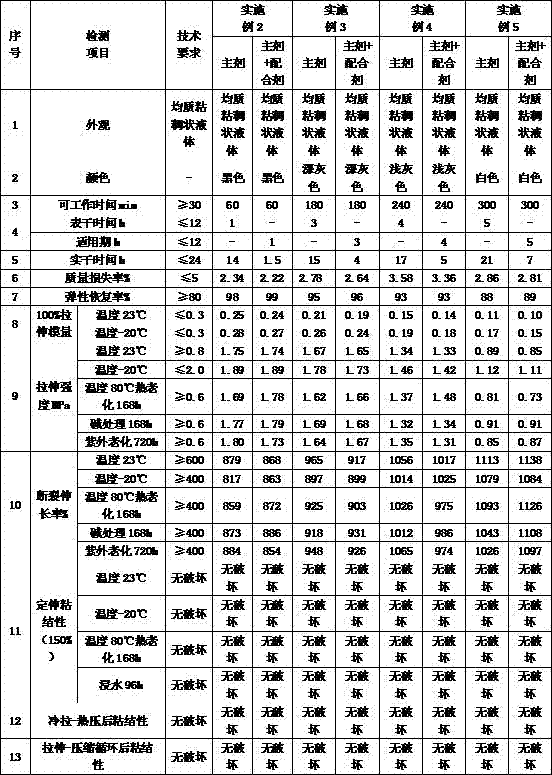

Single/double-component construction type polyurethane joint pouring glue for ballastless track concrete expansion joint and preparation method thereof

ActiveCN107142069AEasy constructionLow tensile modulusNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantEngineering

The invention relates to the technical field of building sealants, and in particular to single / double-component construction type polyurethane joint pouring glue for a ballastless track concrete expansion joint and a preparation method thereof. The single / double-component construction type polyurethane joint pouring glue for the ballastless track concrete expansion joint is prepared from a main agent and an accessory ingredient, wherein the main agent is prepared from a polyurethane prepolymer, filler, a thickening agent, a diluent, a catalyst, a cementation accelerator, a defoaming agent, a light stabilizer, an antioxidant and a water removing agent; the polyurethane prepolymer is prepared from polypropylene oxide glycol, polypropylene triol, polyisocyanate, a plasticizer and the catalyst; the accessory ingredient is prepared from the plasticizer, a thickening agent and micromolecular polyol. The preparation method comprises the following steps: step one, preparation of the polyurethane prepolymer; step two, preparation of the main agent; step three, preparation of the accessory ingredient. After the single / double-component construction type polyurethane joint pouring glue disclosed by the invention is cured, the tensile modulus is low, the anti-displacement capacity is strong, and low-temperature flexibility is good.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

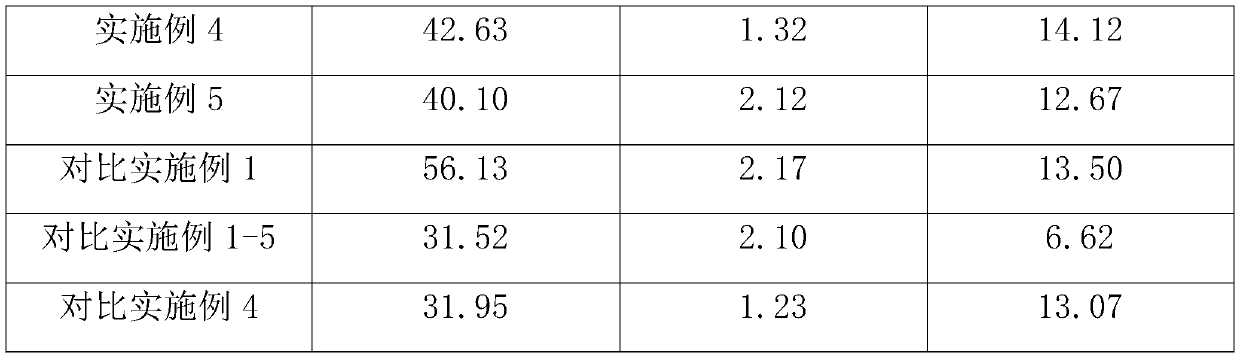

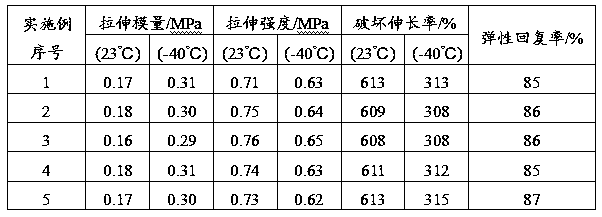

Polypropylene modified material with excellent stiffness and high elongation at break and preparation method of polypropylene modified material

The invention discloses a polypropylene modified material with excellent stiffness and high elongation at break and a preparation method of the polypropylene modified material. The polypropylene modified material comprises the following components: 5-95% of polypropylene, 5-60% of an inorganic filler, 0.1-3% of a hyperbranched resin, 0.1-0.8% of antioxidant and 0.1-1.0% of an antistatic agent. According to introduction of the hyperbranched resin, the elongation at break of the polypropylene modified material is greatly improved, the condition that the flexural modulus and tensile modulus of the polypropylene modified material are reduced is avoided, and the hyperbranched resin is capable of promoting dispersion of the inorganic filler in polypropylene, so that the various mechanical properties of the polypropylene modified material are improved. Furthermore, the introduced hyperbranched resin is capable of improving the melt fluidity of the polypropylene material, the production energyconsumption of the polypropylene modified material is reduced, and the polypropylene modified material is suitable for large-scale production.

Owner:NINGBO ECOT SCI & TECH

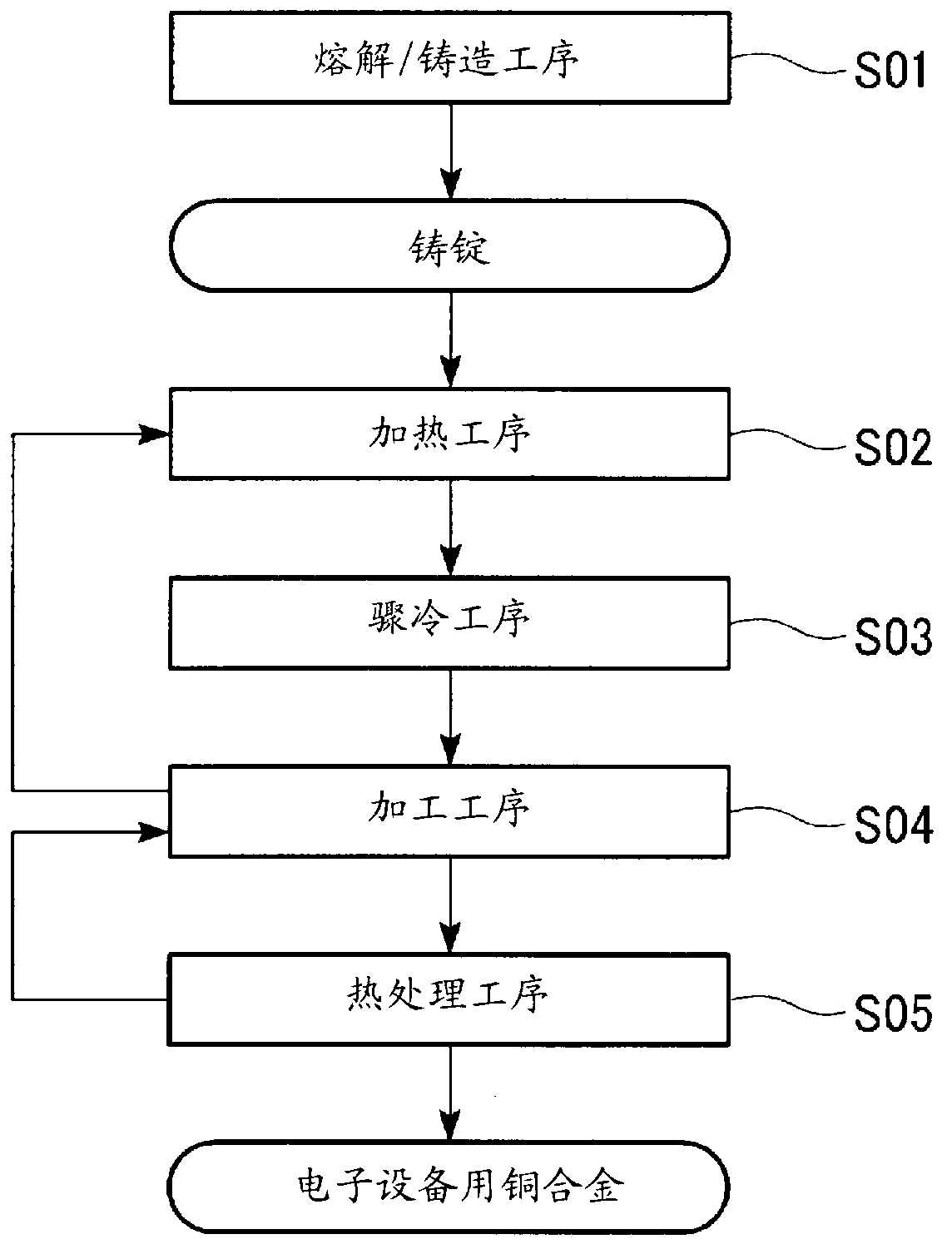

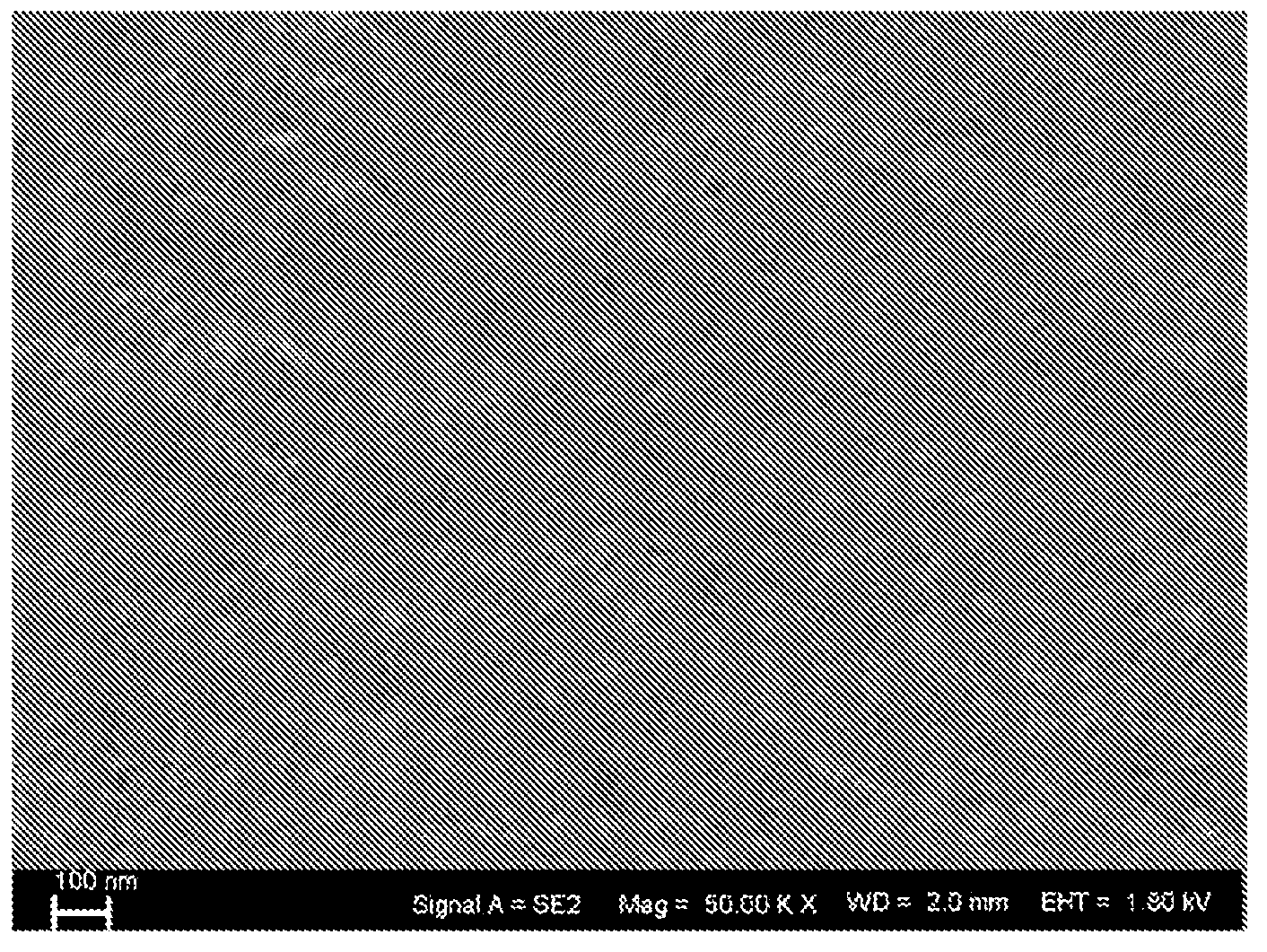

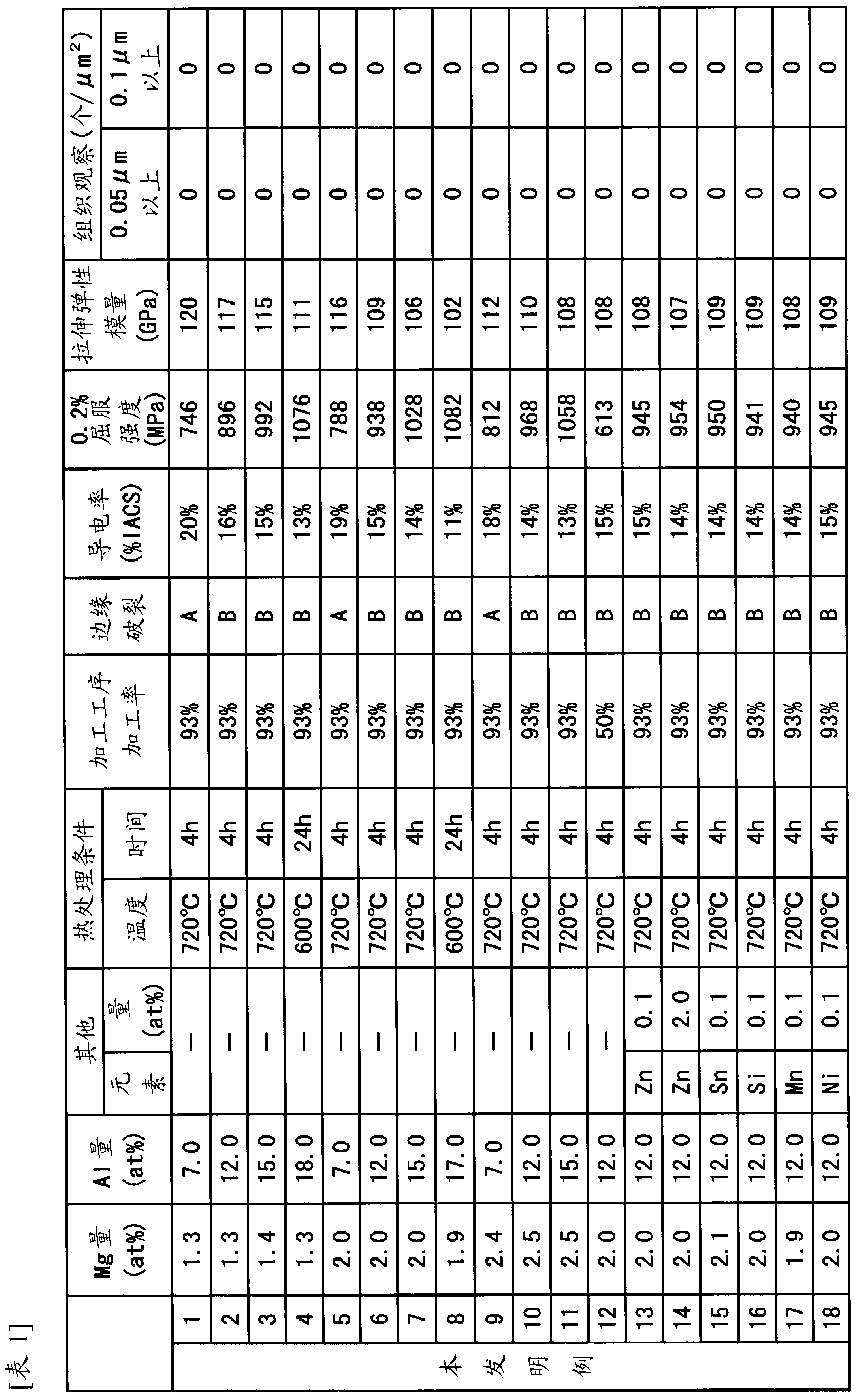

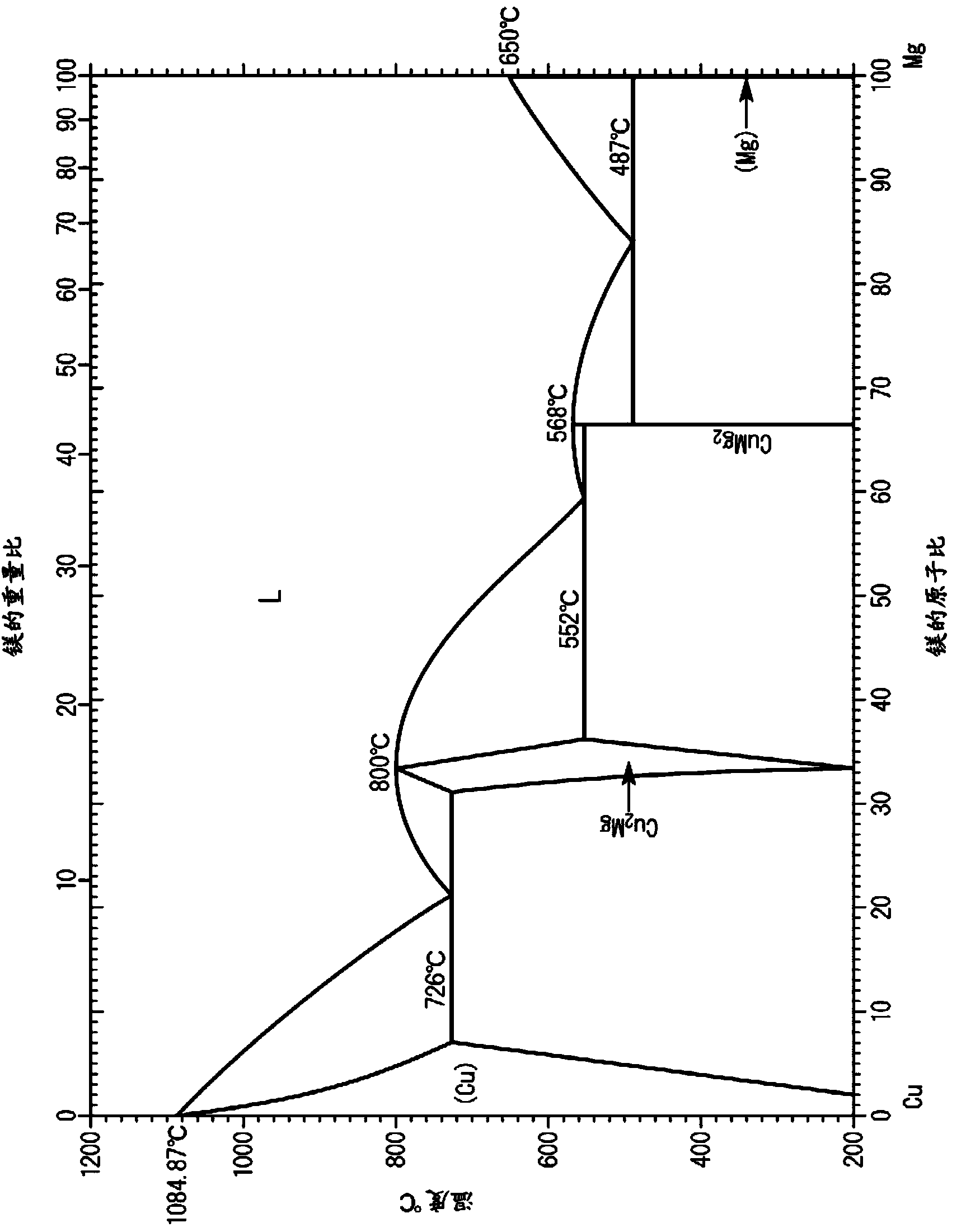

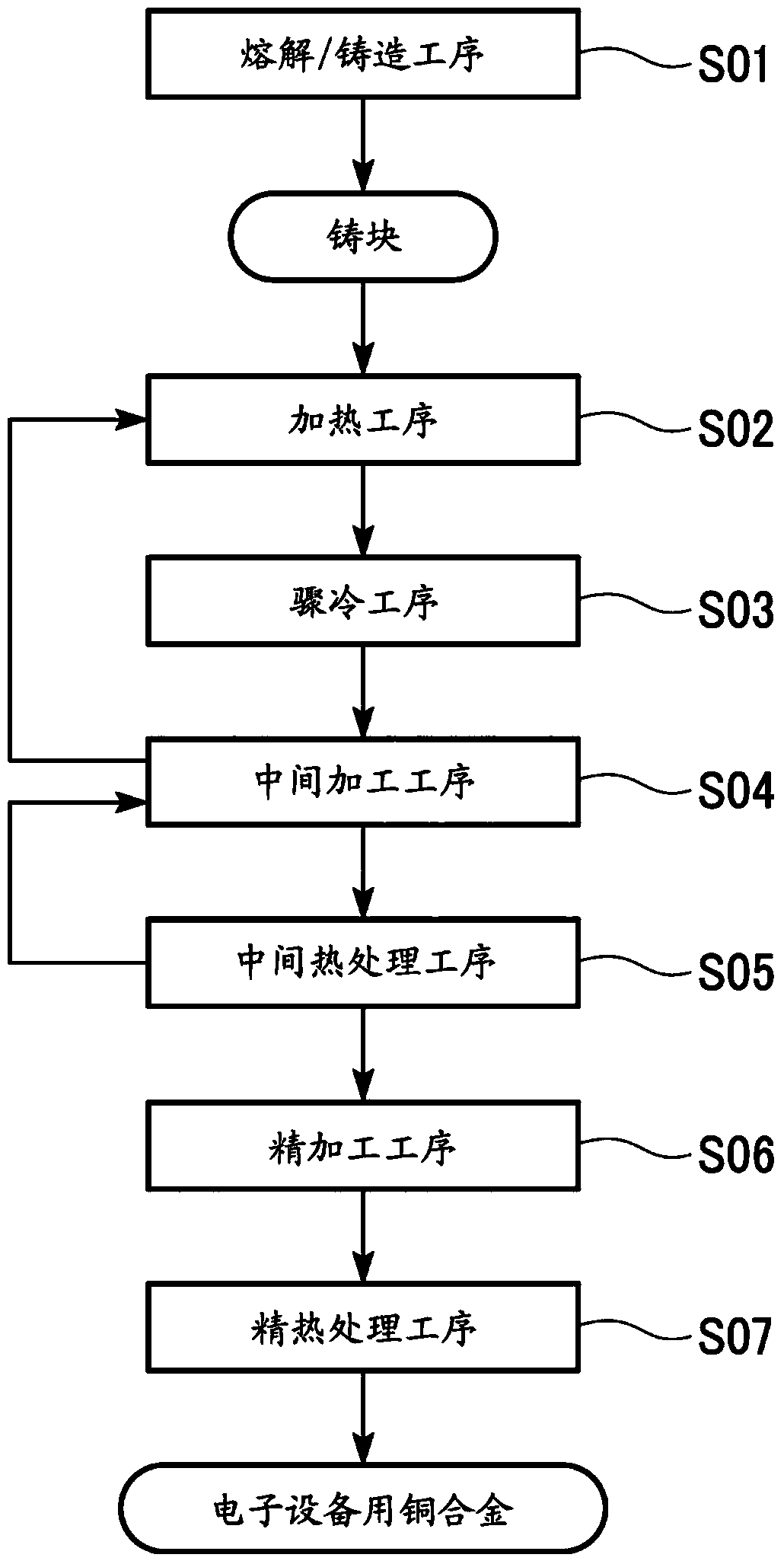

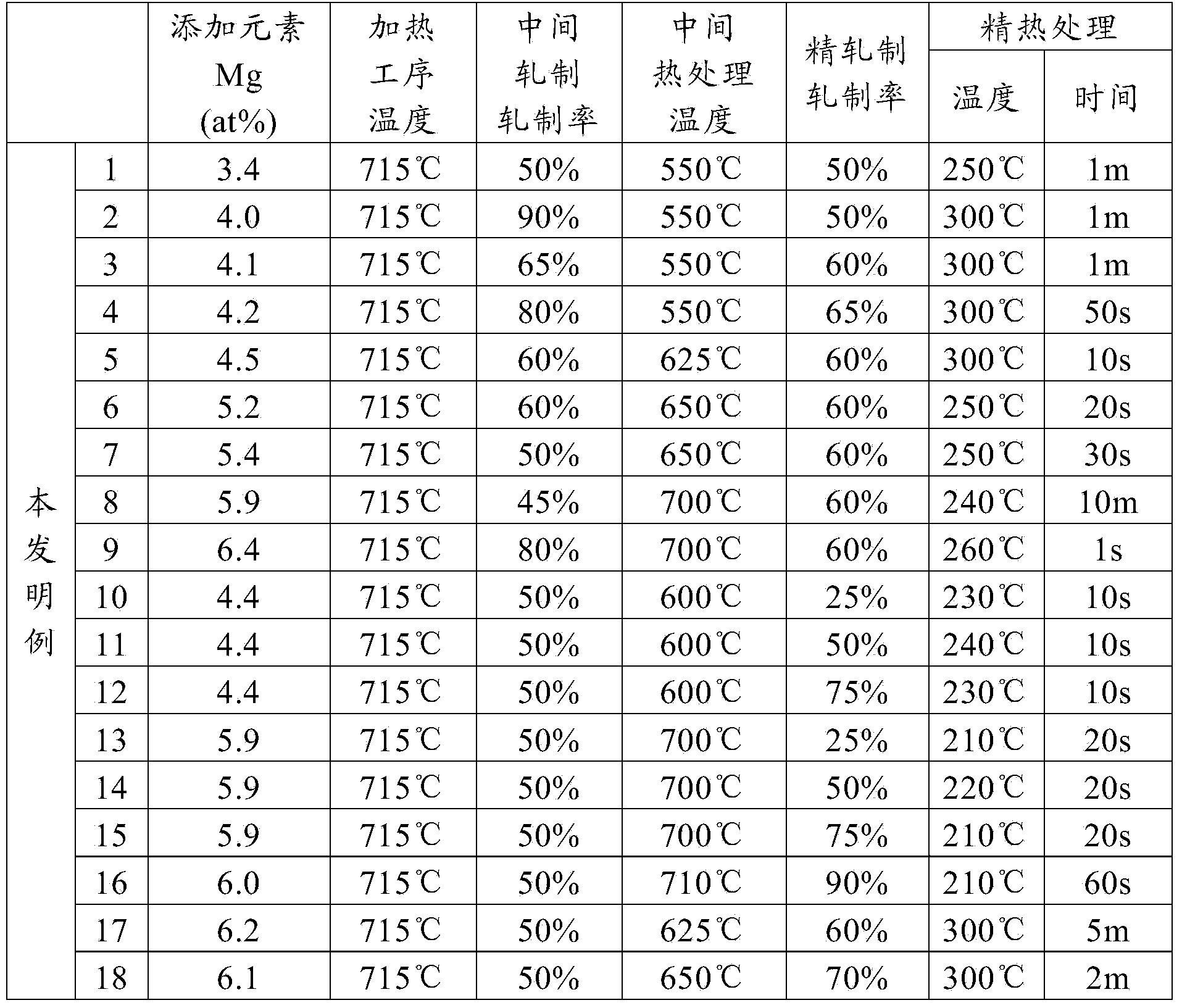

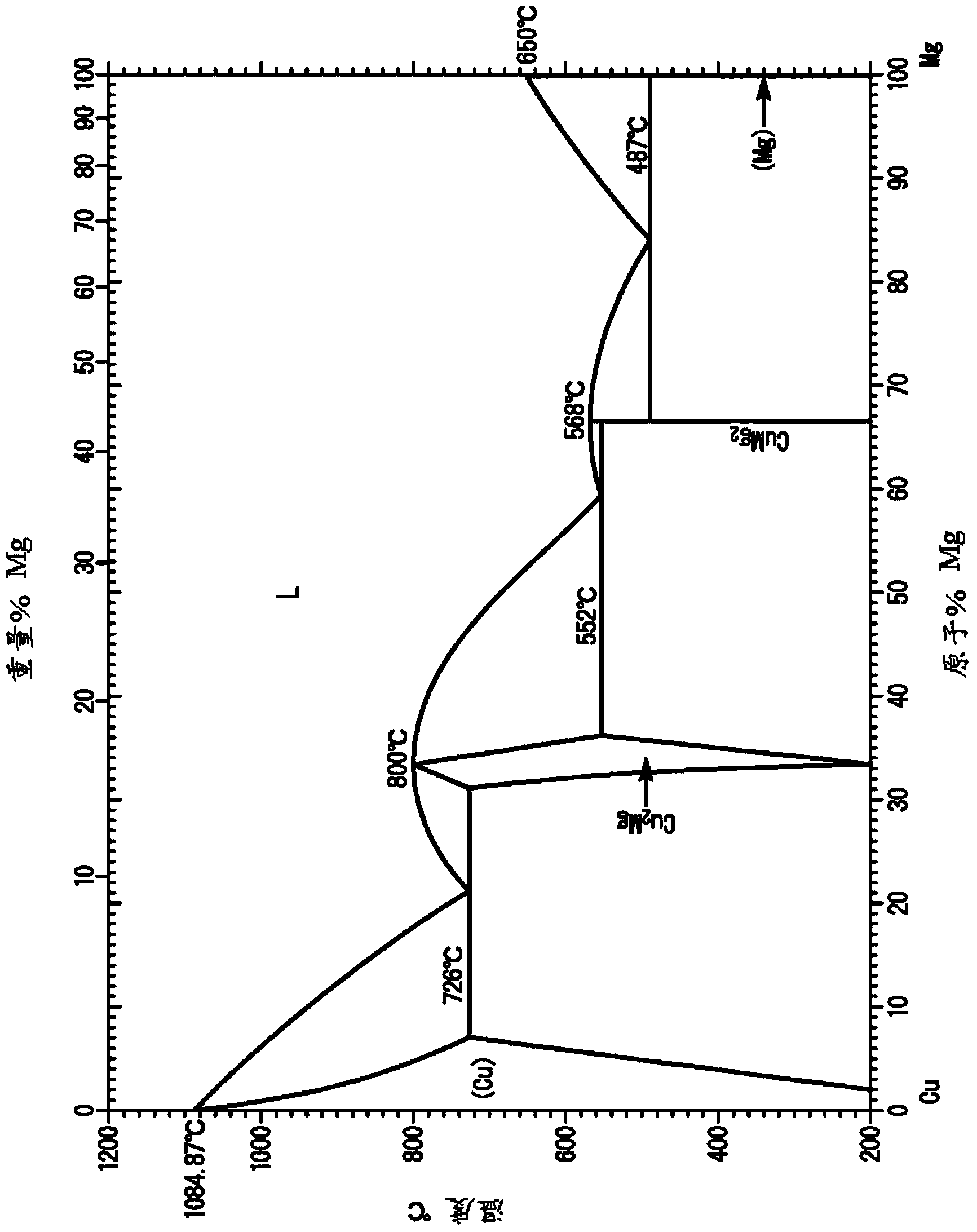

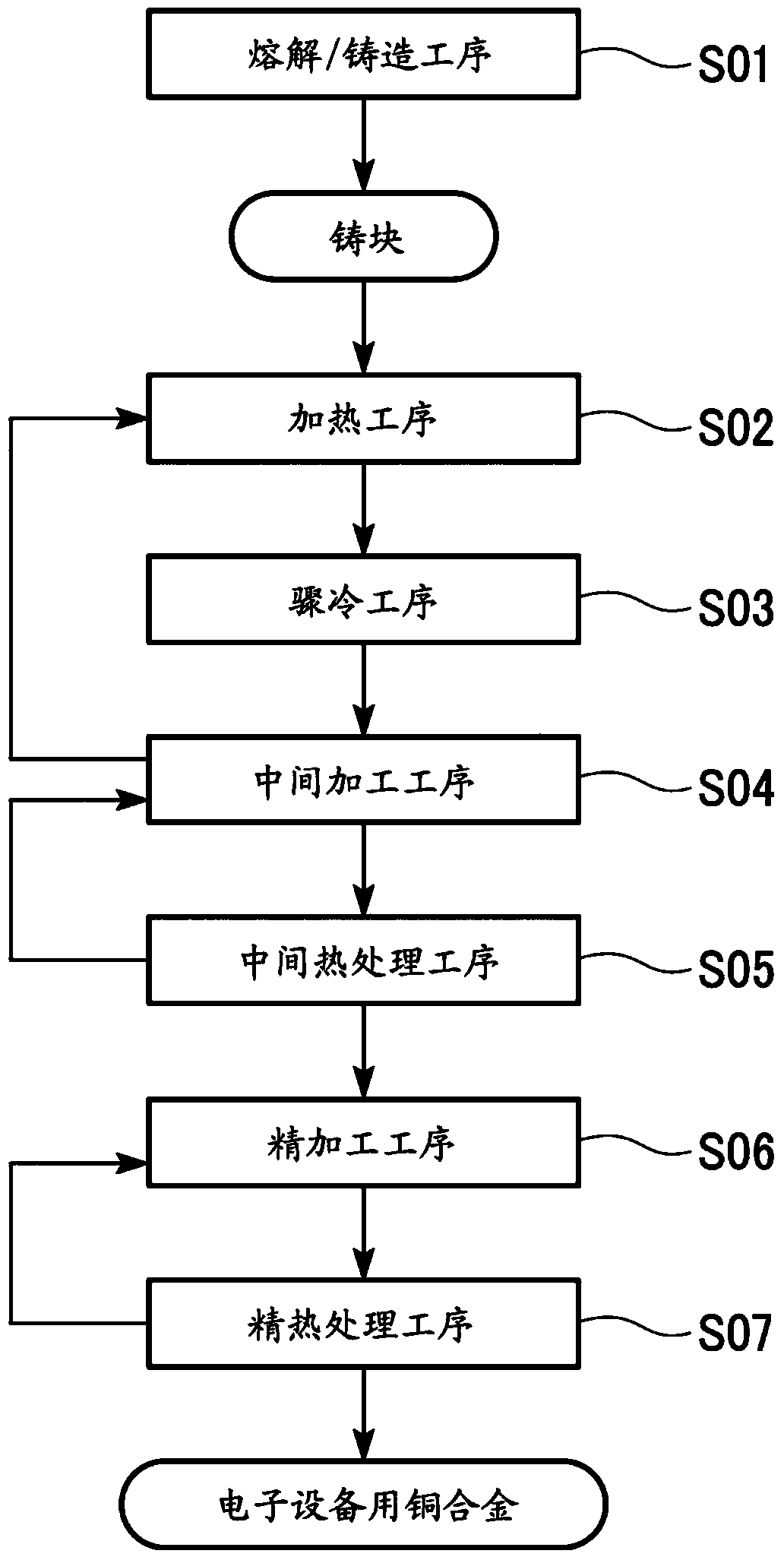

Copper alloy for electronic device, method for producing copper alloy for electronic device, and copper alloy rolled material for electronic device

ActiveCN102892908ALow tensile modulusHigh yield strengthSingle bars/rods/wires/strips conductorsConductive materialMetallurgyImpurity

Owner:MITSUBISHI MATERIALS CORP

Tire cord and pneumatic tire including the same

InactiveCN101922071AGood molding precisionTensile modulus changeMotorcycle tyresPneumatic tyre reinforcementsAramidesEngineering

Owner:SUMITOMO RUBBER IND LTD

Copper alloy for electronic devices, method for producing copper alloy for electronic devices, and copper alloy rolled material for electronic devices

ActiveCN103228804ALow tensile modulusHigh yield strengthApparatus for heat treatmentConductive materialElectric equipmentElectron

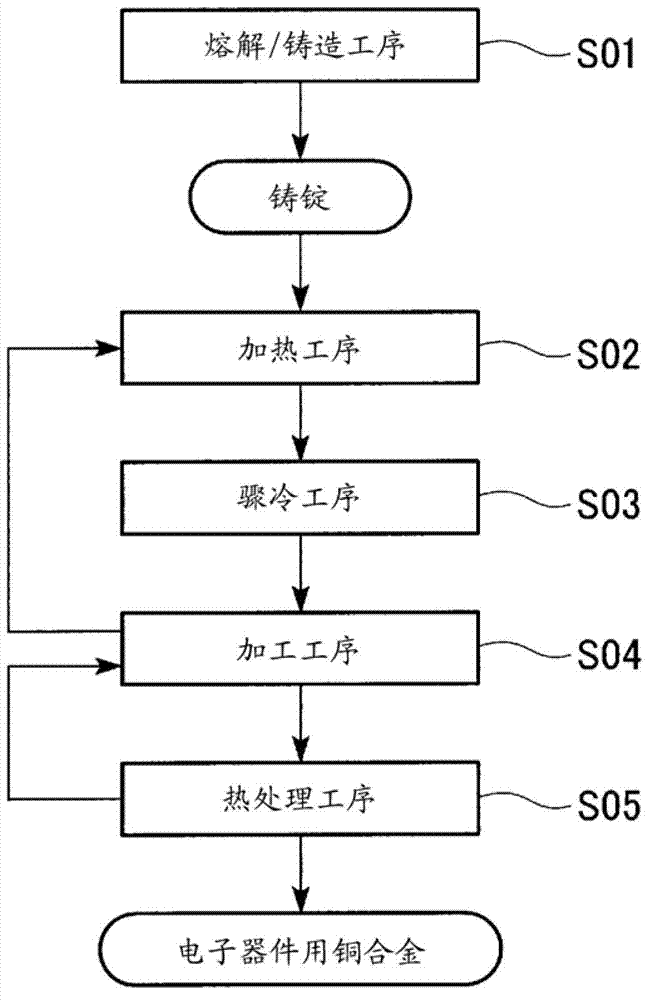

A copper alloy for an electric device contains Mg in a range of 1.3 atomic % or more and less than 2.6 atomic %, Al in a range of 6.7 atomic % or more and 20 atomic % or less, and the balance substantially consisting of Cu and unavoidable impurities. A method of producing a copper alloy includes: performing heating of a copper material to a temperature of not lower than 500° C. and not higher than 1000° C.; performing quenching to cool the heated copper material to 200° C. or lower with a cooling rate of 200° C. / min or more; and performing working of the cooled copper material, wherein the copper material is composed of a copper alloy containing Mg in a range of 1.3 atomic % or more and less than 2.6 atomic %, Al in a range of 6.7 atomic % or more and 20 atomic % or less.

Owner:MITSUBISHI MATERIALS CORP

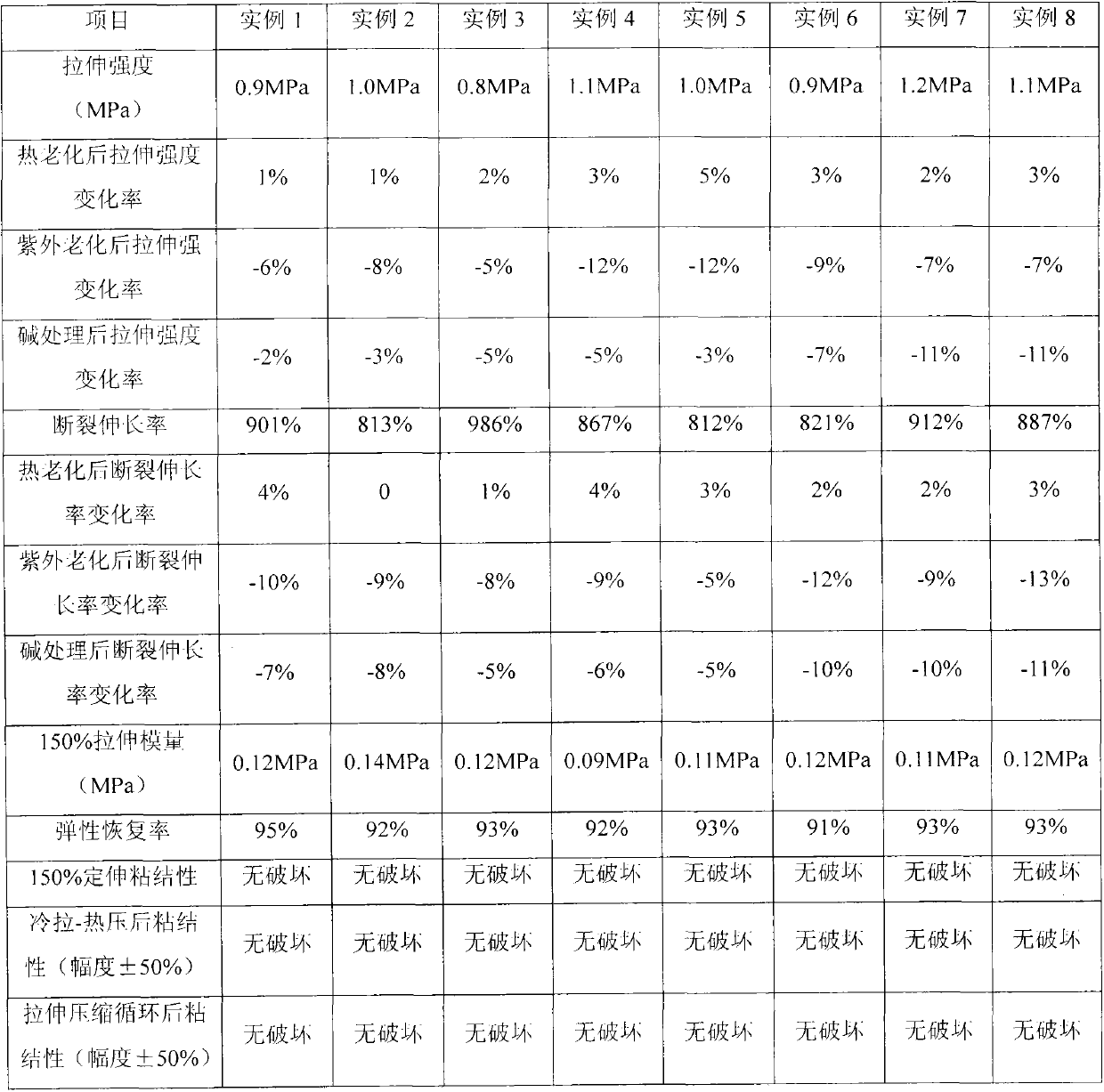

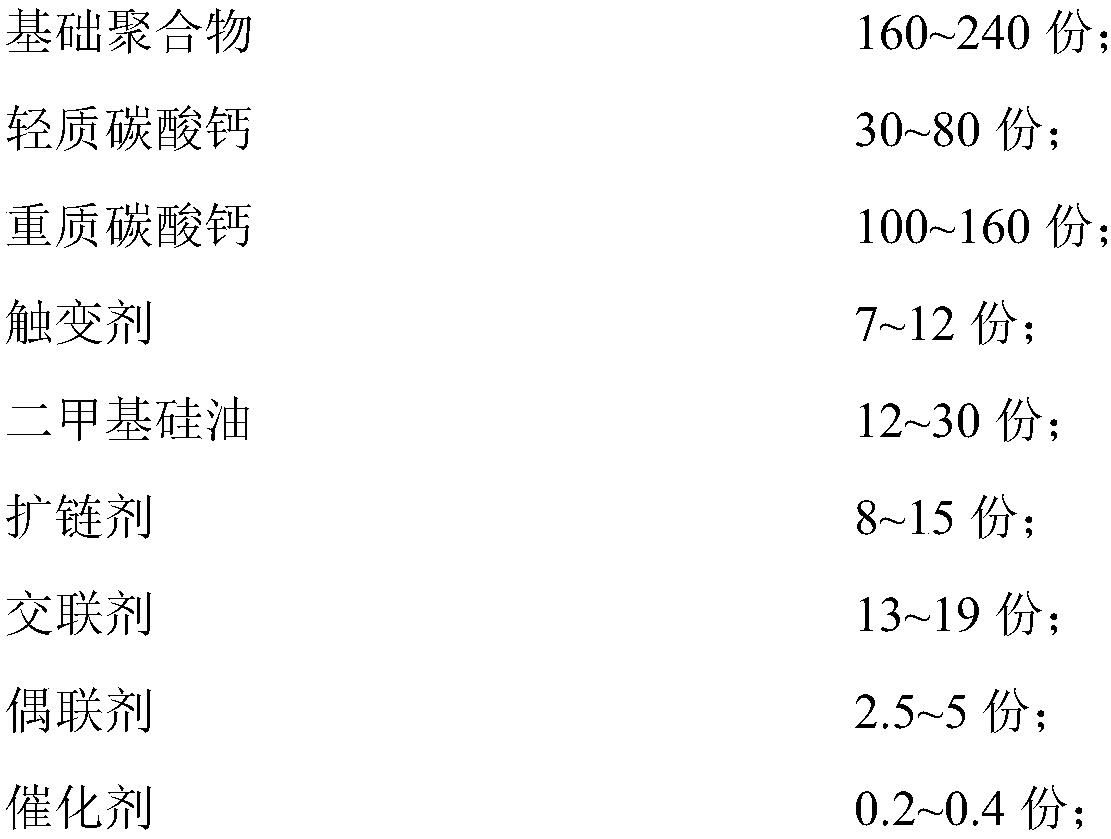

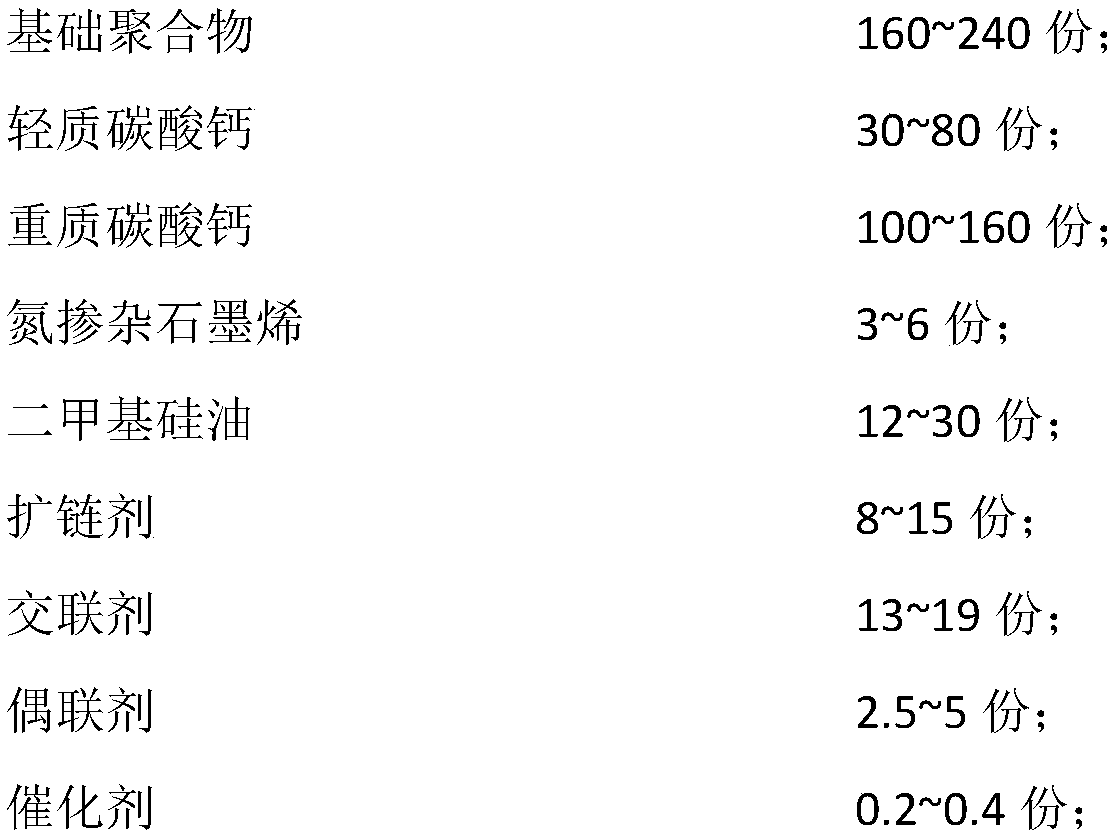

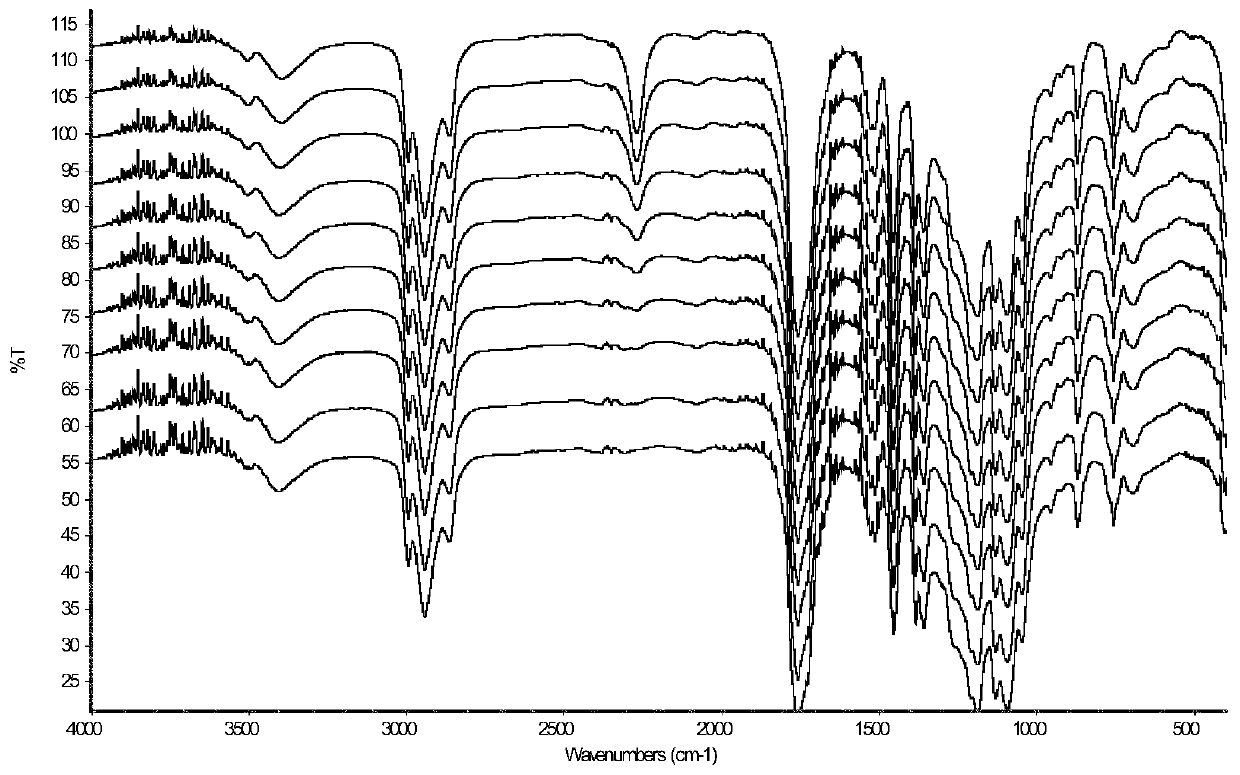

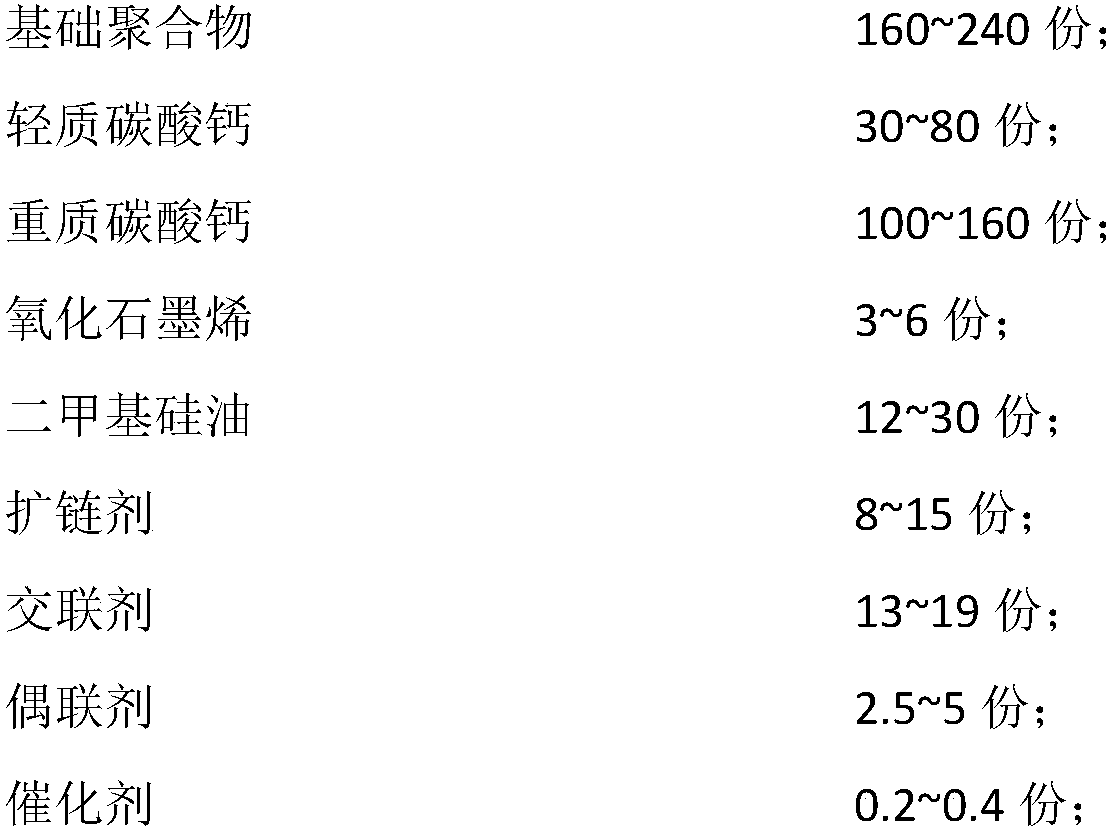

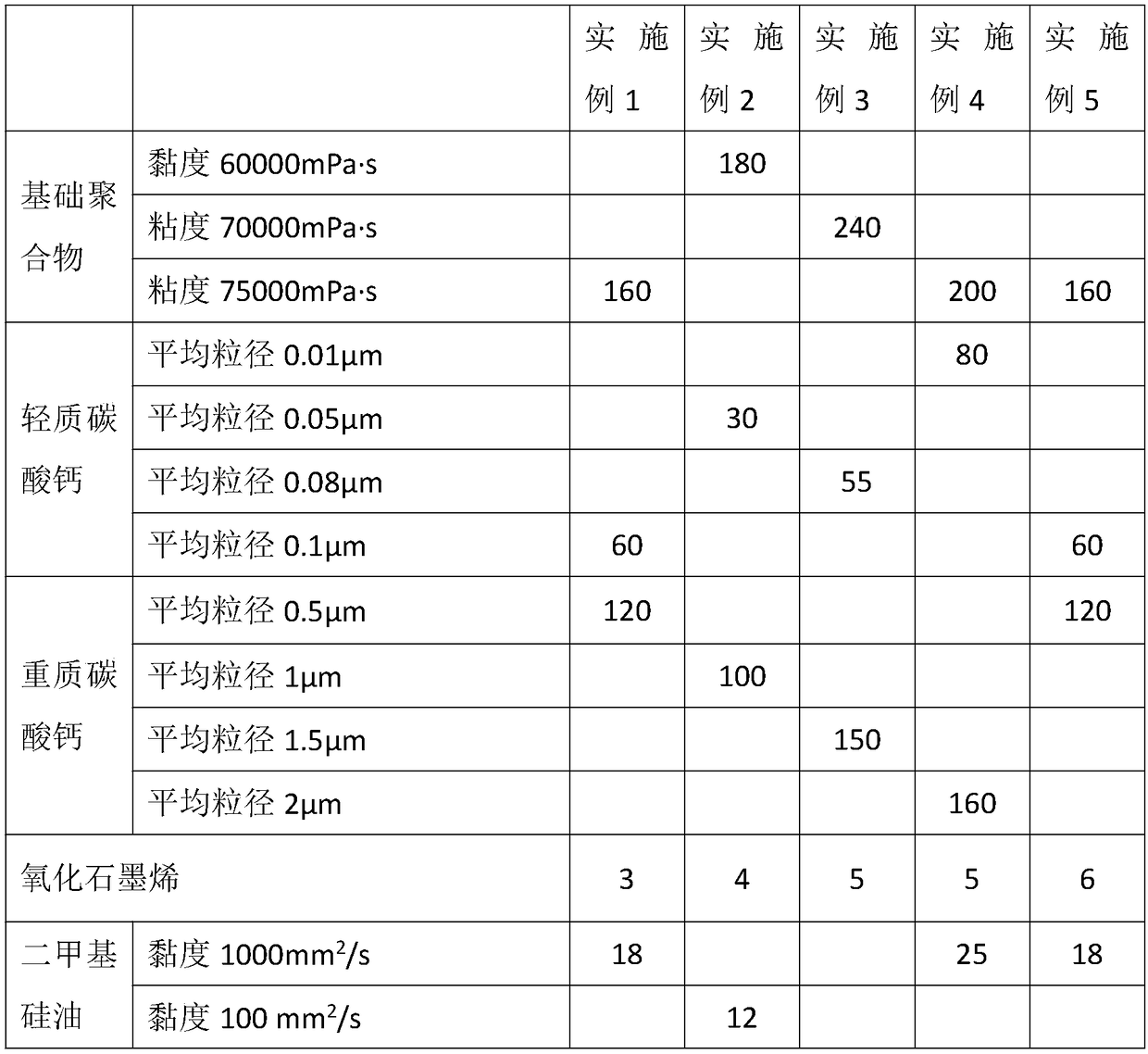

Single-ingredient oxime removal type low-modulus room-temperature vulcanization neutral silicone weather-resistant sealant and preparation method thereof

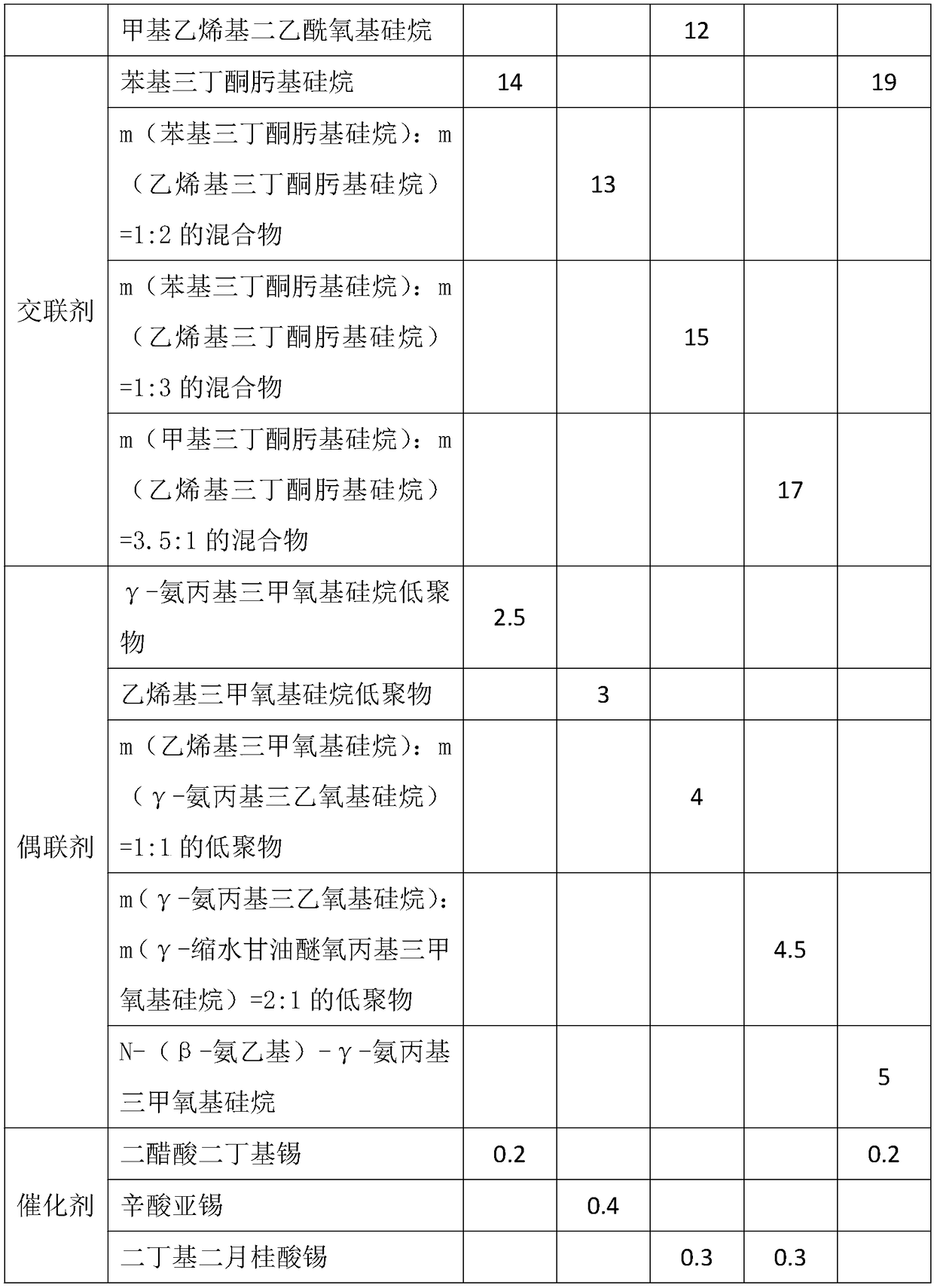

ActiveCN108300407ALow tensile modulusLittle elasticityNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationHigh rise

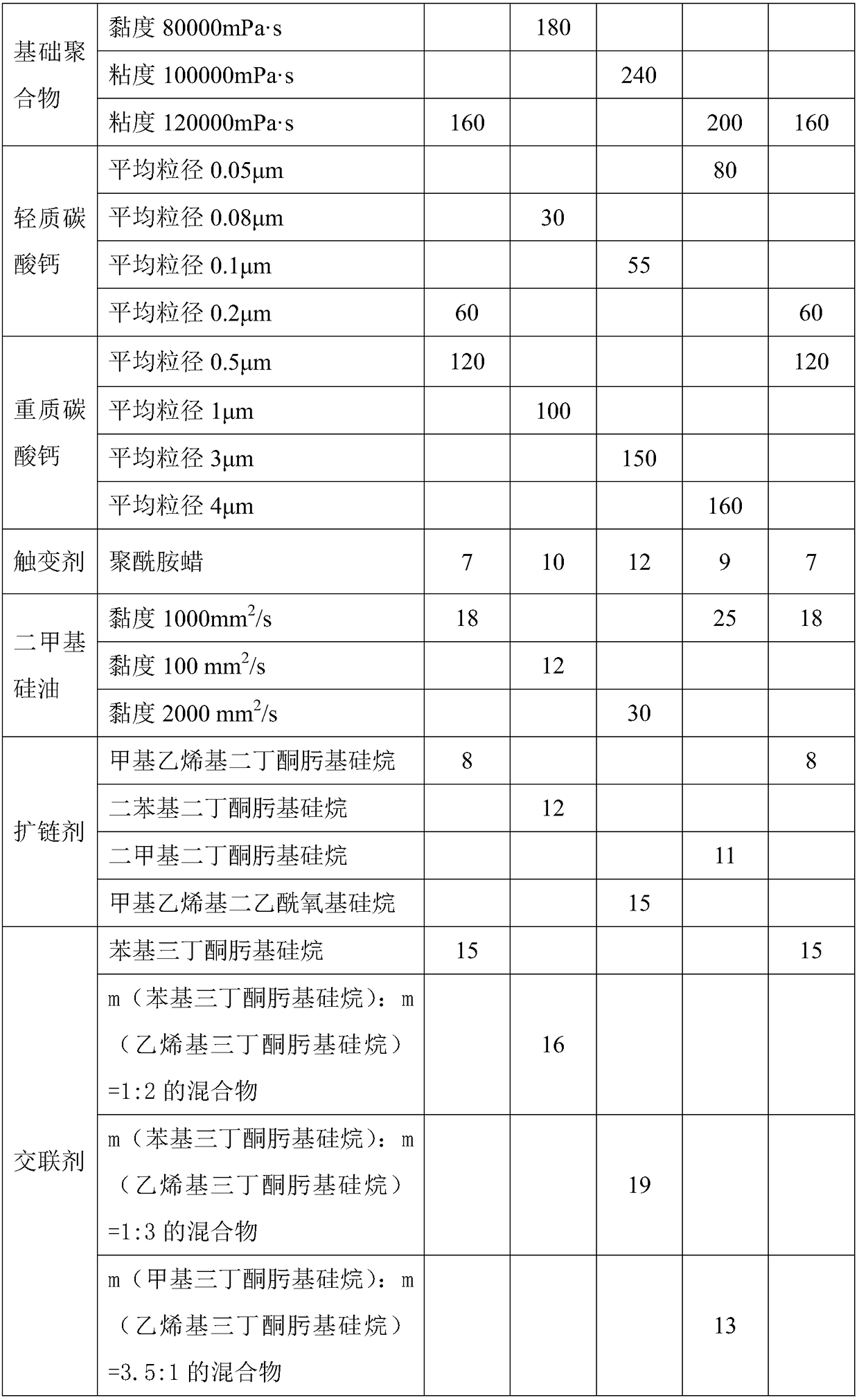

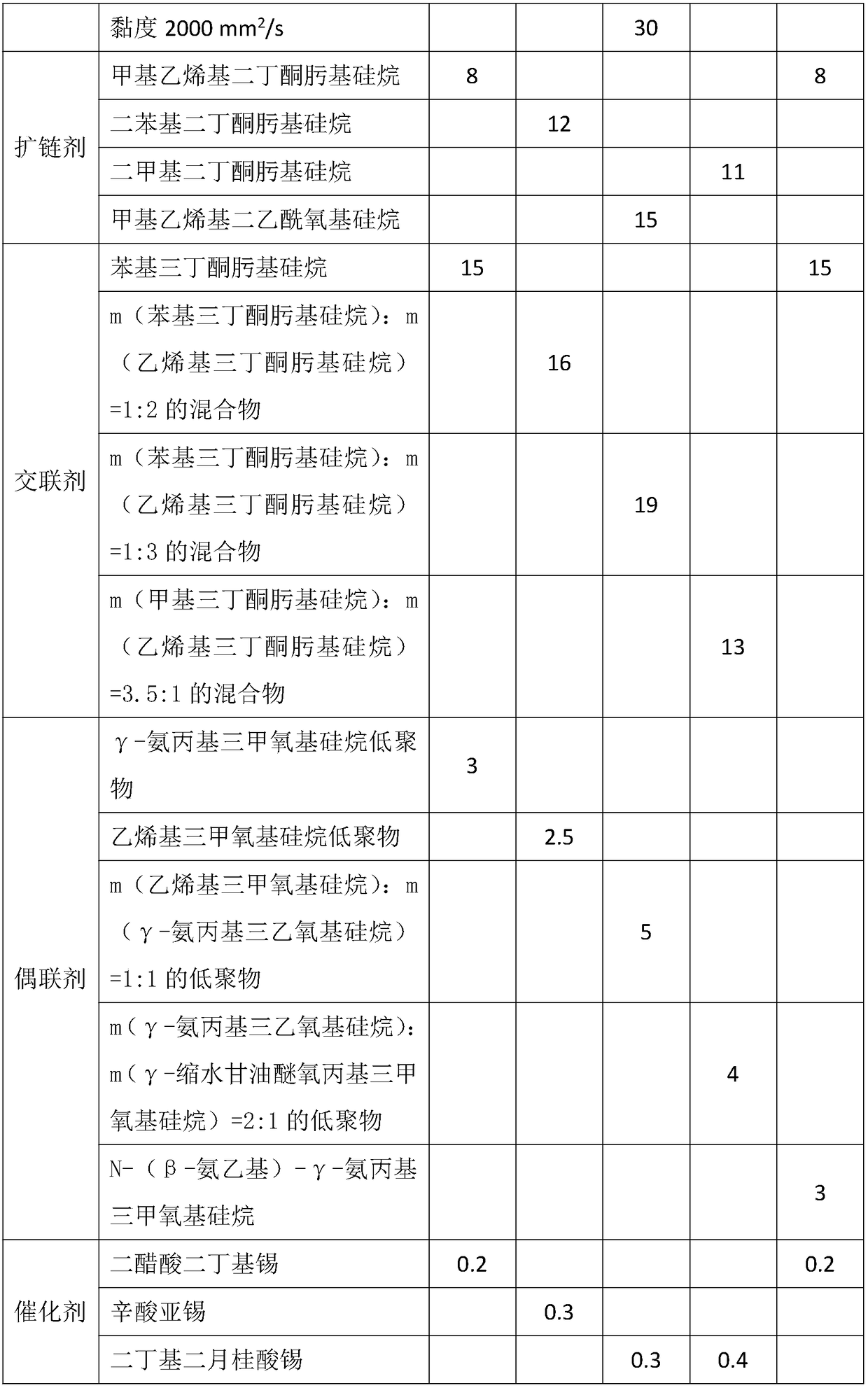

The invention discloses a single-ingredient oxime removal type low-modulus room-temperature vulcanization neutral silicone weather-resistant sealant, which is prepared from the following ingredients in parts by weight: 160 to 240 parts of basic polymers, 30 to 80 parts of light calcium carbonate, 100 to 160 parts of heavy calcium carbonate, 7 to 12 parts of thixotropic agents, 12 to 30 parts of simethicone, 8 to 15 parts of chain expansion agents, 13 to 19 parts of crosslinking agents, 2.5 to 5 parts of coupling agents and 0.2 to 0.4 part of catalysts. The prepared single-ingredient oxime removal type low-modulus room-temperature vulcanization neutral silicone weather-resistant sealant has the advantages of low stretch modulus, high elasticity, high elasticity recovery rate, excellent weather resistance and good bonding performance; after the treatment such as cold pulling-hot pressing and water soaking, the interface bonding damage and cohesive failure cannot occur; the promotion of the high-displacement jointing of the silicone sealant in the super high-rise building and the concrete expansion joint sealing of facilities such as roads, bridges and airfield runway can be facilitated.

Owner:GUANGZHOU JOINTAS CHEM

Multifunctional organogel, and preparation method thereof

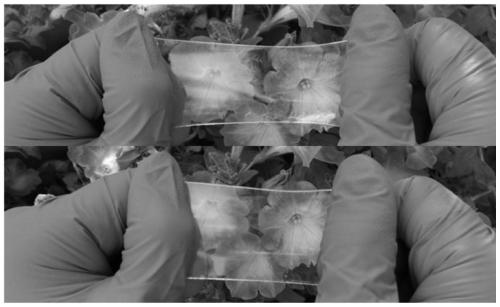

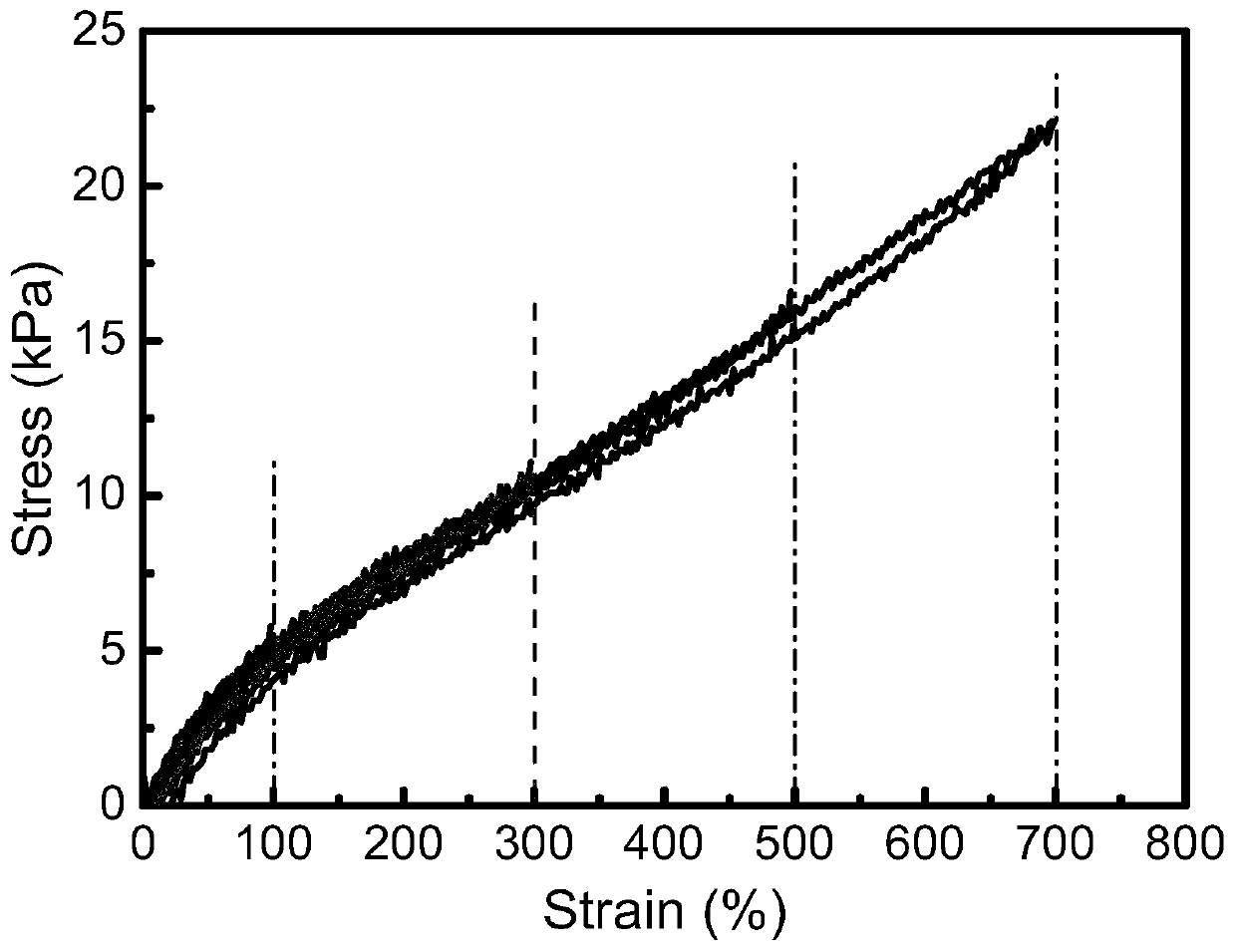

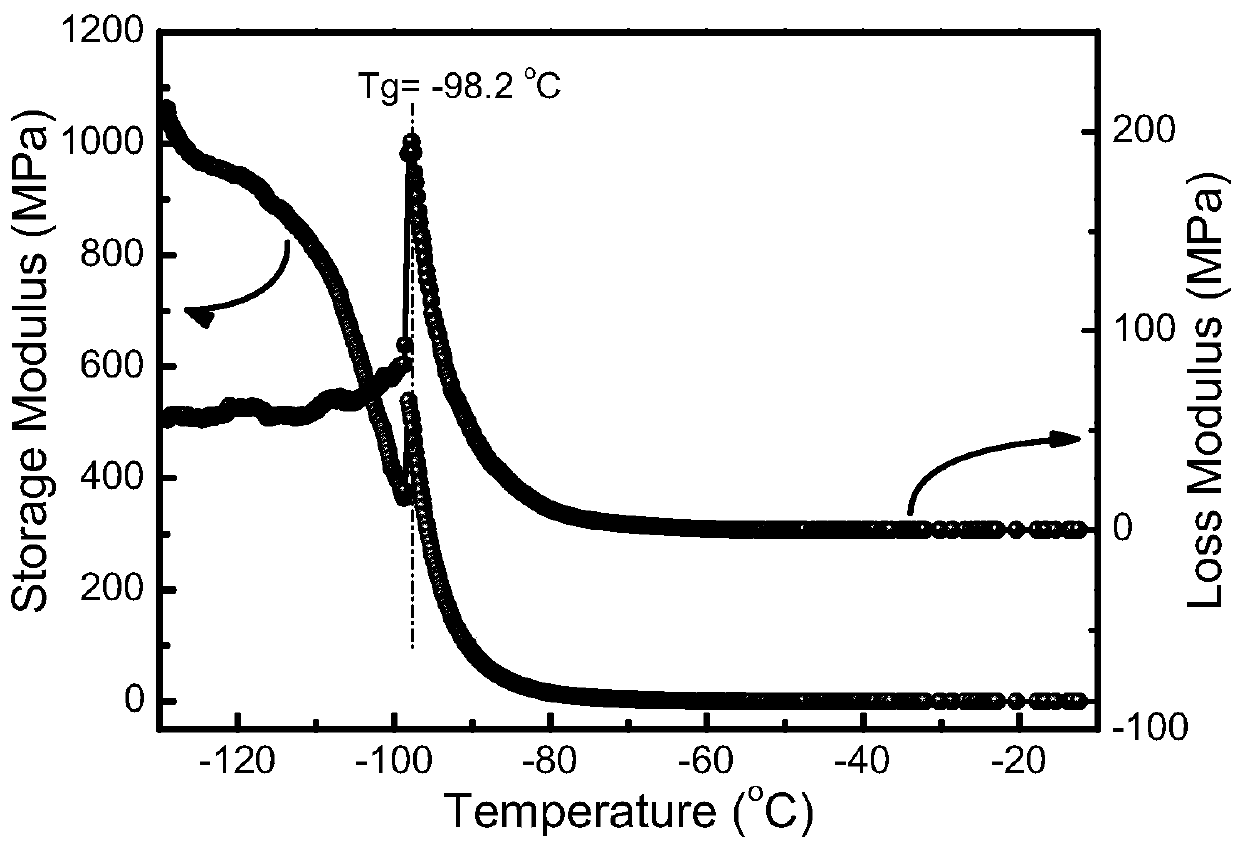

The invention discloses a multifunctional organogel, and a preparation method thereof. The raw materials of the multifunctional organogel comprise a solvent, a monomer, a crosslinking agent, an electrolyte salt, and an initiator; the volume ratio of the solvent to the monomer is controlled to be 1:5-5:1; the molar ratio of the crosslinking agent to the monomer is controlled to be 0.05 to 10%; themolar ratio of the initiator to the monomer is controlled to be 0.1 to 10%; and the concentration of the electrolyte salt in a mixed solution of all the raw materials ranges from 0.1 to 5mol / L. The multifunctional organogel possesses high transparency, high stretching performance, and high conductivity; the temperature resistance and the stability are better than those of conventional hydrogel materials; the temperature resistant range is very wide; the elongation at break is 1219% or higher; and the application prospect in the field of flexible electron and flexible machine is promising.

Owner:XI AN JIAOTONG UNIV

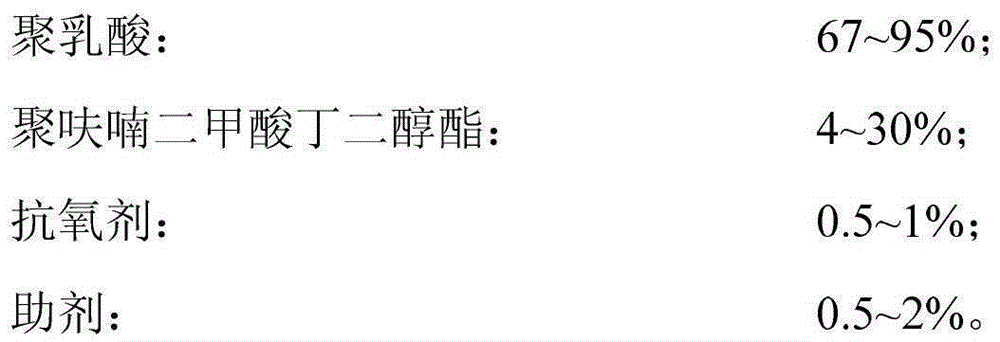

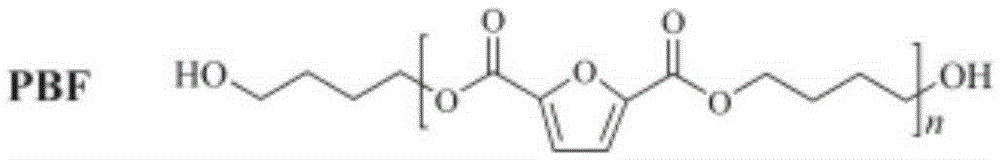

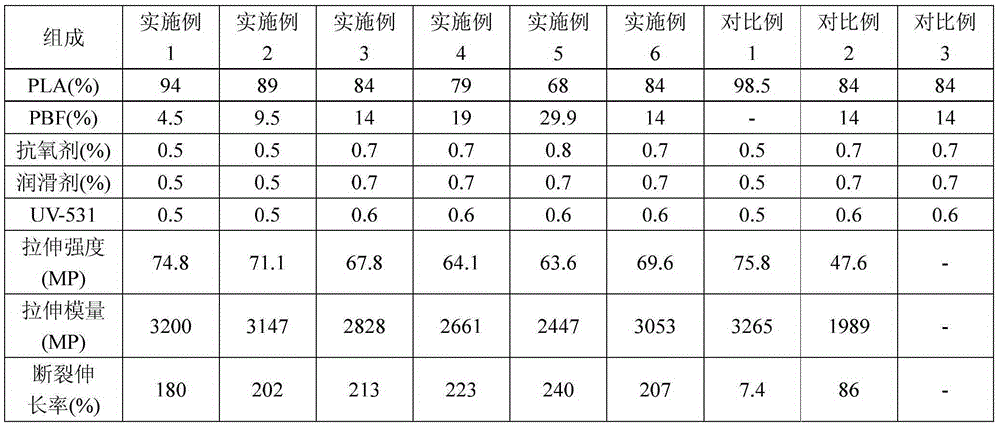

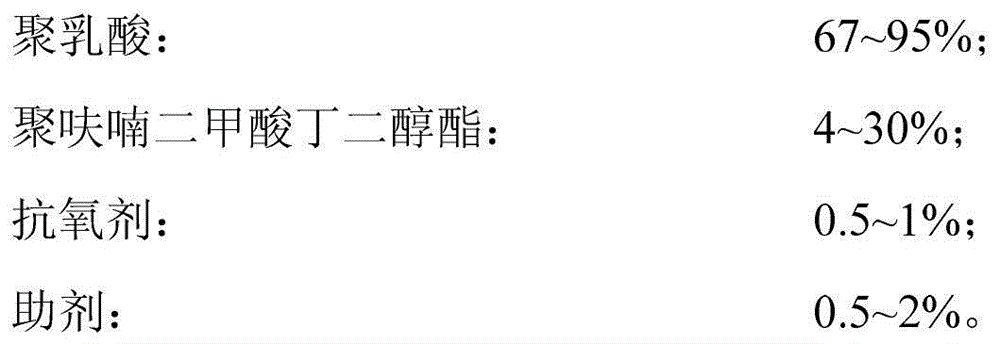

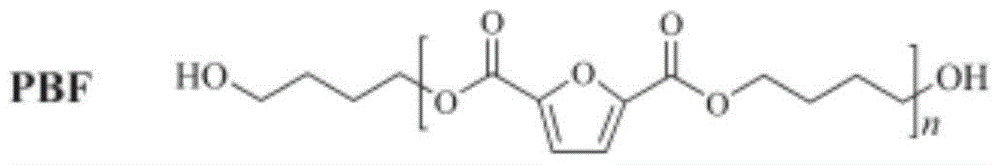

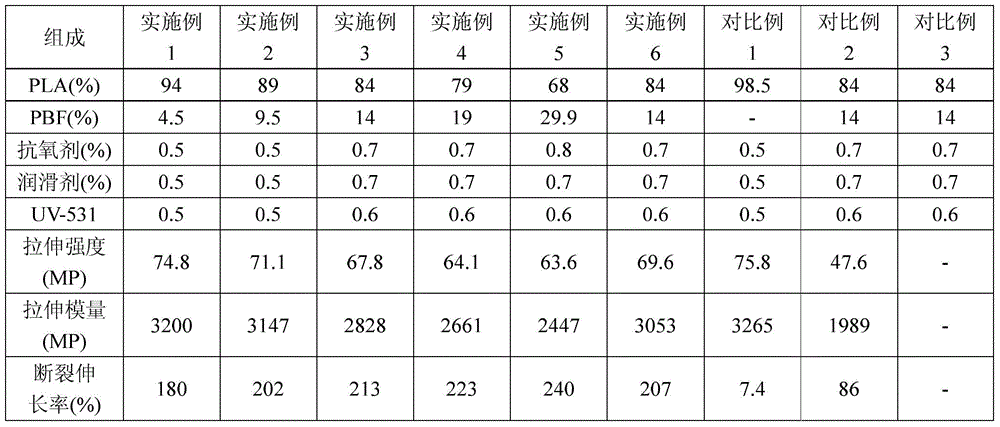

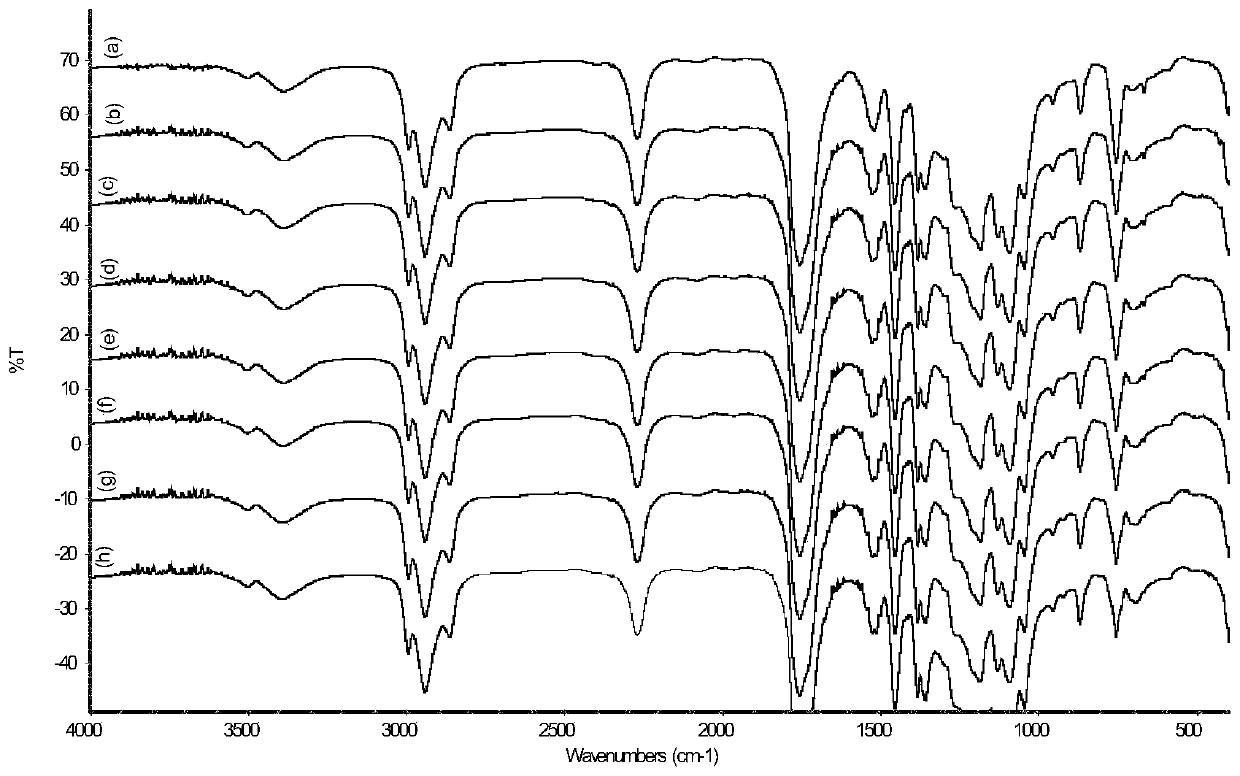

Bio-based polyester modified polylactic resin, preparation method and processing forming method

The invention discloses a bio-based polyester modified polylactic resin, a preparation method and a processing forming method. The modified polylactic resin comprises 67-95wt% of polylactic acid, 4-30wt% of poly(butylene 2,5-furandicarboxylate), 0.5-1wt% of anti-oxidant and 0.5-2wt% of auxiliary agent. The preparation method is as follows: polylactic acid and poly(butylene 2,5-furandicarboxylate) are dried fully, then are subjected to banburying blending with the anti-oxidant and the auxiliary agent and a target product is obtained. The modified polylactic resin is renewable and environmental protection resin, the tensile strength is more than or equal to 60 MPa, the fracture percentage elongation is 180-240%, when the fracture percentage elongation is 240%, the tensile modulus is lowered by only 25%, and the tensile strength is lowered by only 16%, no pearl essence addition is needed, the surface has pearlescent color reflect light, and the modified polylactic resin can be used for preparing films, plates, sheets, foaming and injection molding plastic products and the like, and has wide industrial application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

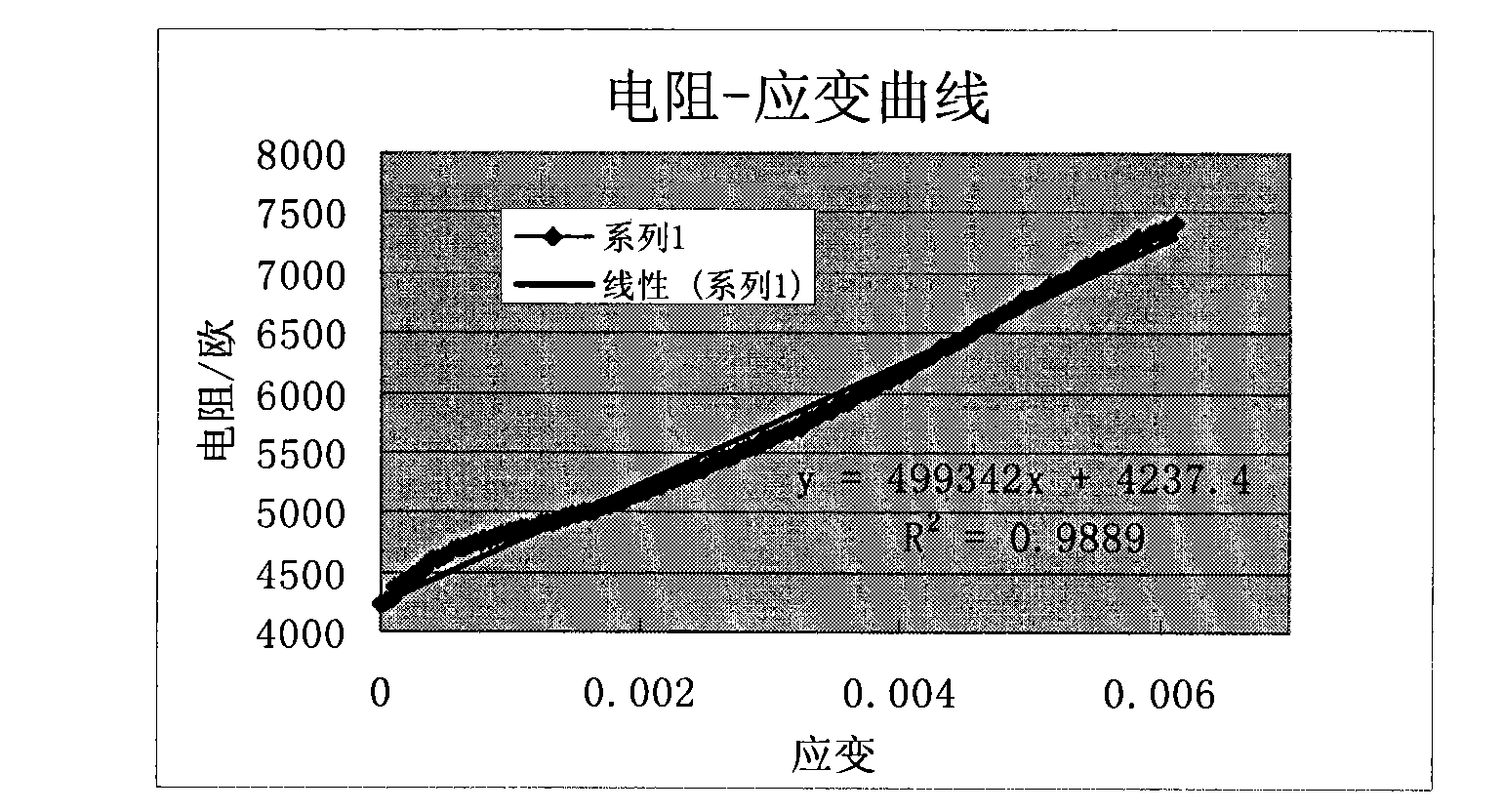

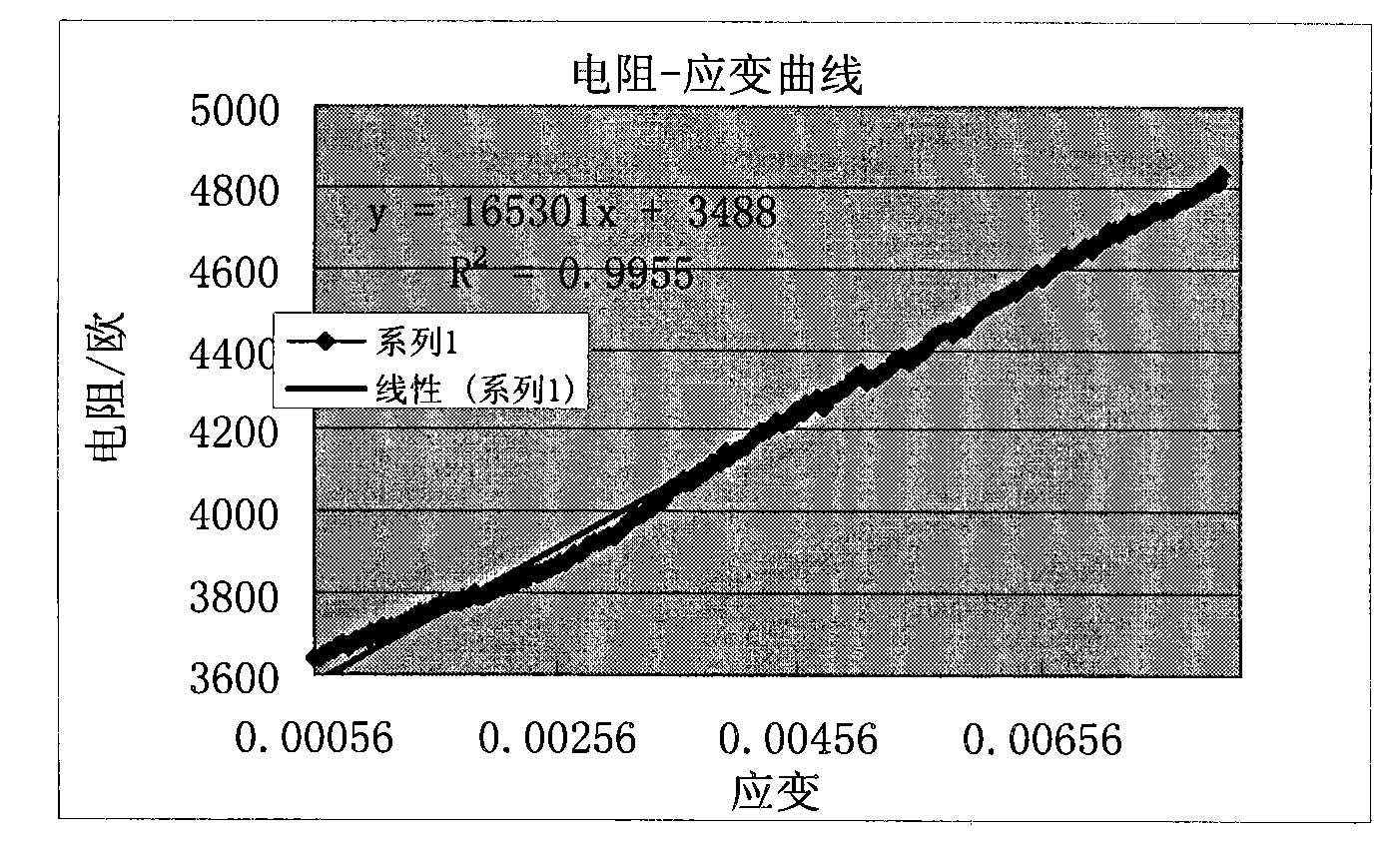

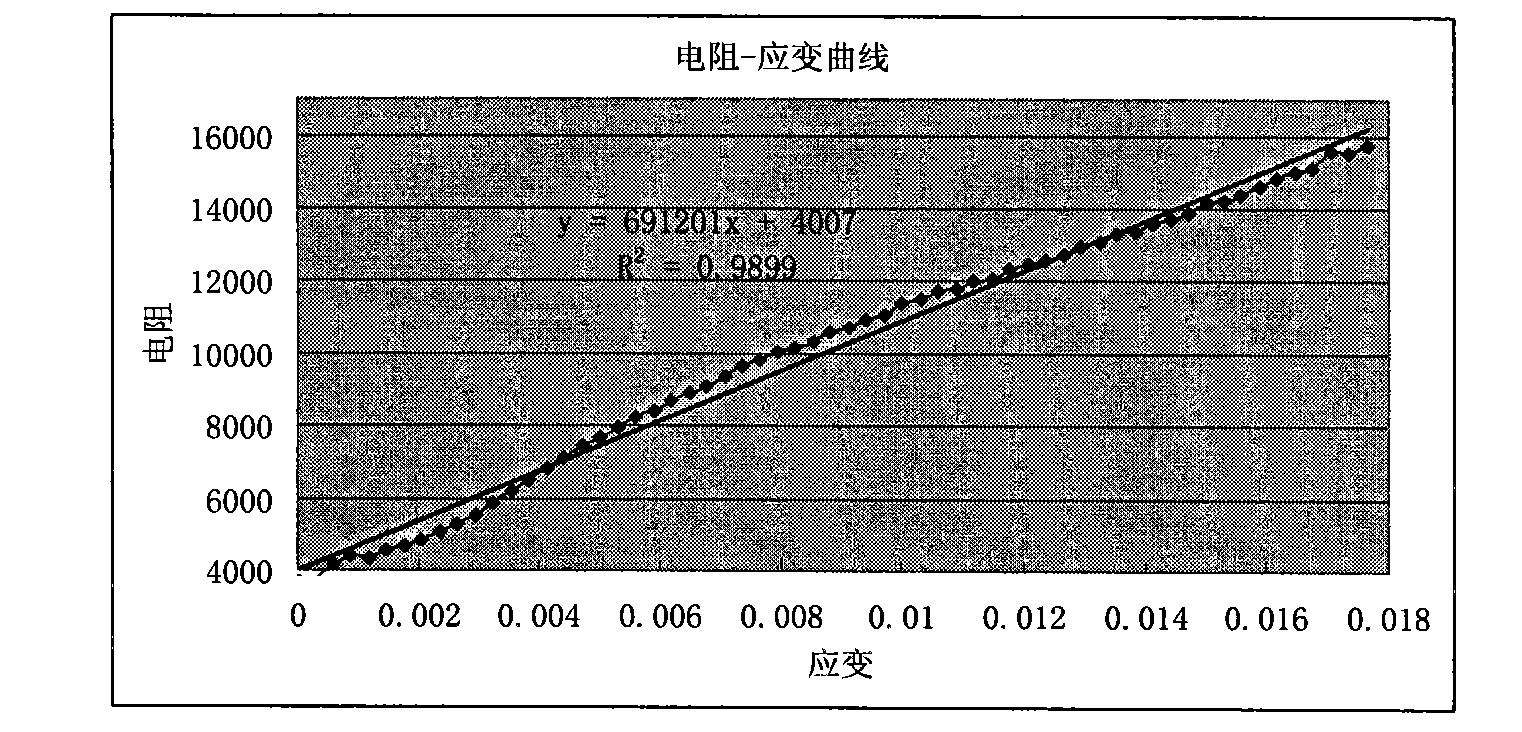

Sensitive material for tensile deformation test and preparation method thereof

InactiveCN101914290AGood flexibilityLow tensile modulusElectrical/magnetic solid deformation measurementFiberNano sio2

The invention relates to a sensitive material for a tensile deformation test and a preparation method thereof. The method comprises the following steps of: stirring and mixing liquid-state silicon rubber, chopped carbon fiber, conductive carbon black, nano-SiO2, a curing agent and a coupling agent serving as raw materials at normal temperature and under normal pressure in turn; removing air bubbles by vacuumizing; and molding. The obtained sensitive material for the tensile deformation test has high flexibility and very small tensile modulus and does not affect the deformation of a test structure or a test material in a testing process; and simultaneously, the sensitive material has the advantages of high sensitivity, performance stability, simple preparation method, wide raw material source and low manufacturing cost.

Owner:CHINA UNIV OF MINING & TECH

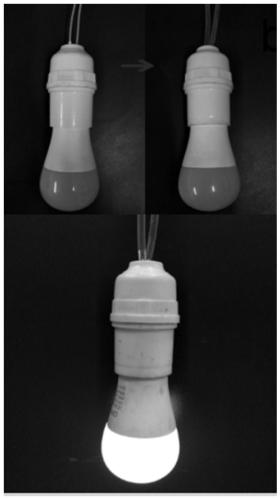

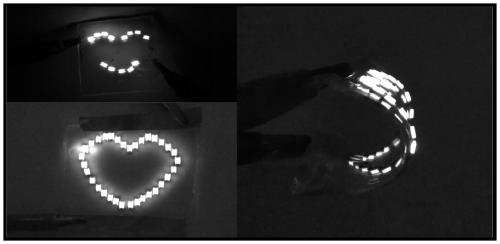

Application of multifunctional organic gel as conductive medium

ActiveCN110111922AImprove solubilityImprove tensile propertiesElectric circuit arrangementsConductive materialPolymer scienceSolvent

The invention discloses the application of a multifunctional organic gel as a conductive medium. The preparation raw materials of the multifunctional organic gel comprise a solvent, a monomer, a crosslinking agent, an electrolyte salt and an initiator, the volume ratio of the solvent to the monomer is 1:5 to 5:1, the molar ratio of the crosslinking agent to the monomer is 0.05% to 10%, the molar ratio of the initiator to the monomer is 0.1% to 10%, and the concentration of the electrolyte salt in a mixed solution of all the raw materials is 0.1 mol / L to 5 mol / L. When the organic gel is used asa conductive medium, since the organic gel has good electrical conductivity, a bulb can be lighted when the organic gel is used as a conductive line to energize the bulb, and an LED lamp bead can belighted when the organic gel is used as a conductive substrate to energize the LED lamp bead attached to the conductive substrate.

Owner:XI AN JIAOTONG UNIV

Wave-absorbing composite foam and preparation method thereof

ActiveCN110699968ABroad application prospectsHigh densityLiquid surface applicatorsSynthetic resin layered productsGlass microspherePolymer chemistry

The invention belongs to the technical field of wave-absorbing materials, and discloses wave-absorbing composite foam and a preparation method thereof. An electromagnetic wave incoming surface comprises a glass fiber reinforced plastic layer, a wave-absorbing layer and a carbon fiber cloth reflecting layer sequentially from outside to inside, and an adhesive layer is arranged between the layers, wherein the wave-absorbing layer is obtained by (1) laying a layer of glass fiber cloth flatly; (2) applying a mixture of liquid thermosetting resin and curing agent onto the surface of the glass fibercloth by liquid electrostatic spraying; (3) vertically and directionally implanting a carbon wave-absorbing material on the basis of the step (2) by adopting an electrostatic flocking method; (4) forming a layer of hollow glass microspheres by powder electrostatic spraying; (5) continuously spraying a mixture of liquid thermosetting resin and curing agent; and (6) stacking a layer of glass fibercloth again on the basis of the step (5) to obtain the wave-absorbing layer. The wave-absorbing composite foam structure obtained herein allows weaponry to be efficiently invisible.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

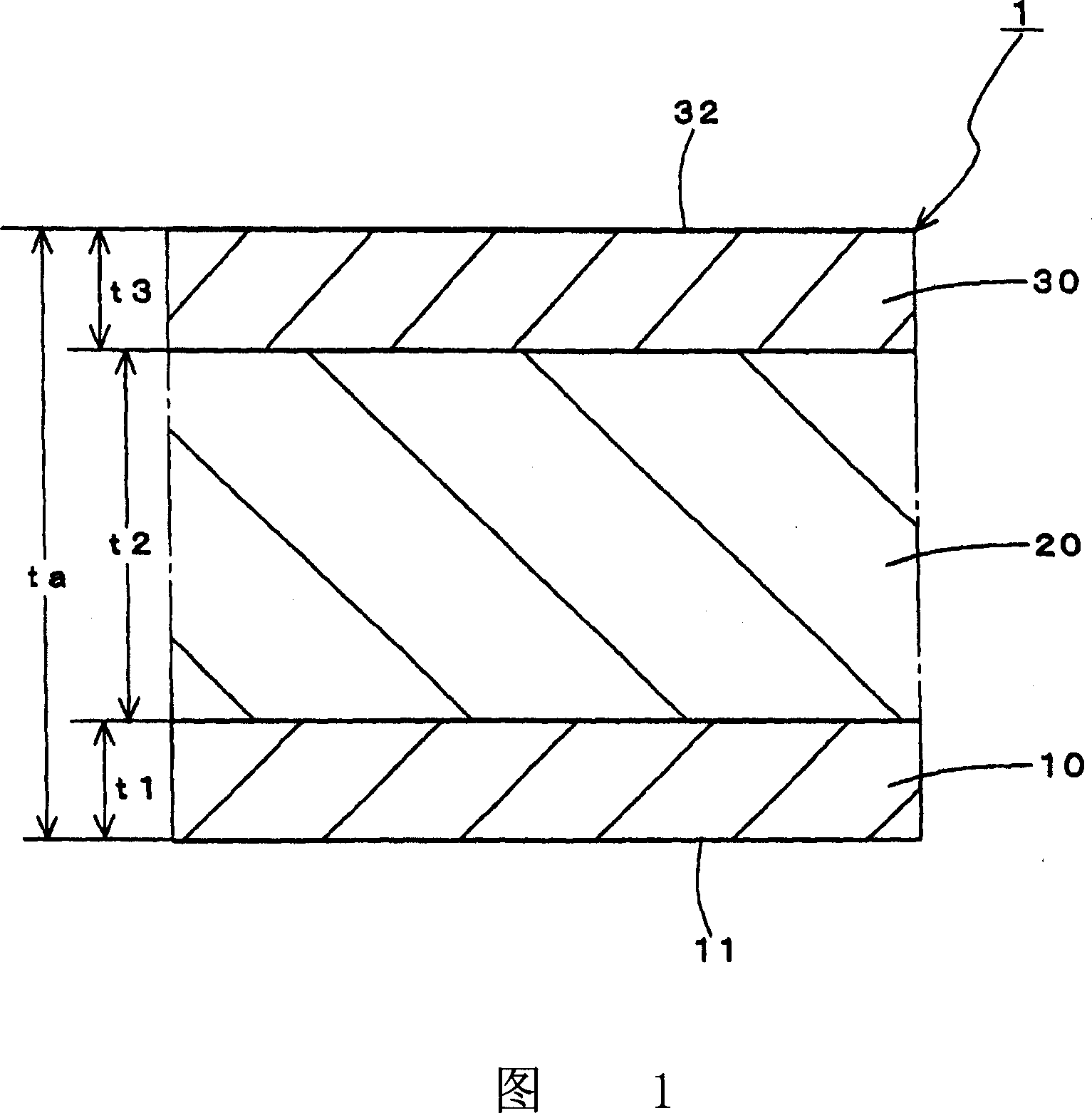

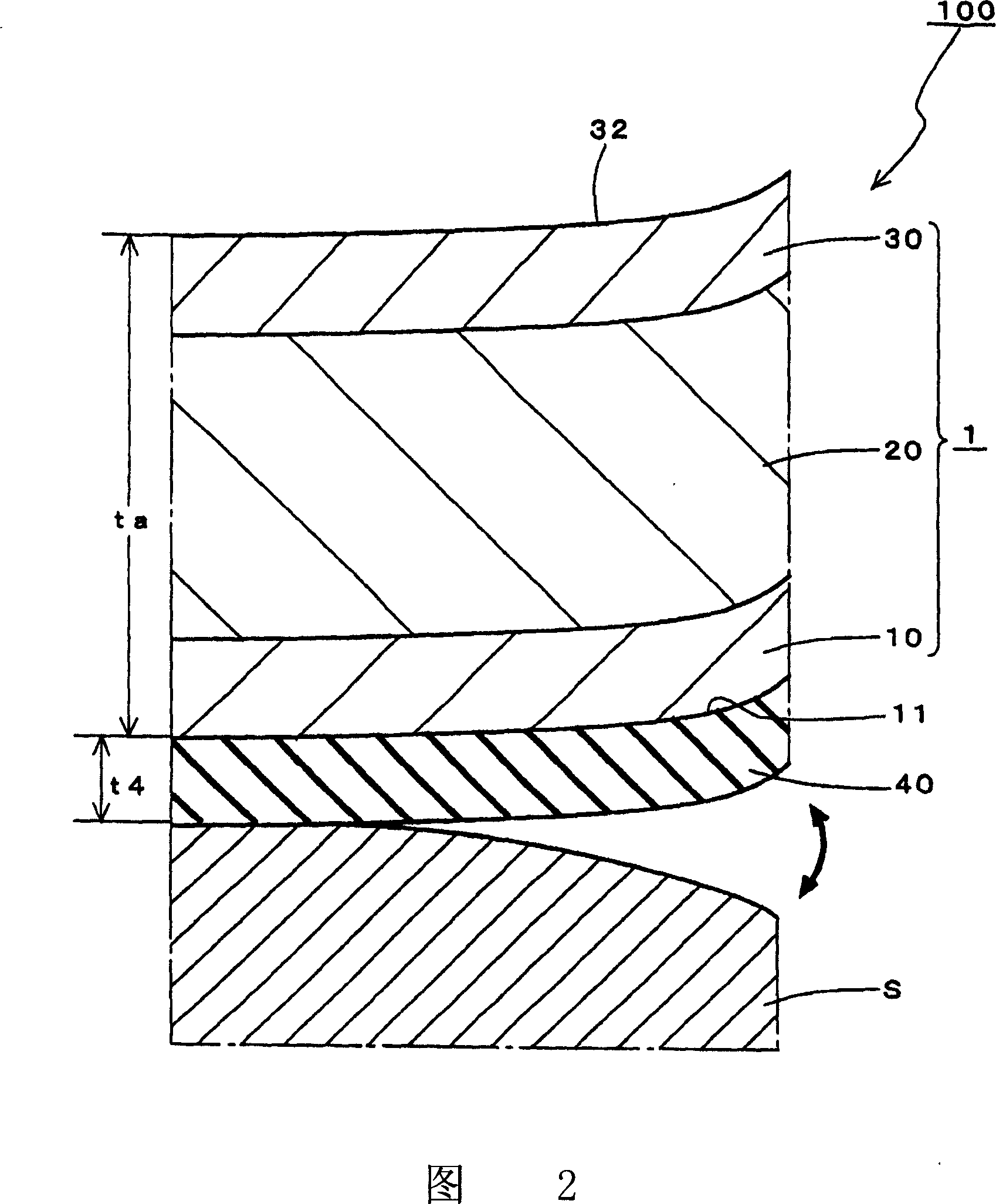

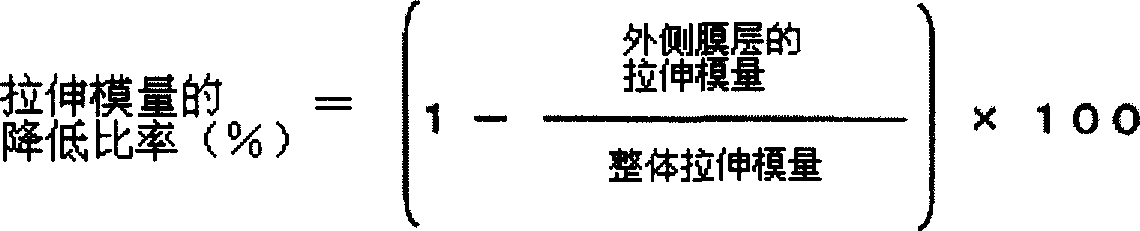

Support substrate for surface protection film and surface protection film

InactiveCN1982048ALow tensile modulusEasy to peelSynthetic resin layered productsDomestic articlesSubstrate (building)Building material

A substrate of the surface protective film giving a film attached to the surface of a building material, a painted steel sheet, etc. for the purpose of prevention of damage easy applicability and easy removability and a surface protective film using the same, that is, a substrate of the surface protective film comprised of at least two film layers with different physical properties, wherein an outermost film layer forming an outermost surface corresponding to another surface facing one surface of the substrate exhibits a tensile modulus of elasticity based on JIS-K-7127 (2000) lower than a tensile modulus of elasticity of the substrate as a whole and a surface protective film comprised of such a substrate of the surface protective film on one surface of which an adhesive layer is formed.

Owner:FUTAMURA CHEM +1

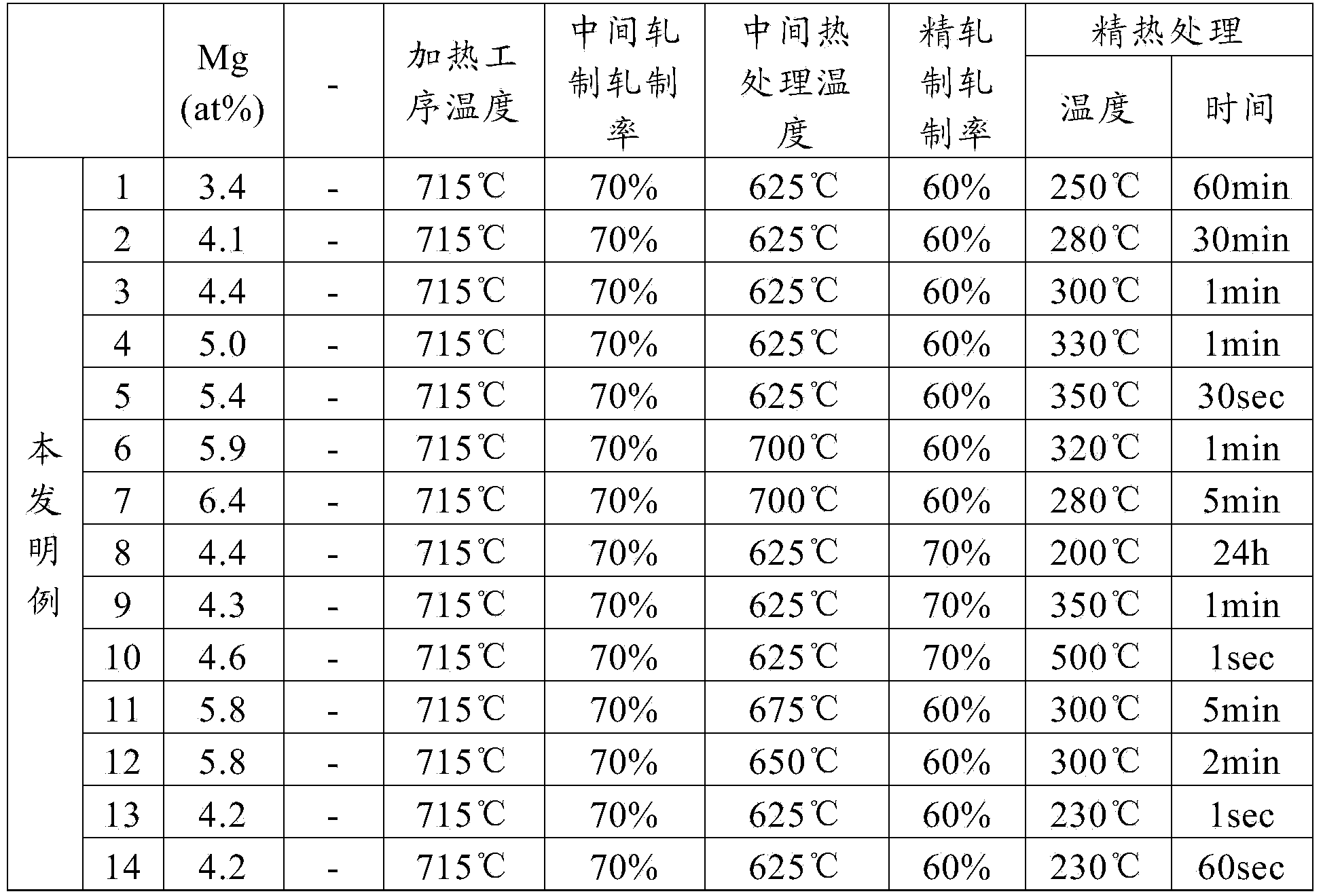

Copper alloy for electronic devices, method of manufacturing copper alloy for electronic devices, copper alloy plastic working material for electronic devices, and component for electronic devices

InactiveCN103842531ALow tensile modulusHigh yield strengthSingle bars/rods/wires/strips conductorsConductive materialYoung's modulusLead frame

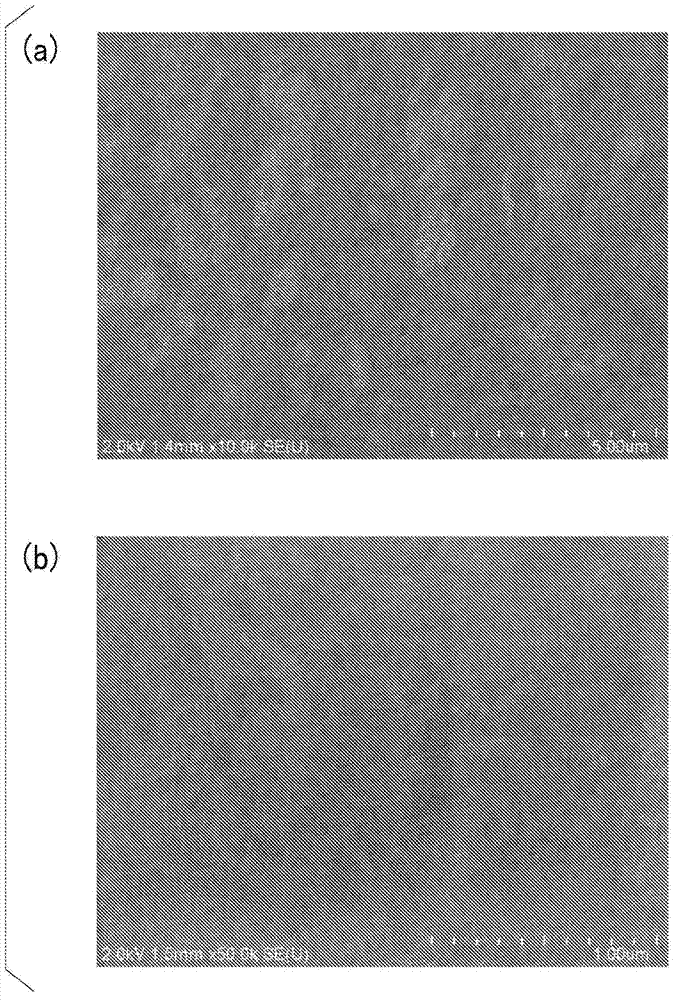

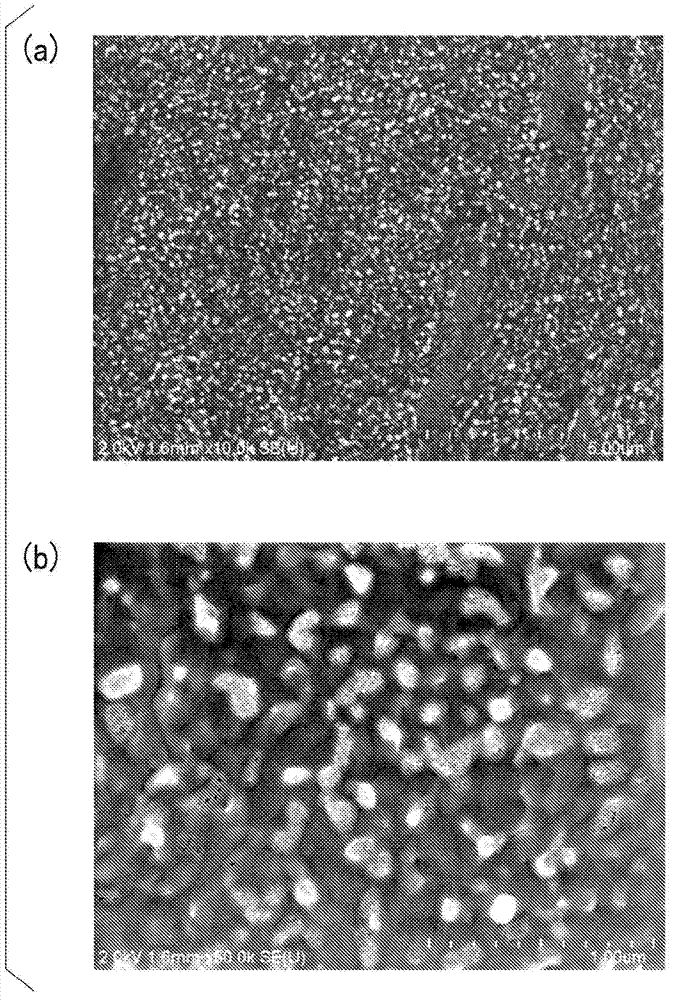

Provided is a copper alloy for electronic devices which has a low Young's modulus, high proof stress, high conductivity and excellent bending workability, and which is suitable for electronic device components such as terminals, connectors, relays, and lead frames; also provided are a method of manufacturing the copper alloy for electronic devices, a copper alloy plastic working material for electronic devices, and a component for electronic devices. This copper alloy contains 3.3-6.9 atom% Mg, the rest being substantially Cu and unavoidable impurities. Setting X to the Mg concentration in atom%, the conductivity sigma (%IACS) is in the range sigma @ {1.7241 / (-0.0347X2 + 0.6569X + 1.7)} 100, and the average crystal particle diameter is in the range 1-100mum. Further, after intermediate heat treatment, the average crystal particle diameter in the copper material before finish processing is in the range 1-100mum.

Owner:MITSUBISHI MATERIALS CORP

Copper alloy for electronic equipment, method for producing copper alloy for electronic equipment, rolled copper alloy material for electronic equipment, and part for electronic equipment

ActiveCN103842551AInhibition of power failureLow tensile modulusSingle bars/rods/wires/strips conductorsApparatus for heat treatmentMetallurgyStress relaxation

A copper alloy for electronic equipment comprises between 3.3 at% and 6.9 at% of Mg, with the balance being substantially Cu and inevitable impurities. When the Mg concentration is X at%, the conductivity sigma (% IACS) is within a range of sigma < {1.7241 / (-0.0347 X2 + 0.6569 X + 1.7)} 100, and the stress relaxation percentage after 1,000 hours at 150 C is 50% or less.

Owner:MITSUBISHI MATERIALS CORP

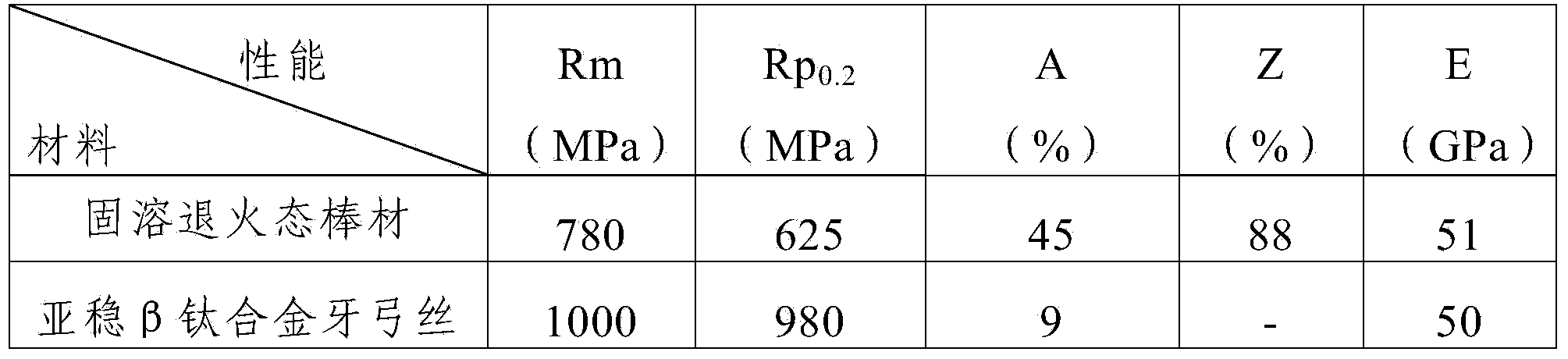

High-intensity low-modulus metastable beta titanium alloy tooth arch wire

InactiveCN103627929AGood biocompatibilityNot corrosiveArch wiresBiocompatibility TestingHigh intensity

The invention provides a high-intensity low-modulus metastable beta titanium alloy tooth arch wire which is characterized by comprising the following nominal chemical components in percentage by mass: 11 percent of Mo, 3 percent of Nb, 5 percent of Zr, 4 percent of Sn and the balance of titanium and unavoidable impurities. The tooth arch wire provided by the invention has good biocompatibility, high tensile strength, low elastic modulus, a wide elastic range and excellent resilience; moreover, the orthodontic force of the high-intensity low-modulus metastable beta titanium alloy tooth arch wire is lower than that of a stainless steel wire, but is higher than that of a nickel-titanium alloy wire, the elastic modulus of the high-intensity low-modulus metastable beta titanium alloy tooth arch wire is only one fourth to one third of that of the stainless steel wire, and the high-intensity low-modulus metastable beta titanium alloy tooth arch wire has a wider elastic range and a wider orthodontic displacement range than the stainless steel wire. Utilization of the tooth arch wire provided by the invention can obtain the stable and mild orthodontic force and durable and moderate displacement and can realize larger displacement of teeth without replacing an orthopedic wire or only by replacing the orthopedic wire a little.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

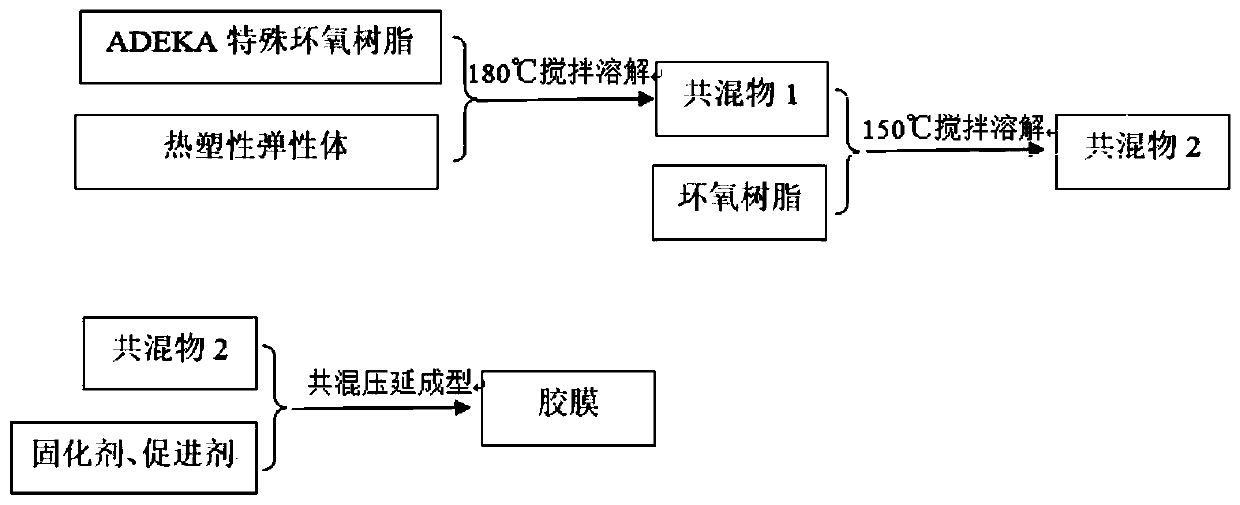

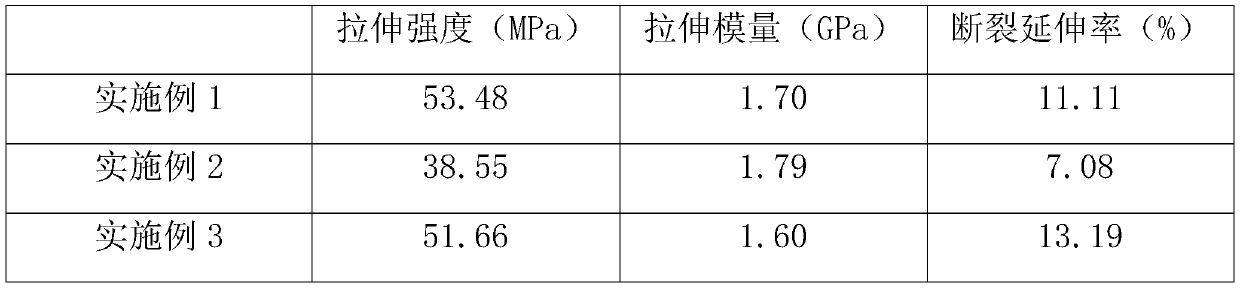

Preparation method of low-modulus and high-strength resin adhesive film

InactiveCN110885652AImprove adhesionImprove application stiffnessPolyureas/polyurethane adhesivesFilm/foil adhesives without carriersElastomerPolymer science

The invention provides a preparation method of a low-modulus and high-strength resin adhesive film. The adhesive film comprises 100 g of ADEKA special epoxy resin, 3-30 g of a thermoplastic elastomer,8-10 g of a common epoxy resin, 4 g of a curing agent and 2 g of a promoter. The preparation method comprises the following steps: blending the thermoplastic elastomer with the ADEKA special epoxy resin at 180 DEG C, cooling the obtained mixture to 150-155 DEG C, mixing the epoxy resin, cooling the mixed resin to 60-70 DEG C, pre-curing the mixed resin with the curing agent, performing blending,and carrying out calendering molding on the carrier in order to prepare the adhesive film. The adhesive film prepared in the invention has the characteristics of high temperature resistance, low modulus, high strength and high toughness, and is mainly used between layers of a composite material laminated plate in the aerospace field to improve the bearing capacity of the laminated plate.

Owner:WUHAN UNIV OF TECH

Low-tensile-modulus one-component moisture cured polyurethane sealant and preparation method thereof

InactiveCN105505281AGood comprehensive mechanical propertiesHigh tensile strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryCalcium carbonate

The invention discloses a low-tensile-modulus one-component moisture cured polyurethane sealant. The low-tensile-modulus one-component moisture cured polyurethane sealant is prepared from, by weight, 15-25 parts of isophorone diisocyanate, 30-45 parts of two-functionality polyether polyol, 10-20 parts of three-functionality polyether polyol, 0-0.5 part of dibutyltin dilaurate, 20-30 parts of calcium carbonate, 5-10 parts of hydrophobic modified gas-phase silicon dioxide, 0.5-1.5 parts of oxazolidinone and 0.5-1.5 parts of iron oxide black. The invention further provides a method for preparing the low-tensile-modulus one-component moisture cured polyurethane sealant. The one-component moisture cured polyurethane sealant still has lower tensile modulus at low temperature; meanwhile, the one-component moisture cured polyurethane sealant further has good tensile strength and excellent elongation at break and elastic recovery, and the comprehensive mechanical property is excellent.

Owner:安徽万诚达新型材料有限公司

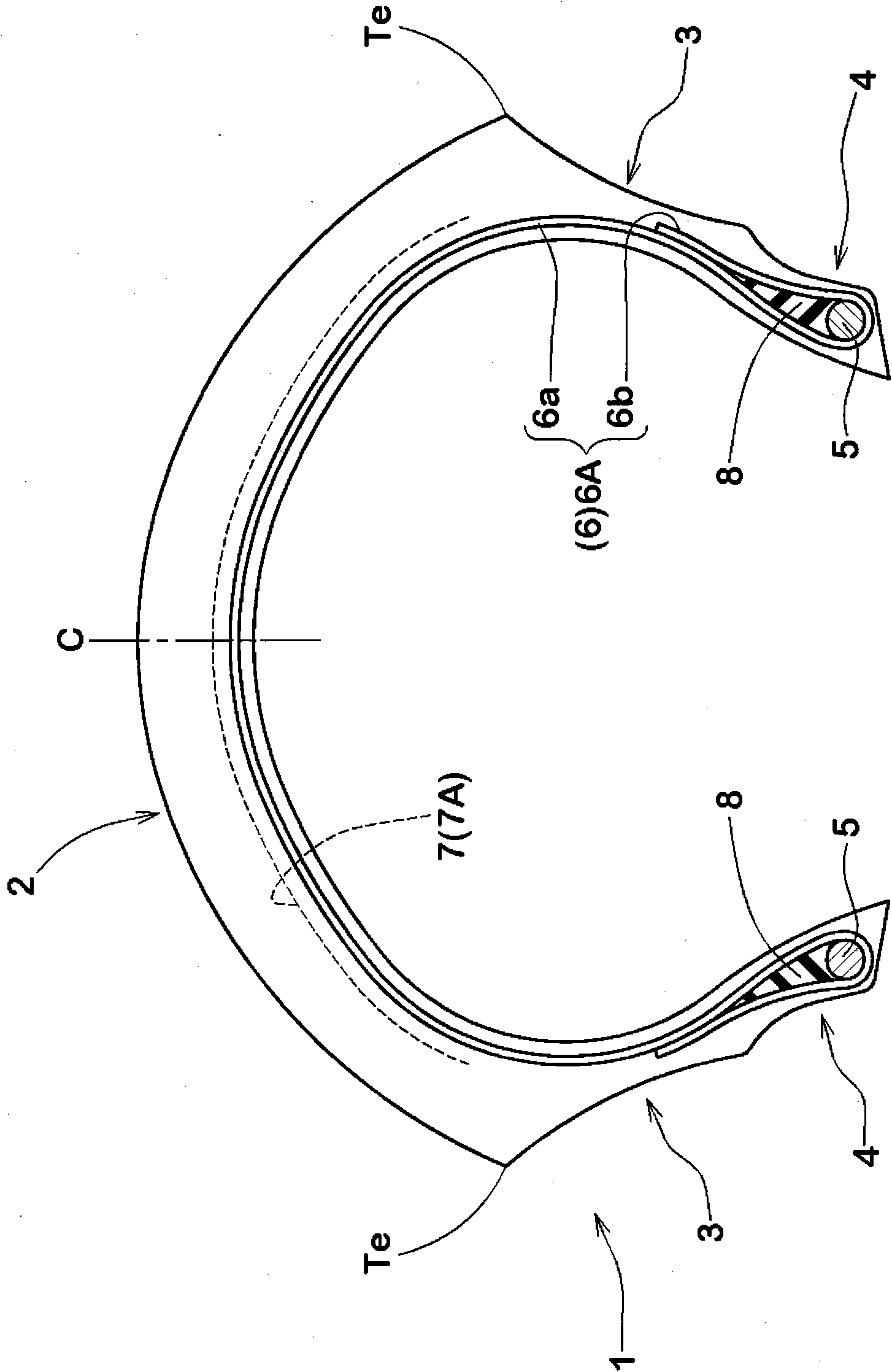

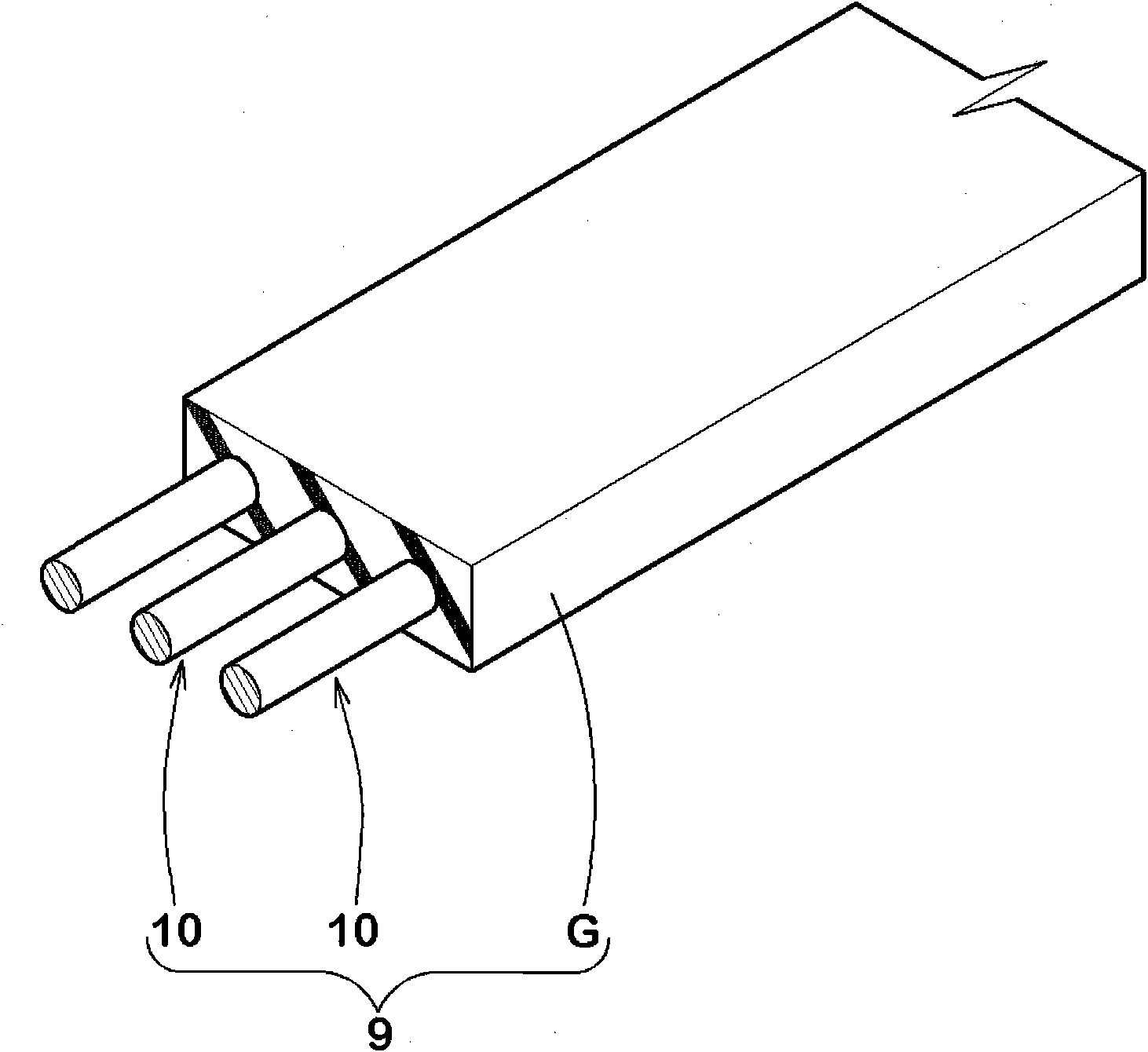

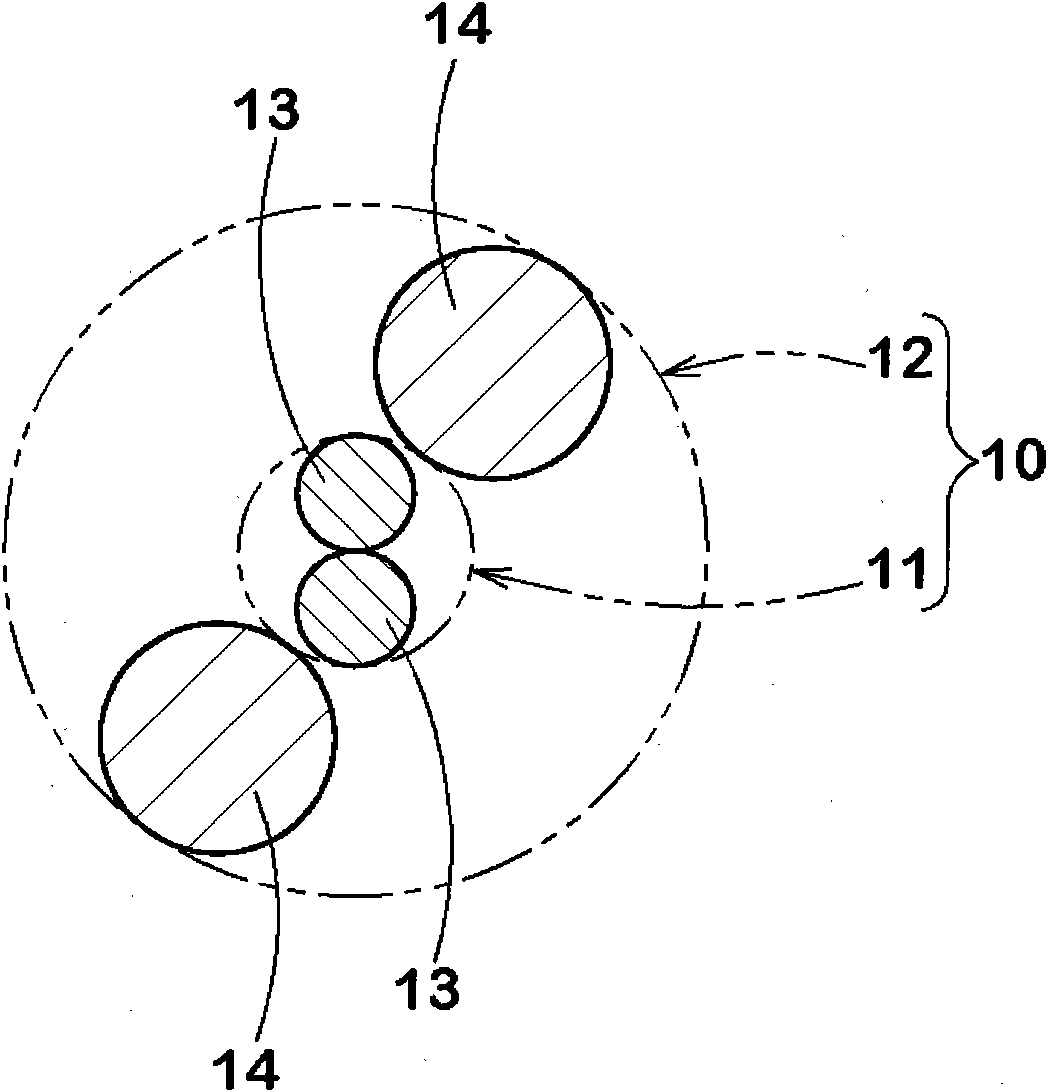

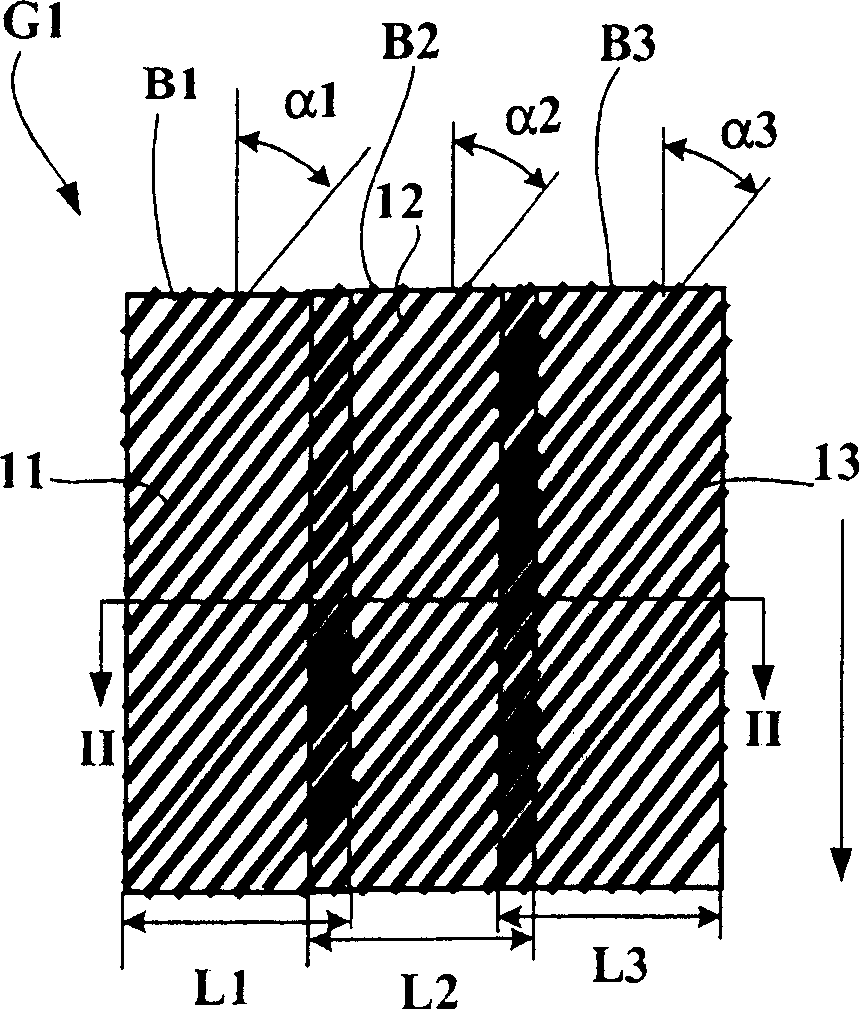

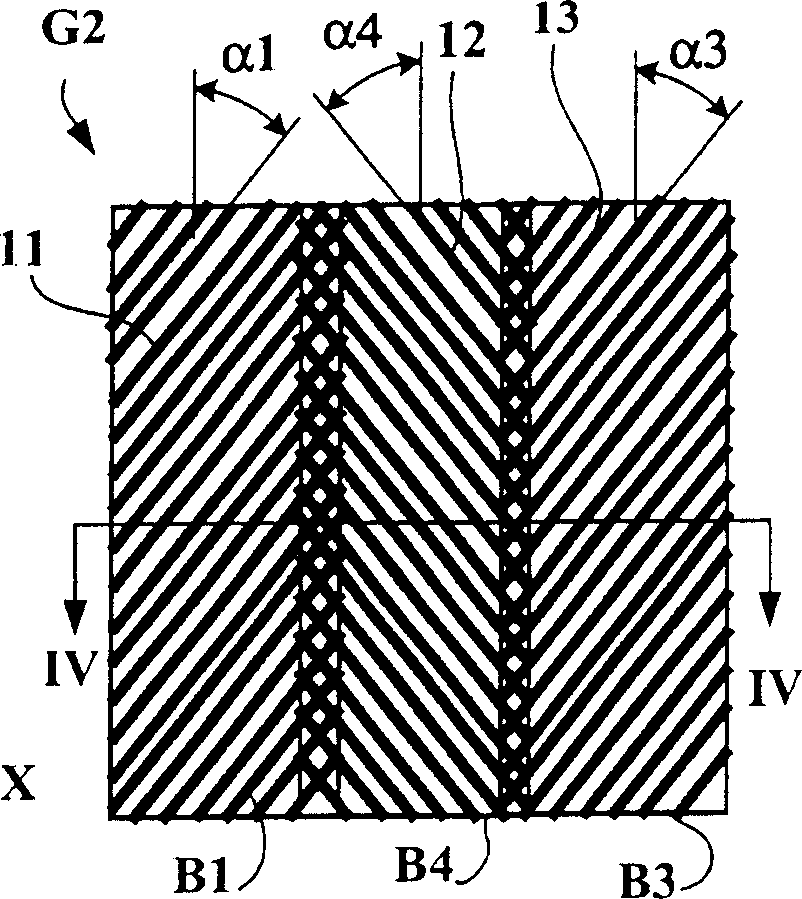

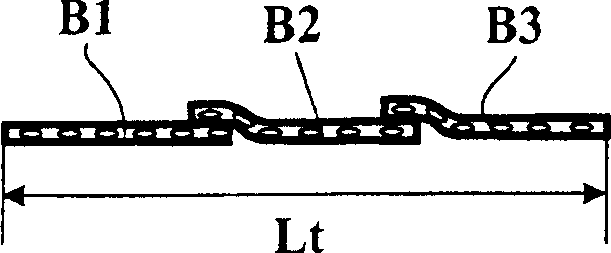

Radial type sidewall reinforcement

InactiveCN1512944AAvoid spreadingFirmly connectedPneumatic tyre reinforcementsTyre sidewallsYarnEngineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

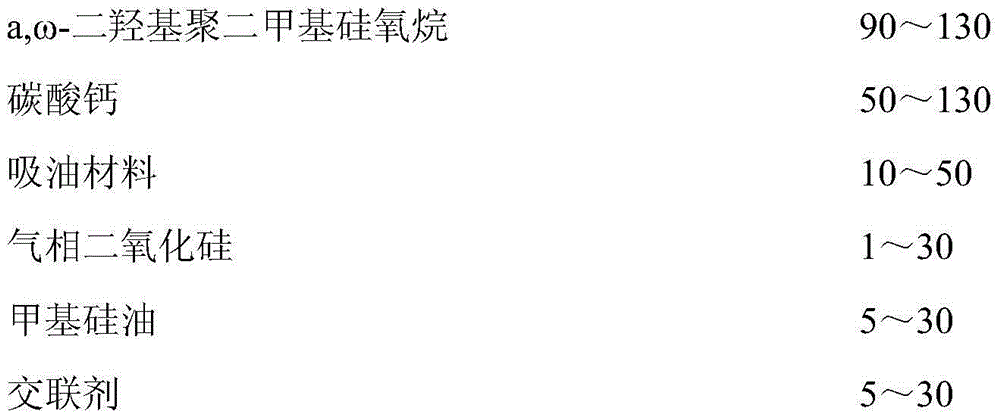

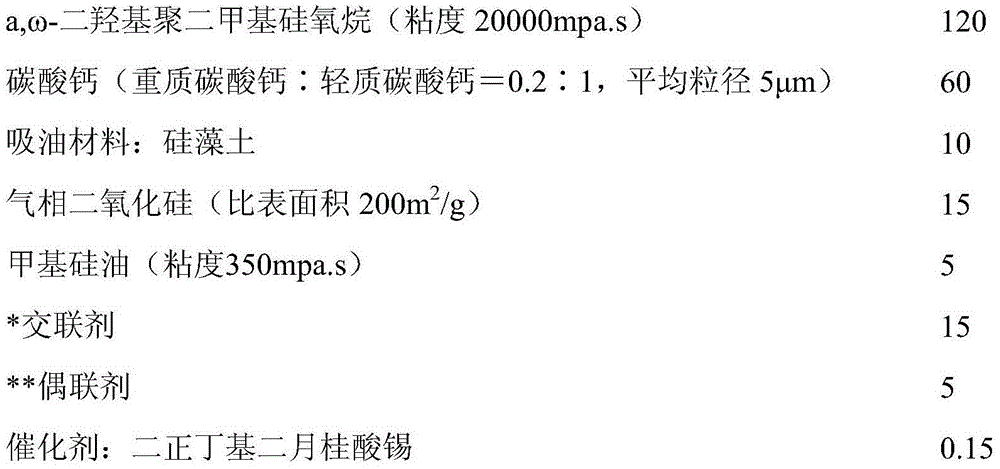

Silicone sealant for asphalt road joints and preparation method thereof

InactiveCN104449549AGood compatibilityMeet the needs of sealingNon-macromolecular adhesive additivesOther chemical processesGas phaseRoad surface

The invention discloses a silicone sealant for asphalt road joints. The silicone sealant for asphalt road joints is prepared from the following raw materials in parts by weight: 90-130 parts of alpha, omega-dihydroxyl polydimethylsiloxane, 50-130 parts of calcium carbonate, 10-50 parts of oil absorption material, 1-30 parts of fumed silica, 5-30 parts of methylsilicone oil, 5-30 parts of cross-linking agent, 0.5-5 parts of coupling agent and 0.01-1 parts of catalyst. The invention further discloses a preparation method of the silicone sealant for asphalt road joints. The silicone sealant disclosed by the invention has excellent weather fastness and ageing resistance, low tensile modulus, and good adhesion performance, solves the problems of adhesion cracking occurring after immersion, heat treatment, and cold-drawing hot-pressing of the silicone sealant for the existing road surface joints in the prior art, and is beneficial to promoting the wide use of the silicone sealant in the field of road sealing, thus the safety of roads can be effectively guaranteed and improved.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

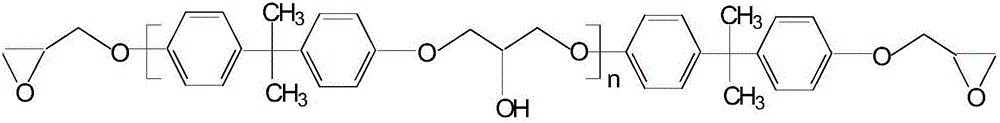

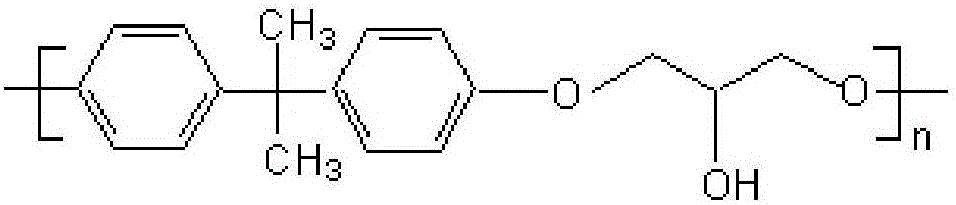

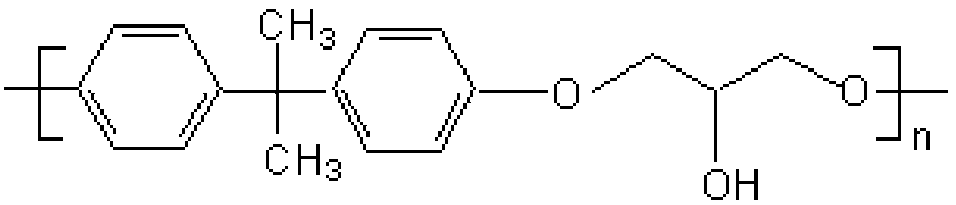

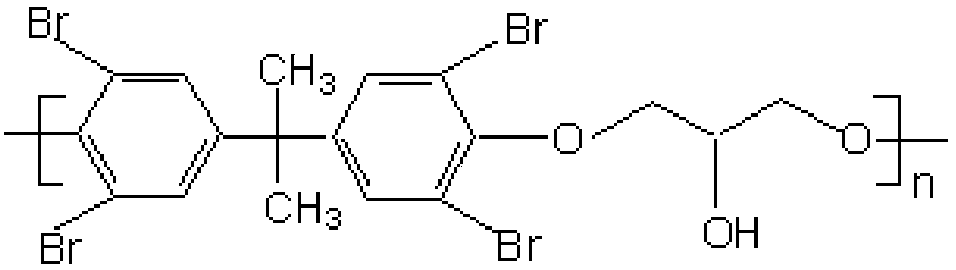

Synthesis method of phenoxy resin

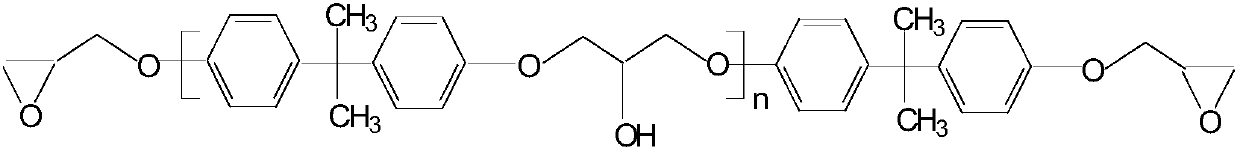

The invention discloses a synthesis method of a phenoxy resin. The method comprises the following steps: 1) uniformly mixing a bisphenol A epoxy resin and BPA (bisphenol A) in a tank reactor, adding an ether solvent or ketone solvent, and heating until the materials are dissolved; 2) adding a catalyst, and heating to react; 3) when the molecular weight of the reaction product reaches 28000-32000, adding a mixed solvent into the tank reactor at uniform speed within 2-5 hours; and 4) filtering and discharging to obtain the phenoxy resin. The phenoxy resin prepared by the method has the advantages of favorable flowability, low viscosity and low facility requests, can perform reaction in the tank reactor, and is suitable for large-scale production. The phenoxy resin has moderate molecular weight, is suitable for participating in blending, and is used as a modifier for plastics, adhesives, paints and other resins. The added phenoxy resin can improve the flexibility of the curing system, lower the stretch modulus of the curing system and enhance the elongation percentage.

Owner:NINGBO ZHETIE JIANGNING CHEM

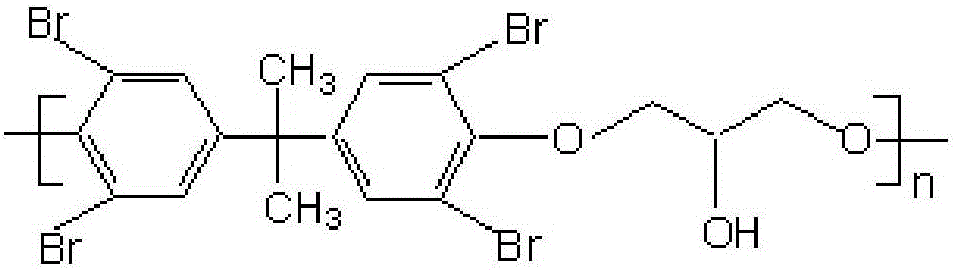

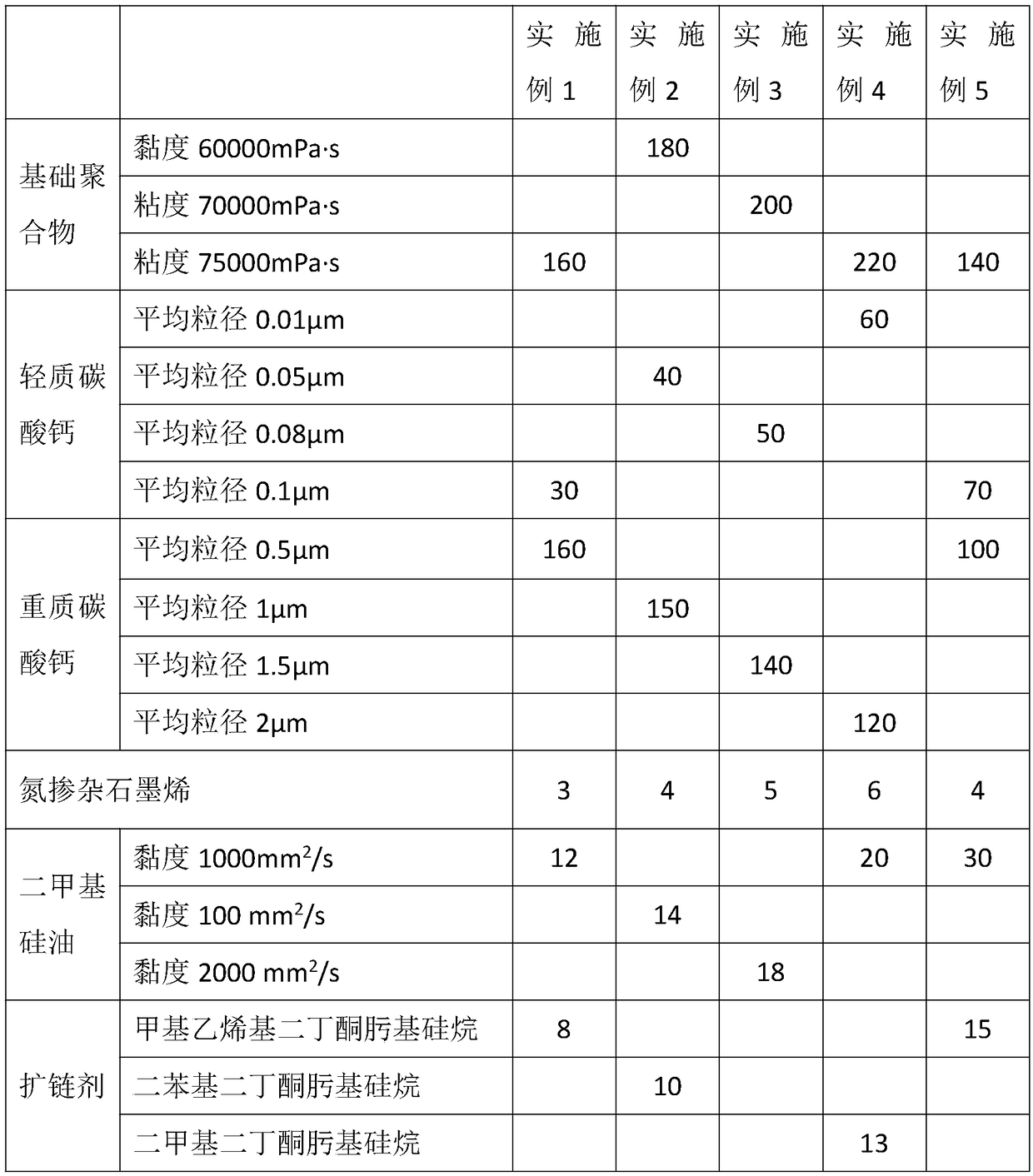

Room-temperature vulcanized neutral silicone weather-proof sealant, preparation method and application thereof

InactiveCN108977164ALow tensile modulusIncrease elasticityNon-macromolecular adhesive additivesCross-linkPolymer science

The invention discloses a room-temperature vulcanized neutral silicone weather-proof sealant which comprises the following components in parts by weight: 160-240 parts of basic polymer, 30-80 parts oflight calcium carbonate, 100-160 parts of heavy calcium carbonate, 3-6 parts of nitrogen-doped graphene, 12-30 parts of simethicone, 8-15 parts of chain extender, 13-19 parts of cross-linking agent,2.5-5 parts of coupling reagent and 0.2-0.4 part of catalyst; the basic polymer is polydimethylsiloxane with two ends terminated by hydroxy; the viscosity of the basic polymer at 25 DEG C is 60000-75000mPa.s. The silicone weather-proof sealant provided by the invention has low tensile modulus, high elasticity, high elasticity recovery rate, excellent weather fastness and excellent adhesive property; after the silicone weather-proof sealant is treated in the manner of cold draw-hot press, water soaking, and the like, the silicone weather-proof sealant is free from interface adhesion failure andcohesive failure; the high-displacement joint filling of the silicone sealant in super high-rise buildings and the sealing for concrete expansion joints of facilities, such as roads, bridges and airport runways, can be promoted.

Owner:林荣铨

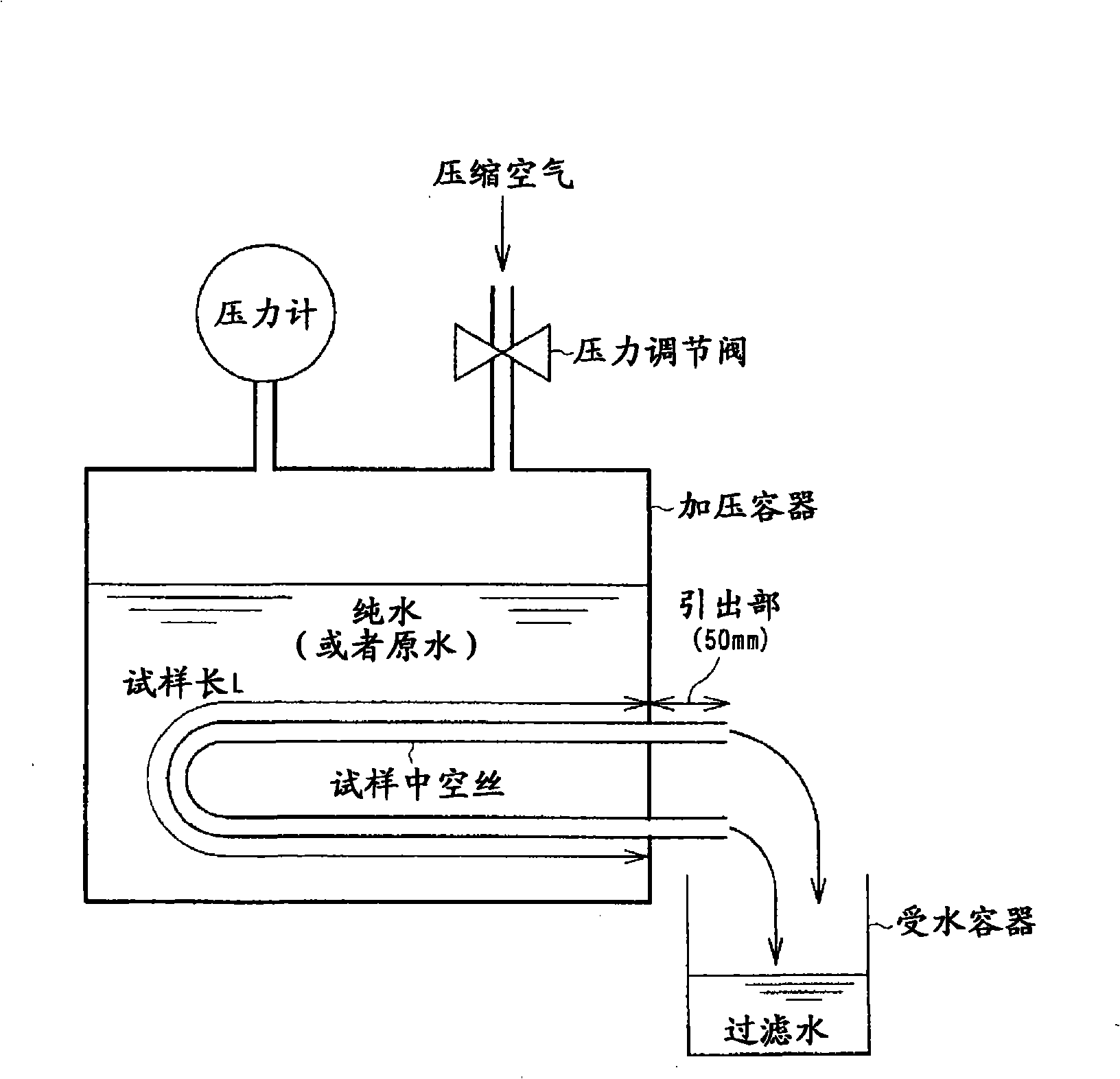

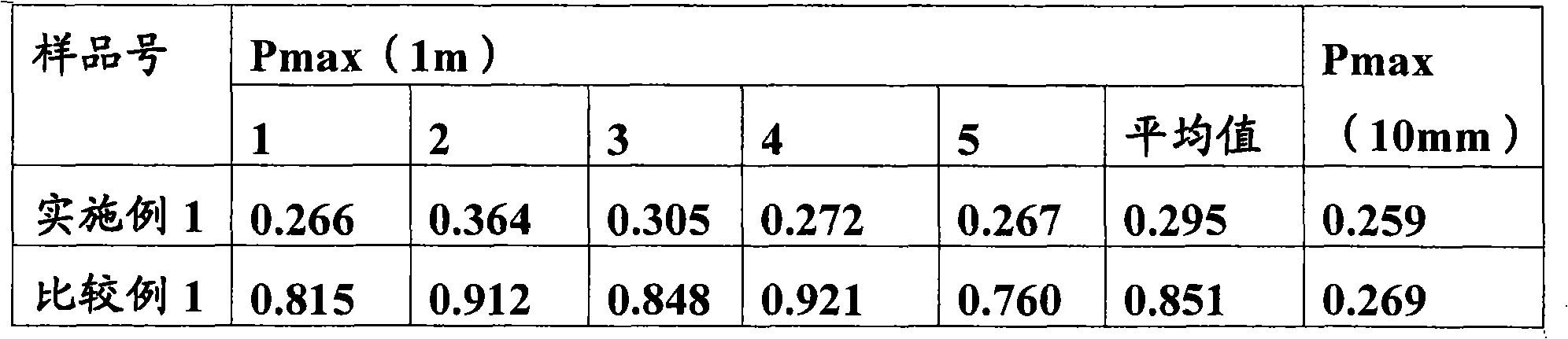

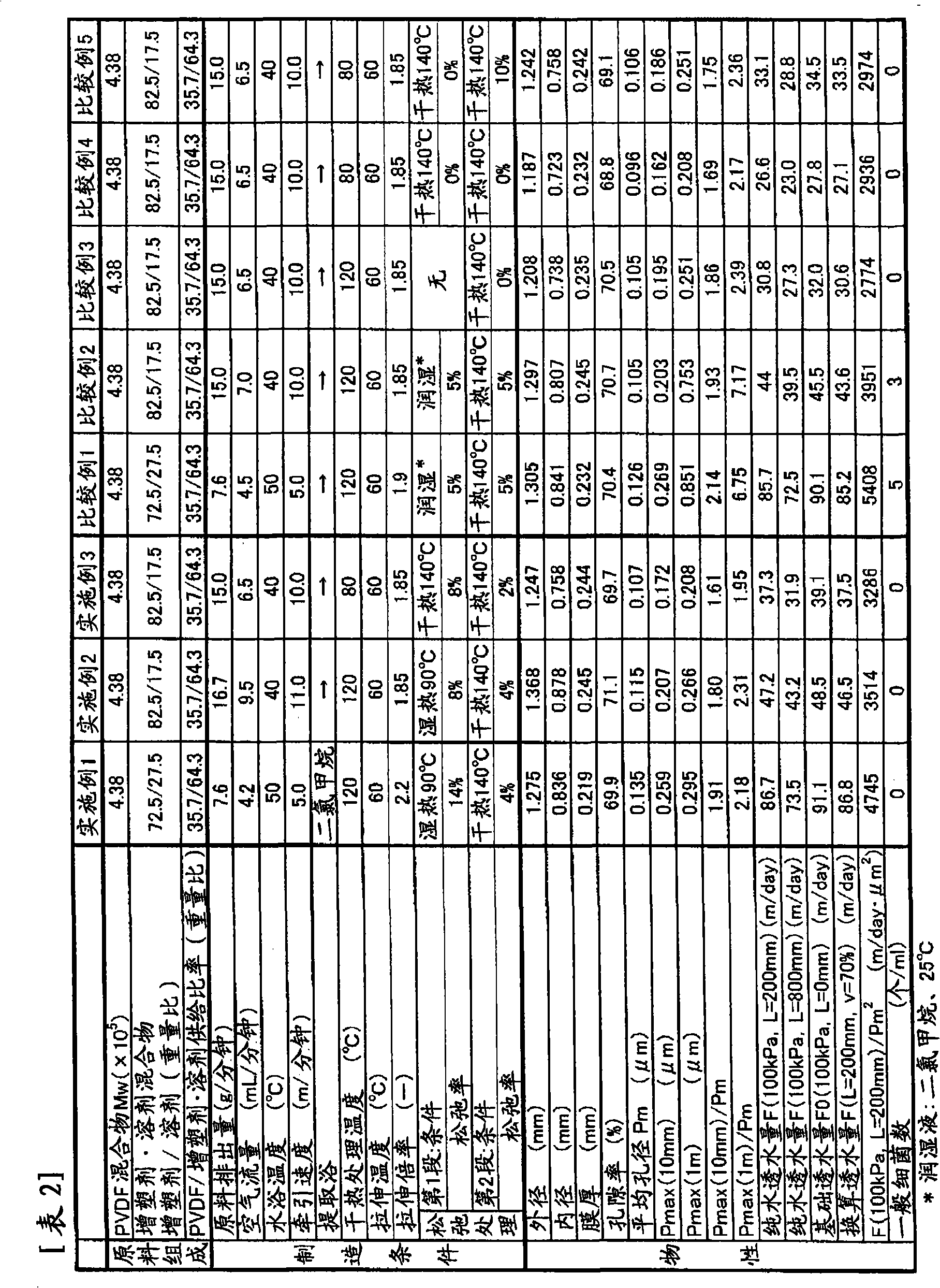

Vinylidene fluoride resin hollow fiber porous membrane and method for production thereof

InactiveCN101262932ALow tensile modulusGood water permeabilitySemi-permeable membranesMembranesFiberPorous membrane

Disclosed is a vinylidene fluoride resin follow fiber porous membrane which has a micropore (A) having a pore size (average pore size) appropriate for the treatment of (filtered) water and a more uniform pore size distribution, has a good microparticle (bacterium)-blocking efficiency through the micropore, and has a large transmissibility (B). The membrane comprises a vinylidene fluoride resin porous membrane in the form of a follow fiber and has the following characteristics (A) and (B): [Pmax(1m) / Pm], which is the ratio of the maximum pore size (Pmax(1m)) as determined by the bubble point method at the length of 1 m to the average pore size (Pm) as determined by the half-dry method (Pm = 0.05 to 0.20 [mu]m), is 4.0 or less; and (B) [F(L=200 mm, v=70%) / Pm<2>], which is the ratio of the converted value (F)(L=200 mm, v=70%)(m / day) in terms of void content (v=70%) of the transmissibility as measured under the conditions of difference in pressure of 100 kPa and water temperature of 25 C at the length (L) of 200 mm to the square value (Pm<2>) of the average pore size (Pm) ([mu]m), is 3000 (m / day[mu]m<2>) or higher. The membrane can be produced by a method comprising the step of subjecting a stretched vinylidene fluoride resin hollow fiber porous membrane to a relaxation process comprising at least two stages in a non-wet atmosphere.

Owner:KUREHA KAGAKU KOGYO KK

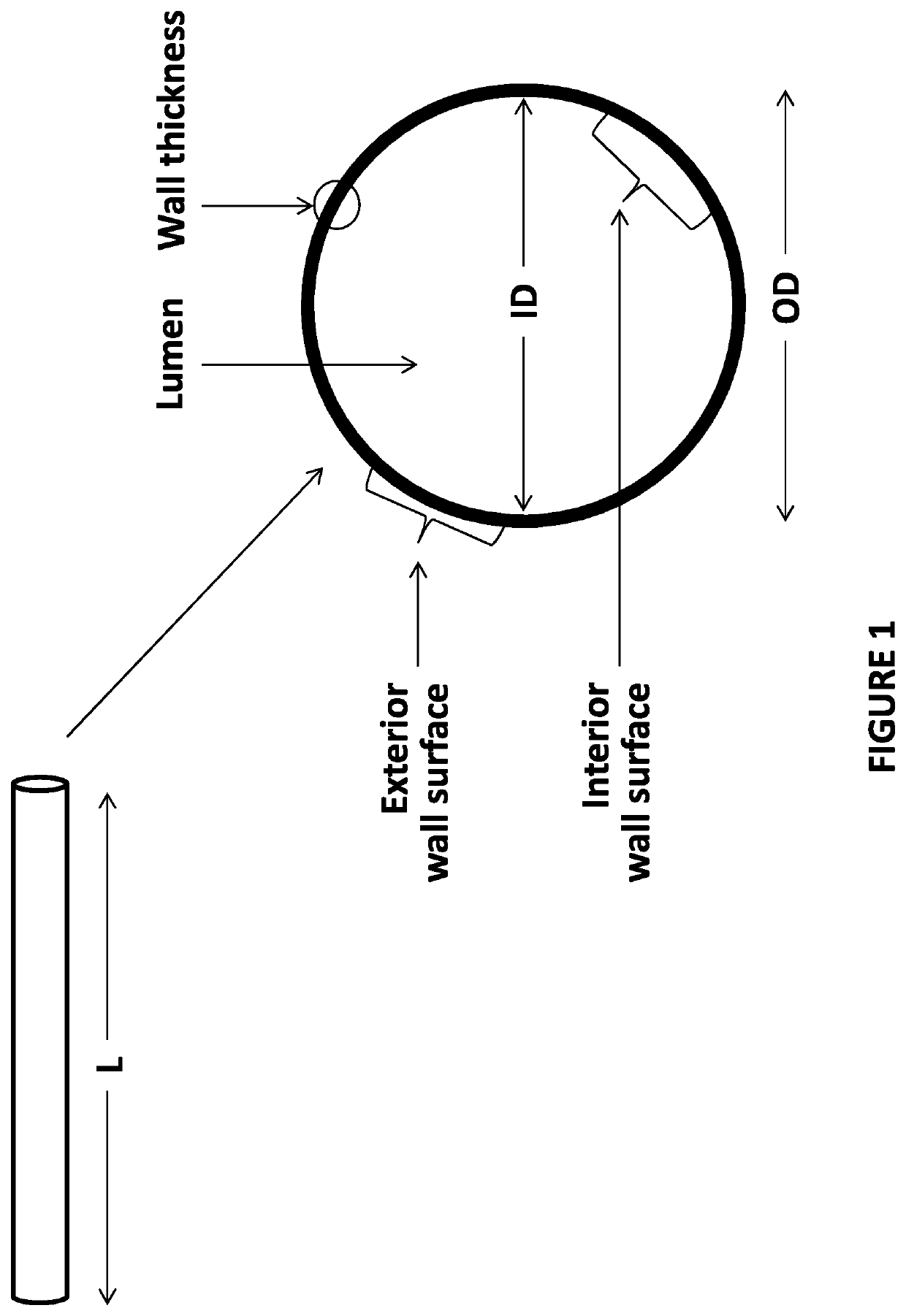

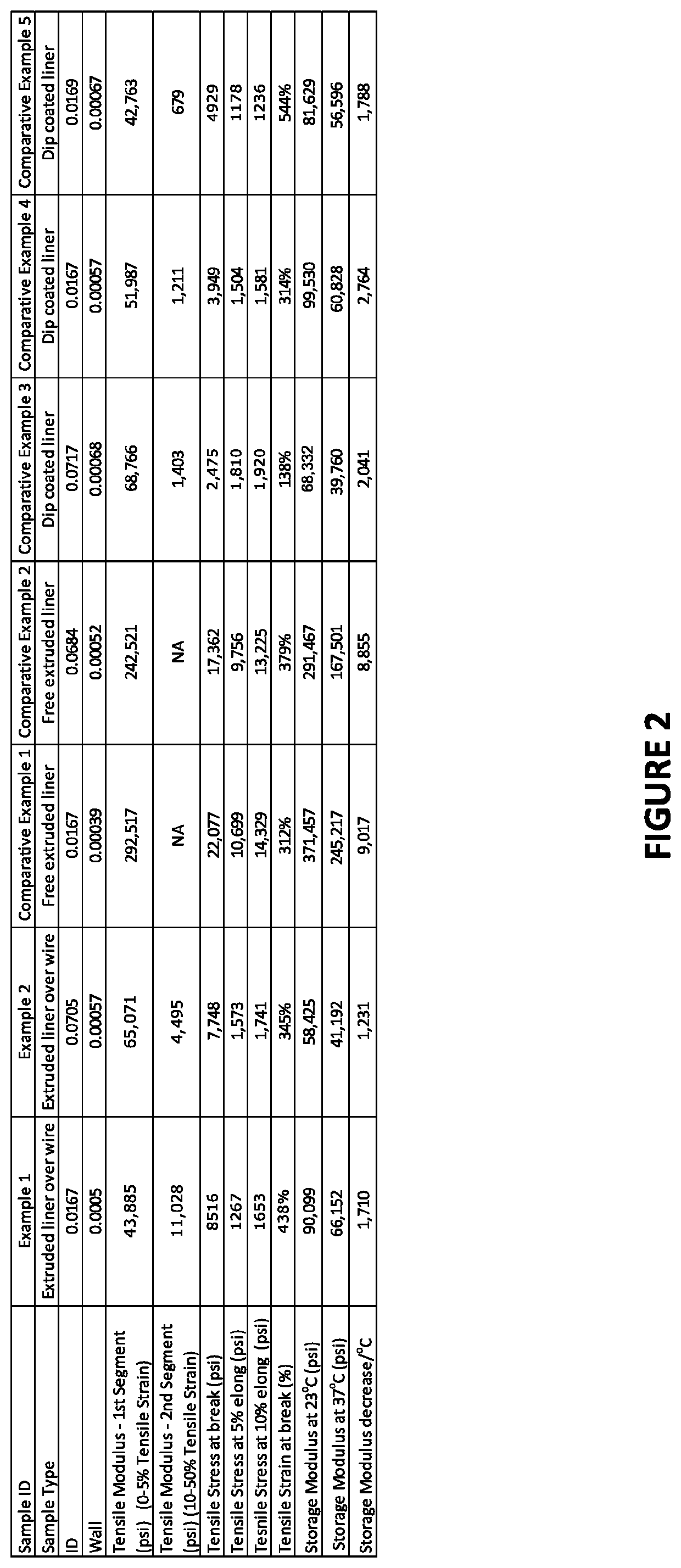

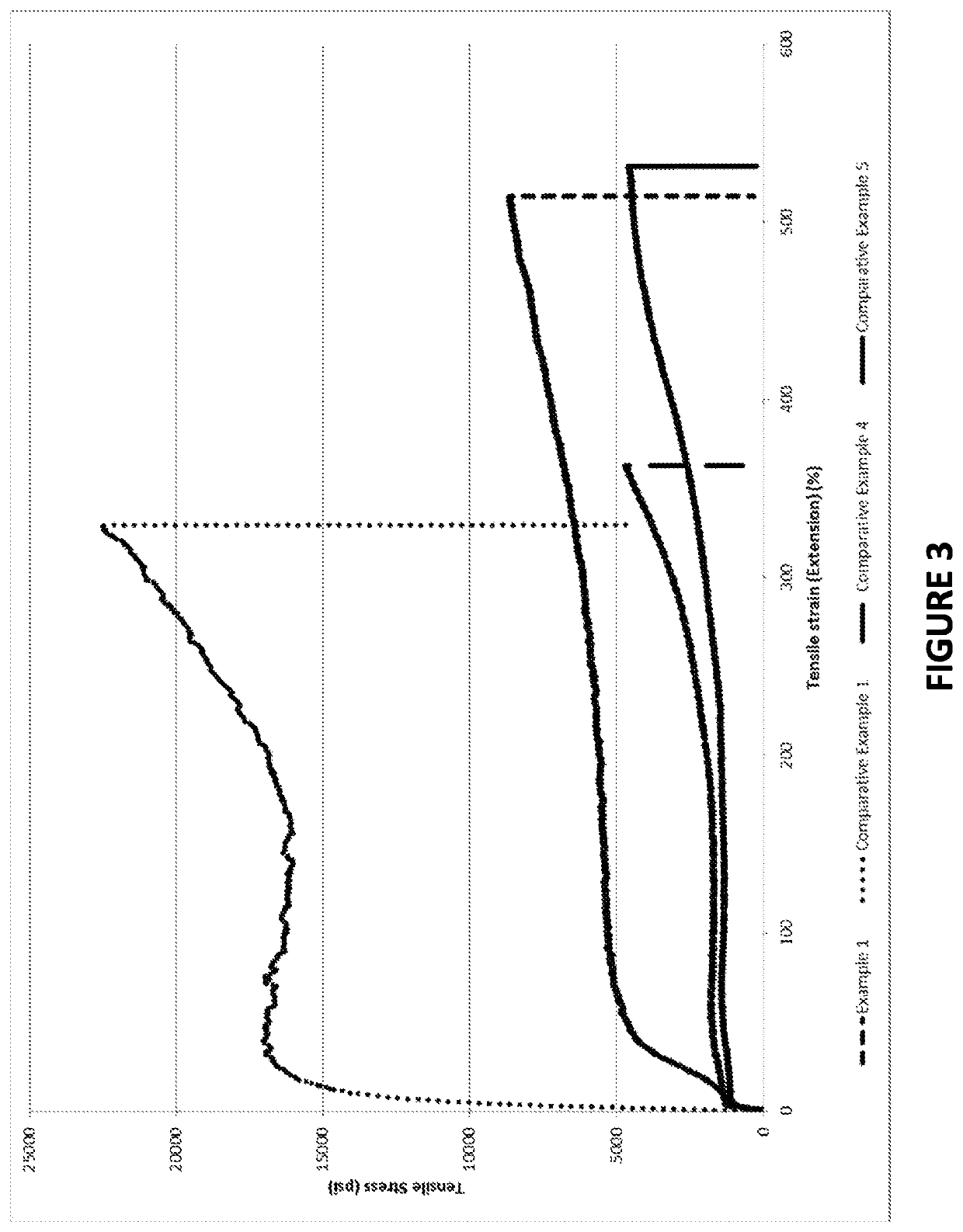

Catheter comprising PTFE liner

ActiveUS10744231B1Intermediate tensile strengthLow tensile modulusPharmaceutical delivery mechanismMedical devicesMedicineEngineering

The present disclosure provides catheters comprising polytetrafluoroethylene (PTFE) tubes with advantageous combinations of strength, flexibility, and size. Such tubes can exhibit features including an average wall thickness of 0.001″ or less, a tensile stress at break of greater than 5000 psi, and a storage modulus of less than 100,000 psi at 37° C. These tubes can be also be provided independently (i.e., not within a catheter) and can be employed in various applications.

Owner:ZEUS COMPANY INC

Bio-based polyester modified polylactic acid resin and its preparation method and processing molding method

The invention discloses a bio-based polyester modified polylactic resin, a preparation method and a processing forming method. The modified polylactic resin comprises 67-95wt% of polylactic acid, 4-30wt% of poly(butylene 2,5-furandicarboxylate), 0.5-1wt% of anti-oxidant and 0.5-2wt% of auxiliary agent. The preparation method is as follows: polylactic acid and poly(butylene 2,5-furandicarboxylate) are dried fully, then are subjected to banburying blending with the anti-oxidant and the auxiliary agent and a target product is obtained. The modified polylactic resin is renewable and environmental protection resin, the tensile strength is more than or equal to 60 MPa, the fracture percentage elongation is 180-240%, when the fracture percentage elongation is 240%, the tensile modulus is lowered by only 25%, and the tensile strength is lowered by only 16%, no pearl essence addition is needed, the surface has pearlescent color reflect light, and the modified polylactic resin can be used for preparing films, plates, sheets, foaming and injection molding plastic products and the like, and has wide industrial application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

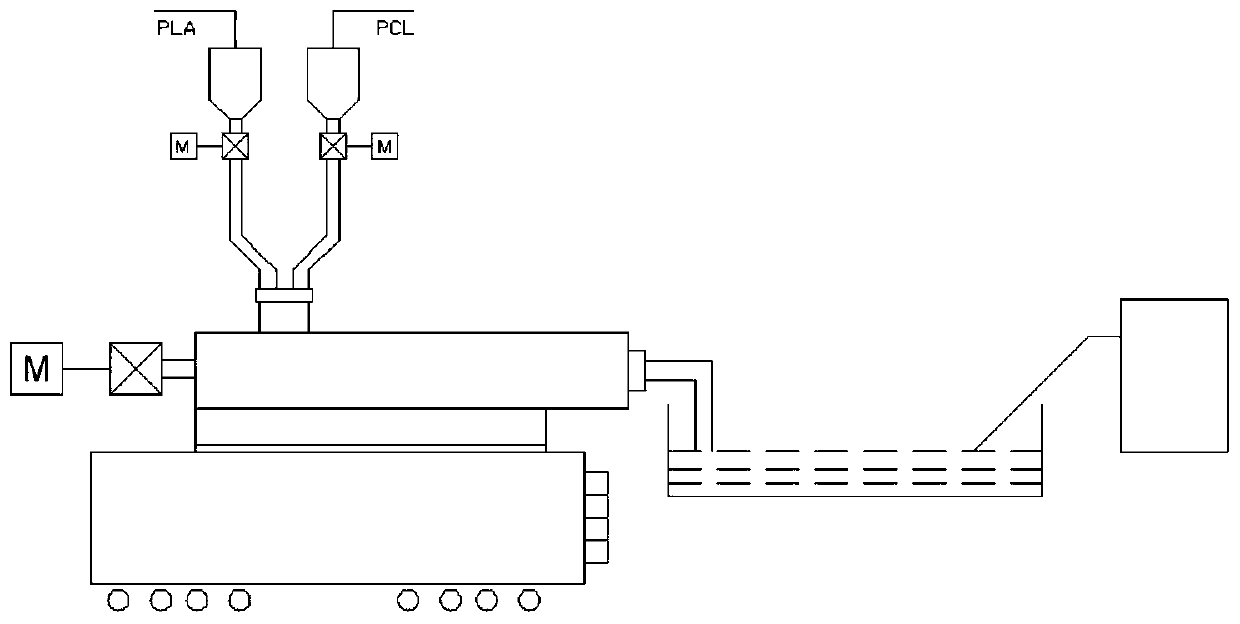

Preparation method of lactic acid copolymer with high relative molecular mass

The invention relates to the field of polymer materials, and discloses a preparation method of a lactic acid copolymer with high relative molecular mass. The preparation method comprises the steps ofpreparing a PLA prepolymer, preparing a PCL prepolymer and preparing a PLA copolymer through double-screw reactive extrusion. Polylactic acid with a certain relative molecular mass is synthesized by amelt polycondensation method and then is copolymerized with a polyurethane prepolymer of polycaprolactone polyol, the lactic acid copolymer is extruded by a double-screw reactor to prepare the lacticacid copolymer with high relative molecular mass, and the lactic acid copolymer prepared through the double-screw reactive extrusion is thermoplastic and has a better mixing effect than a kettle-typereaction. Through reasonable configuration, the product obtained through double-screw reactive extrusion has good mechanical properties, the toughness of the reaction extrusion product is improved due to increase of the PCL content, and the tensile strength and the tensile modulus are reduced.

Owner:广东炬盛新材料科技有限公司

One-component silicone sealant for concrete road joints and preparation method thereof

ActiveCN104357005BGood weather resistanceImprove aging resistanceNon-macromolecular adhesive additivesOther chemical processesGas phaseRoad surface

The invention discloses a single-component silicone sealant for concrete road seaming, which is prepared from the following raw materials in parts by weight: 90-130 parts of alpha,omega-dihydroxy polydimethylsiloxane, 50-130 parts of calcium carbonate, 1-30 parts of vapor-phase silicon dioxide, 5-30 parts of methyl silicone oil, 5-30 parts of crosslinking agent, 0.5-5 parts of coupling agent and 0.01-1 part of catalyst. The invention also discloses a preparation method of the single-component silicone sealant for concrete road seaming. The method solves the problem of bonding cracking after water soaking, heat treatment, cold drawing and hot rolling in the silicone sealant for road seaming in the prior art and the problem of poor compatibility in the polyurethane sealant, and can promote the wide application of the silicone sealant in the field of road sealing, thereby effectively ensuring and enhancing the road safety.

Owner:GUANGZHOU HUINA NEW MATERIAL TECH

Low-modulus room temperature vulcanization neutral silicone weather-proof sealant and preparation method and application thereof

InactiveCN108559443ALow tensile modulusIncrease elasticityNon-macromolecular adhesive additivesOther chemical processesVulcanizationPolymer science

The invention discloses a low-modulus room temperature vulcanization neutral silicone weather-proof sealant. The low-modulus room temperature vulcanization neutral silicone weather-proof sealant is prepared from, by weight, 160-240 parts of basic polymer, 30-80 parts of light calcium carbonate, 100-160 parts of coarse whiting, 3-6 parts of graphene oxide, 12-30 parts of dimethyl silicone, 8-15 parts of chain extender, 13-19 parts of cross-linking agent, 2.5-5 parts of coupling agent and 0.2-0.4 part of catalyst. The basic polymer is polydimethylsiloxane with two hydroxyl terminated ends, and the viscosity of the basic polymer under the temperature of 25 DEG C is 60,000-75,000 mPa s. The silicone weather-proof sealant has the low tensile modulus, high elasticity and high elastic recovery rate, excellent weather resistance and good adhesive property; after cold-drawing, hot-pressing, water immersion and other treatment, no interface bonding damage or cohesive failure appear, high-displacement jointing of the silicone weather-proof sealant in a super high-rise building is promoted, and concrete expansion joint sealing of facilities such as a road, a bridge and an airport pavement is facilitated.

Owner:林荣铨

Preparation method of a biodegradable super-tough flame-retardant polylactic acid-based composite material

Owner:ZHEJIANG UNIV OF TECH

A kind of synthetic method of phenolic resin

Owner:NINGBO ZHETIE JIANGNING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com