High-intensity low-modulus metastable beta titanium alloy tooth arch wire

A technology of β-titanium alloy and dental arch wire, which is applied in the field of dental orthopedic devices, can solve the problems of high tensile strength, low elastic modulus, etc., and achieve high tensile strength, moderate orthodontic strength, and elastic retraction range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

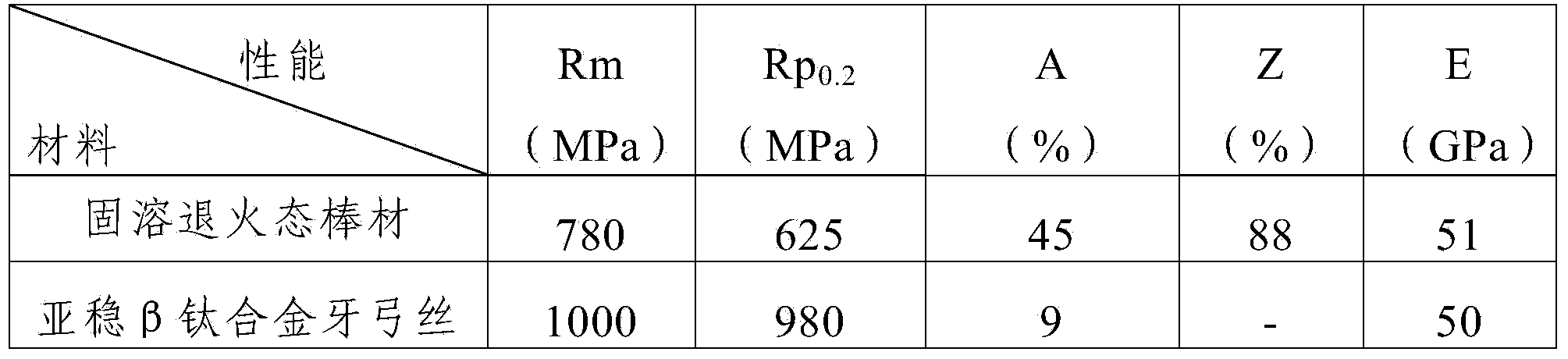

[0016] The nominal chemical composition of the metastable β-titanium alloy dental arch wire of the present invention is calculated by mass percentage: Mo11%, Nb3%, Zr5%, Sn4%, and the balance is titanium and unavoidable impurities.

[0017] The manufacturing method of metastable β titanium alloy dental arch wire of the present invention is: first carry out weighing raw material according to the nominal chemical composition Ti-11Mo-3Nb-5Zr-4Sn of metastable β titanium alloy, after mixing uniformly, press into smelting electrode, and The smelting electrode is subjected to vacuum consumable arc melting twice to obtain an alloy ingot, and then the alloy ingot is subjected to billet forging and repeated upsetting and drawing forging to obtain an alloy bar according to a conventional process, and then the alloy bar is hot-rolled and drawn to obtain a tooth The arch wire is finally subjected to heat treatment for shaping, and finally a metastable β titanium alloy dental arch wire prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com