A kind of synthetic method of phenolic resin

A technology of phenolic resin and synthesis method, which is applied in the field of phenolic resin synthesis, can solve the problems of incapable of large-scale mass production, high viscosity of phenolic resin, and high equipment requirements, and achieve moderate molecular weight, low equipment requirements, and low viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

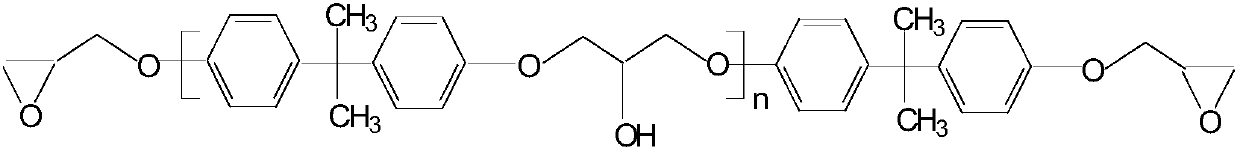

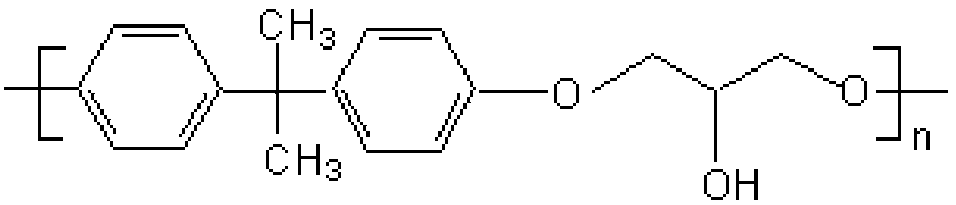

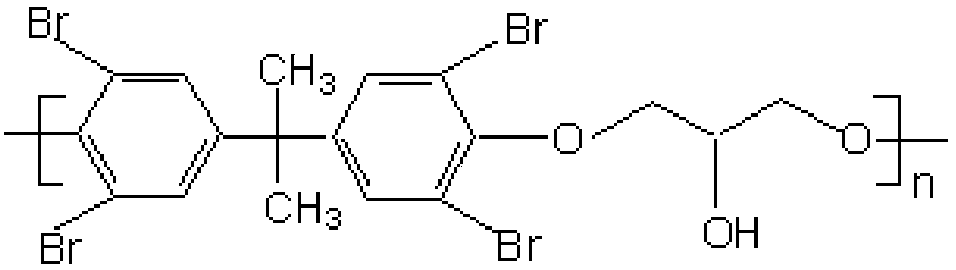

Method used

Image

Examples

Embodiment 1

[0046] A kind of synthetic method of phenolic resin, comprises the steps:

[0047] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 15%, be warming up to material dissolution.

[0048] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.065:1. Among them, the bisphenol A epoxy resin adopts YN1828 / YN1826 of Yangnong, and the BPA adopts the product produced in Changchun, Taiwan.

[0049] 2) Add a bisphenol A type epoxy resin and a catalyst with a total mass of 0.25% of BPA to the tank reactor, and conduct a polymerization reaction at 145° C. for 5 hours.

[0050] The preparation method of the catalyst is as follows: mixing 5.5wt% of 2-methylimidazole and 94.5wt% but...

Embodiment 2

[0055] A kind of synthetic method of phenolic resin, comprises the steps:

[0056] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 10%, be warming up to material dissolution.

[0057] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.01:1.

[0058] 2) Add a bisphenol A type epoxy resin and a catalyst with a total mass of 0.1% of BPA to the tank reactor, and conduct a polymerization reaction at 120° C. for 8 hours.

[0059] The preparation method of the catalyst is as follows: mixing 2-methyl-4-ethylimidazole accounting for 1wt% of the total amount with butanone accounting for 99wt% of the total amount, stirring and dissolving at normal temperature.

[0060] 3),...

Embodiment 3

[0064] A kind of synthetic method of phenolic resin, comprises the steps:

[0065] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 20%, be warming up to material dissolution.

[0066] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.12:1.

[0067] 2), add bisphenol A type epoxy resin and the catalyst of 0.4% of total mass of BPA in the tank reactor, heat up to 170 ℃, polymerization reaction 2h; During the reaction, add bisphenol A type epoxy resin and A mixed solvent of propylene glycol methyl ether and butanone with a total mass of BPA of 28%.

[0068] The preparation method of the catalyst is as follows: 10 wt% of the total amount of 2-methylimidazole is mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com