Vinylidene fluoride resin hollow fiber porous membrane and method for production thereof

A technology of vinylidene fluoride and its manufacturing method, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., and can solve problems such as low particle or bacteria removal performance and increased water permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

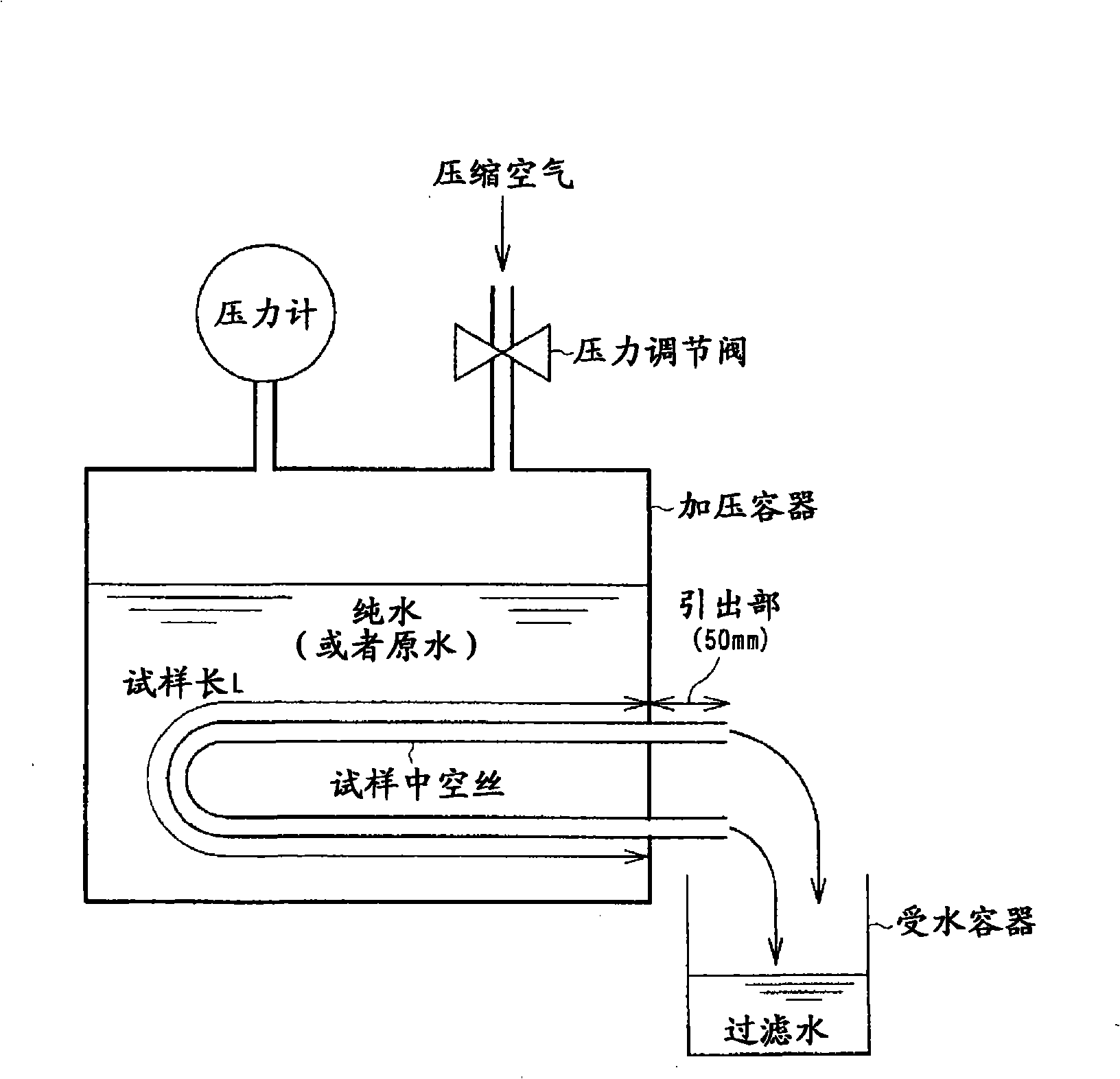

Image

Examples

Embodiment 1

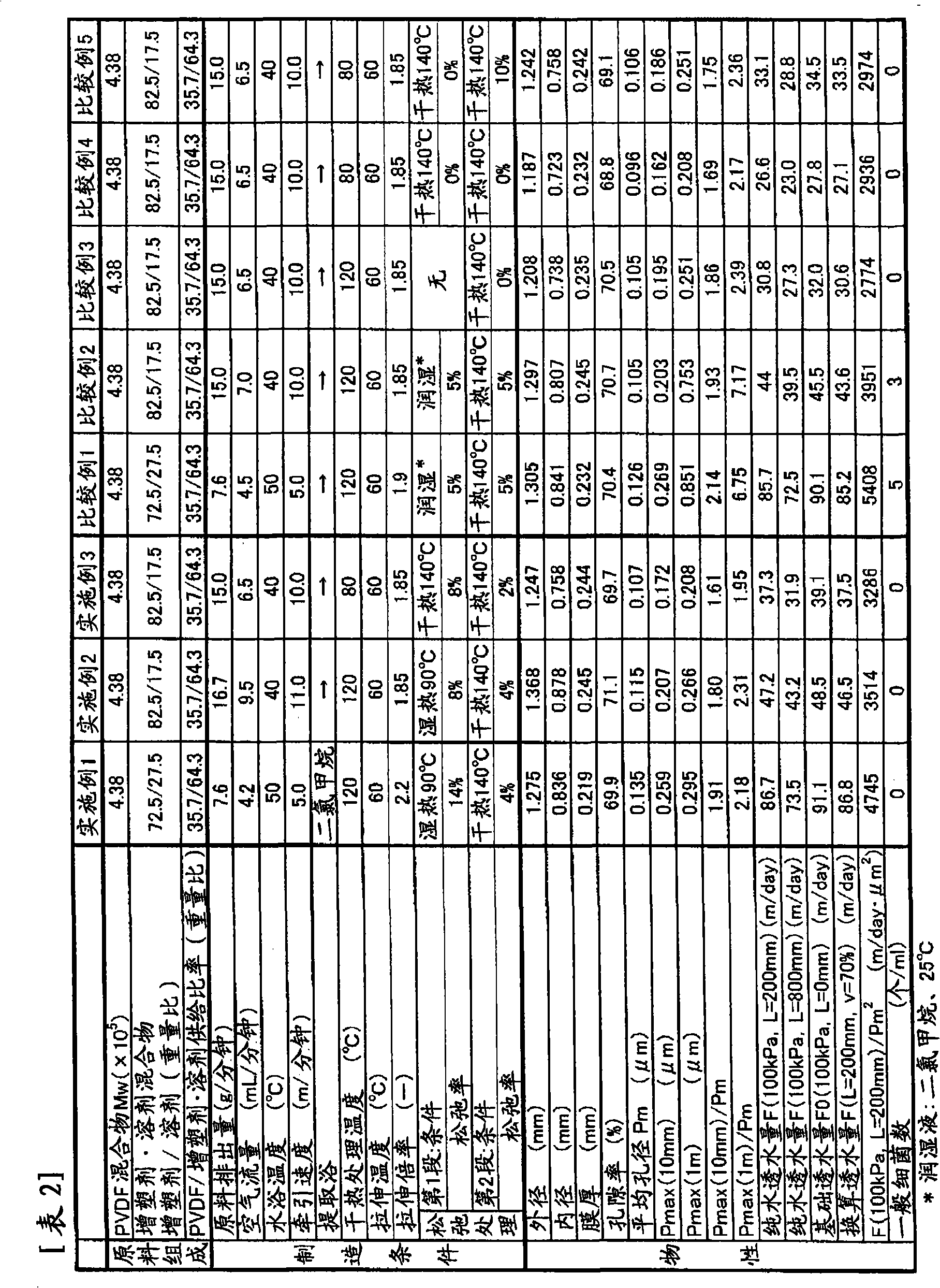

[0079] The weight average molecular weight (Mw) is 4.12×10 5 The main body of polyvinylidene fluoride (PVDF) (powder) and Mw is 9.36×10 5 Polyvinylidene fluoride (PVDF) (powder) used for modifying the crystallinity properties of 95% by weight and 5% by weight was mixed using a Henschel mixer to obtain a Mw of 4.38×10 5 PVDF mixture.

[0080]An adipic acid-based polyester plasticizer ("PN-150" manufactured by Soden Chemical Industry Co., Ltd.) as an aliphatic polyester and N-methylpyrrolidone (NMP) as a solvent were mixed at 77.5% by weight / 22.5% by weight % of the mixture was stirred and mixed at room temperature to obtain a plasticizer-solvent mixture.

[0081] Using a twin-screw extruder that rotates in the same direction ("BT-30" manufactured by Plastic Engineering Research Institute, screw diameter 30mm, L / D=48), from the powder set at a position 80mm away from the most upstream part of the barrel The supply part supplies the PVDF mixture, and according to the ratio of ...

Embodiment 2

[0088] The ratio of the two in the plasticizer-solvent mixture was changed to 82.5% by weight / 17.5% by weight, the discharge amount of the raw material was changed to 16.7g / min, and the air flow rate from the vent hole provided in the center of the nozzle was changed to 9.5mL / min. The temperature of the water bath is changed to 40°C, the pulling speed is changed to 11.0m / min, the stretching ratio is changed to 1.85 times, the relaxation in the first stage is changed to damp heat at 90°C, 8%, and the relaxation in the second stage is changed to dry heat at 140°C, 4%. , except that, in the same manner as in Example 1, a hollow fiber porous membrane was obtained.

Embodiment 3

[0090] Change the discharge rate to 15.0g / min, the air flow rate from the air hole provided in the center of the nozzle to 6.5mL / min, the pulling speed to 10.0m / min, the heat treatment temperature to 80°C, and the first-stage relaxation to A hollow fiber porous membrane was obtained in the same manner as in Example 2 except that it was dry heat at 140° C. and 8%, and the relaxation in the second stage was changed to dry heat at 140° C. and 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com