Preparation method of lactic acid copolymer with high relative molecular mass

A relative molecular weight and lactic acid copolymerization technology, which is applied in the field of preparation of high relative molecular weight lactic acid copolymers, can solve the problems of increased cost, unsatisfactory mixing effect, poor compatibility, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

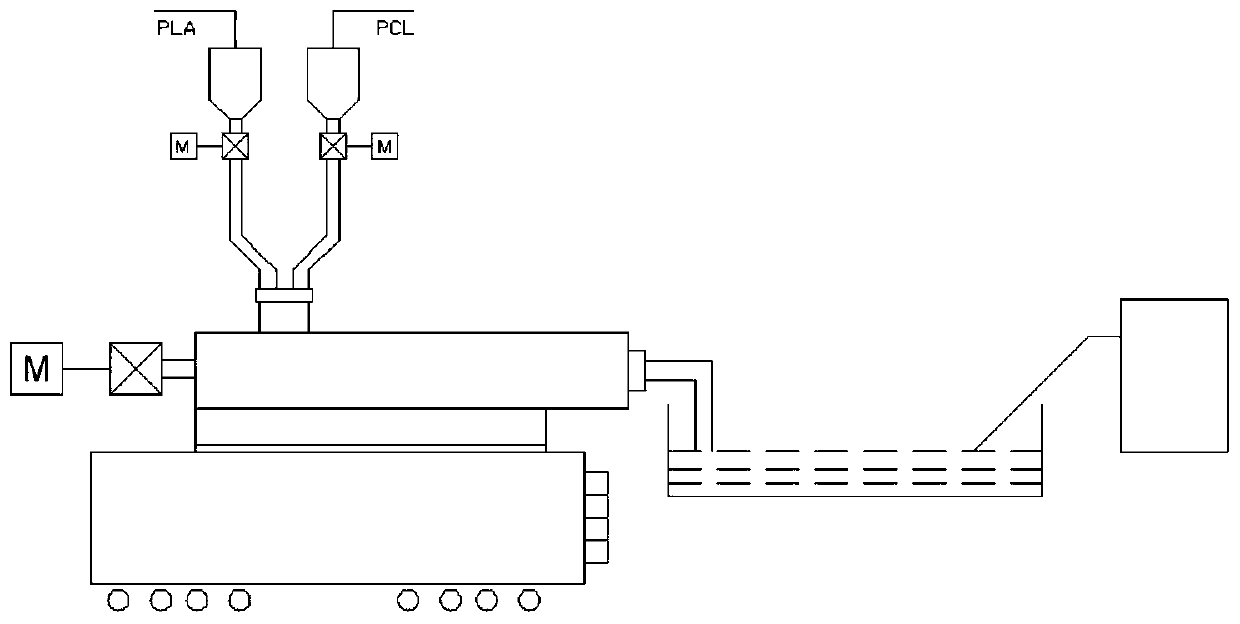

[0033] Such as figure 1 As shown, the invention discloses a method for preparing a high relative molecular weight lactic acid copolymer, including preparing a PLA prepolymer, preparing a PCL prepolymer and preparing a PLA copolymer by twin-screw reactive extrusion.

[0034] The preparation method of PLA prepolymer is the direct melt polycondensation reaction of lactic acid, and the specific steps are: by adding lactic acid in the reaction system, stirring and heating up in a vacuum environment, and adding stannous chloride for vacuum dehydration reaction.

[0035] The specific steps of the PCL prepolymer preparation method are:

[0036] S1: Vacuum dehydrate accurately measured PCL at 120°C for 1-2 hours;

[0037] S2: Cool to 50°C, release the vacuum, add to 1,6-hexamethylene diisocyanate, and protect with nitrogen;

[0038] S3: The reaction is exothermic. After the system naturally heats up for 30-40 minutes, it is slowly heated to 85°C, and the reaction is kept for 2-3 hour...

Embodiment 2

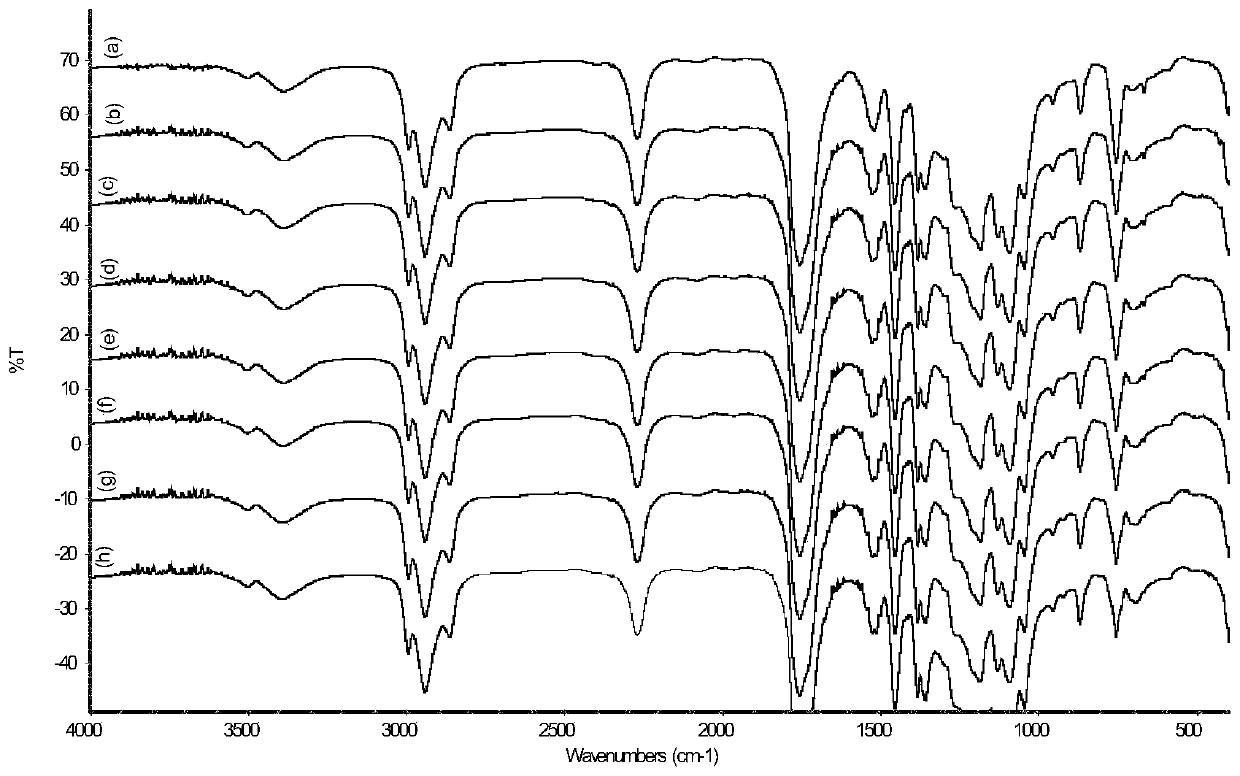

[0042] The reaction process of PLLA and PCL prepolymer was tracked by heating infrared:

[0043] First, a certain amount of PLLA and PCL were dissolved in anhydrous chloroform in a certain proportion, then the two solutions were mixed and stirred evenly, and then coated on a glass slide, and then dried in a vacuum dryer for 4 to 5 hours, and finally blended The material film is tested with the American NicoletNEXUS-670 FTIR spectrometer by the transmission method under different heating conditions.

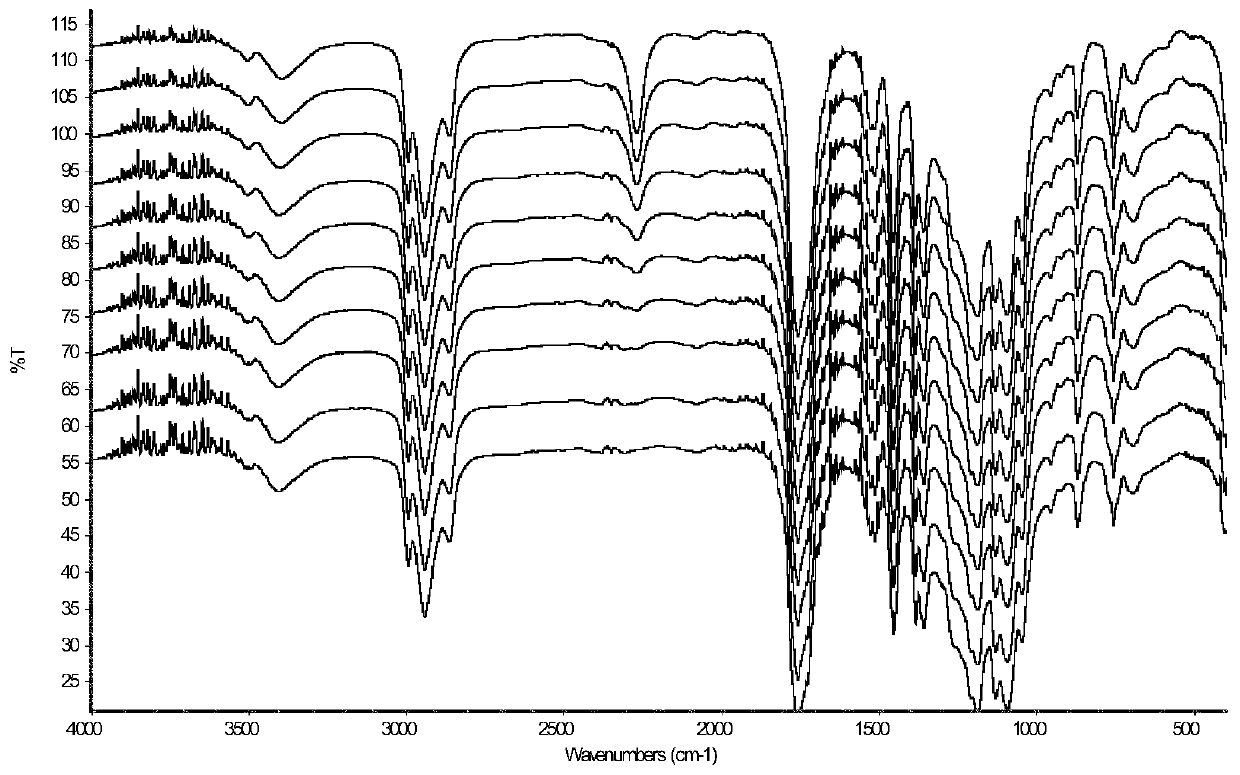

[0044] In order to investigate the reactivity of PLLA with PCL prepolymer (OCN-PCL-NCO), we tracked the reaction process of the two with warming infrared. See you separately figure 2 , 3, 4, 5.

[0045] From figure 2 (a) 20°C, (b) 60°C, (c) 90°C, (d) 105°C, (e) 120°C, (f) 135°C, (g) 145°C, (h) 160°C , it can be seen that the blend of PLLA and PCL prepolymer at 2270cm -1 There is a characteristic absorption peak of -NCO end group. During the heating process, due to the fast...

Embodiment 3

[0050] The influence of the copolymer ratio on the relative molecular mass of the copolymerized product:

[0051] The relative molecular weight of polymers directly affects many properties of polymers. We first prepared PLA copolymers with different PCL ratios to investigate its influence on the relative molecular weight of the product. Using a copolymerization temperature of 180°C and a copolymerization time of 9 minutes, the relative molecular weights of PLLA and its copolymers were measured by viscometry, and the results are listed in Table 1.

[0052] From the data in Table 1, it can be seen that after the chain extension reaction between PLLA and PCL prepolymer, the relative molecular weight has been greatly improved. It reacts with the terminal -OH group of PLLA, and can also react with -COOH at high temperature, so that the molecular chain of PLLA increases and the relative molecular weight increases. And it can be seen that with the increase of the PCL prepolymer con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com