Synthesis method of phenoxy resin

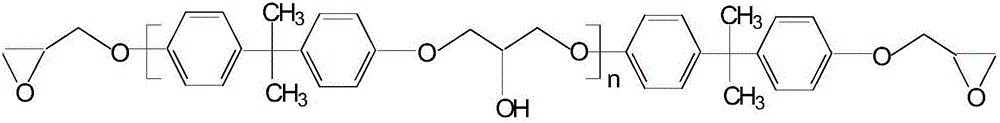

A technology of phenolic resin and synthesis method, applied in the field of phenolic resin synthesis, can solve the problems of inability to mass production, high viscosity of phenolic resin, and high equipment requirements, and achieves improved flexibility, low equipment requirements, and high viscosity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

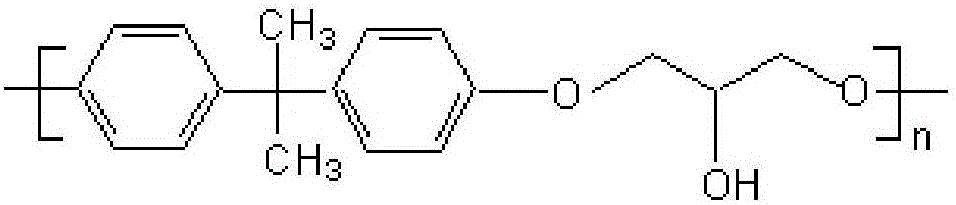

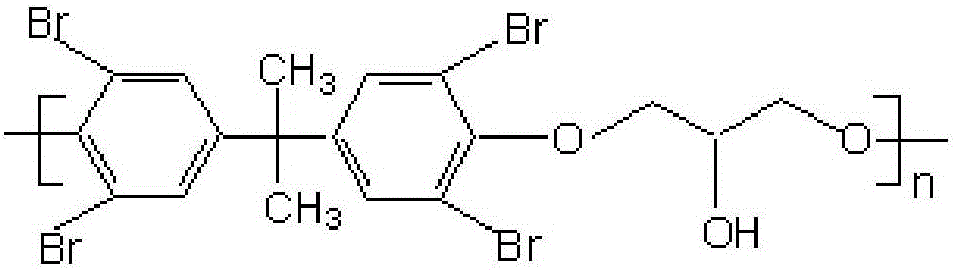

[0045] A kind of synthetic method of phenolic resin, comprises the steps:

[0046] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 15%, be warming up to material dissolution.

[0047] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.065:1. Among them, the bisphenol A epoxy resin adopts YN1828 / YN1826 of Yangnong, and the BPA adopts the product produced in Changchun, Taiwan.

[0048] 2) Add a bisphenol A type epoxy resin and a catalyst with a total mass of 0.25% of BPA to the tank reactor, and conduct a polymerization reaction at 145° C. for 5 hours.

[0049] The preparation method of the catalyst is as follows: mixing 5.5wt% of 2-methylimidazole and 94.5wt% but...

Embodiment 2

[0054]A kind of synthetic method of phenolic resin, comprises the steps:

[0055] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 10%, be warming up to material dissolution.

[0056] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.01:1.

[0057] 2) Add a bisphenol A type epoxy resin and a catalyst with a total mass of 0.1% of BPA to the tank reactor, and conduct a polymerization reaction at 120° C. for 8 hours.

[0058] The preparation method of the catalyst is as follows: mixing 2-methyl-4-ethylimidazole accounting for 1wt% of the total amount with butanone accounting for 99wt% of the total amount, stirring and dissolving at normal temperature.

[0059] 3), ...

Embodiment 3

[0063] A kind of synthetic method of phenolic resin, comprises the steps:

[0064] 1), add bisphenol A type epoxy resin, BPA to the tank reactor that is provided with thermometer, agitator, condensation tube under nitrogen condition and mix evenly, add bisphenol A in the tank reactor Type epoxy resin and the anisole of BPA gross mass 20%, be warming up to material dissolution.

[0065] The ratio of the bisphenol A epoxy resin to BPA is: the molar ratio of the epoxy group in the bisphenol A epoxy resin to the phenolic hydroxyl group in the BPA is 1.12:1.

[0066] 2), add bisphenol A type epoxy resin and the catalyst of 0.4% of total mass of BPA in the tank reactor, heat up to 170 ℃, polymerization reaction 2h; During the reaction, add bisphenol A type epoxy resin and A mixed solvent of propylene glycol methyl ether and butanone with a total mass of BPA of 28%.

[0067] The preparation method of the catalyst is as follows: 10 wt% of the total amount of 2-methylimidazole is mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com