Single/double-component construction type polyurethane joint pouring glue for ballastless track concrete expansion joint and preparation method thereof

A technology for concrete and expansion joints, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of inconvenient construction, poor flexibility at low temperature, uneven mixing, etc., and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

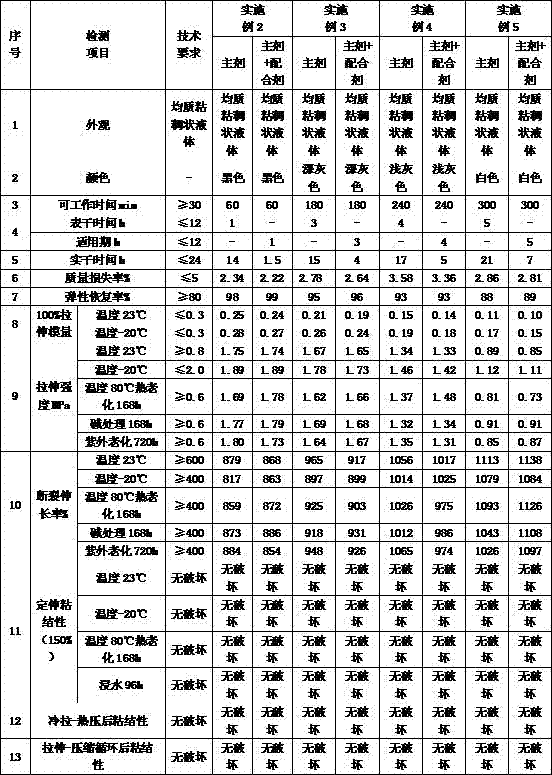

Examples

Embodiment 1

[0088] A single-component dual-purpose construction-type polyurethane joint glue for expansion joints of track-free concrete, which consists of a main agent and a compounding agent, and the main agent is composed of the following components in weight percentage:

[0089] Polyurethane prepolymer 40%~70%

[0090] Filler 20%~35%

[0091] Thickener 1%~10%

[0092] Thinner 1%~5%

[0093] Catalyst 1%~3%

[0094] Adhesion promoter 0.2%~2%

[0095] Defoamer 1%~3%

[0096] Light stabilizer 0.1%~1%

[0097] Antioxidant 0.1%~1%

[0098] Dewatering agent 0.5% ~ 2%;

[0099] Wherein, the polyurethane prepolymer is composed of the following components in weight percent:

[0100] Polyoxypropylene glycol 10%~40%

[0101] Polyoxypropylene triol 10%~30%

[0102] Polyisocyanate 5%~15%

[0103] Plasticizer 20%~50%

[0104] Catalyst 0.1%~1%;

[0105] Wherein, the compounding agent is made up of the following components by weight percentage:

[0106] Plasticizer 15%~35%

[0107] Thic...

Embodiment 2

[0153] A single-component dual-purpose construction type polyurethane joint glue for expansion joints of track-free concrete, which is composed of a main agent and a compounding agent, and the main agent is composed of the following raw materials in mass percentages:

[0154] Polyurethane prepolymer 65%

[0155] Ground calcium carbonate 13%

[0156] Light Calcium Carbonate 8%

[0157] Diatomaceous earth 2%

[0158] Carbon black 5%

[0159] Fumed silica 2%

[0160] Vinyl resin 2%

[0161] Rosin resin 2%

[0162] Xylene 2%

[0163] Ethyl acetate 1%

[0164] Stannous octoate 0.5%

[0165] Dibutyltin dilaurate 1%

[0166] Gamma-Aminopropyltrimethoxysilane 1%

[0167] N-Phenyl-γ-aminopropyltrimethoxysilane 1%

[0168] BYK070 1.2%

[0169] Tinuvin326 1%

[0170] Antioxidant 1010 0.8%

[0171] Toluenesulfonyl isocyanate 1.5%

[0172] Wherein polyurethane prepolymer comprises the raw material composition of following mass percentage:

[0173] Polyoxypropylene glycol 35...

Embodiment 3

[0192] A single-component dual-purpose construction type polyurethane joint glue for expansion joints of track-free concrete, which is composed of a main agent and a compounding agent, and the main agent is composed of the following raw materials in mass percentages:

[0193] Polyurethane prepolymer 58%

[0194] Talc 6%

[0195] PVC paste resin 5%

[0196] Light Calcium Carbonate 10%

[0197] Attapulgite 3%

[0198] Carbon black 2%

[0199] Terpene phenolic resin 3%

[0200] Hydrogenated Castor Oil 3%

[0201] Dichloromethane 1.1%

[0202] Butyl acetate 2%

[0203] Stannous octoate 0.5%

[0204] Bismorpholine diethyl ether 0.6%

[0205] γ-(2,3-Epoxypropyl)propyltrimethoxysilane 1%

[0206] BYK082 2%

[0207] Tinuvin329 0.8%

[0208] Antioxidant 1076 0.5%

[0209] Trimethyl orthoformate 1.5%

[0210] Wherein polyurethane prepolymer comprises the raw material composition of following mass percentage:

[0211] Polyoxypropylene glycol 28%

[0212] Polyoxypropylene Tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com