Polypropylene modified material with excellent stiffness and high elongation at break and preparation method of polypropylene modified material

A modified material, polypropylene technology, applied in the field of polypropylene modified materials and their preparation, can solve the problem of decreased elongation at break, decreased flexural modulus and tensile modulus of polypropylene rigidity, and rigidity of polypropylene modified materials. Can not meet the use requirements and other problems, to achieve the effect of improving the elongation at break, promoting dispersion, and being suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

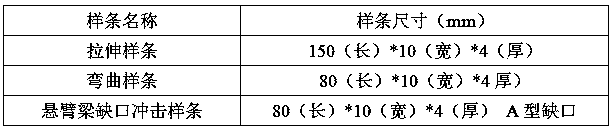

[0045] The preparation method of the polypropylene modified material having both good rigidity and elongation at break of the present invention comprises the following steps:

[0046] (1) Mixing of reagents and raw materials: first put polypropylene and hyperbranched resin into the mixer, stir for 3-5 minutes, then add antioxidant and antistatic agent for subsequent mixing, continue mixing for 2 minutes, and finally obtain mixed raw materials;

[0047] (2) Heated extrusion: Add the mixed raw materials into the main feeding bin of the twin-screw extruder, add the inorganic filler into the side feeding bin, and add the components of the main feeding bin and side feeding bin into the twin-screw extruder according to the proportion. In the extrusion machine, the feeding speed is kept uniform and smooth to ensure that there is no blockage during the extrusion process. During the twin-screw extrusion process, the temperature of the melting section is 190-210 °C, the temperature of th...

Embodiment 1-3 and comparative example 1-3

[0070] According to the composition of each component in Examples 1-3 and Comparative Examples 1-3 in Table 3, polypropylene modified materials were prepared according to the above preparation method and their properties were tested.

[0071] Table 3 embodiment and comparative example formula (weight fraction %)

[0072]

[0073] The properties of the modified polypropylene materials prepared in Examples 1-3 and Comparative Examples 1-3 are shown in Table 4.

Embodiment 1

[0076] The difference between embodiment 1 and comparative example 1 is that comparative example 1 does not add hyperbranched resin, and the melt index, elongation at break and notched Izod impact strength of embodiment 1 are all obviously better than comparative example 1, tensile strength and tensile strength The modulus of elongation increases slightly, indicating that the modified polypropylene material prepared by this patent can not only increase the fluidity of the modified polypropylene material, but also greatly increase the elongation at break and impact performance of the modified polypropylene material. The difference between Example 2 and Comparative Example 2 is that Comparative Example 2 only uses homopolymerized PP, resulting in that the notched Izod impact strength is too low, and the toughness of the polypropylene modified material is too poor. Combining Example 2 and Comparative Example 2 shows that the combination of homopolypropylene and high-impact copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com