Silicone sealant for asphalt road joints and preparation method thereof

A silicone sealant, road technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of low adhesion, affect the application of silicone, poor adhesion, etc., and achieve good adhesion. , the effect of promoting widespread use and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

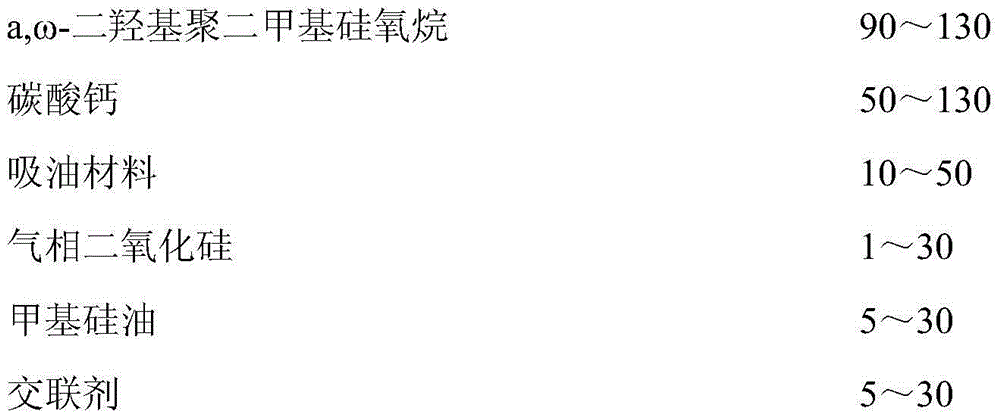

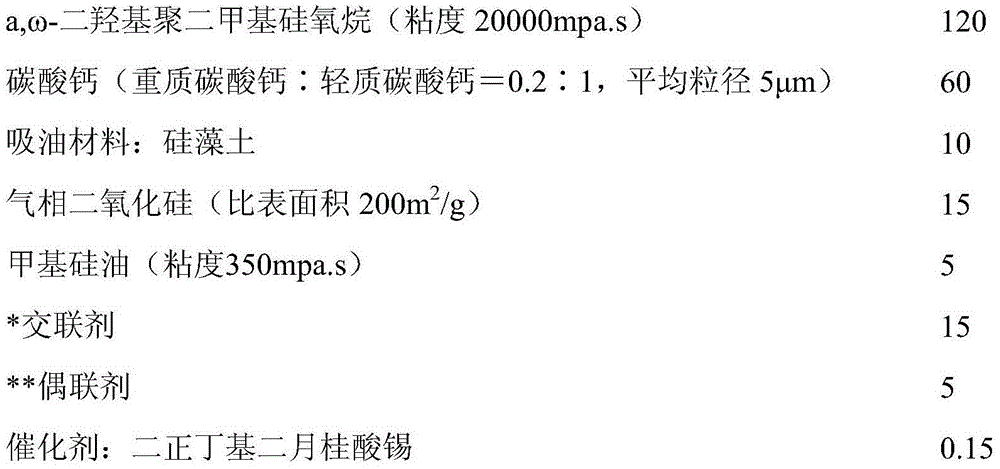

[0017] 1. A kind of silicone sealant for asphalt road joints of the present embodiment is composed of raw materials according to parts by weight:

[0018]

[0019] *The cross-linking agent is: the mixture of phenyltributanone oximinosilane: vinyltributanone oximosilane=1:3 by weight;

[0020] **Coupling agent is: a mixture of isocyanatopropyltriethoxysilane:γ-mercaptopropyltrimethoxysilane=1:10 by weight.

[0021] 2. The preparation method of a silicone sealant for asphalt road joints in this embodiment is as follows: the above-mentioned raw materials are each composed, under the vacuum degree of -0.07Mpa and the stirring speed of 5Hz, stirring and mixing for 40min, discharging and filling to obtain the product .

Embodiment 2

[0023] 1. A kind of silicone sealant for asphalt road joints of the present embodiment is composed of raw materials according to parts by weight:

[0024]

[0025]

[0026] *Coupling agent is: a mixture of -methacryloyloxypropyltrimethoxysilane:N-(β-aminoethyl)-Y-aminopropyltrimethoxysilane=1:3 by weight.

[0027] 2. The preparation method of a silicone sealant for asphalt road joints in this embodiment is as follows: the above-mentioned raw materials are each composed, under vacuum degree -0.08Mpa, stirring speed 10Hz, stirring and mixing for 45min, discharging and filling to obtain the product .

Embodiment 3

[0029] 1. A kind of silicone sealant for asphalt road joints of the present embodiment is composed of raw materials according to parts by weight:

[0030]

[0031] 2. The preparation method of a silicone sealant for asphalt road joints in this embodiment is as follows: the above-mentioned raw materials are composed of each component, under the vacuum degree of -0.09Mpa and the stirring speed of 20Hz, stirring and mixing for 50min, discharging and filling to obtain the product .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com