Polyurethane caulking material for expansion joints of ballastless track of high speed railway

A technology of caulking material and ballastless track, applied in the field of building materials, can solve the problems of high tensile modulus, difficult curing, high sensitivity, etc., achieve moderate molecular chain length and functionality, improve bonding performance and durability Good performance, low temperature curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

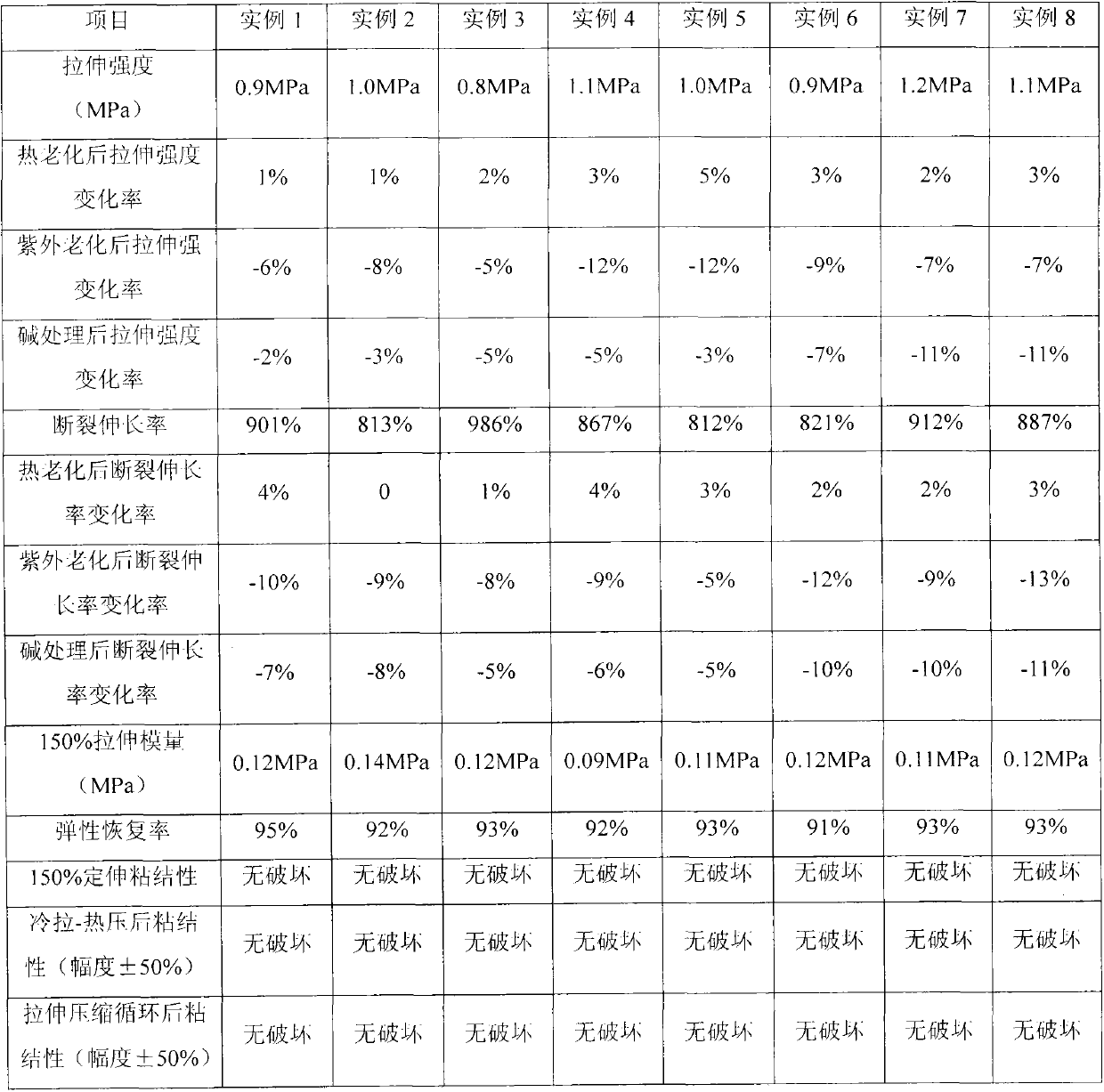

Examples

Embodiment 1

[0035] Composition of polyurethane caulking material:

[0036] Component A: 20 parts of modified TDI and 80 parts of polyoxyethylene-propylene oxide copolyol, a prepolymer with an isocyanate group content of 2.5%, 5 parts of dibutyl phthalate, and dioctyl phthalate 5 parts of ester, 1 part of calcium oxide, parts of titanium dioxide, 2 parts of light calcium carbonate, 1 part of carbon black, 0.5 parts of diacetone alcohol, 0.5 parts of dipropylene glycol, 0.5 parts of silane coupling agent A-186, silane coupling 0.5 part of agent A-1310, 0.5 part of oxazole water remover, 0.5 part of p-toluenesulfonyl isocyanate;

[0037] Part B is composed of the following raw materials in parts by weight: 5 parts of oleochemical polyol, 5 parts of modified epoxy resin, 1 part of butyl acetate, 2 parts of chlorinated paraffin, 2 parts of talcum powder, 3 parts of silicon micropowder, defoaming Agent BYK-070 0.5 parts, light stabilizer 0.05 parts, antioxidant 0.02 parts, hydrolysis stabilize...

Embodiment 2

[0040] Composition of polyurethane caulking material:

[0041] Component A: 30 parts of modified TDI, 20 parts of polyoxyethylene-oxypropylene copolyol and 50 parts of tetrahydrofuran-oxypropylene copolyether polyol, a prepolymer with an isocyanate group content of 0.5%, phthalic acid di 20 parts of butyl ester, 50 parts of dioctyl phthalate, 10 parts of chlorinated paraffin, 100 parts of light calcium carbonate, 30 parts of talcum powder, 10 parts of montmorillonite, 5 parts of cement, 1 part of calcium hydroxide, charcoal 4 parts of black, 10 parts of diacetone alcohol, 10 parts of dichloromethane, 2 parts of silane coupling agent A-1310, 3 parts of silane coupling agent A-LINK35, 6 parts of nano calcium carbonate, 4 parts of fumed silica, 3 parts of toluenesulfonyl isocyanate;

[0042] Part B is composed of the following raw materials in parts by weight: 15 parts of modified vegetable oil polyol, 5 parts of urethane polyol, 2 parts of dipropylene glycol, 3 parts of butyl a...

Embodiment 3

[0045] Composition of polyurethane caulking material:

[0046] Component A: 35 parts of modified MDI, 60 parts of polyoxyethylene-propylene oxide copolyol and 20 parts of polyacrylate polyol, a prepolymer with an isocyanate group content of 1.5%, 100 parts of dibutyl phthalate 50 parts of chlorinated paraffin, 50 parts of silica powder, 10 parts of montmorillonite, 5.5 parts of cement, 5 parts of titanium dioxide, 2 parts of calcium oxide, 5 parts of carbon black, 5 parts of dipropylene glycol, 5.5 parts of dichloromethane , 1 part of silane coupling agent A-1861, 352 parts of silane coupling agent A-LINK, 4 parts of nano calcium carbonate, 1 part of hydrogenated castor oil, 2 parts of oxazole water remover;

[0047] Part B consists of the following raw materials in parts by weight: 5 parts of modified epoxy resin, 10 parts of modified vegetable oil polyol, 3 parts of diacetone alcohol, 10 parts of dioctyl phthalate, 10 parts of light calcium carbonate, Talc powder 7.5 parts,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com