Antifouling silane-modified polyether adhesive and preparation method thereof

A silane-modified polyether, anti-fouling technology, applied in the field of sealants, can solve the problems of affecting the appearance and visual effect of buildings, easy to accumulate on the surface, difficult to maintain buildings, etc., achieve excellent gloss retention, improve adhesion and adhesion Sexuality, high elasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

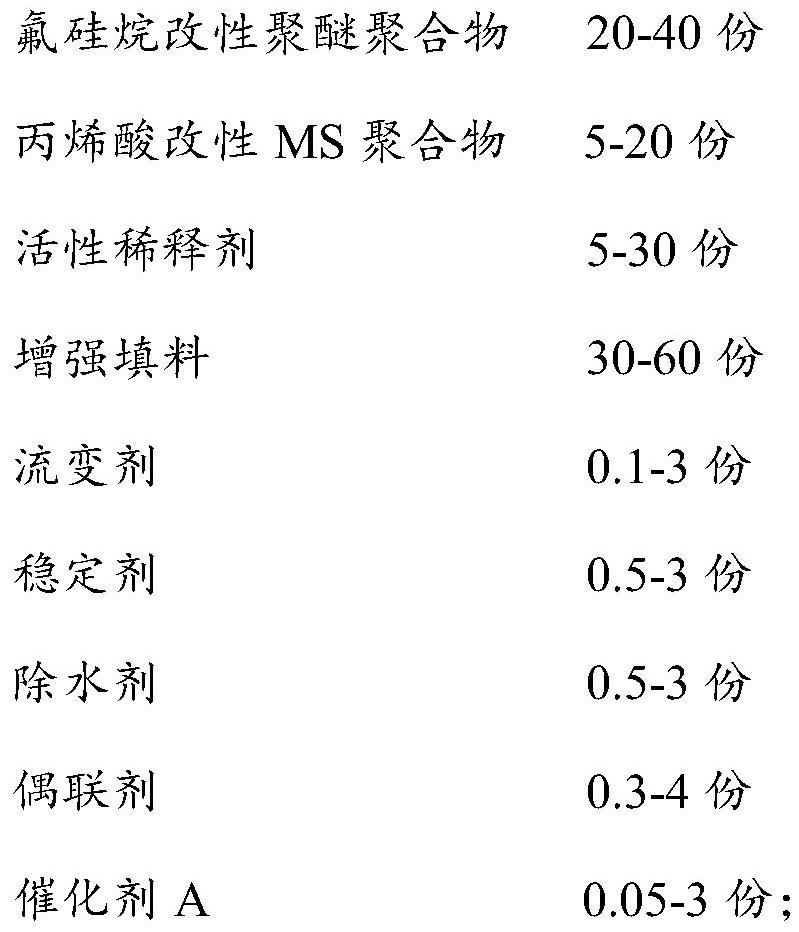

[0055] The antifouling silane-modified polyether adhesive provided in this embodiment is prepared from the following components in parts by weight:

[0056]

[0057]

[0058] Wherein the preparation method of the fluorosilane-modified polyether polymer is as follows:

[0059] The first step, the preparation of amino-terminated fluorosiloxane: ① Under nitrogen protection at a temperature of 60 ° C, according to the mass ratio of 3,3,3-trifluoropropylmethylcyclotrisiloxane (D 3 F): ethylenediamine (catalyst): water=100:0.7:0.2, put D 3 F, ethylenediamine and water are stirred at constant temperature for 10h to carry out anionic ring-opening polymerization to generate hydroxyfluorosilicone oil (D 3 FOH). The reaction mechanism is as follows:

[0060]

[0061] ②The above prepared D 3 The FOH was transferred to the reaction vessel, nitrogen was introduced, and heated, according to the molar ratio of D 3 FOH: Aminosiloxane=1:2.5 Aminosiloxane KH550 was gradually added ...

Embodiment 2

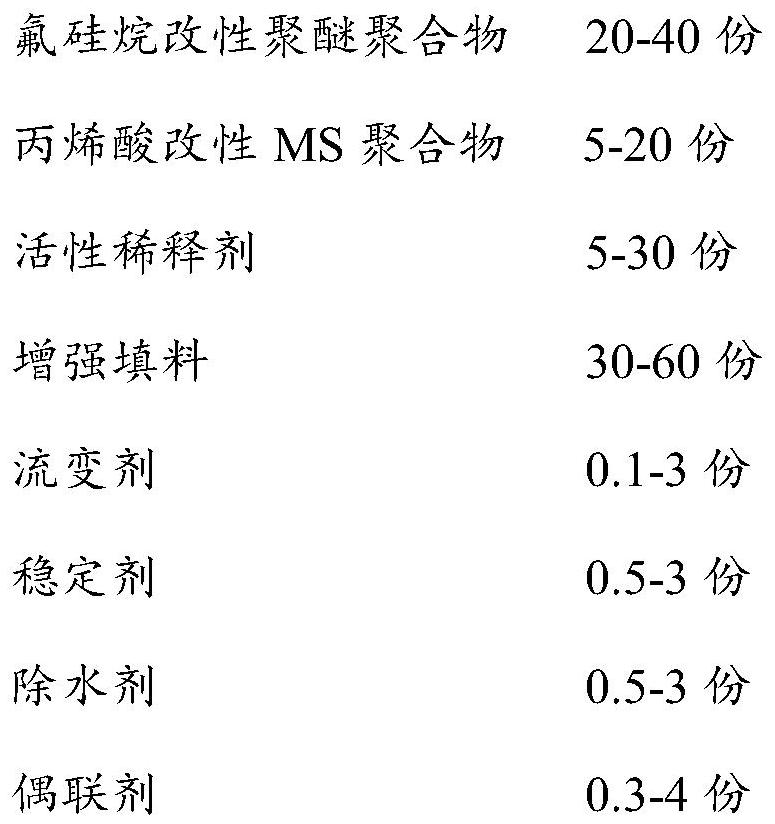

[0069] The antifouling silane-modified polyether adhesive provided in this embodiment is prepared from the following components in parts by weight:

[0070]

[0071] Wherein the preparation method of the fluorosilane-modified polyether polymer is as follows:

[0072] The first step, the preparation of amino-terminated fluorosiloxane: ① Under nitrogen protection at a temperature of 60 ° C, according to the mass ratio of 3,3,3-trifluoropropylmethylcyclotrisiloxane (D 3 F): ethylenediamine (catalyst): water=100:2:0.5, put D 3 F, ethylenediamine and water are stirred at constant temperature for 10, and anionic ring-opening polymerization is carried out to generate D 3 FOH.

[0073] ②The above prepared D 3 The FOH was transferred to the reaction vessel, nitrogen was introduced, and heated, according to the molar ratio of D 3 FOH: Aminosiloxane=1:4 Aminosiloxane KH540 was gradually added dropwise, and the reaction was carried out at a constant temperature of 50° C. for 4 hour...

Embodiment 3

[0080] The antifouling silane-modified polyether adhesive provided in this embodiment is prepared from the following components in parts by weight:

[0081]

[0082]

[0083] Wherein the preparation method of the fluorosilane-modified polyether polymer is as follows:

[0084] The first step, preparation of amino-terminated fluorosiloxane: ① Under nitrogen protection and at a temperature of 60 °C, according to the mass ratio of 3,3,3-trifluoropropylmethylcyclotrisiloxane (D 3 F): ethylenediamine (catalyst): water=100:1.5:0.8, put D 3 F, ethylenediamine and water are stirred at constant temperature for 10h to carry out anionic ring-opening polymerization to generate D3 FOH.

[0085] ②The above prepared D 3 The FOH was transferred to the reaction vessel, nitrogen was introduced, and heated, according to the molar ratio of D 3 FOH: Aminosiloxane=1:5 Aminosiloxane KH792 was gradually added dropwise, and the reaction was carried out at a constant temperature of 80° C. for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com