Mill edge loosening machine

A technology of paper loosening machine and fuselage, which is applied in metal processing and other directions, can solve the problems of paper loosening bottleneck, affecting production efficiency, large labor force, etc., and achieve the effect of improving effect, increasing displacement effect, reducing labor force and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

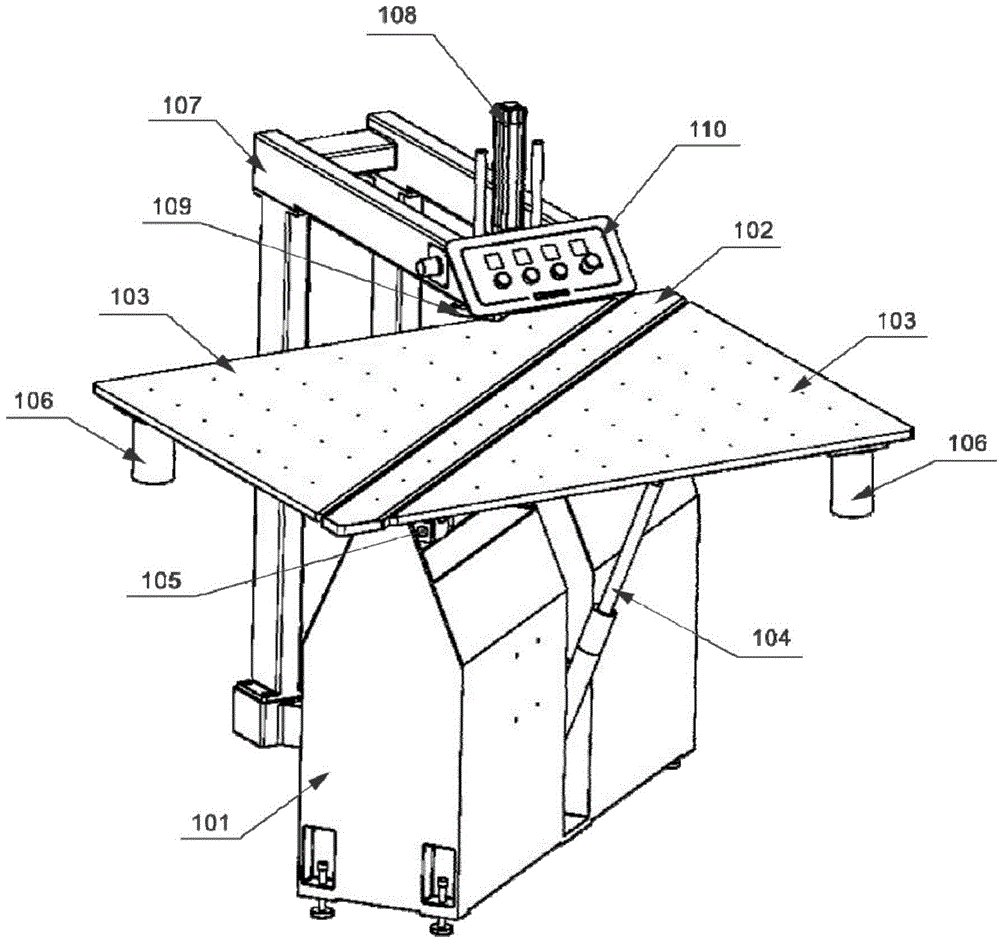

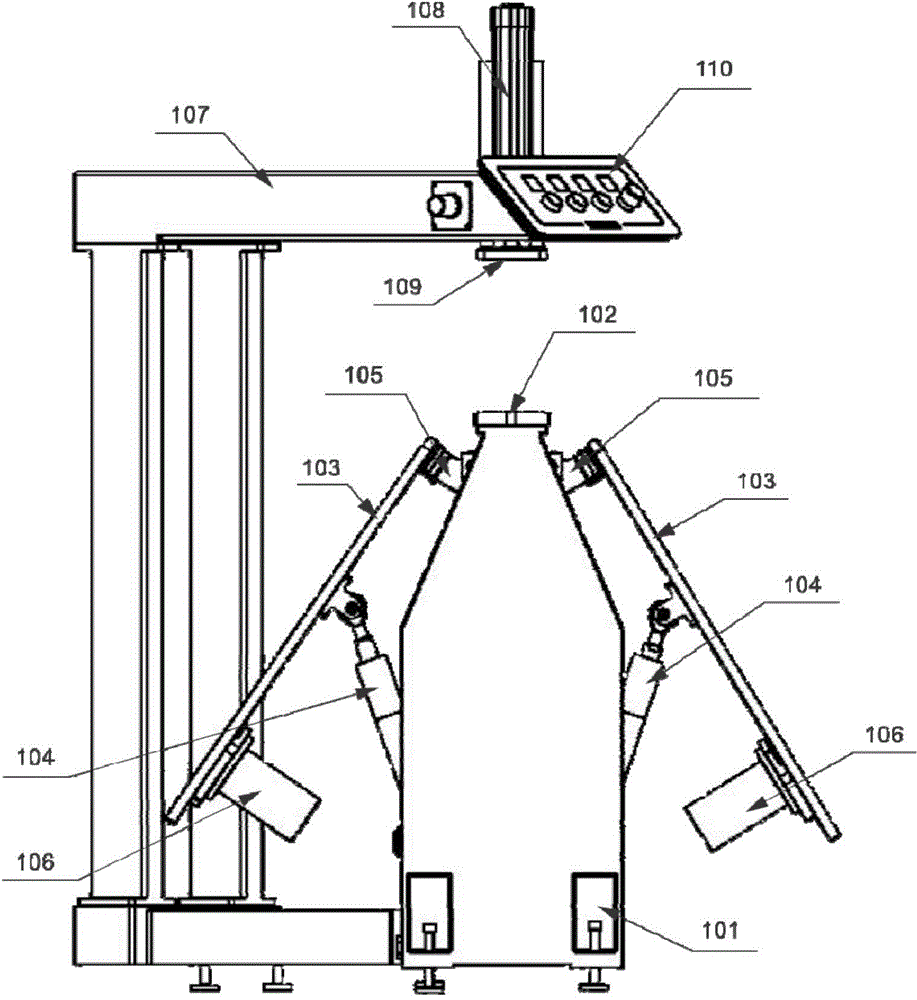

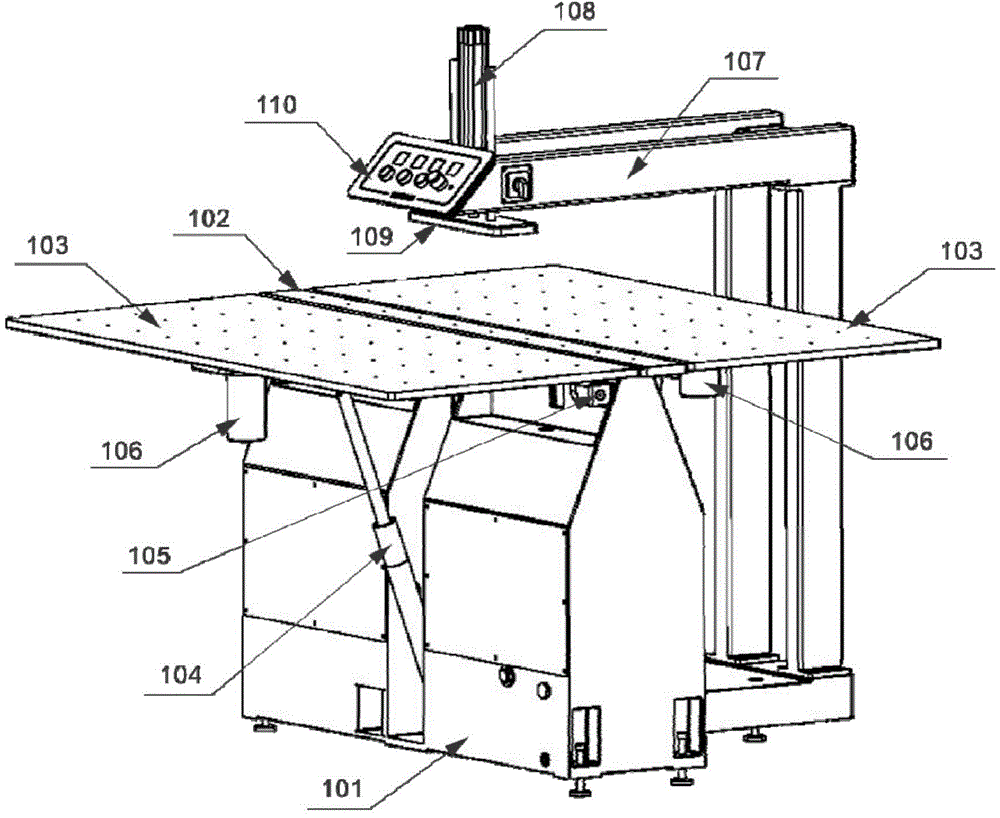

[0020] see figure 1 , figure 2 and image 3 : a kind of loose paper edge machine of the present invention, mainly comprises fuselage 101, fixed table top 102, tiltable table top 103, table top tilting mechanism 104, rotating shaft 105, vibrating device 106, paper press support 107 and paper press driving mechanism 108, Paper presser 109 and electrical control device 110 .

[0021] When the edge loosening machine of the present invention is in the initial state, the paper presser 109 is lifted, the tiltable table 103 is at the highest point, and is at the same level as the fixed table 102, and the vibrating device 106 is turned off.

[0022] After the cutting is completed, place the pile of paper with the bonded paper edge on the center of the table top of the paper loosening machine, start the function of loosening the paper edge, the paper presser driving mechanism 108 drives the paper presser 109 to press the paper pile, and then the table tilting mechanism 104 The tilta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com