An intelligent shock absorbing structure for prefabricated frame shear wall

A technology of intelligent shock absorption and shear wall, applied in the direction of wall, shockproof, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings.

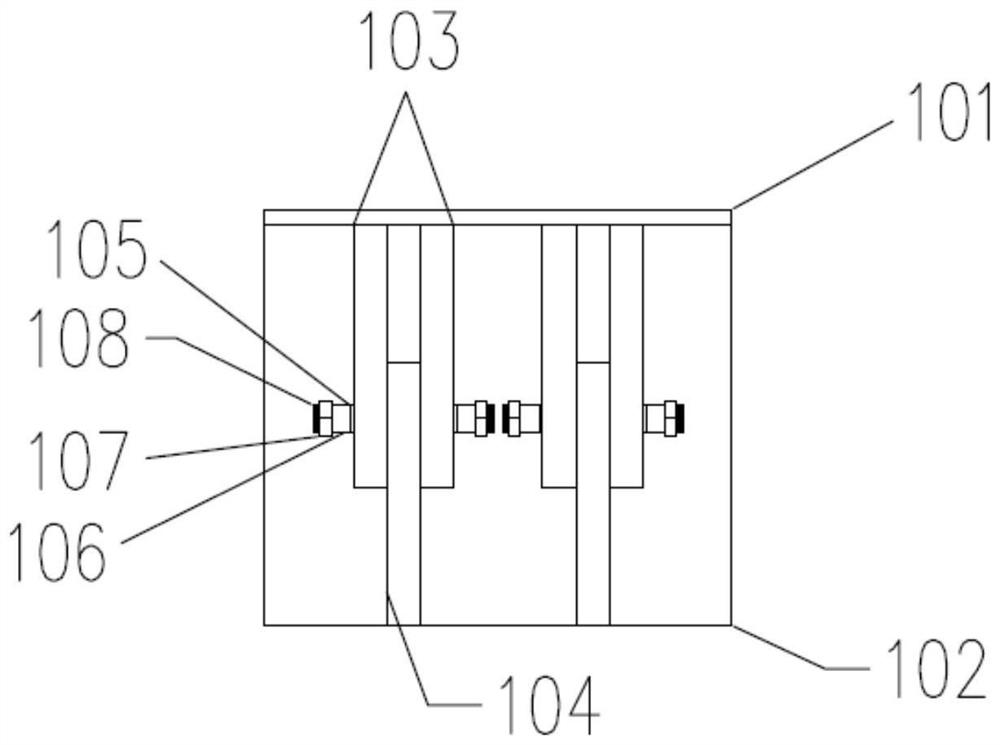

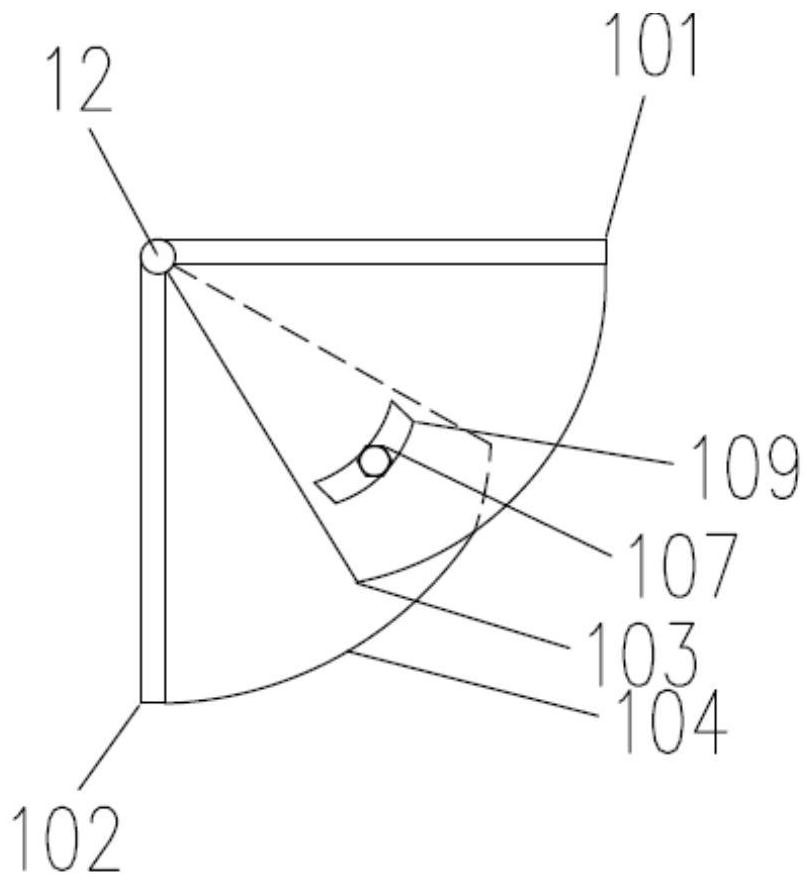

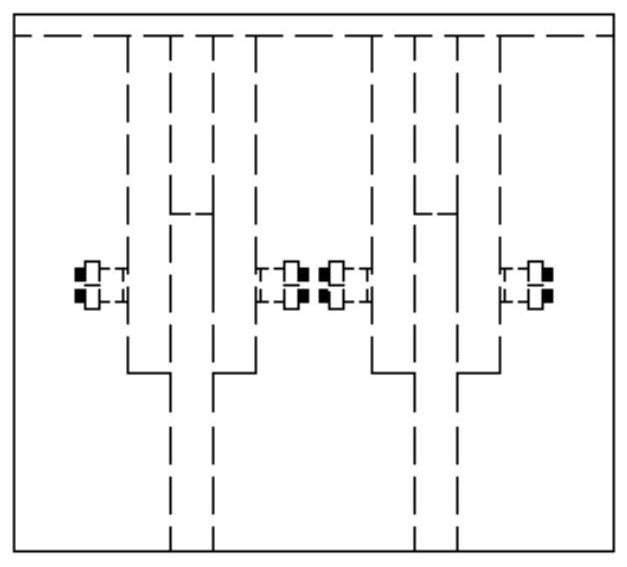

[0043] see Figure 9 , the present invention provides a prefabricated frame shear wall intelligent shock absorbing structure, including prefabricated beam 1, prefabricated column 2, shear wall 5, device 1 and device 2, device 1 is an intelligent shock absorbing device 100 for beam-column nodes, The second device is a prefabricated recycled concrete composite shear wall 200, in which the prefabricated beam 1 is arranged horizontally, the two ends of the prefabricated beam 1 are connected with the prefabricated column 2 through the hinge structure 3, the prefabricated beam 1 is arranged on the top of the shear wall 5, and the shear wall 5 The foam insulation material 4 is filled between both sides and the prefabricated column 2 . A beam-column joint intelligent damping device 100 is installed under the hinged structure 3, and a pre-embedded overall structure, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com