A kind of multi-layer embossed paper and its production process

A technology of embossing paper and process, which is applied in the direction of special paper, layered products, paper/cardboard layered products, etc. It can solve the problems of affecting the quality of paper products, poor three-dimensional effect, shallow embossing depth, etc., and achieve tensile resistance High performance, well-developed pores, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

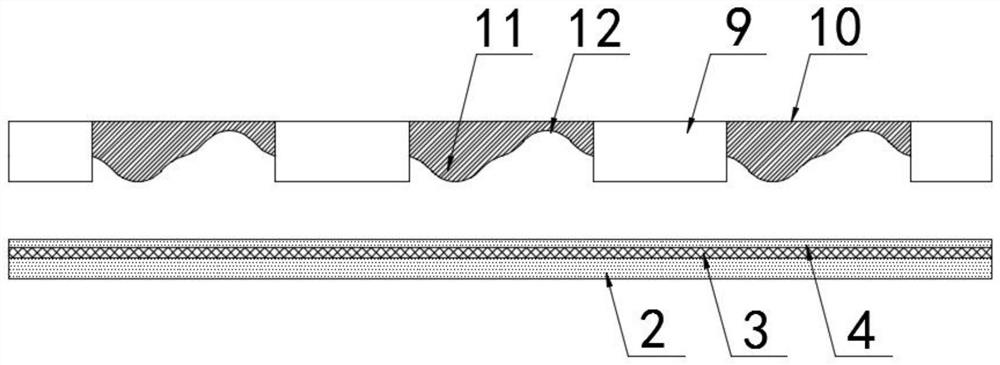

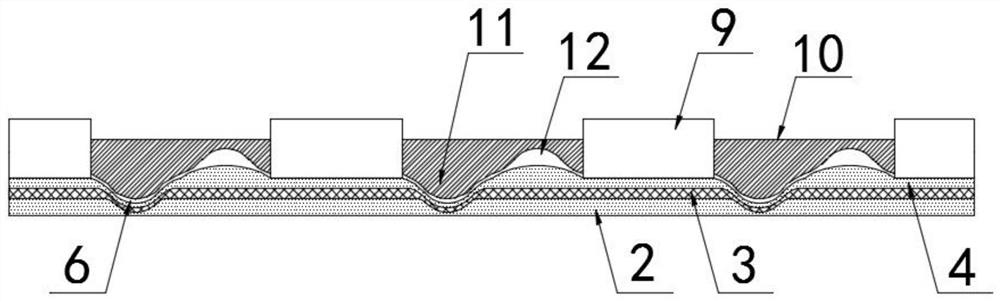

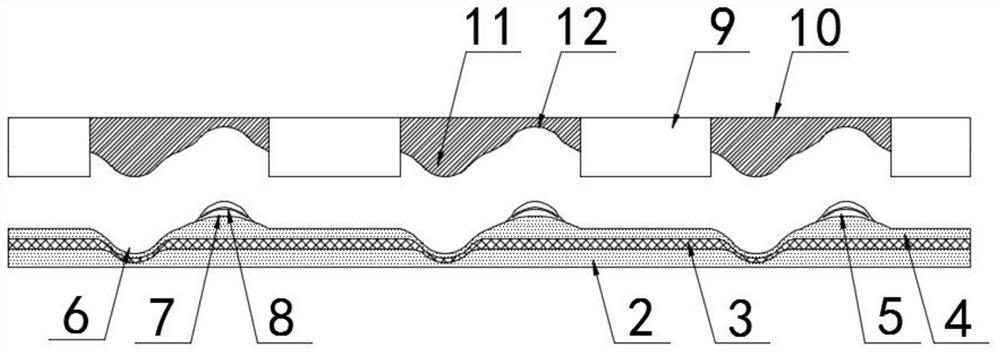

[0028] The present invention provides such Figure 1-4 The multi-layer embossed paper shown includes a paper body 1, and the paper body 1 includes a bottom paper base layer 2, a middle tensile layer 3, a top paper base layer 4 and a raised filling layer 5, and the middle tensile layer The stretch layer 3 is arranged on the top of the bottom paper base layer 2, the top paper base layer 4 is arranged on the top of the middle anti-stretch layer 3, the raised filling layer 5 is arranged on the top of the top paper base layer 4, and the top of the paper body 1 is provided with Pattern groove 6, the raised filling layer 5 includes a paper filling layer 7 and a stretch-resistant interlayer 8, the tensile-resistant interlayer 8 is arranged inside the paper filling layer 7, the bottom paper base layer 2, the top paper base layer 4 And the paper filling layer 7 is made of paper material, and the middle anti-stretch layer 3 and the anti-stretch interlayer 8 are all made of activated carb...

Embodiment 2

[0031] The present invention also provides Figure 1-4 A multi-layer embossed paper mold shown includes a first mold 9 and a second mold 10, the second mold 10 is spaced from the first mold 9, and the top of the first mold 9 and the second mold 10 Both are equipped with a lifting mechanism, and the bottom of the second mold 10 is provided with a first convex plate 11 and a mold groove 12. Groove 6 coincides, and described mold cavity 12 is corresponding to convex filling layer 5, and the top of described convex filling layer 5 is lower than the top of mold groove 12, and the bottom surface of described first mold 9 is arranged as plane and the bottom end is lower than Or parallel to the bottom end surface of the first convex plate 11, so that the first mold 9 surrounds the edge of the pattern groove 6, so that the bottom paper base layer 2, the middle anti-stretch layer 3 and the top paper base layer 4 are pressed against the convex position. Moving inside the mold cavity 12,...

Embodiment 3

[0033] The present invention also provides Figure 1-4 A kind of production technology of multi-layer embossed paper shown, the specific production process steps are as follows:

[0034] Step 1: Prepare the wet paper of the bottom paper base layer 2 and the top paper base layer 4 by pulp, preparation and papermaking processes;

[0035] Step 2: use textile machinery to weave activated carbon fiber cloth, weave different activated carbon fiber cloths according to the thickness of the middle anti-stretch layer 3 and the anti-stretch interlayer 8, and then coat the silicone structural sealant layer on the surface of the textile activated carbon fiber cloth, Obtain the middle anti-stretch layer 3 and the anti-stretch interlayer 8 for subsequent use;

[0036]Step 3: Bond the bottom paper base layer 2, the middle anti-stretch layer 3 and the top paper base layer 4 sequentially from bottom to top, and then press the first mold 9 and the second mold 10 downwards, when the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com