Copper alloy for electronic equipment, method for producing copper alloy for electronic equipment, rolled copper alloy material for electronic equipment, and part for electronic equipment

A technology for electronic equipment and manufacturing methods, which is applied in cable/conductor manufacturing, conductive materials, conductive materials, etc., can solve the problems of components for electronic equipment that cannot be formed into shapes, high tensile elastic modulus, plastic deformation, etc., and achieves excellent resistance. Effects of stress relaxation properties, low tensile elastic modulus, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

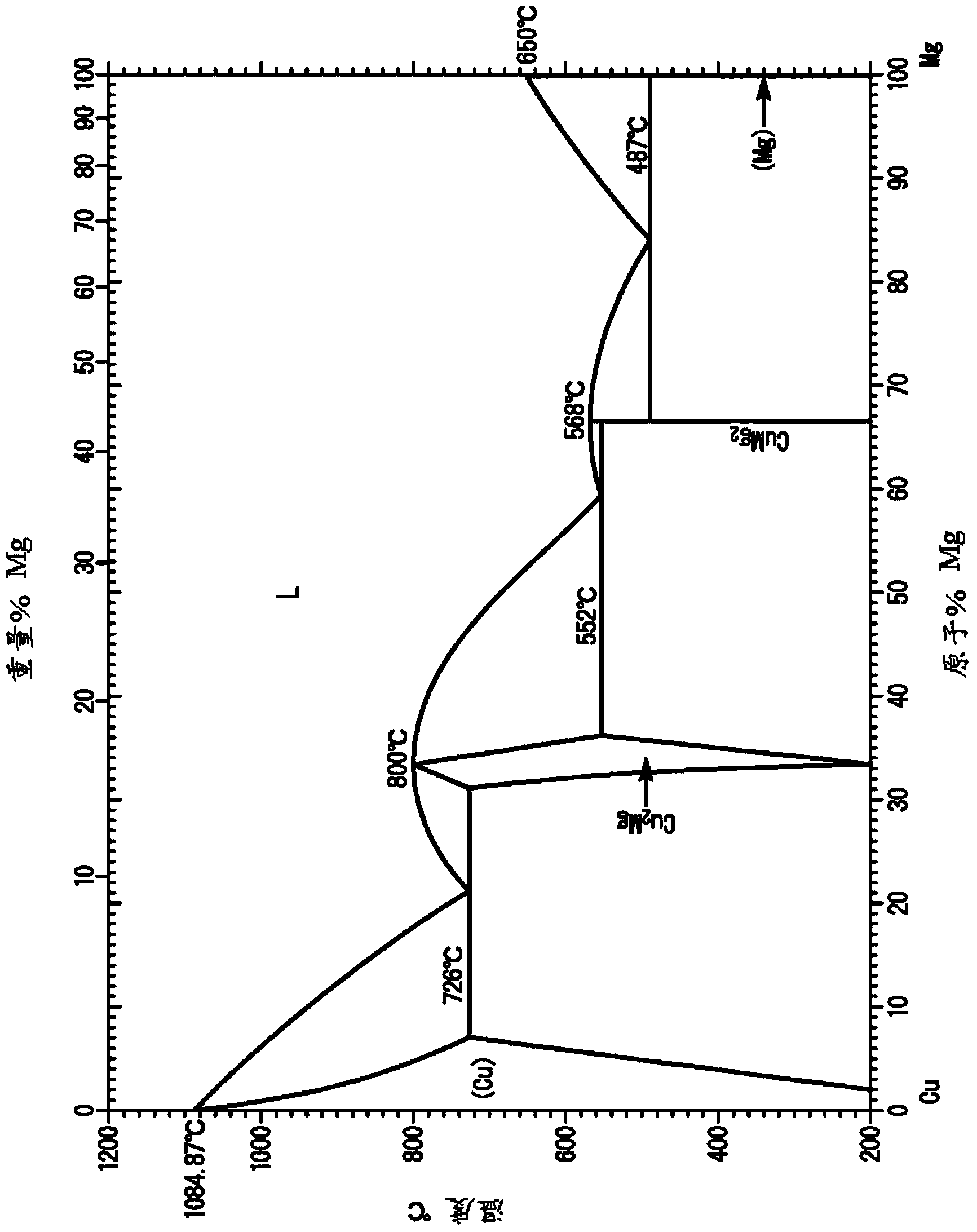

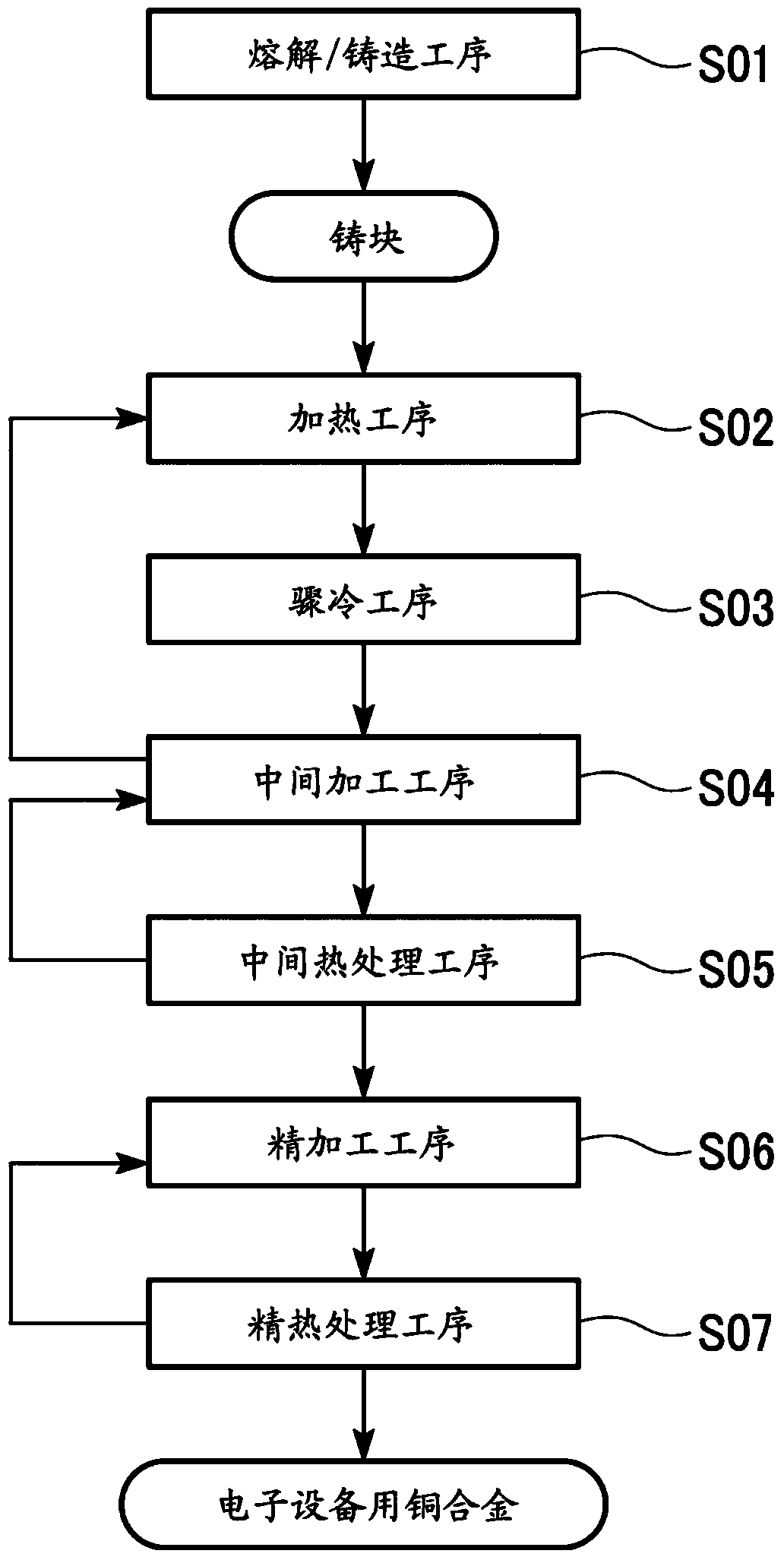

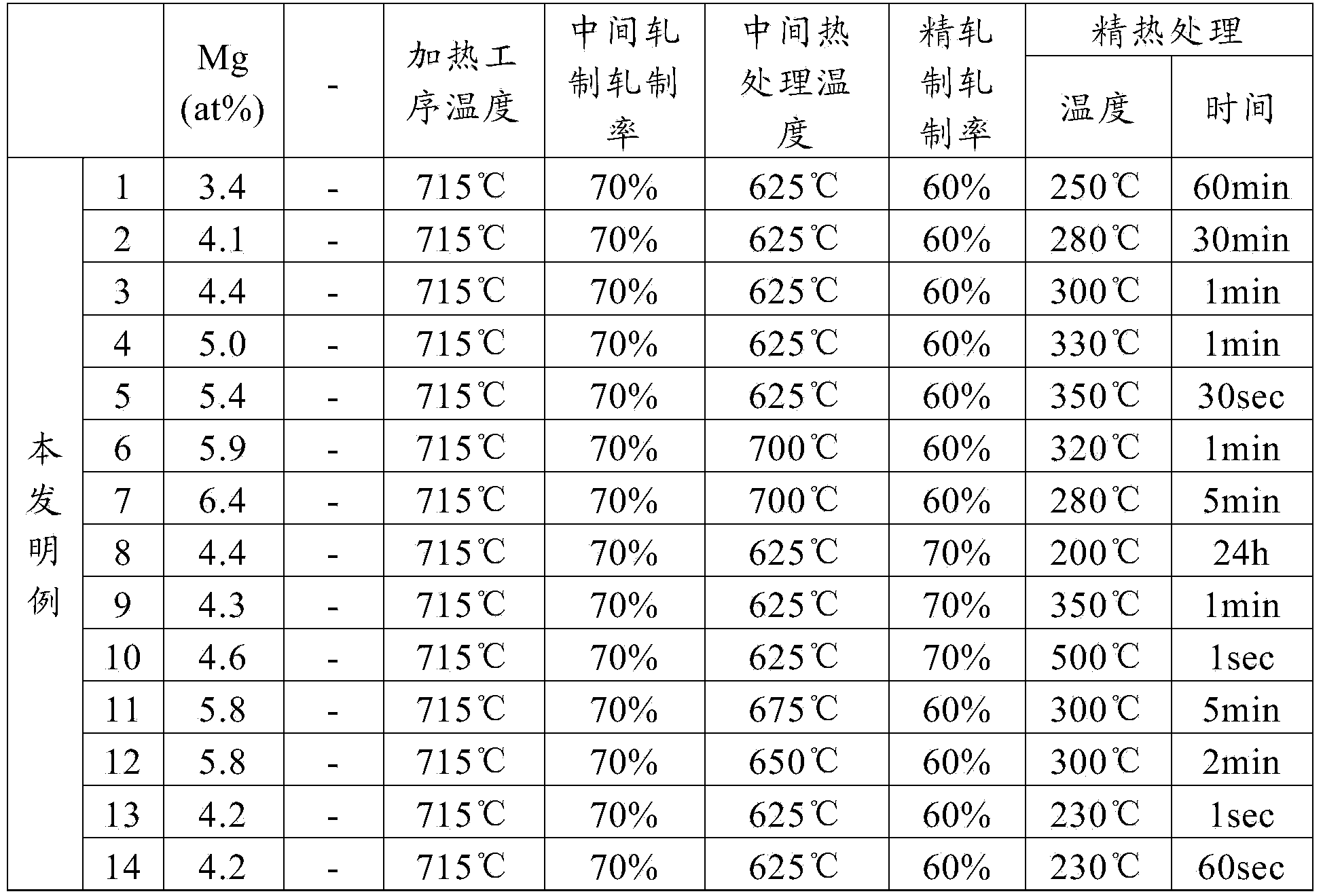

[0125] Hereinafter, the results of confirmation experiments conducted to confirm the effects of the present invention will be described.

[0126] A copper raw material composed of oxygen-free copper (ASTM B152C10100) with a purity of 99.99% by mass or higher was prepared, and the copper raw material was placed in a high-purity graphite crucible and subjected to high-frequency melting in an atmosphere furnace set to an Ar gas atmosphere. Various additive elements were added to the obtained molten copper to prepare the component compositions shown in Tables 1 and 2, and cast into carbon molds to produce ingots. In addition, the size of the ingot was about 20 mm in thickness×about 20 mm in width×about 100 to 120 mm in length.

[0127] The obtained ingot was heated in an Ar gas atmosphere for 4 hours under the temperature conditions described in Tables 1 and 2, and then water quenched (cooling temperature 20° C., cooling rate 1500° C. / min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com